No better ideas, so I'm taking a punt on a couple of the Peerless units, the NE65 (2" alu) and NE123 (4" paper).

The 2" is essentially a big tweeter. Based on specs (and 3rd party tests of other drivers in the range), it looks great, the major caveat being low max SPL. As a direct radiator, it would be excursion limited to 95dB @ 300Hz.

This will be a new thing for me - I've usually compromised in the other direction, accepting worse HF response in favour of efficiency & output.

The 4" appears to be a better version of what I'm used to - it has a more open frame, better motor structure, MUCH smaller (neo) magnet, more Xmax, and the break up modes seem to be higher up.

The attached comparison makes my current favourites look quite primitive.

Will post findings / impressions in a month or so.

The 2" is essentially a big tweeter. Based on specs (and 3rd party tests of other drivers in the range), it looks great, the major caveat being low max SPL. As a direct radiator, it would be excursion limited to 95dB @ 300Hz.

This will be a new thing for me - I've usually compromised in the other direction, accepting worse HF response in favour of efficiency & output.

The 4" appears to be a better version of what I'm used to - it has a more open frame, better motor structure, MUCH smaller (neo) magnet, more Xmax, and the break up modes seem to be higher up.

The attached comparison makes my current favourites look quite primitive.

Will post findings / impressions in a month or so.

Attachments

I have had luck using a TG9FD and many people swear by the SB65WBAC in large horns. I wouldn't worry too much about the frame as you will want to seal the rear of the driver if you are horn loading anyway.

With the TG9, after CD equalisation, the higher frequencies were as loud coming out the back as the front and didn't add anything nice to the overall sound, then after making rear chambers for them, the sound significantly improved

YouTube

With the TG9, after CD equalisation, the higher frequencies were as loud coming out the back as the front and didn't add anything nice to the overall sound, then after making rear chambers for them, the sound significantly improved

YouTube

I have had luck using a TG9FD and many people swear by the SB65WBAC in large horns.

And Frangus (another Aussie who was on this forum) was happily using an even less efficient 2" on a very similar horn

I wouldn't worry too much about the frame as you will want to seal the rear of the driver if you are horn loading anyway.

'Choking' the back of the driver with a bad cutout does bad things to frequency response:

chamfering driver holes

If opening the back of the driver up by chamfering the mounting hole is a good thing, I assume that opening it up further by using a streamlined frame & neo magnet would be more of a good thing.

With the TG9, after CD equalisation, the higher frequencies were as loud coming out the back as the front and didn't add anything nice to the overall sound, then after making rear chambers for them, the sound significantly improved

Not an open baffle fan?

I was thinking of trying an aperiodic (leaky box) or stuffed open line behind the driver, which would let the rear wave leak out, somewhat attenuated - but I'll keep your input in mind, and give sealed a go.

Nice, clean-looking build, by the way.

'Choking' the back of the driver with a bad cutout does bad things to frequency response:

chamfering driver holes

If opening the back of the driver up by chamfering the mounting hole is a good thing, I assume that opening it up further by using a streamlined frame & neo magnet would be more of a good thing.

If you are building the horn you can design it so you screw the driver straight onto the horn mounting plate and you have no chamfering to worry about, then attach an enclosure to that (If you want to

Not an open baffle fan?

I don't mind them, I just found that when you reduce dispersion of a speaker by putting it in a horn, the rear sound is very out of place

Nice, clean-looking build, by the way.

Thanks

Post 52 here puts it nicely.

Innerchoic cabinets - should I?

Pertinent to this thread is his earlier comment (post 48)

...which seems to confirm my suspicion that reducing reflections from the magnet is worthwhile; more important than going nuts with cabinet treatment.

Currently, am still waiting for the delivery from Parts Express. Digikey are much faster and also a bit cheaper, but they don't stock the NE123 I want to try.

Innerchoic cabinets - should I?

Pertinent to this thread is his earlier comment (post 48)

"You should see the clicks reflecting off different things inside the box on the scope [...]

The biggest one for mine was the woofer magnet"

The biggest one for mine was the woofer magnet"

...which seems to confirm my suspicion that reducing reflections from the magnet is worthwhile; more important than going nuts with cabinet treatment.

Currently, am still waiting for the delivery from Parts Express. Digikey are much faster and also a bit cheaper, but they don't stock the NE123 I want to try.

Take a look at Fane 12-250TC full ranger.

I have a couple in a sealed box and they sound good.

Fane : Fane Sovereign 12-250TC :: PS67.30 IN STOCK (10 Apr 2018)

I have a couple in a sealed box and they sound good.

Fane : Fane Sovereign 12-250TC :: PS67.30 IN STOCK (10 Apr 2018)

I admire your enthusiasm for Fane drivers, but what I said in post 1 still stands: I'm after a small-ish driver for horn loading, specifically something with a sleek (low reflection) motor & frame.Take a look at Fane 12-250TC full ranger.

I have a couple in a sealed box and they sound good.

My new neo magnet drivers, which hopefully are a step in this direction, are now in country (Yay!), but the courier service they used (Fastway) is substantially worse/more awkward than the generic Australia Post, so I'm not sure when I'll actually get my hands on them

Interesting discussion in that thread. I always try to put 12-18mm natural wool felt on the magnet of drivers. I'm glad to see more evidence that I'm not crazy

It makes sense to me that felt would scatter (mostly) and reduce (slightly) the reflection, so this should give better sound then a single big reflection.

When I try small driver tweaks like this, the result seems pretty subtle. I see improvements in the impulse plot more than in the FR plot, but I don't know enough to really interpret what this means ...I keep seeing comments from official clever people saying that time-based plots and FR plots can be generated / inferred from each other, and but that info hasn't really sunk in properly with me. I need a dummies guide

can you post some pics of how you constructed these horns?

The smaller horns in post 20 are JBL 2370 flat-front Bi-Radials. These aren't in use.

The larger horns in post 20 are based on no-name plastic horns from ebay (seller = zxpc).

I chose the longest 2" horns I could get at a reasonable price, after rejecting some local options (mostly JBL or JBL clones, with slots and/or sharp angles in the throat).

I modified the throat + extended the mouth with wood and filler.*

Which flare shape did you use?

They look expo, but may not be. I picked them for the relatively low flare rate (to be a reasonable match to old JBL drivers) and smooth walls (low diffraction).

The exact type of curve used doesn't concern me as much as those points.

*In hindsight, I think extending the mouth with foam + a thin rigid layer would have been a lot less work. I keep posting this link cos I think it is a lot more clever than what I did:

Klipsch K402 replica build - DIY Audio Projects - StereoNET

Last edited:

... what I said in post 1 still stands: I'm after a small-ish driver for horn...

Have you considered the drivers JBL make for exactly this application?

The units are made for their own use, optimized for performance rather than sales gimmicks.

The 2164 is a 4" cone optimized for low distortion and inductance minimization with practically every technique known to science - aluminium Faraday plates, copper plated poles, flux stabilization coils inside and out, etc. etc.

There's a JAES paper about it, and a patent.

Not a minimalist frame but not a bulky magnet either.

There is also a 5.5" version updated with Dual Differential Voice Coil - 2165.

They are used in the top-of-the-line line arrays.

They are not inexpensive of course

Best wishes

David

Last edited:

Have you considered the [...] 2164 is a 4" cone optimized for low distortion and inductance minimization with practically every technique known to science

I've never heard of them. This driver?

JBL 5031632X 2164H Woofer - Speaker Exchange

They'd be >Aus $600 a pair delivered. Maybe they are superb, but I'm very hesitant to pay for something with no published FR plot (that I can find).

optimized for performance rather than sales gimmicks.

They certainly didn't waste any money on the frame or on neo magnets

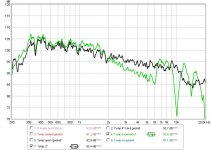

I did some quick tests of the new toys: 4" NE123w-08 and 2" NE65w-04

The 4" isn't made for rear mounting, so it needs a gasket. It seems to be smoother with a leaky gasket, and the response is pretty sensitive to small changes: lots of trial and error needed.

I'm currently working on another horn that may suit it better. If not, I may give up and use it as a typical HiFi midrange.

It does have an obvious difference to my prior 4" drivers: the frame blocks / reflects the HF a lot less, so it is much more extended and intelligible when listening from the back.

The red + green FR plots show it mounted on a 2" throat horn, with different mounting types.

The 2" driver is startlingly tiny. It works nicely on the same horn, with no need for a gasket. The black + green FR plot shows this versus the 4". It sounds good with a bit of eq & some open cell foam (Geddes inspired).

These are full space measurements without eq (just a 200Hz high pass), measured 50cm from horn mouth. Nothing clever done (no windowing, not calibrated with SPL meter, mic is positioned on reflective object).

The 4" isn't made for rear mounting, so it needs a gasket. It seems to be smoother with a leaky gasket, and the response is pretty sensitive to small changes: lots of trial and error needed.

I'm currently working on another horn that may suit it better. If not, I may give up and use it as a typical HiFi midrange.

It does have an obvious difference to my prior 4" drivers: the frame blocks / reflects the HF a lot less, so it is much more extended and intelligible when listening from the back.

The red + green FR plots show it mounted on a 2" throat horn, with different mounting types.

The 2" driver is startlingly tiny. It works nicely on the same horn, with no need for a gasket. The black + green FR plot shows this versus the 4". It sounds good with a bit of eq & some open cell foam (Geddes inspired).

These are full space measurements without eq (just a 200Hz high pass), measured 50cm from horn mouth. Nothing clever done (no windowing, not calibrated with SPL meter, mic is positioned on reflective object).

Attachments

Last edited:

Thanks @hollowboy for posting the results. I get a similar LP rolloff (-6db/octave) that I was trying to "flatten" or at least extend abit more before it rolls off.

