After seeing the videos by Tech ingredients on youtube and reading here I wanted to try to build a DML speaker of my own. Initially I planned to buy an exciter and suitable material for the panel.

However I had the neccesary materials on hand to make a first attempt.

I got some spare 12mm plywood. Approx 120cm X 96cm so I used that.

The driver was placed 2/5 from each side of the panel.

I got a spare Cerwin Vega DM12090 midrange driver from a Cerwin Vega E312 speaker.

I 3d printed an 28mm adapter that i JB welded to the voice coil so that it could touch the plywood and a hole were drilled to allow for a m4 screw to pass through and attach to a nut and washer on the back side.

I 3d printed a flexible attachment to fix the speaker to the plywood.

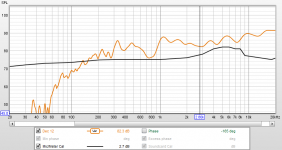

I took a frequency sweep measurement with REW of the driver in its original enclosure to compare to the DML speaker. I used a Rode NT-USB mic with its calibration curve entered to REW.

Unfortunately I forgot to turn off loudness on my reciever prior to the measurement so I left it on for all measurements, the comparison is the most intresting.

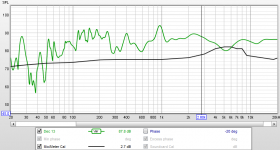

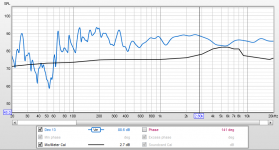

I also measured the DML speaker with REW

I tried to cut the width of the board to see the change in frequency response, it shifted the lowest frequency higher in the range.

For listening I'd say they sound fantastic compared to the midrange driver alone (not using the woofer or tweeter of the E312 speaker).

Initial opinions on the result, my reference is Dali 606 floorstanding speakers. The reciever used was Sankyo SRC 4040.

DML has some advantages in terms of sound quality. My first impression is that the sound is very clear and less messy.

However

Bass is completely lacking, I need to use loudness and max out the bass to get any bass.

It's not very loud, at max volume before distortion it's not enough to annoy any neighbours.

So this DML has an upper hand in some terms, I'm curious if there is more potential to meet the requirements as a main home system.

This was a quick and fun first try.

I suspect based on looking at the design of Dayton audio exciters that the arms on the attachment I designed was a bit thick. (5mm).

I do have a bass driver from a Sony ss A505 speaker I could try next to see if the base response could improve. This is because I'm wondering what part of the speaker influences the low range response. I think the effects of the cone is eliminated when a driver is converted to an exciter, so the motor, spider and surround should determine the response.

However perhaps the Sony woofer would do better in this respect.

However I had the neccesary materials on hand to make a first attempt.

I got some spare 12mm plywood. Approx 120cm X 96cm so I used that.

The driver was placed 2/5 from each side of the panel.

I got a spare Cerwin Vega DM12090 midrange driver from a Cerwin Vega E312 speaker.

I 3d printed an 28mm adapter that i JB welded to the voice coil so that it could touch the plywood and a hole were drilled to allow for a m4 screw to pass through and attach to a nut and washer on the back side.

I 3d printed a flexible attachment to fix the speaker to the plywood.

I took a frequency sweep measurement with REW of the driver in its original enclosure to compare to the DML speaker. I used a Rode NT-USB mic with its calibration curve entered to REW.

Unfortunately I forgot to turn off loudness on my reciever prior to the measurement so I left it on for all measurements, the comparison is the most intresting.

I also measured the DML speaker with REW

I tried to cut the width of the board to see the change in frequency response, it shifted the lowest frequency higher in the range.

For listening I'd say they sound fantastic compared to the midrange driver alone (not using the woofer or tweeter of the E312 speaker).

Initial opinions on the result, my reference is Dali 606 floorstanding speakers. The reciever used was Sankyo SRC 4040.

DML has some advantages in terms of sound quality. My first impression is that the sound is very clear and less messy.

