RA 7 has a thread with corner arrays that he crosses to subs and is happy with.

I think it worth trying to EQ all the way down if you can.

The PC83 looks OK enough excursion and a bit more Sd than the Fountek. If you used the 4ohm version most amps will produce more power into 4ohms than at 8. Not as good for tube amps though.

The only negative thing is the break up peak at 15K which is much worse off axis.

I think it worth trying to EQ all the way down if you can.

The PC83 looks OK enough excursion and a bit more Sd than the Fountek. If you used the 4ohm version most amps will produce more power into 4ohms than at 8. Not as good for tube amps though.

The only negative thing is the break up peak at 15K which is much worse off axis.

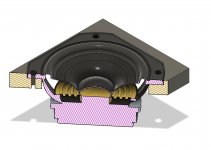

first drawings

Our friend wesayso made a very nice model of the vifa/peerless TC9 3.5" drivers

There is a download link here: http://www.rsr-concepts.com/diyma/Vifa-Branded.zip

Our friend wesayso made a very nice model of the vifa/peerless TC9 3.5" drivers

There is a download link here: http://www.rsr-concepts.com/diyma/Vifa-Branded.zip

Attachments

I have a basic idea of the size of the speakers and a minimum baffle width. Once I get my samples in, I will decide whether I need to remove more material from the back around the edge as he did.

Am I correct in assuming that the narrower the front of the enclosures are, the better things will be?

As noted by Roger Russell in his Audio Express article, you will need to make a couple of small notches for where the terminals on the speakers pass through. Depending on the baffle thickness perhaps this won't be a problem.

Am I correct in assuming that the narrower the front of the enclosures are, the better things will be?

As noted by Roger Russell in his Audio Express article, you will need to make a couple of small notches for where the terminals on the speakers pass through. Depending on the baffle thickness perhaps this won't be a problem.

Attachments

What is the best for internal baffles? Do I make 25 individual sealed enclosures? I saw others leaving open spaces between drivers, and wesayso did his with individual chambers, but all connected.

I'm not sure what material I want to use for the walls yet, for now, likely to use MDF or particle board. I don't trust the baltic birch to be as uniform as those materials. It's still nice looking wood, and I can get 12mm 4x8 sheets for about $32, but like the crappy home center plywood, it too seems to be slowly getting more and more inferior as time goes on. If I go with the particle board or MDF, I can get 3/4" thick stuff easily. If I could find 1" board, I could probably mill a rough surface on the inside of the enclosures to scatter/dampen sound inside of the boxes. Over the small dimensions of boxes (less than 8x11 likely), and with internal baffles supporting every opening, I can probably get away with doing this on 3/4" material, removing up to 1/4" in thickness in places in order to make the rough surface.

I'm wishing I had spend the extra $6.95 for the shipping so that I could start building test enclosures by the weekend...

I'm not sure what material I want to use for the walls yet, for now, likely to use MDF or particle board. I don't trust the baltic birch to be as uniform as those materials. It's still nice looking wood, and I can get 12mm 4x8 sheets for about $32, but like the crappy home center plywood, it too seems to be slowly getting more and more inferior as time goes on. If I go with the particle board or MDF, I can get 3/4" thick stuff easily. If I could find 1" board, I could probably mill a rough surface on the inside of the enclosures to scatter/dampen sound inside of the boxes. Over the small dimensions of boxes (less than 8x11 likely), and with internal baffles supporting every opening, I can probably get away with doing this on 3/4" material, removing up to 1/4" in thickness in places in order to make the rough surface.

I'm wishing I had spend the extra $6.95 for the shipping so that I could start building test enclosures by the weekend...

You could do some excursion modelling using WINISD or other program. In general too big is usually not an issue. Excursion goes up a bit but if you running that close to the wire a little less volume would probably not help you.

I sectioned mine into groups of 6 drivers per sealed section. Had to route out the divider plate in order to not cause problems with driver mounting as the divider overlapped the driver cutout due to center to center spacing. But other have not sectioned the array and have not had problems with the driver shared volume.

I sectioned mine off so I could do some shading testing that I never got around to doing. Mark100 shading looks pretty cool but unless you are planning on doing something like that it may be more trouble than its worth.

There was a fellow here that did some wiring testing on multiple drivers in a sealed box and found it critical to have wired all drivers in the sealed box in parallel and not series. That said it was high excursion subwoofers and not fullrange drivers and a number of builders here have not had that trouble. The subs did not do well because of they were low pass devices in series which created phase shift problems between the drivers. Some would drive in opposite directions and cause pressure on cones. Doesn't seem to be an issue with full range drivers.

I sectioned mine into groups of 6 drivers per sealed section. Had to route out the divider plate in order to not cause problems with driver mounting as the divider overlapped the driver cutout due to center to center spacing. But other have not sectioned the array and have not had problems with the driver shared volume.

I sectioned mine off so I could do some shading testing that I never got around to doing. Mark100 shading looks pretty cool but unless you are planning on doing something like that it may be more trouble than its worth.

There was a fellow here that did some wiring testing on multiple drivers in a sealed box and found it critical to have wired all drivers in the sealed box in parallel and not series. That said it was high excursion subwoofers and not fullrange drivers and a number of builders here have not had that trouble. The subs did not do well because of they were low pass devices in series which created phase shift problems between the drivers. Some would drive in opposite directions and cause pressure on cones. Doesn't seem to be an issue with full range drivers.

It is a good idea to relieve the back of the baffle around the driver, as it lets the driver "breathe" less chance of short distance reflections coming back through the cone. I used 16mm MDF for the front baffle which gave enough thickness to route a 45 degree chamfer on the back side which was quite easy to do once the driver holes were cut. When using wood for the front baffle don't go thin as when you cut 25 holes in it it becomes fragile. Too thick is not good either as you create a tunnel behind the driver.Once I get my samples in, I will decide whether I need to remove more material from the back around the edge as he did.

Am I correct in assuming that the narrower the front of the enclosures are, the better things will be?

Every width of baffle will behave differently as to baffle step diffraction etc. Most choose narrow or wide and stay away from in-between. I made mine as narrow as I could keeping the ~2 Litre volume in mind.

No you don't. I tried to keep the series connected drivers in their own sealed spaces, which didn't work out in the end. What I would do is use the alternative parallel series wiring diagram that byrtt drew in wesayso's thread.What is the best for internal baffles? Do I make 25 individual sealed enclosures? I saw others leaving open spaces between drivers, and wesayso did his with individual chambers, but all connected.

If I could find 1" board, I could probably mill a rough surface on the inside of the enclosures to scatter/dampen sound inside of the boxes.

I wouldn't worry about that if you fill the cavity with a combination of fibreglass and wool sheet, the damping works very well at containing the back wave so there is really no need for scattering as it is already absorbed.

I've run many simulations on volume, no point going bigger than 2 litres it makes no appreciable difference with this driver due to the high Qt. 2 litres gives enough room to damp the back wave and let the driver work as well as it can, unless space is a restriction going smaller is worse, bigger won't gain you anything other than a heavier cabinetI've seen internal sizes of ~ 2 liters per driver. I know going smaller cuts of bass response. Is there a general consensus of how big is too big? is there such a thing?

Our friend wesayso made a very nice model of the vifa/peerless TC9 3.5" drivers

Very nice looking!

I was just looking at drivers, and this little guy popped up: Aurasound NSW1-205-8A 1" Extended Range

High Frequency response curve looks a lot cleaner than many others, and other than the 15db or so dip between 30-200hz, seems to look pretty good on paper. That kind of dip seems like it would be easier to smooth out with equalization boost, or maybe some way of porting it? I know this is stealing away from original intent, but seems like an interesting driver, in that it is so small, and one could cram so many into an 8’ space

The other thing I’m strongly considering is to do the line array with subwoofer for lowest bass notes. I don’t watch a lot of tv/movies, but maybe I’d do more if I had capable speakers.

I want to keep the equalizing analog, mostly to reduce complication in the amount of equipment I need. I feel confident that I can build those components well enough to satisfy my listening needs. Digital signal processing is a rabbit hole i’m Not willing to go down at the moment.

I’m going to order a few drivers and see what I like, and see where this takes me. The little 1” drivers from aurasound are a little pricey for what I want to spend on this project at the moment, but I’m interested to see what can be done with 1 inch “woofers”. The travel on them is seems very big for something that small, and I’m curious to see what they will do without blowing up.

Part of me is thinking to just buy a bunch of the cheapest 3” speakers, and throw something together out of MDF just to see what they sound like. The hardest part in building is going to be cutting 25+ holes per speaker in the front baffle, and this is a relatively trivial job with the CNC router. I should probably go minimalist like this, and see if I can eek out a set of speakers from a single piece of MDF. Refine and tweak from there.

