I wired it up as shown above and gave it a low volume whirl. No magic smoke escaped and all the drivers seem to be happy and making the sounds they should be making! Didn't sound too bad considering it was just propped up on my table saw. Obviously, I have no idea what it's going to sound like for real, but it's a major milestone nonetheless!

Still need to get the other one wired up. And I have a new idea about the mounting that I think will be an excellent solution. I'll sketch it out for feedback in the next day or two.

Still need to get the other one wired up. And I have a new idea about the mounting that I think will be an excellent solution. I'll sketch it out for feedback in the next day or two.

Did you see the discussions and simulations over at fluids thread, based on those if you could get away isolate their back chambers four at a time think there is theoretical improvement run them wired as a 4x paralleled group and then series connect those 7 groups. Separating enclosure or not verse choosing parallel or series groups is the big question, although we up at lightspeed and can't hear or see that process if we think about it its a sequential process where power goes from positive to negative return point so if we could recognize up that speed and it was LEDs then lightning would probably run a little bit or feather, also when series wired its probably not rock solid stiff impedance they see from their neighbors when some voice coils is not at rest position either because its pushed by some electric power or other surrounding acoustic pressure.

Last edited:

Hi all,

I'm revisiting the plan with MLV. At the moment, I have the CLD layer integrated onto both sides of the baffle (Dynamat-like material). So I'm good to go there. I'm considering attaching the MLV to the drywall behind the speakers now. Sounds like the prevailing wisdom is to attach with some neoprene between the wall and the MLV. Do you think that is still valuable? I know it makes sense for stand alone speakers, but for something built into a wall with framing and concrete floor and so on, will it matter?

I'm revisiting the plan with MLV. At the moment, I have the CLD layer integrated onto both sides of the baffle (Dynamat-like material). So I'm good to go there. I'm considering attaching the MLV to the drywall behind the speakers now. Sounds like the prevailing wisdom is to attach with some neoprene between the wall and the MLV. Do you think that is still valuable? I know it makes sense for stand alone speakers, but for something built into a wall with framing and concrete floor and so on, will it matter?

To give an example of the MLV I use:

Bestel Isomat TS geluidsisolatiematten direct online op Akoestiekwinkel.nl!

The 3.2 mm thick Mass Loaded Vinyl weighs 8 Kg per square meter (!)

The thicker 5.7 mm weighs 14 Kg per square meter (!)

Mostly used as a sound barrier, with excellent results. Look at this pfd file to see some graphs (sorry it's in Dutch)

http://www.merford.com/media/202645/isomat-ts.pdf

I use it in my car on the back of my door card to block sound as it's the enclosure for my mids.

The CLD damping I use is 4mm thick Silent Coat:

Silent Coat Extra - Shop Pack - 4mm - 6 sheets - Caraudioshop.nl

This consists of mostly butyl with an aluminium foil layer as the sheer layer. This is the stuff comparable to Dynamat etc.

To me: yes, it would make perfect sense to have a neoprene layer in between the MLV and the wall. The MLV is a sound blocker, being made of a relative flexible but heavy material it will have a low base frequency or "eigenmode" of its own. By separating it from the wall with neoprene you isolate whatever movement it does have even further from that wall.

It will result in less transferred energy to that large area that runs further than "just" being one of the sides of your enclosure.

When you apply the MLV directly to the wall it will just weigh down the wall and have an eigenmode or natural resonance determined by the MLV's natural resonance + wall's natural resonance combined. It will probably lower the wall's natural resonance or eigenmode due to the added weight but you would transmit more direct energy to that wall.

That's how I interpret the theory I've read about applying MLV within sound proofing. I would think different if the wall was made of heavy bricks or concrete.

Still worried about the internal volume of that corner of yours though. If you have the whole thing mounted to the corner I'd like to see an impedance test of it for the complete speaker. Your wiring scheme will determine part of it, I'm just curious how it will look for your speaker/enclosure as a whole.

I'd be looking for weird wiggles etc. (which could lead to FR dips/peaks).

BYRTT also mentioned this a couple of posts ago. In your pré program in this thread we were treated to ideas that made sure there was plenty of air space behind the drivers (cavity in wall etc). The MLV and neoprene would further reduce that (already tight) total enclosure volume.

