vdijev --

From a purely empirical perspective and new thoughts on things I've posted prior...

Experiment 1

Speculation & reverie ...

Next

Updates to follow.

-- Andreas

From a purely empirical perspective and new thoughts on things I've posted prior...

Experiment 1

I've had (if subjectively) great success with large (approx. 28" wide X 72" high) aluminum honeycomb core covered with aluminum skin panels. A single (Dayton Audio Thruster) exciter on each can drive them louder than I can stand.

Note: these panels have a modest aluminum edging covered by the the skins.

I could continue to tweak these DMLs, but they sound so good as I have them, I just don't get around to it.

Note, these panels have nothing resembling "dampening".

Note: these panels have a modest aluminum edging covered by the the skins.

I could continue to tweak these DMLs, but they sound so good as I have them, I just don't get around to it.

Note, these panels have nothing resembling "dampening".

Speculation & reverie ...

I originally conjectured that the key to the performance of, the above described, panels rested in some function of size vs weight vs rigidity.

I've begun reconsidering rigidity or perhaps expanding my notion of it. More specifically, I think the compressive strength (across its narrowest dimension) better maps to what I had earlier thought about "rigidity"

XPS panels painted with PVA or epoxy have a lot of this kind of compressive strength. Carbon fiber, spruce, and various plywoods do too. While very thin, I think a canvas panel treated with PVA also does, it really creates a stress skin panel/membrane.

This said, I don't think this kind of compressive strength accounts for everything.

It may seem like a contradiction, but I now believe effective/successful panels need to flex/wobble (and maybe a lot).

Experiment 2I've begun reconsidering rigidity or perhaps expanding my notion of it. More specifically, I think the compressive strength (across its narrowest dimension) better maps to what I had earlier thought about "rigidity"

XPS panels painted with PVA or epoxy have a lot of this kind of compressive strength. Carbon fiber, spruce, and various plywoods do too. While very thin, I think a canvas panel treated with PVA also does, it really creates a stress skin panel/membrane.

This said, I don't think this kind of compressive strength accounts for everything.

It may seem like a contradiction, but I now believe effective/successful panels need to flex/wobble (and maybe a lot).

My next DML build used 1/16" thick plexiglass. Plexiglass has high compressive strength (almost to the point of brittleness), but it (at least the 1/16th inch plexiglass) wobbles like crazy, "especially" in its long dimension.

These panels measure approximately 18" wide X 32 1/2" high.

I still have work to do on them, but they sound pretty darn good.

Again, these panels have no dampening and no frame (I hang them with fishing line).

These panels measure approximately 18" wide X 32 1/2" high.

I still have work to do on them, but they sound pretty darn good.

Again, these panels have no dampening and no frame (I hang them with fishing line).

Next

I plan to pick up some aluminum flashing. Essentially, aluminum, as thin as possible, while remaining a sheet rather than foil.

I remain unclear why Steve (spedge) thinks a bass drum head wouldn't work. Maybe too piston like rather than wobbly? ;-)

I remain unclear why Steve (spedge) thinks a bass drum head wouldn't work. Maybe too piston like rather than wobbly? ;-)

The creation of something new is not accomplished by the intellect but by the play instinct.

—Carl Jung

Updates to follow.

-- Andreas

A couple of M######rs used an array of exciters arround the whole perimeter of a plate to cancel the reflections, and kind of achieved an infinite plate repsonse.

Very interesting concept. Is there a link to this?

XRK the papper is called: "A simulation study on the array control of a rectangular panel speaker for improving the sound radiation performance". Its no in researchgate, i'm not sure how i got it... so i made a drive link to the papper collection: DML - Google Drive

Interesting findings aagas, honeycomb is really expensive here but not an option... was thinking about making my own using the carborad honeycomb fill for hollow doors, wich is cheap as lead. I should find a way to glue the faces tho... maybe a slow drying agent, it will take me about 20 min to put glue in all the honeycomb...

About your speculation, you are right according to Kirchoff-love theory and the refined models for bending waves, the math is quite clear in the Kuonan Li thesis. In that link there is an excell that applies the math to find f0 and fc, wich may be flawed tho, i should speak with some acoustic teachers to be sure... But yes what matters the most is the bending stiffness (young modulus * Inertia momment) over mass (expressed as linear or area depending on the expression used). So yes, the main concerns about materialss are density and Young modulus. Inertia momment for a plate is fixed (for same thickness) and depends on poisson ratio, but i dont think there is too much variation AKA poisson ratio influences less. As stated before, ratio B/m should be kept low, as a high mass would create little efficiency, the choice is a low B, but not too low, cant remember why, its in Kuonan Li. For the honeycomb, its a high anisotropy material (propierties differ depending on the direction considered) so take into account the aspect ratio conslucions of Zeker.