However

Bass is completely lacking, I need to use loudness and max out the bass to get any bass.

It's not very loud, at max volume before distortion it's not enough to annoy any neighbours.

So this DML has an upper hand in some terms, I'm curious if there is more potential to meet the requirements as a main home system.

This was a quick and fun first try.

I suspect based on looking at the design of Dayton audio exciters that the arms on the attachment I designed was a bit thick. (5mm).

I do have a bass driver from a Sony ss A505 speaker I could try next to see if the base response could improve. This is because I'm wondering what part of the speaker influences the low range response. I think the effects of the cone is eliminated when a driver is converted to an exciter, so the motor, spider and surround should determine the response.

However perhaps the Sony woofer would do better in this respect.

Attachments

Thanks. Has anyone used and recommend a temp adhesive to mount the exciters?

I can offer a couple of thoughts:

I contacted Dayton Audio and asked what adhesive they use. They pointed me to these 3M VHB adhesive tapes:

https://parafix.com/wp-content/uploads/2019/01/3M-vhb-9473-data-sheet-parafix.pdf

the VHB 9460 is the thinnest, and I bought a roll. Works well, not as strong as the thicker stuff listed on the sheet (which the exciters ship with), and good for being acoustically transparent -- the thicker the adhesive, the more it will colour the sound. so this one seems good for testing.

Just use less VHB adhesive (i.e. don't cover the entire mounting plate, like it is when it ships), attach the exciter, test, and then pull it off before the adhesive sets (say within an hour or so).

As a cheaper option, double sided ducked tape works well. it's thinner than a lot of other double sided tape options, but you won't be able to use it when its time to go permanent, of course.

Hope this helps,

Cheers

Attachments

What happens, if you simply fix the driver to the panel, allowing the surround and the cone to hit the panel? Without those extra legs? Actually, only the driver's surround would hit the panel, transferring the vibrations to the panel.

Hang them parallel to the long walls. They will disrupt you less while walking up and down the room, and still give you "nice stereo" either end. The magic of DML's.

So counter-intuitive, based on cone speaker thinking! And frankly might be more easily implemented. Great idea!

Thanks,

Eric

Agreed on all fronts. The spiral design seems harder to pull off just for purpose of testing. Less of larger fins also would reduce cancellations/interactions... though the small footprint benefit starts to get lost. There’s lots of things that could be tried: oval wafers, offsetting/staggering wafers, mixing materials, a Christmas tree shape, etc. Standard logic doesn’t always apply to DML. So that is why it may be worth testing—could prove useful in some way.

I built the PGodas. No scientific testing whatsoever was done though. My ears confirmed some ideas and fears. No matter how many discs I add, there just isn’t excellent bass with exciters. In this case I used Visaton exciters, which unfortunately look to be made in China. I also think that matching disc sizes creates more interaction nulls/peaks. They sound like speakers for sure, not super great though. They do solve my pet peeve about exciters, the super brightness is tamed.

These get top heavy quick even when using styrofoam. Despite the lightweight of material, a lot of leverage is created by the vertical length and double sided tape doesn’t want to hold while doing temporary testing. I think this might be worth pursuing for someone else. I only want full-range speakers—no subs.

