So I was calculated horn for TB-1772 and... it requires 320L

Such a HUGE one, but it goes from 37hz without any dips! horn lenght same as Jericho horn, about 2.9m

Hey methodarn,

I assume 320l is the chamber right?

In the sofware can you simulate a corner placement?

I got similar results with Barbara Gerhold calculation Spreadsheet and AJHorn.

They all say I will have around 350 and 400l.

Looks like my dream of a rear loading horn is fading away

I starded my Solidworks drawings which I will share here.

My aim is to keep internal ressonance to a minimum so the cabinet will have an eliptical shape with several braces.

Basically, the only feasible solution for this driver, seems to be the one I showed some posts back.

relatively large chamber and a tiny horn, most like a BR with a linear function.

Gents,

my wife set the deadline for the home theater for the end of the year (this year), so I need to get this horn going.

Just finished the "slice" for the CNC router.

In the middle there will be 2 braces on the X and Y axis.

Will not be hard to draw, I need to figure out a way to make the horn mouth look good (suggestions are most welcome) ;-)

I wanted to have it in the back but due to space constraints and the fact the front is the only flat surface, I will be forced to put it in front.

my wife set the deadline for the home theater for the end of the year (this year), so I need to get this horn going.

Just finished the "slice" for the CNC router.

In the middle there will be 2 braces on the X and Y axis.

Will not be hard to draw, I need to figure out a way to make the horn mouth look good (suggestions are most welcome) ;-)

I wanted to have it in the back but due to space constraints and the fact the front is the only flat surface, I will be forced to put it in front.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