Elastic-Viscoelastic Frames seem essential to me, there is some real cheap pitch material wich is used to fill concrete expansion joints (quite flammable prob). They really reduce the amount of FIR or IIR used after in low freq.

Hail Jung forever young to!

But, its always important to have an objective measurment to contrast with (not the other way arround as its usually made by researchers). It helps you understand why some things happens. For example i listen to alots of new details if the Freq response is quite hi end oriented, but the overall response may be awfull... If you made it the other way arround you would prob say, in that case, this will sound like sh·t and you wouldnt realize the "pros" of listening with another parciality, lets face it, partiality is always there when you diy, each time i turn my speakers i`m like a child in christmass opening a gift, expectetion and satisfaction is too high, cant help it

About your speculation, you are right according to Kirchoff-love theory and the refined models for bending waves, the math is quite clear in the Kuonan Li thesis. In that link there is an excell that applies the math to find f0 and fc, wich may be flawed tho, i should speak with some acoustic teachers to be sure... But yes what matters the most is the bending stiffness (young modulus * Inertia momment) over mass (expressed as linear or area depending on the expression used). So yes, the main concerns about materialss are density and Young modulus. Inertia momment for a plate is fixed (for same thickness) and depends on poisson ratio, but i dont think there is too much variation AKA poisson ratio influences less. As stated before, ratio B/m should be kept low, as a high mass would create little efficiency, the choice is a low B, but not too low, cant remember why, its in Kuonan Li. For the honeycomb, its a high anisotropy material (propierties differ depending on the direction considered) so take into account the aspect ratio conslucions of Zeker.

Elastic-Viscoelastic Frames seem essential to me, there is some real cheap pitch material wich is used to fill concrete expansion joints (quite flammable prob). They really reduce the amount of FIR or IIR used after in low freq.

Hail Jung forever young to!

But, its always important to have an objective measurment to contrast with (not the other way arround as its usually made by researchers). It helps you understand why some things happens. For example i listen to alots of new details if the Freq response is quite hi end oriented, but the overall response may be awfull... If you made it the other way arround you would prob say, in that case, this will sound like sh·t and you wouldnt realize the "pros" of listening with another parciality, lets face it, partiality is always there when you diy, each time i turn my speakers i`m like a child in christmass opening a gift, expectetion and satisfaction is too high, cant help it

Last edited:

XRK the papper is called: "A simulation study on the array control of a rectangular panel speaker for improving the sound radiation performance". Its no in researchgate, i'm not sure how i got it... so i made a drive link to the papper collection: DML - Google Drive

That’s a nice library of papers on DML’s!

I hope you keep it around - I’ll put a link to it from Post 1 so it won’t get lost.

Thanks!

quote

It would be interesting to see what happens if you do do tests on drums , so don't let me put you off.

It would all be useful information.

hi Andreas.

i did not say a drum head would not work .

it will work to some extent ,but how well it will sound i don't know ?

its a bit of a balancing act with the tension, if you are trying to run the drum panel full range.

the art panel and my hoop are very similar to a drum head , but not as tight.

steve.

It would be interesting to see what happens if you do do tests on drums , so don't let me put you off.

It would all be useful information.

hi Andreas.

i did not say a drum head would not work .

it will work to some extent ,but how well it will sound i don't know ?

its a bit of a balancing act with the tension, if you are trying to run the drum panel full range.

the art panel and my hoop are very similar to a drum head , but not as tight.

steve.

U.U. Thank you XRK for all your wurk here  , some day i ll make some XPS cabinets

, some day i ll make some XPS cabinets

. I have more in the wave field synthesis folder, will check again if the arent some DML around there, im sure they are, and add them.

. I have more in the wave field synthesis folder, will check again if the arent some DML around there, im sure they are, and add them.

Also will make it editable for anyone with the link so anyone can add papers or things

Regaards ! <3

Also will make it editable for anyone with the link so anyone can add papers or things

Regaards ! <3

That’s a nice library of papers on DML’s!

I hope you keep it around - I’ll put a link to it from Post 1 so it won’t get lost.

Thanks!

Yes, thank you for this collection vdljev!

Many I have read but not all. In particular, IIRC, I have tried finding the Panzer Harris paper before without and luck. Thanks!

Eric

.. As stated before, ratio B/m should be kept low, as a high mass would create little efficiency, the choice is a low B, but not too low, cant remember why, its in Kuonan Li.

Hmm..was that a typo? Generally high B/m (or more specifically high B/m^3) is preferred over low B/m, mainly for radiation efficiency. Generally, stiff light materials provide the highest efficiency. PS foam (XPS or EPS) is particularly good in this respect. Low B/m materials don't radiate enough sound, and have to be driven hard, leading to high harmonic distortion.

There are two trade offs, however. First is production of low frequencies (i,e f0). High B/m increases f0. However, this can be overcome simply by increasing the panel size. Or even more simply, by using a subwoofer.