Attachments

-

BD2C3C3A-080A-4048-84C7-9F03AD9CA114.jpg992.3 KB · Views: 195

BD2C3C3A-080A-4048-84C7-9F03AD9CA114.jpg992.3 KB · Views: 195 -

7533A57F-9B99-463E-A4A4-2F6EF9DFF716.jpg992.5 KB · Views: 170

7533A57F-9B99-463E-A4A4-2F6EF9DFF716.jpg992.5 KB · Views: 170 -

403D32FE-41D0-466A-8F07-9EBA3B4C444F.jpg995.9 KB · Views: 109

403D32FE-41D0-466A-8F07-9EBA3B4C444F.jpg995.9 KB · Views: 109 -

E60280A8-23FC-4A0F-AF2F-ACC58D7D0EBC.jpg988.9 KB · Views: 124

E60280A8-23FC-4A0F-AF2F-ACC58D7D0EBC.jpg988.9 KB · Views: 124 -

22E86BD7-B790-4B12-8BED-DCD7EC03CE98.jpg998.1 KB · Views: 122

22E86BD7-B790-4B12-8BED-DCD7EC03CE98.jpg998.1 KB · Views: 122

^^

What can a pagoda bring in to distributed mode? The distributed mode happens in one plane, or both sides of the material used, so what would the different planes placed at different levels give? Does the pvc tube transfer the vibrations to the next plane/material? Or, is it what you expected?

What happens, if you put all the circles on top of each other?

What can a pagoda bring in to distributed mode? The distributed mode happens in one plane, or both sides of the material used, so what would the different planes placed at different levels give? Does the pvc tube transfer the vibrations to the next plane/material? Or, is it what you expected?

What happens, if you put all the circles on top of each other?

Last edited:

^^

What can a pagoda bring in to distributed mode? The distributed mode happens in one plane, or both sides of the material used, so what would the different planes placed at different levels give? Does the pvc tube transfer the vibrations to the next plane/material? Or, is it what you expected?

What happens, if you put all the circles on top of each other?

It’s pretty much what I expected. It does a capable job of producing music sans bass. For $60ish, can you buy or build a better speaker... I don’t know. Magnepan will not be going out of business as a result of these.

Multiple large discs seemed to have more peaks and dips. Some configurations had more separation, etc.. But nothing was horrendous or tremendous. So the configurations are having an effect, not giant though.

I named them PGodas. Working with these was a pain and I don’t feel like continuing. The rod is extruded styrofoam. Styrofoam from discs literally goes everywhere. I had to magnetically mount driver to a metal cage to keep driver flat and prevent disc from touching ground. It would be better to use semi-permanent methods to affix everything for testing.

Last edited:

^^

That is not the idea of distributed mode. The vibrations are supposed to move along the surface of a plane, not through a polystyrene rod to give sound. As the rod is round, the vibrations won't go along it's surface, for the cross section of a round rod is quite stiff.

Instead of a pagoda looking structure, if you put all those disks on top of each other, glue them to each other, you'd get a better sound. But, not bass as you get from a 8" woofer.

That is not the idea of distributed mode. The vibrations are supposed to move along the surface of a plane, not through a polystyrene rod to give sound. As the rod is round, the vibrations won't go along it's surface, for the cross section of a round rod is quite stiff.

Instead of a pagoda looking structure, if you put all those disks on top of each other, glue them to each other, you'd get a better sound. But, not bass as you get from a 8" woofer.

I built the PGodas. No scientific testing whatsoever was done though. My ears confirmed some ideas and fears. No matter how many discs I add, there just isn’t excellent bass with exciters. In this case I used Visaton exciters, which unfortunately look to be made in China. I also think that matching disc sizes creates more interaction nulls/peaks. They sound like speakers for sure, not super great though. They do solve my pet peeve about exciters, the super brightness is tamed.

These get top heavy quick even when using styrofoam. Despite the lightweight of material, a lot of leverage is created by the vertical length and double sided tape doesn’t want to hold while doing temporary testing. I think this might be worth pursuing for someone else. I only want full-range speakers—no subs.

Very creative and out of the box thinking.

I built the PGodas. No scientific testing whatsoever was done though. My ears confirmed some ideas and fears. No matter how many discs I add, there just isn’t excellent bass with exciters. In this case I used Visaton exciters, which unfortunately look to be made in China. I also think that matching disc sizes creates more interaction nulls/peaks. They sound like speakers for sure, not super great though. They do solve my pet peeve about exciters, the super brightness is tamed.