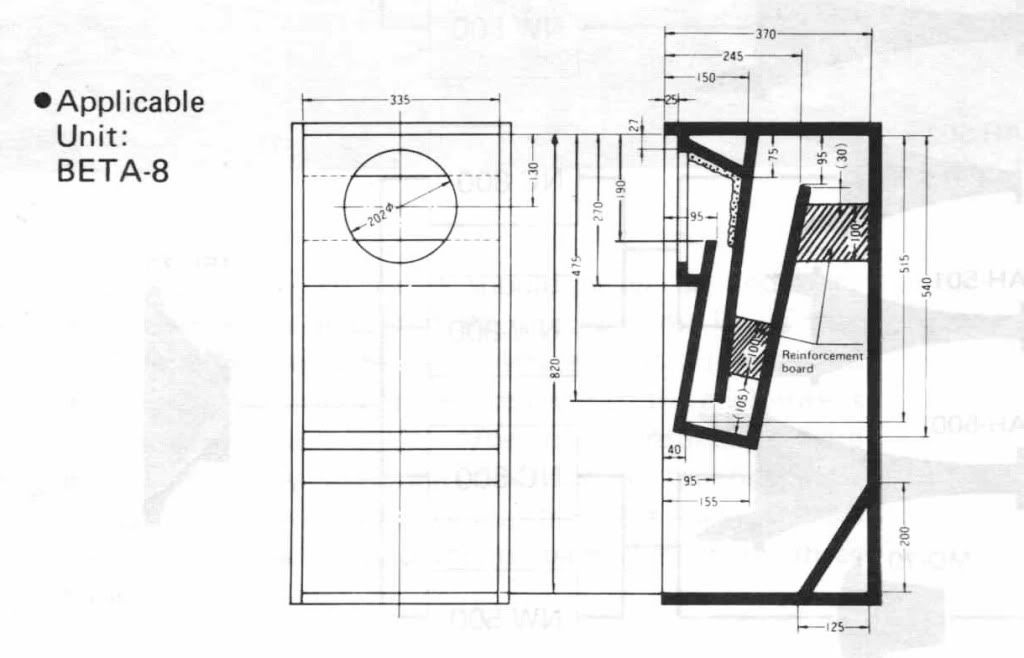

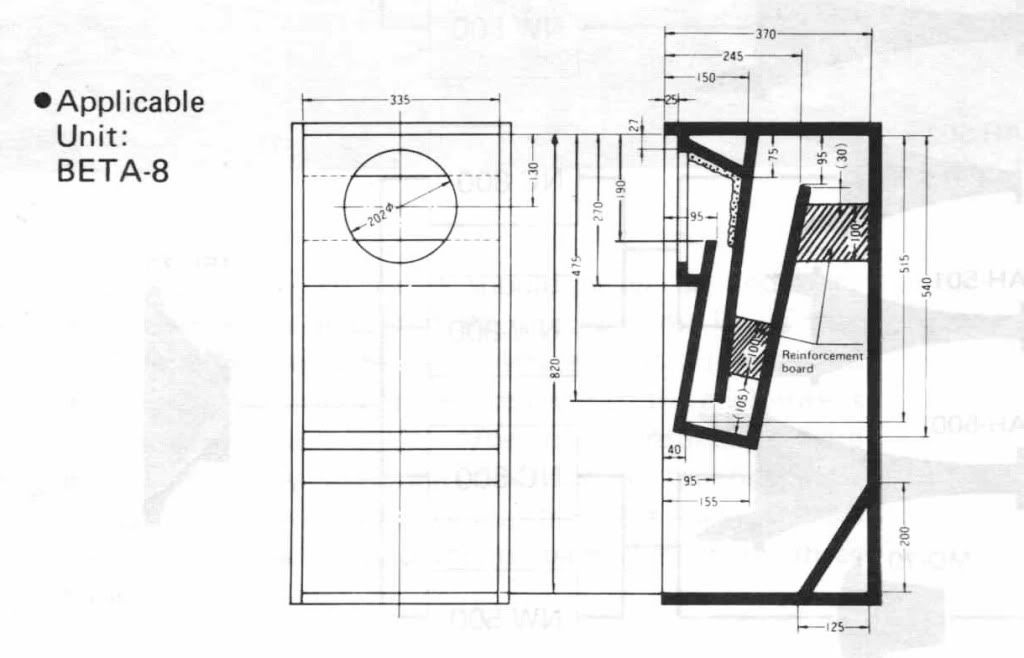

Yesterday I was tried to simulate coral beta-8 in my modified jericho horn. And I was surpised, beta's 8 have absolutely same behavior as w8-1772. So you can use Coral BLH plans with 1772

With a little modification it should work really well:

1) increase chamber to about 9-12L

2) turn horn to the corner

3) place horn about 40-60cm from corner

4) enjoy

Regards, Dima Kohan

With a little modification it should work really well:

1) increase chamber to about 9-12L

2) turn horn to the corner

3) place horn about 40-60cm from corner

4) enjoy

Regards, Dima Kohan

I am slightly more radicaland would like to have point source, with only one driver.

Decware has a nice design, but only for 6,5” drivers

http://www.decware.com/CORNERHORNPLANS.pdf

I built a set of these Decware horns years ago and highly recommend them.

If you happen to have a Shopbot CNC I can even send some cutting patterns. It really helps to have a well defined template when building these in that any deviation from well placed perfectly vertical panels can result in wonkiness quickly.

Search through the archives and you can find my report.

These are heavy and big. The upside is that everyone who has heard them comments that they are the cleanest speakers that they have ever heard. The 6.5 inch speaker barely moves and all sorts of very clean base comes out. Compared to a sub woofer, these sound like they have zero distortion. After 200 hz, they sound like Fostexs. Very good.

An issue that you will have in your small room is that a base note may not fully evolve before cancelling itself out. This horn will go down to 50 cycles but needs a 22 foot diagonal room to do it.

Speaker size means little in a horn. It is the size of the mouth that determines cut off frequency. The walls of the horn prevents the sound wave from cancelling itself so it is very efficient. Probably 10 db better than conventional under 110 hz. That's a lot. A well designed base reflect cabinet gives you 3 db.

The small driver responds instantly to changes in frequency. No inertia, no distortion. Great dynamic range.

These speakers are difficult to build. Lots of steep angles and no place for large hands. You will need lots of glue, caulking and a nail gun.

Dennis

Actually BLH not a good idea for 845 tube, cause these tubes have Ri about 1700, with good transformer and primary 3.5kOhm and secondary 8Ohm you will get about 4Ohm or more of output impedance. So set in hornresp Rg value = 4, and you will see how degradate lower bass response. Also I do not recommended amp with high output impedance for drivers with high mechanical losses such a 1772. I'm tried various of amps on these drivers and it sound best with lower than 1 Ohm output impedance tube amps.

Last edited:

Hi Methodarn,

I agree, adding to that the low force factor of these drivers almost make them unsuitable for a BLH.

Anyway, it is what it is, since I was on a budget and bought these drivers

my approach changed to a flared port BR.

Hey Dennis,

my CNC router runs on pretty standard G codes, if you have them I would be highly interested!

Regards,

Dieter

I agree, adding to that the low force factor of these drivers almost make them unsuitable for a BLH.

Anyway, it is what it is, since I was on a budget and bought these drivers

my approach changed to a flared port BR.

Hey Dennis,

my CNC router runs on pretty standard G codes, if you have them I would be highly interested!

Regards,

Dieter

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Corner Horn for TB W8-1772