The other trade-off is coincidence frequency (fc). High B/m decreases fc. Above fc, radiation efficiency is high (good), but but radiation is directed mainly at large angles (bad).

So the trick seems to be to have:

a) a high enough value of B/m^3 for good efficiency, and,

b) a large enough panel for f0 to be low enough (for your needs), and,

c) a low value of B/m (and hence a high enough fc) so that the tendency to beam at large angles happens mainly above your hearing range.

The best material I know of for balancing these trade-offs is balsa wood at about 1/16" thickness. But truth be told, I have not yet tried it well enough to convince myself. Also, balsa (like all wood) is very anisotropic, and I am not certain exactly how this may influence its overall performance. Also, it's very fragile, so not ideal in that respect. But if you want to try a promising material, I highly suggest trying out thin (1/16") balsa for a good compromise between radiation efficiency, f0, and coincidence frequency.

Eric

I foundation a page with some DML info that might (or might not) be of interest. Could be that it has been posted here before.

Current Drive & DML

It’s more about current amp drive and DML combo then DML technology alone.

Current Drive & DML

It’s more about current amp drive and DML combo then DML technology alone.

Last edited:

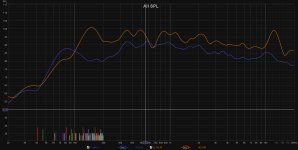

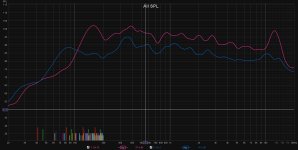

A tale of two panel materials

I just had to do it. I fancied trying 2mm ceiba plywood panels to see how they would compare with the ultra high density EPS.

There was something about the sound of the EPS panels that just sounded a bit 'off'.

So with broadly similar constructions (40x30 panel partially bonded to neoprene foam which in turn is stuck to a canvas frame minus the canvas, here are the plots. I measured the panels from a distance of 1.0m

The first is of the left, the second the right. The plywood is the less efficient one (volume control was identical for each).

Early days on the listening front, but the ply is very promising.

I just had to do it. I fancied trying 2mm ceiba plywood panels to see how they would compare with the ultra high density EPS.

There was something about the sound of the EPS panels that just sounded a bit 'off'.

So with broadly similar constructions (40x30 panel partially bonded to neoprene foam which in turn is stuck to a canvas frame minus the canvas, here are the plots. I measured the panels from a distance of 1.0m

The first is of the left, the second the right. The plywood is the less efficient one (volume control was identical for each).

Early days on the listening front, but the ply is very promising.

Attachments

Thanks for the data Veleric! I believe a low B/m ratio is desired because it produces a low F0 and a high Fc. Apparently if mass is low and B not that low, you achieve enough radiation efficiency. From Kuonan Li page 27:

"As a consequence, one usually wants the B/m” ratio lower, which means either the mass per unit area should be higher, or the bending stiffness should be lower. The choice is often to find a material with lower bending stiffness since high density

implies low radiated sound power and that is usually one does not want to see. Another important reason to keep f0 low is that the asymptotic modal density is inversely proportional to the ratio of bending stiffness B and the mass per unit area

m”, and one wants it as high as possible. The same reason applies for the critical frequency, because below the critical frequency the directivities of DML behave more omni-directional. However, to achieve a proper radiation efficiency and radiated

sound power, the Young’s modulus cannot be too low. Thus one needs to carefully trade between E and the density ρ to accomplish one’s goal of design".

I could try balsa, easy to work with and cheap. I'm thinking of making a cardboard honeycomb with 20mm XPS faces, just to see what i get. I'm a little inclined to XPS because of potentially higgher modal density (more flat i believe, more "peaky" if lower) and damping. I dont remember where but a higher damping achieved less inter exciter interaction, for multiactuator panels. The "honeycomb" is just that i havent found any academic info about them but would like to see its influence, i believe it would add more damping and stiffness, without knowing anything.

in "Optimization of Aspect Ratio and Material Parameters of a DML Membrane" Zeker et al make an extensive studie on aspect ratios and anisotropy of materials used. But i dont understand! wouldnt an aspect ratio of 0.5 be the same as an aspect ratio of 1.5? i need to read it more carefully...

Using iDynamics app is real handy to use cellphone accelerometer (sample rate make alias appear arround 200 Hz usually) to find the low response and fundamental frecuency.

Regards!

"As a consequence, one usually wants the B/m” ratio lower, which means either the mass per unit area should be higher, or the bending stiffness should be lower. The choice is often to find a material with lower bending stiffness since high density

implies low radiated sound power and that is usually one does not want to see. Another important reason to keep f0 low is that the asymptotic modal density is inversely proportional to the ratio of bending stiffness B and the mass per unit area

m”, and one wants it as high as possible. The same reason applies for the critical frequency, because below the critical frequency the directivities of DML behave more omni-directional. However, to achieve a proper radiation efficiency and radiated

sound power, the Young’s modulus cannot be too low. Thus one needs to carefully trade between E and the density ρ to accomplish one’s goal of design".