These get top heavy quick even when using styrofoam. Despite the lightweight of material, a lot of leverage is created by the vertical length and double sided tape doesn’t want to hold while doing temporary testing. I think this might be worth pursuing for someone else. I only want full-range speakers—no subs.

Hi

From the pictures It seems to me you are using polyethylene foam, and not styrofoam (polystyrene)

Styrofoam is made of little balls you can take apart. It is the kind of foam that came with a new TV, and it is much more rigid, even with reduced thickness it is quite rigid.

I noticed you are using a very big thicknesit is beter to use reduced thickness.

PE foam is not that rigid, it is used to protect from drops and vibrations (bad!) so won't work that well

M

First attempt

Finally got around to building something. Went out and did it without much experimentation or good design... Your suggestions welcomed! Sound is listenable, but nothing to write home about. Driver seems too low powered for panel. Will experiment with adding more drivers at a later stage.

Goal was to get output closer to 50Hz. Roughly inspired by Burntcoil's design. Clamped the bottom of the plywood between rubber pads and 3D printed wedge to bend it and increase stiffness lengthwise. Bend proved insufficient to keep the ply stiff. Ended up sawing a bit off the top (which was good since the ends were water damaged) and adding an adjustable tensioner (attaches a the top). Hopefully tensioning can keep the wood from deforming over time because of moisture absorption (avoiding painting as it changes the colour and decreases WAF).

Materials:

Dayton Audio DAEX32EP-4

3.5mm Commercial plywood

3D printed wedge (PLA)

Vibration absorbing rubber matt (used on floor underneath heavy machinery)

M8 and M10 hardware

Brake disc as base (with felt pads to protect floor)

Frequency response:

Impulse response:

Finally got around to building something. Went out and did it without much experimentation or good design... Your suggestions welcomed! Sound is listenable, but nothing to write home about. Driver seems too low powered for panel. Will experiment with adding more drivers at a later stage.

Goal was to get output closer to 50Hz. Roughly inspired by Burntcoil's design. Clamped the bottom of the plywood between rubber pads and 3D printed wedge to bend it and increase stiffness lengthwise. Bend proved insufficient to keep the ply stiff. Ended up sawing a bit off the top (which was good since the ends were water damaged) and adding an adjustable tensioner (attaches a the top). Hopefully tensioning can keep the wood from deforming over time because of moisture absorption (avoiding painting as it changes the colour and decreases WAF).

Materials:

Dayton Audio DAEX32EP-4

3.5mm Commercial plywood

3D printed wedge (PLA)

Vibration absorbing rubber matt (used on floor underneath heavy machinery)

M8 and M10 hardware

Brake disc as base (with felt pads to protect floor)

Frequency response:

Impulse response:

Another dml video

https://www.youtube.com/watch?v=n7WIrFeCwK0

I did a youtube search with a 1 month filter for dml speakers / flat panel speakers as i figured more people would be tinkering lately. I found a few:

tiny balsa panel on a box

YouTube

slim and tall ply panels:

YouTube

plywood with resin (i think)

YouTube

basic 3 mm ply

YouTube

sand on a plate

YouTube

tonewood (idk, sound seems pretty terrible)

https://www.youtube.com/watch?v=uFnWQgmuwUo

guitars in stereo (older)

https://www.youtube.com/watch?v=eN5gihTm5lk

https://www.youtube.com/watch?v=n7WIrFeCwK0

Hey everyone,

I've been slightly out of the loop as work has been keeping me occupied. I wanted to share with you my experiments. During the pandemic I tried working with all sorts of canvases as art shops were the only shops open in Warsaw.

I tried all sorts of canvases: Linen, Cotton and Polyester. What I found out was, that the thinner the material, the fuller sound it produced, but the key to getting a deep sound was not only sticking a wooden “plate” onto the canvas, but also drilling a hole in the piece of wood. It didn’t make a difference whether you drilled 1 or 10 holes. The size of the hole mattered the most. Since I couldn’t get any double sided tape during this time, I only pressed the excited to the wooden plate. My further observations were:

1) Linnen was too thick and the sound was simply muffled.

2) Cotton was decent, but I couldn’t get a universal speaker out of it.

3) Ikea painting was GREAT! Unfortunately I salvaged only 1 painting from my office and it was the largest size that Ikea had. I must say that it was fantastic, but I kept getting some buzzing sound with a lot of base. I can bet that with a smaller sized painting things would have been a lot better

I planned on priming all of them with 50/50 wood glue & water, but never got around to it as I had to commit all my free time to my business and also because I hooked up my Kenwood ls-880 ‘s and they just sound so good that I never had the motivation afterwards

Just my $0.02 that I wanted to add to the conversation.

I've been slightly out of the loop as work has been keeping me occupied. I wanted to share with you my experiments. During the pandemic I tried working with all sorts of canvases as art shops were the only shops open in Warsaw.

I tried all sorts of canvases: Linen, Cotton and Polyester. What I found out was, that the thinner the material, the fuller sound it produced, but the key to getting a deep sound was not only sticking a wooden “plate” onto the canvas, but also drilling a hole in the piece of wood. It didn’t make a difference whether you drilled 1 or 10 holes. The size of the hole mattered the most. Since I couldn’t get any double sided tape during this time, I only pressed the excited to the wooden plate. My further observations were:

1) Linnen was too thick and the sound was simply muffled.

2) Cotton was decent, but I couldn’t get a universal speaker out of it.

3) Ikea painting was GREAT! Unfortunately I salvaged only 1 painting from my office and it was the largest size that Ikea had. I must say that it was fantastic, but I kept getting some buzzing sound with a lot of base. I can bet that with a smaller sized painting things would have been a lot better

I planned on priming all of them with 50/50 wood glue & water, but never got around to it as I had to commit all my free time to my business and also because I hooked up my Kenwood ls-880 ‘s and they just sound so good that I never had the motivation afterwards

Just my $0.02 that I wanted to add to the conversation.

Last edited:

I tried all sorts of canvases: Linen, Cotton and Polyester. What I found out was, that the thinner the material, the fuller sound it produced, but the key to getting a deep sound was not only sticking a wooden “plate” onto the canvas, but also drilling a hole in the piece of wood. It didn’t make a difference whether you drilled 1 or 10 holes. The size of the hole mattered the most. Since I couldn’t get any double sided tape during this time, I only pressed the excited to the wooden plate.

Hi raph1978

Which hole sizes did you find work best?

Any idea what type of canvas the Ikea painting uses?

Regards

Dirk

I took a standard size 6 drill as that's the only one that I had. I tried making 1 hole, 2 holes, 5 & 10 and actually the more I made, the flatter the sound became.

I'm sorry but it seems that I forgot to add the part that Ikea canvases are made out of Poliester. They were the thinnest ones of the whole bunch.

The thicker the canvas, the more muffled the sound.

My recommendation would be to get a small / medium size Ikea painting when they're gonna be on sale for a few bucks and give them a go. When I'm gonna have some extra free time I might actually prime the one that I have and gonna try to put some windows seals where they canvas meets the metal frame.

Unfortunately I don't know when I'm gonna have the time to do that, as I'm currently preoccupied with other things.

Hope this helps.

I'm sorry but it seems that I forgot to add the part that Ikea canvases are made out of Poliester. They were the thinnest ones of the whole bunch.

The thicker the canvas, the more muffled the sound.

My recommendation would be to get a small / medium size Ikea painting when they're gonna be on sale for a few bucks and give them a go. When I'm gonna have some extra free time I might actually prime the one that I have and gonna try to put some windows seals where they canvas meets the metal frame.

Unfortunately I don't know when I'm gonna have the time to do that, as I'm currently preoccupied with other things.

