Freddi,

Wing thickness is 1/2inch ply, but needs to be much more rigid. So far they are violently vibrating.

The mock up box plywood is just scrap material. Nothing fancy just 3/4 inch ply, except for the wings.

I do have some questions:

1. What bracing is needed on large panels? Back wall and base and top are very resonant.

2. What panel damping is recommended if any? Constrained layer?

Is Greg B the best person to make recommendation on this box?

Wing thickness is 1/2inch ply, but needs to be much more rigid. So far they are violently vibrating.

The mock up box plywood is just scrap material. Nothing fancy just 3/4 inch ply, except for the wings.

I do have some questions:

1. What bracing is needed on large panels? Back wall and base and top are very resonant.

2. What panel damping is recommended if any? Constrained layer?

Is Greg B the best person to make recommendation on this box?

GregB and XRK971 would both have good ideas on bracing the Karlsonator12

mine does pretty well with no bracing but of course could benefit - here's one loaded with Jesse's BG20 -dowel struts to the wings would work - K15 benefits a lot from simple bracing and can do jaw dropping transients. I think a couple of vertical 1.5" by 0.75" plywood strips on-edge would help the back panel. Screws with large heads or even drywall screws with fender cup washers might help the wings.

sturdy cleats for wings and back (if removable) help.

if I ever get some space cleared, then will try an Eminence 12cx in a Karlsonator 12 - its the best I've heard for 12LTA and

Nirvana Super10 so far

mine does pretty well with no bracing but of course could benefit - here's one loaded with Jesse's BG20 -dowel struts to the wings would work - K15 benefits a lot from simple bracing and can do jaw dropping transients. I think a couple of vertical 1.5" by 0.75" plywood strips on-edge would help the back panel. Screws with large heads or even drywall screws with fender cup washers might help the wings.

sturdy cleats for wings and back (if removable) help.

if I ever get some space cleared, then will try an Eminence 12cx in a Karlsonator 12 - its the best I've heard for 12LTA and

Nirvana Super10 so far

Last edited:

Freddi,

Wing thickness is 1/2inch ply, but needs to be much more rigid. So far they are violently vibrating.

The mock up box plywood is just scrap material. Nothing fancy just 3/4 inch ply, except for the wings.

I do have some questions:

1. What bracing is needed on large panels? Back wall and base and top are very resonant.

2. What panel damping is recommended if any? Constrained layer?

I just sent you a PM with suggestions, but didn't notice you used 1/2" material for the wings. Constrained layer might work well here. If it were mine, I'd laminate some 1/4" hardboard to the wings with Sikaflex or something similar.

Is Greg B the best person to make recommendation on this box?

Probably not...

advancing...

Greg B,

Thanks for your input. Yes it's exactly per Karlsonator 12 plans. I'm using a 12" coaxial Tannoy driver. Moving along... after more listening I really feel this design is wonderful and should be taken to the max as far as fine tuning. It's worth it.

My application will be high SPL (outdoors).

Box needs to as light as possible so I will use medium thickness baltic ply with lots of bracing.

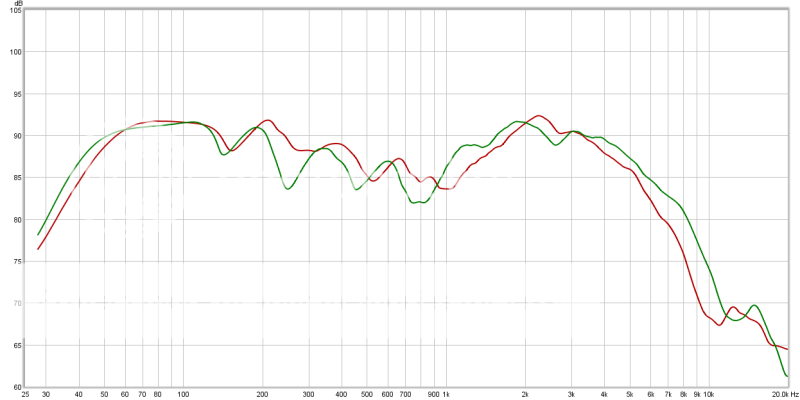

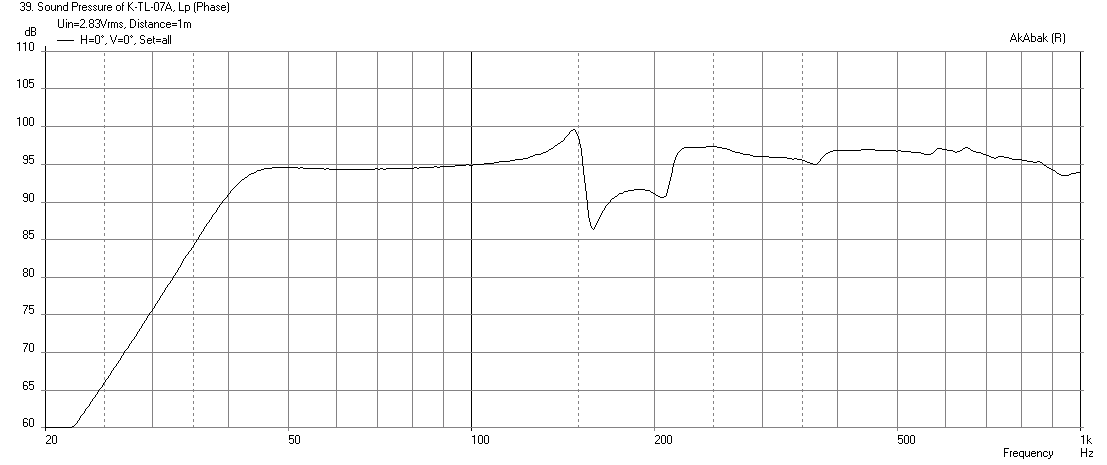

So far here are some measurements "as is" box, 1 meter from mic. Disregard blue trace.

Any thoughts on what's causing 250hz dip?

Plate amp:

I will need a very good sounding plate amp with balanced in. Any good options beside Hypex and miniDSP for PA style plate amp?

Greg B,

Thanks for your input. Yes it's exactly per Karlsonator 12 plans. I'm using a 12" coaxial Tannoy driver. Moving along... after more listening I really feel this design is wonderful and should be taken to the max as far as fine tuning. It's worth it.

My application will be high SPL (outdoors).

Box needs to as light as possible so I will use medium thickness baltic ply with lots of bracing.

So far here are some measurements "as is" box, 1 meter from mic. Disregard blue trace.

Any thoughts on what's causing 250hz dip?

Plate amp:

I will need a very good sounding plate amp with balanced in. Any good options beside Hypex and miniDSP for PA style plate amp?

Attachments

The dip was predicted in x's sims. Adding damping will likely reduce it significantly. You will see soon. The vibrating thin wings probably aren't helping. High efficiency speakers typically aren't going to be ruler flat anyway.

For high SPL and outdoors, I might consider open cell 'eggcrate' foam for lining. IME this stuff sucks the life from the music at low volumes, so I don't generally use if for hifi, but it works well when things are cranked.

Sorry, no experience with plate amps. Someone must know.

FWIW, I found wheels to be very useful in my band gigging days. Seems dorky, but it really helps with moving heavy speaker boxes around.

For high SPL and outdoors, I might consider open cell 'eggcrate' foam for lining. IME this stuff sucks the life from the music at low volumes, so I don't generally use if for hifi, but it works well when things are cranked.

Sorry, no experience with plate amps. Someone must know.

FWIW, I found wheels to be very useful in my band gigging days. Seems dorky, but it really helps with moving heavy speaker boxes around.

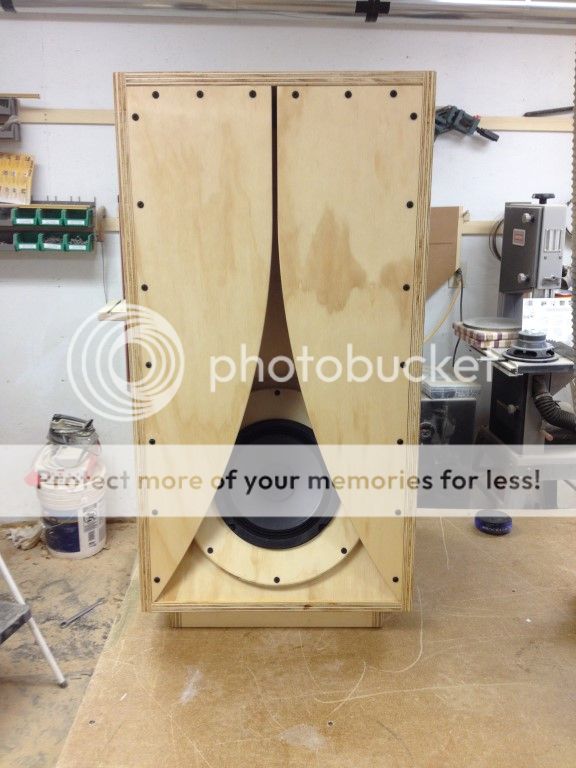

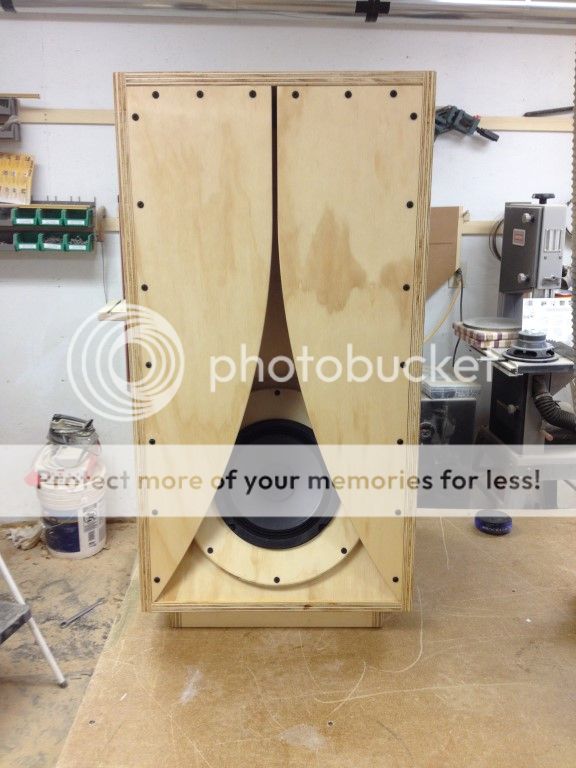

Just a quick update. One mock up box made per plans. Sounds promising. Next step is to do proper bracing and damping.

View attachment 501645

View attachment 501646

View attachment 501647

Novi:

Looks great!

if the K-aperture is vibrating try adding strips of wood internally as bracing. Or add second layer of plywood bonded on with semi viscous glue like PL or Liquid Nails for CLD. Put drywall screws through several places though to lock edges together - should be stiffer and better damping.

The 250Hz dip may be the normal band pass cancellation caused by having the rear wave pass over the front cone. If the distance from the rear cone to the front cone is 27in - that is the half wave cancellation dip at 250Hz. Otherwise may be combination of that and floor bounce cancellation. Where is speaker mounted? Try putting on 30in tall stand and mic 0.5m away and see if dip is still as bad.

Last edited:

Yes, I will be bracing the heck out of this box. For now I'd like to ask about the wings:

Once they are made very rigid, is it possible that the high frequencies are bouncing around in this cavity? Bad thing? Has anyone lined the inside of the wings with absorption?

It seems to me that absorbing all freq above the karlson aperture loading freq is like "cleaning up the dirt". I may be wrong because I have not tried this yet. But I will.

What type/thickness felt would be optimal for this area? On the other hand, do not like dead sound -- just a little cleaner.

Once they are made very rigid, is it possible that the high frequencies are bouncing around in this cavity? Bad thing? Has anyone lined the inside of the wings with absorption?

It seems to me that absorbing all freq above the karlson aperture loading freq is like "cleaning up the dirt". I may be wrong because I have not tried this yet. But I will.

What type/thickness felt would be optimal for this area? On the other hand, do not like dead sound -- just a little cleaner.

Last edited:

Just a quick update. One mock up box made per plans. Sounds promising. Next step is to do proper bracing and damping.

View attachment 501645

View attachment 501646

View attachment 501647

Nice Karlsonators, novigera!

By the way, are those Funktion one's in the background? Kool!

the original Karlson sat on the floor and used coaxial or fullrange speaker so it was useful to angle the higher frequency lobes upwards. Also, Karlson spoke of reverberation/"controlled ringing" effects - his first Acoustic Transducer patent stated - greater tilt = more bass, greater ring, poorer transient response. Another feature was in hope to dump energy to the room as the baffle angle tapered the volume down towards zero when the aperture's expansion is finished.

Nice Karlsonators, novigera!

By the way, are those Funktion one's in the background? Kool!

Those do like F1's - looks like he has a mixing studio. Very Kool now with a K.

Another stupid question:

what is the purpose of angling the driver into the aperture?

Also reduces flat-flat half wave interference cancellation of cone direct radiation reflected off inside of K aperture.

Yep, those are F1's that I currently use. RES1.5 tweeter, RES3 mid, DS15 midbass.

Getting the second karlsonator box built for a stereo pair...

Few questions:

Is it a good strategy to build as rigid as possible to eliminate any panel vibrations (with lots of cross bracing) or can I let it "sing" along a bit?

So far I'm planning to get the karlson wings be made from solid cedar to let them "sing", while the rest of box is made very rigid from plywood...

Getting the second karlsonator box built for a stereo pair...

Few questions:

Is it a good strategy to build as rigid as possible to eliminate any panel vibrations (with lots of cross bracing) or can I let it "sing" along a bit?

So far I'm planning to get the karlson wings be made from solid cedar to let them "sing", while the rest of box is made very rigid from plywood...

Is it a good strategy to build as rigid as possible to eliminate any panel vibrations (with lots of cross bracing) or can I let it "sing" along a bit?

So far I'm planning to get the karlson wings be made from solid cedar to let them "sing", while the rest of box is made very rigid from plywood...

If you let them flex and "sing" you may get a smoother overall frequency response and deeper bass extension because it acts as a passive radiator. I have done this, but the harmonic distortion may be noticeably higher, and even downright bad in some cases with a panel resonance becoming a "buzzing" sound at some frequencies. Strategic bracing behind the K-aperture or wing can help and still let it vibrate some. A stiff K-aperture will have the lowest HD, but the largest magnitude frequency response dips. Lining the back side of the K-aperture with felt helps quite a bit.

Based on the following T/S parameters that I got for this driver:

Code:| Tannoy 12 in paper cone with Qts=0.50 Sd=531.0cm2 fs=57Hz Mms=75.0g Qms=8.065 Qes=0.573 Re=5.128ohm Le=0.38mH Vas=36.8L

The optimal size of the Karlsonator is close to a standard 12in Karlsonator per GregB's design. In fact, you could use it as drawn and it would work very nicely with about 44Hz f3. However, if you want a little more bass extension and a flatter response, scale the height by 13/12x (taller) and the width by 11/12x (narrower) and you will get this for SPL vs frequency - good for about 95dB sensitivity with an f3 of 41Hz:

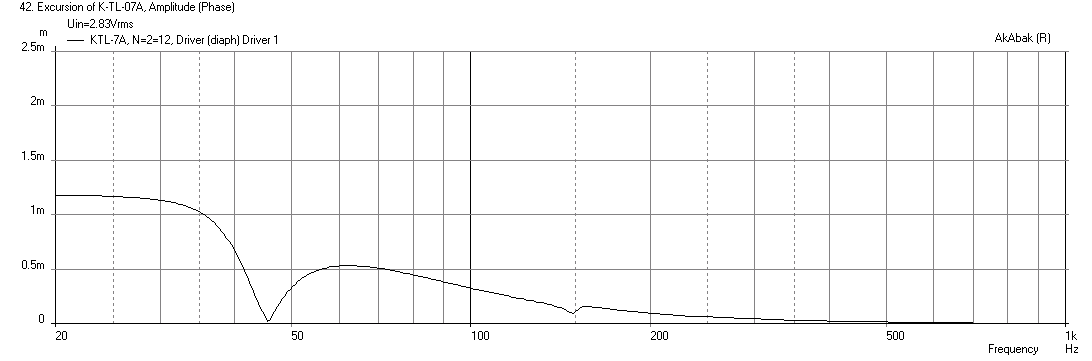

Here is predicted cone displacement - nice how it is well controlled and no runaway excursion:

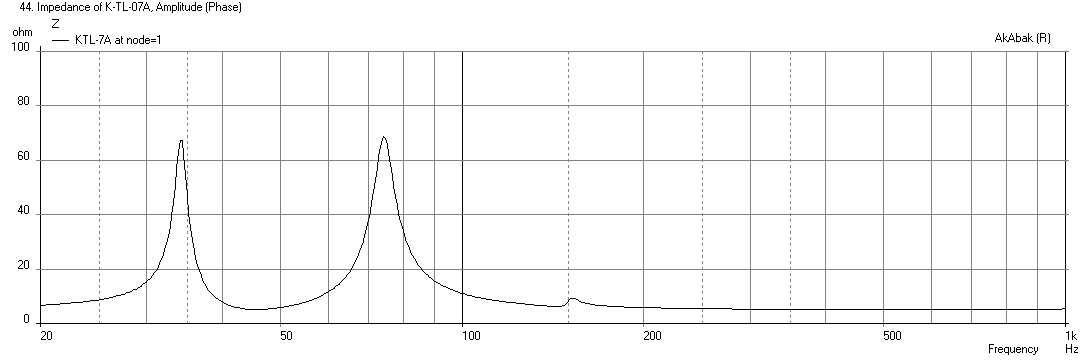

Here is predicted impedance:

I hope this helps and you make it.

Hi, thank you for running these sims on the Tannoy driver. I have the same driver. I had a question on the scaling. Would it be multiplying the vertical dimensions by 1.3 and dividing the horizontal dimensions by 1.1? Thank you.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- 12" tannoy paper coax and box type. Karlsonator or...?.