So, I managed to grab a pair of these during the raffle at Burning Amp 2018. They are large, and a simple test session shows that they sound very, very nice open air. I would like to actually build them up an use them, and was wanting to find a nice design that can easily be built with decent plywood. I have sporadic and limited access to advanced woodworking tools at my work, but can manage on many things. I can't do curved walls or anything too complicated. I really, really want to use these in something!

Very little info is available for these online, but I did find this, where Papa Pass mentions them-

A poor man Feastrex !

Here is a product listing for the drivers, mine is the white cone, not that it matters much

声韵12寸全频钴磁喇叭hifi发烧钢磁铝镍钴扬声器超古董全频非同轴

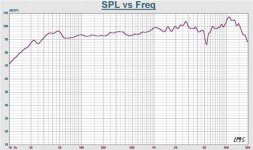

Here are the relevant specs, straight from the datasheet, I've also attached the full PDF-

Aucharm UR330B8-11F full range 12"

Impedance : 8 Ohm

Minimum Frequency Response: 34 Hz

Reproduction Frequency Response: Fo~18K

S.P.L. : 92.806 dB/W(m)

Rated Input : 30W

Music Power : 45W

Equivalent Diaghram Radius: 132mm

Equivalent Mass : 26.419 g

Magnet Weight : 1100g

Net Weight : 11900 g

Fs : 34.942 Hz

Re : 7.2 Ohm

Mms : 32.964 g

BL : 8.135 TM

Qts : 0.691

Qms : 5.647

Qes : 0.787

Vas : 228.816 Ltr

That high Qts seems to be pretty damning is my first impression.

I initially asked Xrk971 to try a sim for a karlsonator, here in the Karlsonator thread, and unfortunately the driver is ill suited to such an application, and would need to be prohibitively large, with wonky performance for the effort. Something along the lines of a 1.5x~2x scaling! He suggested a Rondo style cab, but I'm not sure I could do the teardrop shape, other than maybe an angular approximation? His initial suggestion was maybe 16in W x 24in deep x 60 in tall... 4in gap on floor, which is a little taller than I would like to do...

What would be a decent cabinet design that would not be excessively large for this driver? Ideally I would like to do some sort that would have the driver approximately ear level to seated listeners. Maybe some sort of back-loaded horn? I'm not interested in large open baffle types, as I just plain don't have the space for it, and don't really care for them all that much personally. She who must be appeased must also be taken into account

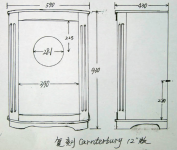

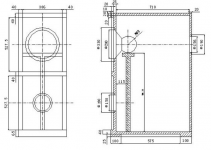

There are a few goofy suggested(?) designs on the product page as well, and other than the "Canterbury" style, they all look pretty much to be oddly sized. I'll attach a few for reference, just in case the product listing disappears later. Something of a similar form factor would be nice, and I can go maybe 18" deep, maybe 20~24" wide, by 32~36" tall I suppose, but depending on what works I can be a bit flexible on things. I really wish I had a PC that I could set up some simulation software on, I don't have access to a windows machine for more than an hour or two a night at home, and what I do have is old and tired. Everything I can use at work is Chrome OS, so unless I find some sort of web-based solution I don't really know of much, other than basic vented/sealed box calculators.

So, what do you guys think? Any ideas? Maybe just a basic version of the "Canterbury" with some nice stain? Could double as a stand for a small aquarium to take up less space

Very little info is available for these online, but I did find this, where Papa Pass mentions them-

A poor man Feastrex !

Here is a product listing for the drivers, mine is the white cone, not that it matters much

声韵12寸全频钴磁喇叭hifi发烧钢磁铝镍钴扬声器超古董全频非同轴

Here are the relevant specs, straight from the datasheet, I've also attached the full PDF-

Aucharm UR330B8-11F full range 12"

Impedance : 8 Ohm

Minimum Frequency Response: 34 Hz

Reproduction Frequency Response: Fo~18K

S.P.L. : 92.806 dB/W(m)

Rated Input : 30W

Music Power : 45W

Equivalent Diaghram Radius: 132mm

Equivalent Mass : 26.419 g

Magnet Weight : 1100g

Net Weight : 11900 g

Fs : 34.942 Hz

Re : 7.2 Ohm

Mms : 32.964 g

BL : 8.135 TM

Qts : 0.691

Qms : 5.647

Qes : 0.787

Vas : 228.816 Ltr

That high Qts seems to be pretty damning is my first impression.

I initially asked Xrk971 to try a sim for a karlsonator, here in the Karlsonator thread, and unfortunately the driver is ill suited to such an application, and would need to be prohibitively large, with wonky performance for the effort. Something along the lines of a 1.5x~2x scaling! He suggested a Rondo style cab, but I'm not sure I could do the teardrop shape, other than maybe an angular approximation? His initial suggestion was maybe 16in W x 24in deep x 60 in tall... 4in gap on floor, which is a little taller than I would like to do...

What would be a decent cabinet design that would not be excessively large for this driver? Ideally I would like to do some sort that would have the driver approximately ear level to seated listeners. Maybe some sort of back-loaded horn? I'm not interested in large open baffle types, as I just plain don't have the space for it, and don't really care for them all that much personally. She who must be appeased must also be taken into account

There are a few goofy suggested(?) designs on the product page as well, and other than the "Canterbury" style, they all look pretty much to be oddly sized. I'll attach a few for reference, just in case the product listing disappears later. Something of a similar form factor would be nice, and I can go maybe 18" deep, maybe 20~24" wide, by 32~36" tall I suppose, but depending on what works I can be a bit flexible on things. I really wish I had a PC that I could set up some simulation software on, I don't have access to a windows machine for more than an hour or two a night at home, and what I do have is old and tired. Everything I can use at work is Chrome OS, so unless I find some sort of web-based solution I don't really know of much, other than basic vented/sealed box calculators.

So, what do you guys think? Any ideas? Maybe just a basic version of the "Canterbury" with some nice stain? Could double as a stand for a small aquarium to take up less space

Attachments

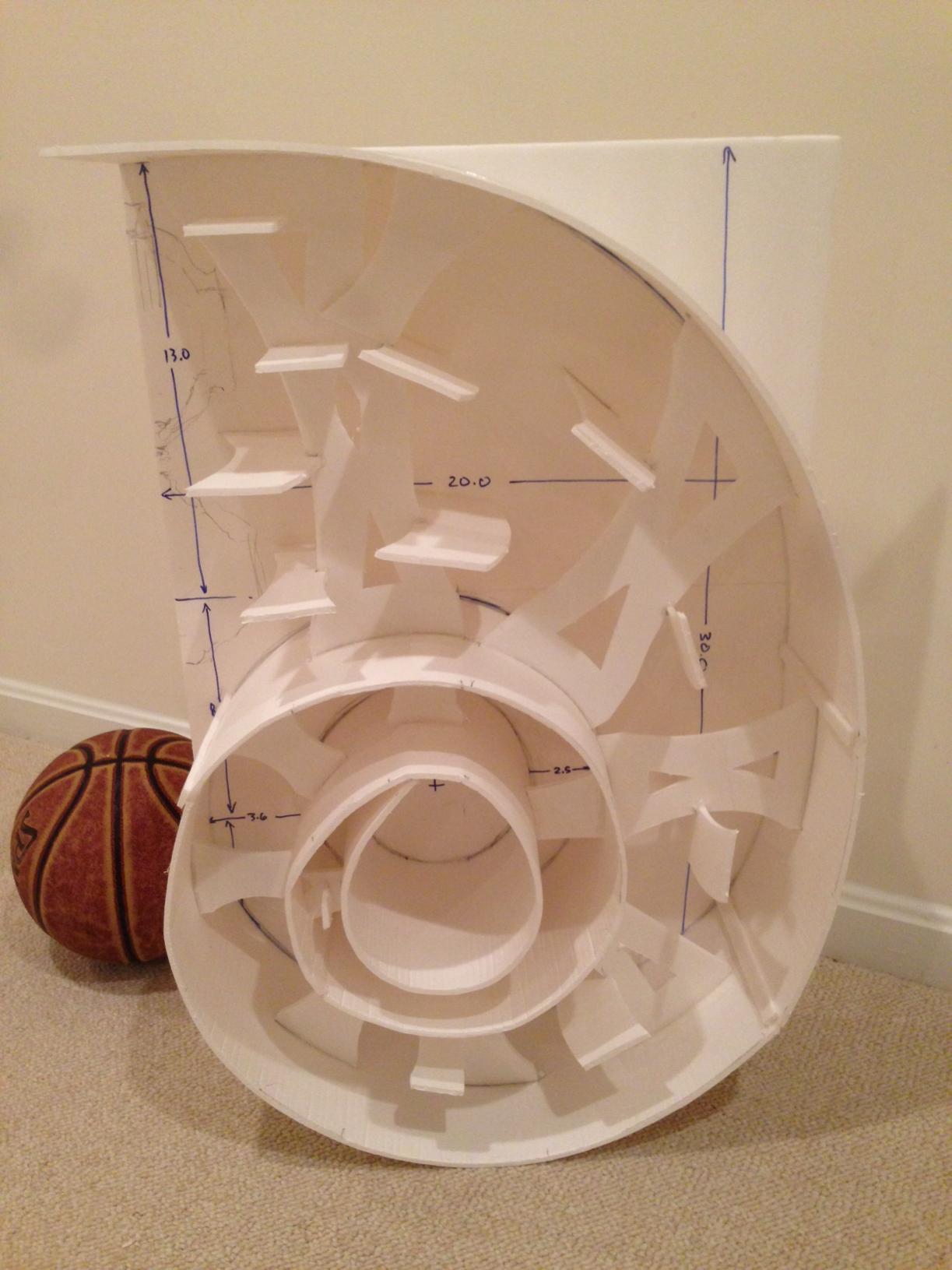

Maybe a large Nautaloss sealed spiral TL?

https://www.diyaudio.com/forums/full-range/247598-nautaloss-ref-monitor-5.html#post3748607

https://www.diyaudio.com/forums/full-range/247598-nautaloss-ref-monitor-5.html#post3748607

Hmmmm. Foamcore for the spiral, with 1/2" plywood sides? If people can get away with building 48" cornus with foamcore channels, I bet that might work here with some added bracing, you think? I can double layer the initial sections as needed. This is actually a very interesting idea!

How big? Looking at sealed box ideas I may be able to build something with a 28" wide, 44" high, 17" deep sort of form factor, with maybe .88 system Q, which may be too high I'm thinking? That's already a 350L box, not counting the driver displacement, and that's already getting pretty big. Any smaller box and I'm thinking it would make the bass too warm and boomy.

I think I should have been looking more at 8" class drivers at the raffle, but I had poor reception so couldn't pull up driver info easily before the time to grab was happening I'll make these work somehow lol.

I'll make these work somehow lol.

How big? Looking at sealed box ideas I may be able to build something with a 28" wide, 44" high, 17" deep sort of form factor, with maybe .88 system Q, which may be too high I'm thinking? That's already a 350L box, not counting the driver displacement, and that's already getting pretty big. Any smaller box and I'm thinking it would make the bass too warm and boomy.

I think I should have been looking more at 8" class drivers at the raffle, but I had poor reception so couldn't pull up driver info easily before the time to grab was happening

Is there a way to move the posts over here?

Call me old fashioned, but vintage type drivers seem to work well in vintage spec cabs with best overall power handling short of a BLH, especially if tube driven, so thinking a Vb = Vas/1.44 tuned with a vent area [Av] = [Sd] and damped to 'taste'. Worst case is one winds up stuffing it enough to be a 'Pensil' type alignment.

Assuming a ~38" seated ear height minus 1.5" thick base = ~63.37" x ~153.14"^2 WxD, ~547.39"2 vent x 0.75" baffle thickness with driver, vent offset = ~26.87", ~53.74" from top. All dims inside [i.d.].

GM

Are those dimensions in inches accurate? 153 inches?

I'm having a hard time visualising this...

you could poke one in a sealed box - for the cap to work, amp output Z needs to be low

a semi open back box (one patent showed a "K" slot)- maybe aperiodic

I think it would work in a sealed - aperiodic vent back chamber K - my Fane 12FR didn't have any noticeable peaking (nor bass) in a K12 with slit vents damped

GM's idea sounds good - lots of wood - What would G.A. Briggs done for this speaker?

What's the cap for?

I'm a tube guy, so keep in mind I will have transformer coupling to most of my builds. I can do flea power just as easily as I can do 20-25 watts with what I have on hand. I generally run push-pull with global negative feedback. I can do pretty respectable damping factor , especially with my preference to low-impedance tubes for moderate power applications, such as the EL86 and an upcoming horizontal sweep build using the 12AV5GA.

Hmmm. Aperiodic sounds interesting. I vaguely remember trying this out with plastic mesh sandwiching bits of wool stuffing a while bag, with somewhat favorable results.

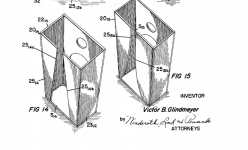

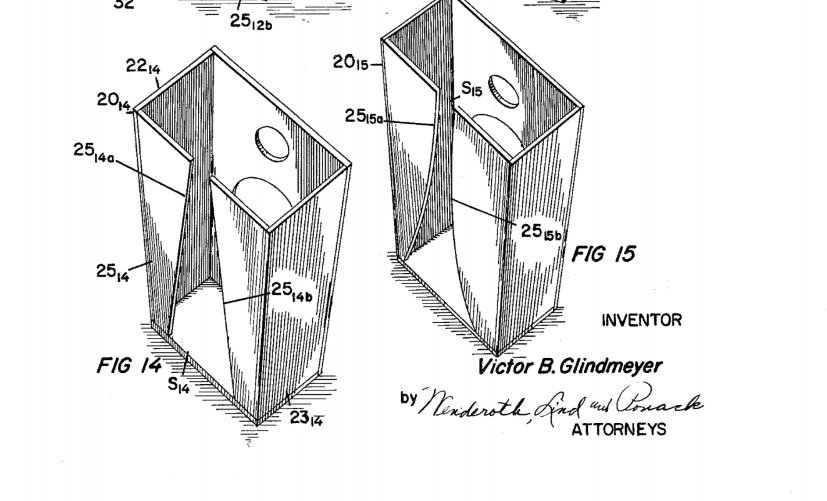

maybe someone here can guess how this arrangement of an open top pipe might work in practice - - one variant for the rear slot is "K-ish"

US3138220.pdf

US3138220.pdf

Last edited:

You mean this one?

I like it. Kind of an almost-open baffle. Wonder how far from the wall it would need to be to perform well, and if closing the top would adversely effect it? I bet it would sound pretty neutral about 18~20" away from the wall, and with some felt or carpet padding type of lining on the inside of the box/wings.

I like it. Kind of an almost-open baffle. Wonder how far from the wall it would need to be to perform well, and if closing the top would adversely effect it? I bet it would sound pretty neutral about 18~20" away from the wall, and with some felt or carpet padding type of lining on the inside of the box/wings.

Attachments

Are those dimensions in inches accurate? 153 inches?

I'm having a hard time visualising this...

Yes, inches squared [I forgot the ^], i.e. 153"^2 = cross sectional area of the cab, so you decide the width x depth.

This is a vented column speaker [aka MLTL nowadays] that has a high enough aspect ratio for its 1/4 WL TL resonances to damp the driver and vent to the point where if you size the vent per simple reflex/vented alignments the cab will be tuned somewhat lower than predicted.

All the mind numbing techno babble plus a lot more here: Quarter Wavelength Loudspeaker Design

GM

maybe someone here can guess how this arrangement of an open top pipe might work in practice - - one variant for the rear slot is "K-ish"

Well, they would mimic any number of spray/bleed nozzles used in fuel, etc., systems.

Shades of B0$3 'cherry picking', with others being Klipsch, Jensen, R-J, etc......... apparently all those earlier patents had been abandoned by '60. Noticed they misspelled Voight's name [Voigt] among other words

GM

Last edited:

de-Q-ing hole array in the baffle might help (?)

I did that with a $10 Boss 6x9 - could have lived with it other than cardboard and duct tape

I think this shallow Kazba baffle could sound pretty good.

If one took the Acoustic Control 115BK cabinet and scaled it to ~K15 bulk then the following might happen

assuming an amp with low output Z

Last edited:

dunno - perhaps it could be a bit shorter in height but a bit wider - like 18" - -might have to provide a means to tilt it back more if the central HF lobe is needed for balance at your listening position. If you had some cheap particleboard or scrap then could make a test baffle - even doubled up cardboard might suffice for test wings to get an idea of the tone as the aperture width and starting gap is varied.

An aperture like below might work for starter

An aperture like below might work for starter

I know next to nothing about speaker building, but I have a decent knowledge of woodworking. With regard to the original post and teardrop shape, you wouldn't need an angular approximation, as the outside would almost be definitely constructed using a thin plywood, that will be flexible enough to bend, and stay in place with glue. Of course, given that the main concern is with the insulative properties of the cabinet, I see two feasible options, one of which I predict will appeal to you far more than the other. The first, and by far the most complex, is to use multiple layers of thin birch plywood and glue them up in a big made from MDF. The jig could be cut out by hand, or with a cnc cutter, and you would need two parts, a front and a back, with a gap in between for the plywood. As individual layers the plywood would be able to bend into place, and then the wood glue would create a rigid bond when dry, and would prevent the wood from springing back out of shape.

The second option, is to create an angular approximation first, using mdf, to act as the functional part of the speaker cabinet, and then get a single layer of thin plywood to bend around the outside. This would be simple enough to do, so long as there is a curved surface (I would assume the top and bottom panels) for the plywood to bend around. You would need to tack the plywood in place occasionally, to help keep it tight around the form, but these would be removed afterwards, and the small holes could be filled with some wood filler. The other option to keeping the plywood in place would be to cut an inverse mould to help clamp the cabinet in place against while it dries, but doing that, one might as well create both moulds, and do the first method mentioned.

*edit* (my phone died) You might also want to look at flexible plywood. This is similar to ordinary plywood, but the veneer grain all runs in the same direction to allow it to be flexible, but I am not sure how this affects the properties of the material when concerned about sound.

Hope this helps.

The second option, is to create an angular approximation first, using mdf, to act as the functional part of the speaker cabinet, and then get a single layer of thin plywood to bend around the outside. This would be simple enough to do, so long as there is a curved surface (I would assume the top and bottom panels) for the plywood to bend around. You would need to tack the plywood in place occasionally, to help keep it tight around the form, but these would be removed afterwards, and the small holes could be filled with some wood filler. The other option to keeping the plywood in place would be to cut an inverse mould to help clamp the cabinet in place against while it dries, but doing that, one might as well create both moulds, and do the first method mentioned.

*edit* (my phone died) You might also want to look at flexible plywood. This is similar to ordinary plywood, but the veneer grain all runs in the same direction to allow it to be flexible, but I am not sure how this affects the properties of the material when concerned about sound.

Hope this helps.

Last edited:

True. Though, with the split moulds, you would definitely avoid a few problems. Interestingly, I was getting a little bored during the middle of my exams last summer, so I decided to make myself a shield, because, why not? It was made from three (or four, I forget) sheets of 3mm plywood, that were put in a large shield press contraption. This contained five arc shaped ribs, screwed in to large sheet of mdf from the underside, and a small lip, for the plywood to spot into. I put glue over the layers of plywood, and then put all the layers together in the one end of the shield press. I then used some ratchet straps, and pulled the wood slowly down onto the form. These might be a good way of pulling the two moulds together.

Does anyone think something like this could be scaled to work well, or are we looking at a five foot tall, foot and a half, two foot deep cab?

She who must be obeyed isn't too negative surprisingly, so tall may work fine up to 48" or so... I was thinking the driver mounted around seated listening height and a 42~48" height would work, with maybe a 16" width, if there are any designs that may work that way. She doesn't like the wide and square looks, and really doesn't like the big OB types, although with some scrap finish moulding the canterbury type may work, she doesn't seem too hot on that idea because it looks too "squat" for her. Maybe 50-60" tall pensil types?

Hmmmm.

Also, I'm a reasonably skilled woodworking sort of guy, I just don't have the tools to do more advanced stuff at this time, other than the occasional project snuck in on the weekends at work.

I have a jigsaw, and could make support frames/gluing jigs to try the bendy-ply types of cabs I suppose. Back in high school I was pretty heavy into archery, and actually made a handful of fiberglass/wood laminate recurve bows, and it's a pretty similar technique to get them clamped and glued.

She who must be obeyed isn't too negative surprisingly, so tall may work fine up to 48" or so... I was thinking the driver mounted around seated listening height and a 42~48" height would work, with maybe a 16" width, if there are any designs that may work that way. She doesn't like the wide and square looks, and really doesn't like the big OB types, although with some scrap finish moulding the canterbury type may work, she doesn't seem too hot on that idea because it looks too "squat" for her. Maybe 50-60" tall pensil types?

Hmmmm.

Also, I'm a reasonably skilled woodworking sort of guy, I just don't have the tools to do more advanced stuff at this time, other than the occasional project snuck in on the weekends at work.

True. Though, with the split moulds, you would definitely avoid a few problems. Interestingly, I was getting a little bored during the middle of my exams last summer, so I decided to make myself a shield, because, why not? It was made from three (or four, I forget) sheets of 3mm plywood, that were put in a large shield press contraption. This contained five arc shaped ribs, screwed in to large sheet of mdf from the underside, and a small lip, for the plywood to spot into. I put glue over the layers of plywood, and then put all the layers together in the one end of the shield press. I then used some ratchet straps, and pulled the wood slowly down onto the form. These might be a good way of pulling the two moulds together.

I have a jigsaw, and could make support frames/gluing jigs to try the bendy-ply types of cabs I suppose. Back in high school I was pretty heavy into archery, and actually made a handful of fiberglass/wood laminate recurve bows, and it's a pretty similar technique to get them clamped and glued.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Aucharm UR330B8-11F full range 12" cabinet ideas?