Hope this helps.

multiple exciters placing criteria

Hi everyone,

this is my first post here. When I found out about DML I wanted to try myself to experiment with them. I was initially skeptic but after I started doing first tests I realized how greatly these panels sound. I made several panels with different aspect ratio till I came across this great forum, I read all of its 264 pages and finally I achieved the best trade off with panels 120x40x2 cm. I want to thank all the people here who have chipped in with their suggestions, questions, technical discussions and so forth.

Well, I was enthusiastic about the way my panels used to sound till the day which accidentally I switched the source on my amplifier, a Denon PMA-60, while the volume was at maximum and a music was playing.

According to my wife there is no difference in comparison to the sound that panels used to deliver prior the incident but maybe male hearing is different and since then I couldn't appreciate the clarity and definition that my loved panels used to play.

For example, in My Sharona by Knack sound of basses is rather fluffy than punchy as it was earlier and by and large sounds of instruments like piano and classic guitar that were impressively accurate and realistic are not unfortunately anymore the same. Weirdly the overall loudness is not affected though.

So, I want to be sure I'm not having hallucination and I have bought the same exciters that are now glued on panels, that are dayton daex32qmb-4. Currently is one exciter per panel, placed precisely using the rule 2/5 - 3/5 but, I've bought four because I would like to place two on each panel. This way I can connect them in series so that I get 8 ohm impedance and there is no risk to get them damaged again in future.

Now, the dayton guide suggests to use the well-known rule 2/5-3/5 for placing one exciter but which rule has to be followed to place more exciters. Dayton guide reads -If multiple exciters are needed for a panel or surface, it is not recommended to space the exciters evenly across the surface. This will result in very narrow sound dispersion at upper midrange and treble frequencies. Instead, place the exciters together in a group, with exciters at unequal distances from the panel edges and from one another. - but with no precise instructions. Now if we consider the proportion of 2/5 - 3/5 is the best one for placing the exciter close to the center and at the same time avoiding standing waves.

Please, if someone of you has got to do already with multiple exciters placing I would be really grate you could share your experience on this.

Hi everyone,

this is my first post here. When I found out about DML I wanted to try myself to experiment with them. I was initially skeptic but after I started doing first tests I realized how greatly these panels sound. I made several panels with different aspect ratio till I came across this great forum, I read all of its 264 pages and finally I achieved the best trade off with panels 120x40x2 cm. I want to thank all the people here who have chipped in with their suggestions, questions, technical discussions and so forth.

Well, I was enthusiastic about the way my panels used to sound till the day which accidentally I switched the source on my amplifier, a Denon PMA-60, while the volume was at maximum and a music was playing.

According to my wife there is no difference in comparison to the sound that panels used to deliver prior the incident but maybe male hearing is different and since then I couldn't appreciate the clarity and definition that my loved panels used to play.

For example, in My Sharona by Knack sound of basses is rather fluffy than punchy as it was earlier and by and large sounds of instruments like piano and classic guitar that were impressively accurate and realistic are not unfortunately anymore the same. Weirdly the overall loudness is not affected though.

So, I want to be sure I'm not having hallucination and I have bought the same exciters that are now glued on panels, that are dayton daex32qmb-4. Currently is one exciter per panel, placed precisely using the rule 2/5 - 3/5 but, I've bought four because I would like to place two on each panel. This way I can connect them in series so that I get 8 ohm impedance and there is no risk to get them damaged again in future.

Now, the dayton guide suggests to use the well-known rule 2/5-3/5 for placing one exciter but which rule has to be followed to place more exciters. Dayton guide reads -If multiple exciters are needed for a panel or surface, it is not recommended to space the exciters evenly across the surface. This will result in very narrow sound dispersion at upper midrange and treble frequencies. Instead, place the exciters together in a group, with exciters at unequal distances from the panel edges and from one another. - but with no precise instructions. Now if we consider the proportion of 2/5 - 3/5 is the best one for placing the exciter close to the center and at the same time avoiding standing waves.

Please, if someone of you has got to do already with multiple exciters placing I would be really grate you could share your experience on this.

Attachments

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker