It looks like in a 100% throretical tractrix curve, the expansion would approach 180 degrees as the size approaches infinity. Note - I've never really looked at this before, cos I'm not a purist for any particular horn curve.I am not sure from a purist point of view that the 2 flat sides model gives a true tractrix. The tractrix expands out to 180 degrees, which cannot be realised with flat sides.

Tractrix - Wikipedia

IRL, nobody has an infinite horn, they are usually truncated at 90 degrees or less.

A quick image search shows that these do not open to 180 degrees - I'd guesstimate 90 (but maybe I'm looking at the wrong thing).The drivers that will be used were used for the Voigt corner horn.

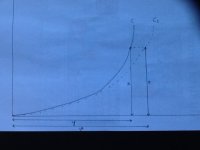

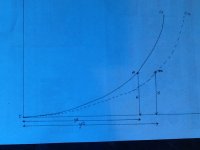

I have found a way to create the curve for the 4 petals: with apologies for the appalling drawing.

The curve "c" is the tractrix required. The curve c1 is the curve for the petal. The measurement x is the same for both. The measurement y2 is the length of the curve from t to m. One could do this by say marking out the curve "c" with panel pins, and following the curve with thread tethered at t.

The curve "c" is the tractrix required. The curve c1 is the curve for the petal. The measurement x is the same for both. The measurement y2 is the length of the curve from t to m. One could do this by say marking out the curve "c" with panel pins, and following the curve with thread tethered at t.

Attachments

Does anyone have a pdf or any other file for a cut sheet ? I’m a pretty accomplished Carpender have always been fascinated with the use and I would like to try to make one work course or pair of them but make warm for proof of concept and test and I would like to try to do him for drivers ranging from 8 inch 10 inch and 12 inch so any thoughts or information that could be passed on to me would be greatly appreciated and I would also published my work as I go through it and I have the equipment for doing the REW

Test

Test

HornResp will allow you to print a horn profile or export the profile data so you can apply the measurements to a large sheet of material. I've made a few, this is the Tractrix profile, expansion on both axis Dayton PC83-8 (3") test results

The only trick is being in "schematic" view then file export, then pick the construction type, then save the file. The profile X-Y data points can be used directly or read by excel and printed if your printer is large enough.

The only trick is being in "schematic" view then file export, then pick the construction type, then save the file. The profile X-Y data points can be used directly or read by excel and printed if your printer is large enough.

A friend of mine has asked for some advice about making a large (3 foot square mouth) tractrix horn. He wants to make it out of four pieces of thin ply, joined edge to edge. It will then be strengthened. His problem is how to draw the curve of each edge.

I cannot get my head round how to create that curve. Any suggestions?

You are making heavy work out of what can be reduced to a very simple exercise using Hornresp

Given that the intended mouth size is 3' x 3', what are the proposed throat size (W x H), and tractrix horn length (or horn cutoff frequency)? If you care to post this information I will provide you with the details you are seeking - and you won't even have to learn how to use Hornresp!

Assuming the 3' x 3' mouth is that of a fully-formed (90 degree) tractrix horn, then the cutoff frequency will be 106.12 Hz. If the throat is 2 cm x 2 cm, then the length will be 181.39 cm.

In the attached file, the 'Side Len' values give the x distances along centre-line axis of the side walls, and the 'Width / 2' values give the y distances from the centre-line to the wall edge.

In the attached file, the 'Side Len' values give the x distances along centre-line axis of the side walls, and the 'Width / 2' values give the y distances from the centre-line to the wall edge.

Attachments

Hello David McBean. Thank you for your kind offer. I will get back to you with the imformation that you asked me to supply. It might be a few days. Basically it is the mouth size that I need to get hold of.

I will look at RHINO 3d too, but neither myself or my friend are particularly savvy with computer software.

I will look at RHINO 3d too, but neither myself or my friend are particularly savvy with computer software.

With Rhino you can easily ply the horn in a desired pattern defined by an independent curve ,so that waves that are already propagating at the troth reach the mouth reflected , hence avoid cavernous sound and of course more compact horn . See ex. Of WE and several Japanese realizations. Most popular material used is mazonite. It can easily get formed by steam iron , temporary wooden structures holding than fiberglassed. The first 1/8th wave length is transformed externally into cylindrical so that the fiber glass fiber is wound around. This avoids the low frequencies be attenuated . Internally the mazonite can be painted with Elastomer of

Desired color used to waterproof house decks.

Desired color used to waterproof house decks.

You are making heavy work out of what can be reduced to a very simple exercise using Hornresp.

Given that the intended mouth size is 3' x 3', what are the proposed throat size (W x H), and tractrix horn length (or horn cutoff frequency)? If you care to post this information I will provide you with the details you are seeking - and you won't even have to learn how to use Hornresp!

Thank you for this kind offer which I now wish to accept.

The throat size is 4" x 4".The mouth size is 3ft x 3ft. A full tractrix is what my friend is seeking (as I interpreted the example spreadsheet you provided)

I am very grateful not to have to learn how to use Hornresp.

Do any of the numbers supply the tractrix curve that the four petals construct into. (Just wondering for ease of making supports for the petals)

With thanks.

Hi midrange,

The tractrix horn meeting the above specification has a throat area of 103.23 cm^2, a mouth area of 8361.27 cm^2, an axial length of 97.69 cm and a flare cutoff frequency of 106.12 Hz.

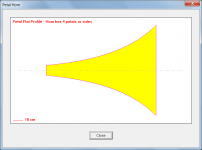

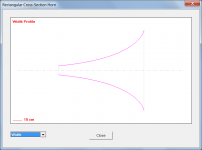

Plot 'Side Len' against 'Width /2' to obtain the cutting pattern for one half of a flat uncurved petal. The full flat uncurved petal should look like the one shown in Attachment 1.

Plot 'Length' against 'Inradius' to obtain the profile for the petal supports. The petal support profile (for both the width and height supports) should look like the one shown in Attachment 2.

Kind regards,

David

The throat size is 4" x 4".The mouth size is 3ft x 3ft. A full tractrix is what my friend is seeking (as I interpreted the example spreadsheet you provided).

The tractrix horn meeting the above specification has a throat area of 103.23 cm^2, a mouth area of 8361.27 cm^2, an axial length of 97.69 cm and a flare cutoff frequency of 106.12 Hz.

Plot 'Side Len' against 'Width /2' to obtain the cutting pattern for one half of a flat uncurved petal. The full flat uncurved petal should look like the one shown in Attachment 1.

Do any of the numbers supply the tractrix curve that the four petals construct into. (Just wondering for ease of making supports for the petals).

Plot 'Length' against 'Inradius' to obtain the profile for the petal supports. The petal support profile (for both the width and height supports) should look like the one shown in Attachment 2.

Kind regards,

David

Attachments

I note that in #27 I was asked for three variables: throat size, mouth size, and horn length, and that horn length would affect the cutoff frequency. So if the horn was longer, the cutoff frequency would be lower, at the expense of ripples in the bass due to the mouth no longer being optimal? Would the ripples begin below where the mouth is too small?

If this is the case it seems that it could be a viable compromise (within limits) in that in a normal living room bass response is fairly non linear anyway.

If this is the case it seems that it could be a viable compromise (within limits) in that in a normal living room bass response is fairly non linear anyway.

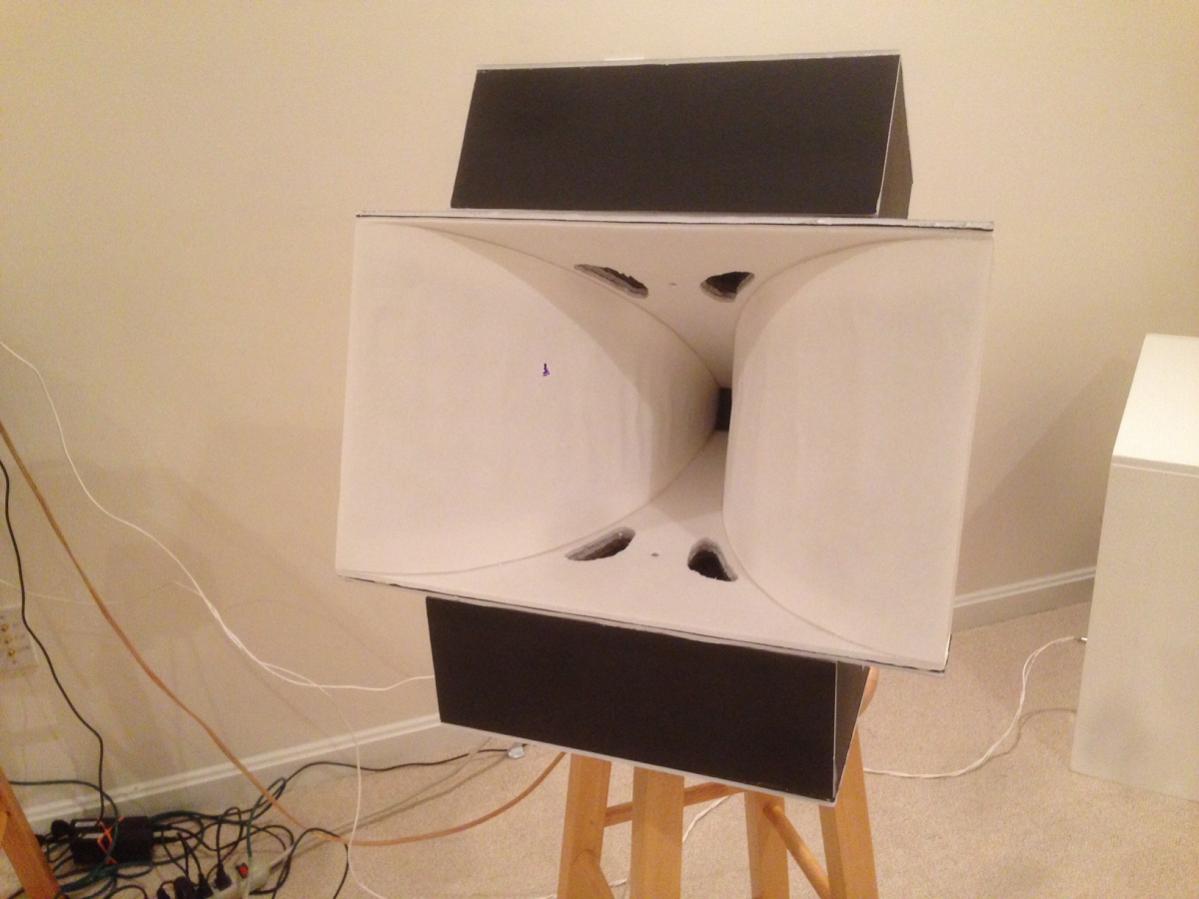

I've made a few smaller petal horns using hornresp.

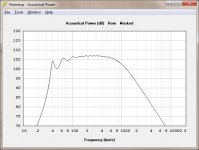

If you make the horn longer, with the same mouth and throat area, it will not be fully formed (exit <90deg) but will go lower with ripples (see pic). I don't think the exit angle matters at these low freq but the size (3m long) will surely roll some eyes. I attached a sample graph from hornresp.

There is also the possibility of using more petals (than 4) to get the side width smaller to make to wood easier to bend and easier to dampen.

If you make the horn longer, with the same mouth and throat area, it will not be fully formed (exit <90deg) but will go lower with ripples (see pic). I don't think the exit angle matters at these low freq but the size (3m long) will surely roll some eyes. I attached a sample graph from hornresp.

There is also the possibility of using more petals (than 4) to get the side width smaller to make to wood easier to bend and easier to dampen.

Attachments

There is also the possibility of using more petals (than 4) to get the side width smaller to make to wood easier to bend and easier to dampen.

Yep, second that. With 4 petals, depending on the thickness of the material, there will be quite a lot of tension around the mouth. Might need to be attached to a support frame to stop the panels from bowing. But then again, the bowing can look really nice .......

8 petals is a lot easier to work with. 16 petals would be a doddle - virtually a round circular mouth exit. OK, its four times the work, but as you know, building horns is just crazy anyway.

If you do go with four petals, you can work with either Masonite or MDF that is pregrooved on one side to make a somewhat easier bend without too much effort.

@tapestryofsound : I prefer odd number of petals to avoid symmetry. I believe your past horns have been in this size range.

@midrange : if you want I can run a few hornresp models for you as well, if you let me know what changes you need. It would also help to have the driver you intend to use so it could be included in the sim.

@midrange : if you want I can run a few hornresp models for you as well, if you let me know what changes you need. It would also help to have the driver you intend to use so it could be included in the sim.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Making a Square Tractrix Horn