Is there a reason you're using woofers instead of full range drivers? In my simulations, drivers with higher Qms seemed to work better.

Is there a reason you're using woofers instead of full range drivers? In my simulations, drivers with higher Qms seemed to work better.

Yes...This driver?

They'd be >Aus $600 a pair delivered. Maybe they are superb, but I'm very hesitant...

Perhaps a little less than $600 if you can find a reasonable postal rate, but over AU$500 for sure so I understand the hesitation

They have posted linearity and inductance data out to 15 kHz but no FR plot AFAIK.

They are from one of JBL's top systems so I expect they are excellent but I am curious to see FR data too.

You will become the leader if you measure one yourself

They certainly didn't waste any money on the frame or on neo

It does use neo magnets, frame looks plain but is cast aluminium and used as part of the Faraday flux stabilization and inductance reduction system.

Best wishes

David

The 2" driver doesn't have this much rolloff - a 6dB/octave rolloff would mean a drop of 24dB from 500Hz-8kHz. The FR plot for the 2" (black line) shows only 10dB difference over this range.I get a similar LP rolloff (-6db/octave) that I was trying to "flatten" or at least extend abit more before it rolls off.

10dB gain at the low end of the driver's range is (largely) the point of the horn loading

With a larger (~4") driver, two additional things you might try to get more extension:

1) in my chart (green vs red) for the 4" peerless, the green goes almost 1kHz further before the rolloff. The only difference is that the green uses a leaky gasket.

I noticed that when I made a cardboard gasket (cut from a cardboard box), I got different FR plots depending on whether I taped up the edges of the cardboard, to seal the corrugations. If I recall correctly, there was something similar in the old Edgar midrange horn articles.

2) My P.Audio SN4-60F drivers have been smoother up to 4kHz than the other similarly-sized drivers I've tried. My guess is that their thicker, stiffer cones that are more suited to horn loading. Switching to these, or something similarly stiff (e.g. PRV Audio 5MR450-NDY-4) might help.

? These Tympany drivers, and other cone drivers I've tried (P.Audio SN4-60F, Fostex FF105WK) are marketed as full range drivers, and their (raw) FR plots support this.Is there a reason you're using woofers instead of full range drivers?

It seems to me that HF response cannot be predicted from TSP.In my simulations, drivers with higher Qms seemed to work better.

1) My 4" P.Audio drivers have a Qms of 1.69 (spec sheet), but they have more flat bandwidth on a horn than the 4" Tymphany (Qms 4.98). This is the opposite of your simulations.

2) One of my P.Audio drivers has a faulty (weak) magnet, but the HF extension of the faulty driver is exactly the same as the others, which goes against ye olde horn lore.

Midrange (cone driver) horns; low relevance of magnet strength and Qts

A couple more photos. Hopefully the order I see is the order you see.

Pic 1: modded horn, mounted in cabinet (50x70cm face).

Pic 2: ditto, still in progress but looking better - smoothed curves and less hideous paint.

Pic 3: this other project is what I'm considering for the 'skin'.*

Pic 4: the stock horn, with a JBL 2445 driver and boots for scale.

*the pale front = wide grain natural bamboo, the darker exterior is strand woven carbonised bamboo, both 5mm thick ...and the white thing on the floor is a cast for yet another horn

Ima have to find my 'real' camera for this. The bamboo is more pretty than I can show with a phone camera.

Pic 1: modded horn, mounted in cabinet (50x70cm face).

Pic 2: ditto, still in progress but looking better - smoothed curves and less hideous paint.

Pic 3: this other project is what I'm considering for the 'skin'.*

Pic 4: the stock horn, with a JBL 2445 driver and boots for scale.

*the pale front = wide grain natural bamboo, the darker exterior is strand woven carbonised bamboo, both 5mm thick ...and the white thing on the floor is a cast for yet another horn

Ima have to find my 'real' camera for this. The bamboo is more pretty than I can show with a phone camera.

Attachments

Last edited:

Update: a very positive review.

My Parts Express order had 8 items in it - the cone drivers, some adapters, and a couple of cheap 1" CDs.

Most of the parcel was fine, but one of the CDs arrived broken. They had been packaged in individual bundles, but in such a way that the terminals protruded from bundle. One of the terminals had snapped. It might be fixable - there may be a point that I can solder onto.

I sent them photos of the packaging and damage, hoping to get a refund for that item. They refunded me for the ENTIRE order.

My Parts Express order had 8 items in it - the cone drivers, some adapters, and a couple of cheap 1" CDs.

Most of the parcel was fine, but one of the CDs arrived broken. They had been packaged in individual bundles, but in such a way that the terminals protruded from bundle. One of the terminals had snapped. It might be fixable - there may be a point that I can solder onto.

I sent them photos of the packaging and damage, hoping to get a refund for that item. They refunded me for the ENTIRE order.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- paper cone open frame driver for front horn