The NSW-1 is a nice solid little driver easy to mount and use, unlike other small drivers, but has almost a 5 db step in its response just below 4 khz that might be hard to equalize but probably do-able with steep FIR filter.

You should check out the Fountek FR58EX which has a nice, smooth response all the way up, like the SB65WAC25. Both of these get you well down into subwoofer range but do need some help down low. A primary benefit to you as a sculptor may be that they need a fraction of the volume as does the TC9. You can get a really small footprint and much closer wall or corner placement if going that way.

Their smaller diaphragm size also pays dividends in wider dispersion and later onset of combing (which likely doesn't matter much) compared to TC9. The drawback is cost but substantial discounts are available in line array quantities. I just signed off on an order for 64 SB65's.

The SB65 has a rising HF response while the Fountek has a flat response making the former slightly better for line arrays. The SB65 has quick disconnect terminals while the Fountek has solder terminals. Either could be curse or blessing depending on your wiring plans or if you should ever need to rewire. Fountek spaces 6mm closer, 60 vs 66 mm.

Hope that helps although I see you may have already chosen TC9. I just noticed this thread last night.

What is the best for internal baffles? Do I make 25 individual sealed enclosures? I saw others leaving open spaces between drivers, and wesayso did his with individual chambers, but all connected.

I'm not sure what material I want to use for the walls yet, for now, likely to use MDF or particle board. I don't trust the baltic birch to be as uniform as those materials. It's still nice looking wood, and I can get 12mm 4x8 sheets for about $32, but like the crappy home center plywood, it too seems to be slowly getting more and more inferior as time goes on. If I go with the particle board or MDF, I can get 3/4" thick stuff easily. If I could find 1" board, I could probably mill a rough surface on the inside of the enclosures to scatter/dampen sound inside of the boxes. Over the small dimensions of boxes (less than 8x11 likely), and with internal baffles supporting every opening, I can probably get away with doing this on 3/4" material, removing up to 1/4" in thickness in places in order to make the rough surface.

I'm wishing I had spend the extra $6.95 for the shipping so that I could start building test enclosures by the weekend...

Hi Anchorman,

I went with about 2L per TC9 and no internal baffles. Simple fiberglass stuffing running top to bottom.

I didn't see any need to to randomize anything inside, and so far measurements don't seem to show any particular resonance issues.

Box picts below. (Driver baffles fit either type box, I'm testing one of each right now and thought you might like to see empty box)

Are you talking about true 9 ply baltic birch, or birch faced plywood?

i ask because $32 a sheet for 4x8 12mm BB sounds almost impossibly cheap, and ime there is no comparison between the dimensional stability and work-ability of BB vs equivalent thickness plywood and MDF. but ymmv

If i had it to do over...at this point i still wouldn't change anything re the box construction ..FWIW

Attachments

Last edited:

I did a quick cad drawing of the basic shape tapered shape in the original IDS-25 speakers, and without internal baffles, it comes to about 31 liters inside, which works out to about 1.25L/driver. Surprisingly small?

in terms of front baffle, how wide is too wide for something like this? The originals are relatively narrow. I'm trying to get a handle on how wide I can push this without ruining the sound quality. I imagine that the narrower you go, the better it will be. rounded corners or at least truncated at ~45° angle is better for keeping edge diffraction under control

from: Speaker baffle design, diffraction and baffle step | Audio Judgement

"half of wavelength of a particular frequency, when it diffracts, it will be 180° out of phase with the original wave and cancellation will occur. The cancellation is not perfect though, but it will translate into a dip in the frequency response, at that particular frequency. This also happens if the distance is a wave and a half, 2 waves and a half etc.

one wavelength of a particular frequency, when it diffracts it will be 360° out of phase with the original wave and that is basically in phase. Which means it will reinforce the original wave, for an up to +3 db. This happens if the distance is 2 wavelengths, 3 wavelengths etc."

I believe I'm starting to overthink this, but that's half the fun, eh?

in terms of front baffle, how wide is too wide for something like this? The originals are relatively narrow. I'm trying to get a handle on how wide I can push this without ruining the sound quality. I imagine that the narrower you go, the better it will be. rounded corners or at least truncated at ~45° angle is better for keeping edge diffraction under control

from: Speaker baffle design, diffraction and baffle step | Audio Judgement

"half of wavelength of a particular frequency, when it diffracts, it will be 180° out of phase with the original wave and cancellation will occur. The cancellation is not perfect though, but it will translate into a dip in the frequency response, at that particular frequency. This also happens if the distance is a wave and a half, 2 waves and a half etc.

one wavelength of a particular frequency, when it diffracts it will be 360° out of phase with the original wave and that is basically in phase. Which means it will reinforce the original wave, for an up to +3 db. This happens if the distance is 2 wavelengths, 3 wavelengths etc."

I believe I'm starting to overthink this, but that's half the fun, eh?

Last edited:

Are you talking about true 9 ply baltic birch, or birch faced plywood?

i ask because $32 a sheet for 4x8 12mm BB sounds almost impossibly cheap, and ime there is no comparison between the dimensional stability and work-ability of BB vs equivalent thickness plywood and MDF. but ymmv

If i had it to do over...at this point i still wouldn't change anything re the box construction ..FWIW

real deal baltic birch, with the purple rubber stamp from russia with love. though It's more like BB/BB quality than B/B or better. I'm finding more voids/repairs to veneer than on stuff I'm seeing now than stuff I bought even a year ago. It's not terrible, but not as perfect as it once was. Still worlds better than home center garbage for less cost. I get from a cabinet supply. 12mm. 18mm is ~ $52 per 4x8 in pallet quantity, though there's another place a friend buys from that sells it in smaller amounts for a few $ more (minimum $300 order).

It may be that in order to get the truly beautiful stuff, you have to resign yourself to 5x5 sheets. I imagine that it's harder to cut a nice 8' wide piece with the grain pointed towards the 4' side of veneer than to do 5', and so they end up with more difficulty/loss/expense, and it ends up costing a bit more per square foot. But that's pure speculation on my part.

Hi Anchorman,

I went with about 2L per TC9 and no internal baffles. Simple fiberglass stuffing running top to bottom.

I didn't see any need to to randomize anything inside, and so far measurements don't seem to show any particular resonance issues.

Box picts below. (Driver baffles fit either type box, I'm testing one of each right now and thought you might like to see empty box)

Thanks for the pics! Are these meant to go flush in the corner of the room?

Hope that helps although I see you may have already chosen TC9. I just noticed this thread last night.

Thanks for the tips! I haven't decided which driver yet, but am leaning towards the TC9. Waiting on the arrival of my test units. If I make these look and sound nice enough, maybe I can sell them and use that money to try out some other things

I tried to stay as narrow as i could too, just because 'why not?'

And i at least managed a 1/4" roundover on the edges.

Beyond that seemed impractical to chase for my goals.

And honestly, I'm glad I didn't try to do more there.

From experimentation so far, I think driver size and spacing have one or more orders of magnitude more impact, than potential diffraction issues.

But don't let me be a downer when it comes to overthinking...it can sure be fun, huh?

I've just kinda turned into a old guy whose mellon gets tired and wants to know "what works? .... what matters most, and in what order?" LoL

And i at least managed a 1/4" roundover on the edges.

Beyond that seemed impractical to chase for my goals.

And honestly, I'm glad I didn't try to do more there.

From experimentation so far, I think driver size and spacing have one or more orders of magnitude more impact, than potential diffraction issues.

But don't let me be a downer when it comes to overthinking...it can sure be fun, huh?

I've just kinda turned into a old guy whose mellon gets tired and wants to know "what works? .... what matters most, and in what order?" LoL

Oh that's waay cool about the BB. I get what you're saying about the grading.

If I couldn't get 8 ft BB I like , I would use some other good 8ft material....would hate to get into splicing...

Yes, they are meant to go flush in the corners. I have interchangeably bases for them, freestanding vs corner.

If I couldn't get 8 ft BB I like , I would use some other good 8ft material....would hate to get into splicing...

Yes, they are meant to go flush in the corners. I have interchangeably bases for them, freestanding vs corner.

Hi Anchorman,

I went with about 2L per TC9 and no internal baffles. Simple fiberglass stuffing running top to bottom.

I didn't see any need to to randomize anything inside, and so far measurements don't seem to show any particular resonance issues.

Box picts below. (Driver baffles fit either type box, I'm testing one of each right now and thought you might like to see empty box)

If you want to know how the inside works out, a simple impedance sweep tells us a lot. The TC9 impedance is pretty clean. So if the sweep of drivers in enclosure shows some weird bumps, you'd have internal resonances. Even a small bump like that can result in dips in the frequency response. Easy enough to check.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Yet another IDS-25 clone?