It will result in less transferred energy to that large area that runs further than "just" being one of the sides of your enclosure.

When you apply the MLV directly to the wall it will just weigh down the wall and have an eigenmode or natural resonance determined by the MLV's natural resonance + wall's natural resonance combined. It will probably lower the wall's natural resonance or eigenmode due to the added weight but you would transmit more direct energy to that wall.

That's how I interpret the theory I've read about applying MLV within sound proofing. I would think different if the wall was made of heavy bricks or concrete.

Still worried about the internal volume of that corner of yours though. If you have the whole thing mounted to the corner I'd like to see an impedance test of it for the complete speaker. Your wiring scheme will determine part of it, I'm just curious how it will look for your speaker/enclosure as a whole.

I'd be looking for weird wiggles etc. (which could lead to FR dips/peaks).

BYRTT also mentioned this a couple of posts ago. In your pré program in this thread we were treated to ideas that made sure there was plenty of air space behind the drivers (cavity in wall etc). The MLV and neoprene would further reduce that (already tight) total enclosure volume.

Last edited:

Got it. The beauty of my new idea on how to mount to the wall will allow some flexibility to the "enclosure" volume. For example, I can account for the thickness of the MLV layer pretty easily.

Related question for the MLV... if isolating it from the wall with neoprene is good, would letting it hang loose from the top to the bottom be even better? I was thinking that I could just screw it to the top of the wall near the ceiling and let it hang. Or perhaps do so in a top section and a bottom section since it would be very heavy.

Related question for the MLV... if isolating it from the wall with neoprene is good, would letting it hang loose from the top to the bottom be even better? I was thinking that I could just screw it to the top of the wall near the ceiling and let it hang. Or perhaps do so in a top section and a bottom section since it would be very heavy.

Wouldn't more internal volume lead to bigger discontinuities between baffle and wall? I'd try and prevent sharp corners.

Yes indeed. I'll sketch up my idea for baffle to wall interface and share that for input later this week. But to your point, my idea solves for this and other considerations as well. I'm half way through wiring up the second array but I'm on business travel this week so it may have to wait until the weekend. But I look forward to your thoughts on my idea.

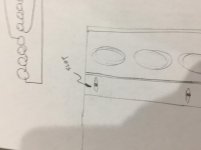

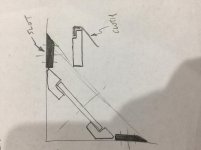

Here’s the idea for affixing the baffles to the corner. Basically, it’s just a piece of thin wood with slotted holes that I can press against the baffles to squeeze it into the corner compressing the neoprene seal before tightening the screws.

Nice thing is that I can use a spacer to get more volume and then cut a new side piece to match the new width and even profile it to minimize any sharp edges.

And of course, removal is easy too. Side note, in the sub sketch you can see I plan s shallow rabbet along the outside edge that will accommodate a strip of wood that the grill cloth will be wrapped around a couple times. Should simply wedge in tightly.

Nice thing is that I can use a spacer to get more volume and then cut a new side piece to match the new width and even profile it to minimize any sharp edges.

And of course, removal is easy too. Side note, in the sub sketch you can see I plan s shallow rabbet along the outside edge that will accommodate a strip of wood that the grill cloth will be wrapped around a couple times. Should simply wedge in tightly.

Attachments

Got everything ready to rock and roll today. And did a quick Dirac Live setup with my XMC-1. Sounds pretty good but I need to fix some things.

First, the braces I sketched out were too thin. I tried using some 1/4” MDF I had lying around but I think I need 1/2” thick material to make a more solid “clamp” so to speak.

Second, I still need to apply the felt to the sides and the MLV to the wall.

Third, and perhaps more importantly, I need to start studying my convolution stuff again!

Then there are the corroborating projects to get moving on. Namely the subs and the room treatments.

First, the braces I sketched out were too thin. I tried using some 1/4” MDF I had lying around but I think I need 1/2” thick material to make a more solid “clamp” so to speak.

Second, I still need to apply the felt to the sides and the MLV to the wall.

Third, and perhaps more importantly, I need to start studying my convolution stuff again!

Then there are the corroborating projects to get moving on. Namely the subs and the room treatments.

Attachments

Last edited:

I got everything buttoned up today. Still need to clean up some of the not so clean parts of the grill cloth at the ceiling. But otherwise, it turned out pretty nicely.

I ended up just screwing the baffle directly to the wall partially so I could use the braces purely to hold the grill cloth in place and partly because it was just stronger and simpler that way. Originally, I was not going to do so because I was concerned about not having plywood behind it but it turns out the shear wall was there on all three walls.

Next I need to think of a way to trim the grill cloth at the top and bottom. And of course, get out my convolution tutorials.

I ended up just screwing the baffle directly to the wall partially so I could use the braces purely to hold the grill cloth in place and partly because it was just stronger and simpler that way. Originally, I was not going to do so because I was concerned about not having plywood behind it but it turns out the shear wall was there on all three walls.

Next I need to think of a way to trim the grill cloth at the top and bottom. And of course, get out my convolution tutorials.

Attachments

That's an especially big and noisy Mac tower to put in the music/movie room!

It's actually broken. And I have a friend's matching Mac Pro. I was considering using them both as part of my shelving build.

Still TBD until I figure out exactly how I'm going to build the subwoofers into the wall. I bought that Mac Pro about 10 years ago and it actually worked fine when I put it in storage before our remodel. But I think it was too humid where it was stored and it didn't survive.

Still considering a small NUC or similar PC for JRiver/HTPC duties. Any suggestions?

Could be just corroded connections.

Take everything apart, memory sticks, PCIs, HD cables, etc...

Then, when you start rebuilding it, insert the cable/connectors a few times in and out. That should clean the connections a bit and see if it fires up.

If not, lots of people are using those towers and putting PC parts in them. Either making them a Windoz machine or a hackintosh.

Having lived with the real thing, a hackintosh and a Windoz, I suggest staying with PC and JRiver. The audio driver with JRiver and using it as output is very handy, saving a lot of steps. To my ears, the Core Audio Mac drivers are a tad cleaner compared to their PC Asio counterparts, but the easiness of JRiver on the PC side wins the balance.

I'm using Win8 here, as all the Win10 privacy issues are quite bad... My box rarely connects to the internet. It's mostly a local music/movie server.

Take everything apart, memory sticks, PCIs, HD cables, etc...

Then, when you start rebuilding it, insert the cable/connectors a few times in and out. That should clean the connections a bit and see if it fires up.

If not, lots of people are using those towers and putting PC parts in them. Either making them a Windoz machine or a hackintosh.

Having lived with the real thing, a hackintosh and a Windoz, I suggest staying with PC and JRiver. The audio driver with JRiver and using it as output is very handy, saving a lot of steps. To my ears, the Core Audio Mac drivers are a tad cleaner compared to their PC Asio counterparts, but the easiness of JRiver on the PC side wins the balance.

I'm using Win8 here, as all the Win10 privacy issues are quite bad... My box rarely connects to the internet. It's mostly a local music/movie server.

Thanks for the tip. I may try that.

Also, I am leaning towards PC and JRiver for much of why you mention. I hadn't thought about using an older version of Windows but I would be using the machine for netflix and PS Vue and such. Would that mean using a more recent version would be better? I was thinking about a Intel NUC with win 10 built in would be an option. And I would add an external blu-ray player to play content that I couldn't stream.

Any suggestions for an external blu ray?

Also, I am leaning towards PC and JRiver for much of why you mention. I hadn't thought about using an older version of Windows but I would be using the machine for netflix and PS Vue and such. Would that mean using a more recent version would be better? I was thinking about a Intel NUC with win 10 built in would be an option. And I would add an external blu-ray player to play content that I couldn't stream.

Any suggestions for an external blu ray?

For audio and JRiver suggest go for highest real single core performance CPU you can afford/get, the newer generations of CPU's with high numbers of core and threads won't help its better use ones with few real cores and highest as possible single core clock performance.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- "Wall-integrated" corner loaded line array with Vifa TC9 drivers