Ok, I see it if I download the PDF just not in the image in the post. The dimensions are very close to what I ended up at for the foam core homage.

http://www.diyaudio.com/forums/atta...ore-mini-build-fh3-inspired-foamcore-plan.jpg

http://www.diyaudio.com/forums/atta...ore-mini-build-fh3-inspired-foamcore-plan.jpg

Last edited:

http://www.diyaudio.com/forums/full...pired-foam-core-mini-build-3.html#post3339779

And it looks like this:

And it looks like this:

Last edited:

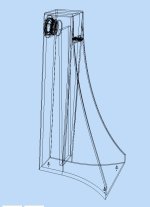

Beautiful design, I modeled up with a little larger horn back and slender curve.

Tony

Tony

Attachments

-

frugal lite.jpg73.2 KB · Views: 80

frugal lite.jpg73.2 KB · Views: 80 -

58708BB1-3225-4324-BFFB-673AD7F5E956.jpeg26 KB · Views: 77

58708BB1-3225-4324-BFFB-673AD7F5E956.jpeg26 KB · Views: 77 -

D03CE0D7-834B-4DB7-A3FD-6A51A5F23B45.jpeg25.3 KB · Views: 62

D03CE0D7-834B-4DB7-A3FD-6A51A5F23B45.jpeg25.3 KB · Views: 62 -

1A3CC9DE-7D71-4EC1-AA0D-528946643FB7.jpeg25.8 KB · Views: 62

1A3CC9DE-7D71-4EC1-AA0D-528946643FB7.jpeg25.8 KB · Views: 62 -

DFED426E-CB8A-420E-843C-92FC0CF1FC0E.jpeg22 KB · Views: 61

DFED426E-CB8A-420E-843C-92FC0CF1FC0E.jpeg22 KB · Views: 61 -

CB7E5CC7-633A-4AC2-8585-5C5776B2E878.jpeg24.1 KB · Views: 73

CB7E5CC7-633A-4AC2-8585-5C5776B2E878.jpeg24.1 KB · Views: 73

Last edited by a moderator:

Hi Tony,Beautiful design, I modeled up with a little larger horn back and slender curve.

Tony

That’s superb modeling you did there to get compound curves like that - was that done using a “swept curve” approach?

A curved plywood implementation would look fantastic.

Thanks for looking into this. I really like the organic shape - like a sail on a boat filled with wind.

Thanks X, here is pictures of the 3d print of the model.Hi Tony,

That’s superb modeling you did there to get compound curves like that - was that done using a “swept curve” approach?

A curved plywood implementation would look fantastic.

Thanks for looking into this. I really like the organic shape - like a sail on a boat filled with wind.

View attachment 1204827

View attachment 1204828

Attachments

I was going to wait to play music until I got the pair done but been having a little trouble with my printer for my last piece. The bottom part took 10 day to print. The top half took 6 days. I may plug the on in this weekend. Inhale the two pieces clamped together and have acoustic stuffing in place.here is a picture of two pieces looking at the joint.

Attachments

no, printing 20% infillAre you printing these as Solids !?

- Home

- Loudspeakers

- Full Range

- XRK Homage tp the Frugel-Horn but for 3" drivers