I could try balsa, easy to work with and cheap. I'm thinking of making a cardboard honeycomb with 20mm XPS faces, just to see what i get. I'm a little inclined to XPS because of potentially higgher modal density (more flat i believe, more "peaky" if lower) and damping. I dont remember where but a higher damping achieved less inter exciter interaction, for multiactuator panels. The "honeycomb" is just that i havent found any academic info about them but would like to see its influence, i believe it would add more damping and stiffness, without knowing anything.

in "Optimization of Aspect Ratio and Material Parameters of a DML Membrane" Zeker et al make an extensive studie on aspect ratios and anisotropy of materials used. But i dont understand! wouldnt an aspect ratio of 0.5 be the same as an aspect ratio of 1.5? i need to read it more carefully...

Using iDynamics app is real handy to use cellphone accelerometer (sample rate make alias appear arround 200 Hz usually) to find the low response and fundamental frecuency.

Regards!

Last edited:

CoAP.

Interesting, 2011 patent, it is a shame he restricted the patent to low frequencies only ?

The new patent does not.

WO2019061685A1 - Full-frequency sounding structure of loudspeaker

- Google Patents

Steve.

Interesting, 2011 patent, it is a shame he restricted the patent to low frequencies only ?

The new patent does not.

WO2019061685A1 - Full-frequency sounding structure of loudspeaker

- Google Patents

Steve.

Really interesting, i was thining about such schemes in the last couple of days, to achieve "mechanical" crossovers in the same system comprising several materials or different material conditions.

The elastic vibrating diaphragm is like a net to actually let the upper range go thru?

Also there seems to be a "highly" localized hi freq, but may be non important if directivity is high (little plates have high Fcoincidence i believe).

Hot stuff

The elastic vibrating diaphragm is like a net to actually let the upper range go thru?

Also there seems to be a "highly" localized hi freq, but may be non important if directivity is high (little plates have high Fcoincidence i believe).

Hot stuff

Last edited:

KoAP.

in the patent It looks like he is using a powerful 2inch coil and magnet from a bass unit ?

And using pistonic motion only.

they look pretty much the same except for the type of exciter in the new patent.

For me ,finding a material that sounds good or can be manipulated to sound good ,has been my goal.

The technical specs in the patents have never helped me much as they do not say how the panel material will sound in combination with the exciter ?

This is the reason I have made the recordings , so that people can hear for themselves what different sounds they produce.

Although they all produce the dml sound , which hopefully comes through in the recordings, but the presentation in the room can be quite different ,which will not come through in the recordings.

Recording in an ordinary room is always going to be a problem, but I think I have managed to minimise the room noise as much as possible (but it is still there).

So the recordings are a worst case scenario with the room and microphone and conversion issues all striving to ruin the sound.

But hopefully everyone can get the drift of what the panels are producing?

Steve

in the patent It looks like he is using a powerful 2inch coil and magnet from a bass unit ?

And using pistonic motion only.

they look pretty much the same except for the type of exciter in the new patent.

For me ,finding a material that sounds good or can be manipulated to sound good ,has been my goal.

The technical specs in the patents have never helped me much as they do not say how the panel material will sound in combination with the exciter ?

This is the reason I have made the recordings , so that people can hear for themselves what different sounds they produce.

Although they all produce the dml sound , which hopefully comes through in the recordings, but the presentation in the room can be quite different ,which will not come through in the recordings.

Recording in an ordinary room is always going to be a problem, but I think I have managed to minimise the room noise as much as possible (but it is still there).

So the recordings are a worst case scenario with the room and microphone and conversion issues all striving to ruin the sound.

But hopefully everyone can get the drift of what the panels are producing?

Steve

I just had to do it. I fancied trying 2mm ceiba plywood panels to see how they would compare with the ultra high density EPS.

There was something about the sound of the EPS panels that just sounded a bit 'off'.

So with broadly similar constructions (40x30 panel partially bonded to neoprene foam which in turn is stuck to a canvas frame minus the canvas, here are the plots. I measured the panels from a distance of 1.0m

The first is of the left, the second the right. The plywood is the less efficient one (volume control was identical for each).

Early days on the listening front, but the ply is very promising.

In your plots you can see the uncorrected massive peak above 10k in the eps panel , the ply panel is damping this a little bit but will still be heard especially from the rear, this is to do with the so called oil can problem.

There are also some bumps in the 2k to 3k regions which are probably caused by coil cavity resonance.

These are the two main problems I have found when using coil drivers.

These two distortions need to be sorted out ,for a good sounding dml panel.

Steve.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker