Hi bradleypnw. Are you using REW for the above? I'm not (that) familiar with HolmeImpulse if you're using that, as 'dbjohns' mentioned. I tend to use REW for measurements, DRCDesigner to play with DSP/DRC, and then playback through JRver to test measurements and implement any DSP/DRC. Not saying these are the best software to use, just don't cost that much (some free) and work well for me.

I have started to look into room diffusers and bass traps, but these really have a low WAF.But in the end, would probably, in terms of performance increase be worth the grief.

I use REW for equalization. If you build a DML you probably won't need room diffusers because DMLs solve room reflections above the Schroeder transition frequency due to the type of soundfield they generate.

I use REW for equalization. If you build a DML you probably won't need room diffusers because DMLs solve room reflections above the Schroeder transition frequency due to the type of soundfield they generate.

I'm glad you used the word probably,all panels that I know of ,use a primary drive area to drive the dml mode ,my exciters have a 1inch voice coil plus the foot mounting ,and the coil drives the area outside the coil to some extent ,I have not measured this but at a guess depending on materials ,the drive area could be about 2inches ,this can easily be measured by moving a microphone across the panel .

So basically you have a 2inch full range driver in the middle (or whatever you put it) of your panel,this is a pulsed direct radiator,not dml,the dml comes after.

I have mentioned this over the years ,but it seems to be ignored for some reason?

There is also the problem with the tin can effect,but i will not go into that now.

If like me you have a narrow room , reflections will sometimes give a false impression of a harshness in say the vocals,in the past I have spent ages trying to cure a problem I never had,it was only after playing the offending piece of music over and over again while playing around with the panel,that I realized it disappeared when i was up close to the panel,now when I hear what can be a painful noise ,I just turn my head to one side so that my ears are not receiving the full blast from the walls and ceiling and hey presto it is gone.

A panel can never (unless someone can show otherwise) be 100% dml, how much dml and how much postonic(oh no not again) depends on material (flexibility).

I think that's enough for now,just thought I'd mention this.

Steve

Last edited:

I modified my plastic honeycomb polyester skin panels to see what would happen.

1) one side resin other side original polyester fabric

2) both sides resin

3) Number 2 plus exciter side cut with hacksaw between exciters to form alternating trapezoid shaped surfaces for each exciter - simple angled cuts with the hacksaw. (see image)

4) Number 3 plus holes punched into resin side opposite exciters (see image)

They all sounded bad without DSP equalization. Number 2-4 required more high frequency reduction at a large bandwidth than the Number 1.

My subjective perception was number 1 and 4 sounded the best. I'm thinking that a single modal radiating surface is better than two. Which might be a reason to ditch foam.

I'm going to build a new set. I'll use the same plastic honeycomb polyester skinned material. I'm going to use carbon fiber on the active side. I will probably cut the active side like Number 3. I will not punch holes in the polyester fabric side. Which is too bad because the polyester is ugly and difficult to dye.

Honestly, I don't know if I'm imagining things or not between one hard modal surface vs two. I'd describe the difference in sound as "closed" with two surfaces and "open" with one surface. It's such a subjective observation that I'm embarrassed to say it. I notice it most clearly on piano solo music. The single surface sounds more like a real piano.

1) one side resin other side original polyester fabric

2) both sides resin

3) Number 2 plus exciter side cut with hacksaw between exciters to form alternating trapezoid shaped surfaces for each exciter - simple angled cuts with the hacksaw. (see image)

4) Number 3 plus holes punched into resin side opposite exciters (see image)

They all sounded bad without DSP equalization. Number 2-4 required more high frequency reduction at a large bandwidth than the Number 1.

My subjective perception was number 1 and 4 sounded the best. I'm thinking that a single modal radiating surface is better than two. Which might be a reason to ditch foam.

I'm going to build a new set. I'll use the same plastic honeycomb polyester skinned material. I'm going to use carbon fiber on the active side. I will probably cut the active side like Number 3. I will not punch holes in the polyester fabric side. Which is too bad because the polyester is ugly and difficult to dye.

Honestly, I don't know if I'm imagining things or not between one hard modal surface vs two. I'd describe the difference in sound as "closed" with two surfaces and "open" with one surface. It's such a subjective observation that I'm embarrassed to say it. I notice it most clearly on piano solo music. The single surface sounds more like a real piano.

Attachments

Hi Dave,

How is the honeycomb CF coming along I saw your last result wich was kind of a bummer but Like you say it a learning curve point. Here is a bit of some information that may be enlightening to the group. I cant up load it exceeds the limit of the file space I will see if I can break it into smaller pieces Structure-Borne Sound

Cheers,

Steve

How is the honeycomb CF coming along I saw your last result wich was kind of a bummer but Like you say it a learning curve point. Here is a bit of some information that may be enlightening to the group. I cant up load it exceeds the limit of the file space I will see if I can break it into smaller pieces Structure-Borne Sound

Cheers,

Steve

Here is the link to the chapter on Structure-Borne Sound Sci-Hub | Structure-Borne Sound. Foundations of Engineering Acoustics, 270?314 | 10.1016/B978-012247665-5/50011-4

Here is the link to the chapter on Structure-Borne Sound Sci-Hub | Structure-Borne Sound. Foundations of Engineering Acoustics, 270?314 | 10.1016/B978-012247665-5/50011-4

great link tagis. Thanks.

Dave, see the second full paragraph on page 273 of tagis link. That's what I was trying to explain in my PM:

Over much of the audio-frequency range, bending waves in thin plates and shells have the lowest mechanical impedance of the structure-borne wave family; they therefore tend to be most strongly excited by vibrational forces. Per unit of energy density, they also impose the largest normal displacements on contiguous fluids. For these two reasons, acoustic interaction between fluids and structures tends to be dominated by flexural waves.

in the context of a DML speaker, the fluid is air and the structure is the plate.

For clarification of the difference between transverse flexural (i.e. bending) waves and transverse shear waves, see sections 10.6 and 10.7 respectively.

Eric

I'm going to build a new set. I'll use the same plastic honeycomb polyester skinned material. I'm going to use carbon fiber on the active side.

Do you have enough of the core to try carbon fiber or fiberglass on both sides?

How thick is your carbon cloth?

When I finally get my pp honeycomb (back ordered, drat), I'm planning to try one or both of the above. My CF is 3K that finishes out to about 9 mils which I think is way too stiff with that core. But thinner FG is cheap and easy to get so that may be a better choice.

I know what you mean about having two radiating surfaces possibly not being ideal. But my thinking is that it's probably fine if both surfaces are actually doing the same thing. Seems to me the problem would come in if they are not.

Eric

Do you have enough of the core to try carbon fiber or fiberglass on both sides?

How thick is your carbon cloth?

When I finally get my pp honeycomb (back ordered, drat), I'm planning to try one or both of the above. My CF is 3K that finishes out to about 9 mils which I think is way too stiff with that core. But thinner FG is cheap and easy to get so that may be a better choice.

I know what you mean about having two radiating surfaces possibly not being ideal. But my thinking is that it's probably fine if both surfaces are actually doing the same thing. Seems to me the problem would come in if they are not.

Eric

I don't know. And I don't know how to measure what I perceive as better sound. I hope people try different things and give their feedback so I can see if I'm imagining something that isn't there.

At this point I think I'm biased in one direction and can't give objective feedback. Also, a traditional rectangle DML similar to Tectonic might sound better with both sides covered in CF.

I don't know. And I don't know how to measure what I perceive as better sound. I hope people try different things and give their feedback so I can see if I'm imagining something that isn't there.

At this point I think I'm biased in one direction and can't give objective feedback. Also, a traditional rectangle DML similar to Tectonic might sound better with both sides covered in CF.

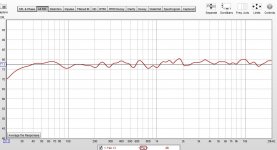

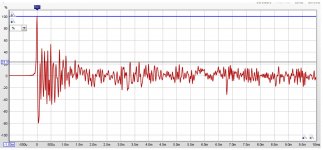

I settled on 2’ high by 1’ wide CF/cardboard panels and a pair of cone driver subwoofer speakers (for below 120Hz). I used DSP for EQ and crossover.

I glued (spray adhesive) CF fabric to heavy-duty two-ply cardboard. Then applied a two-part epoxy coating on the CF. The panel was mounted between two picture frames supported by foam tape around all four edges (both sides of the panel). I used a PUI 20watt exciter mounted slightly off center on the CF side and attached to a spline. The amplifiers I'm using are 25w class A current drive.

The sound is very dynamic and detailed. Since I only have one layer of CF I'm wondering what the sound difference would be to add a second CF layer to sandwich the cardboard?

Thanks, Dave

Attachments

Is that response the raw, unequalised panel?I settled on 2’ high by 1’ wide CF/cardboard panels and a pair of cone driver subwoofer speakers (for below 120Hz). I used DSP for EQ and crossover.

I glued (spray adhesive) CF fabric to heavy-duty two-ply cardboard. Then applied a two-part epoxy coating on the CF. The panel was mounted between two picture frames supported by foam tape around all four edges (both sides of the panel). I used a PUI 20watt exciter mounted slightly off center on the CF side and attached to a spline. The amplifiers I'm using are 25w class A current drive.

The sound is very dynamic and detailed. Since I only have one layer of CF I'm wondering what the sound difference would be to add a second CF layer to sandwich the cardboard?

Thanks, Dave

Is that response the raw, unequalised panel?

No, the response is with DSP EQ and includes the subwoofer. The panel by itself starts to drop off below about 140Hz. I also added a +5 dB shelf above 10KHz.

I settled on 2’ high by 1’ wide CF/cardboard panels and a pair of cone driver subwoofer speakers (for below 120Hz). I used DSP for EQ and crossover.

I glued (spray adhesive) CF fabric to heavy-duty two-ply cardboard. Then applied a two-part epoxy coating on the CF. The panel was mounted between two picture frames supported by foam tape around all four edges (both sides of the panel). I used a PUI 20watt exciter mounted slightly off center on the CF side and attached to a spline. The amplifiers I'm using are 25w class A current drive.

The sound is very dynamic and detailed. Since I only have one layer of CF I'm wondering what the sound difference would be to add a second CF layer to sandwich the cardboard?

Thanks, Dave

This is valuable. You proved you can get a flat frequency response from the upper range of human hearing all the way down to Schroeder with a 1x2 panel.

Does your frequency response remain flat as you rotate the speaker off-axis? Do you get good intelligibility (human voices spoken at frequencies above Schroeder - female voices or children) as you walk around the room?

This is valuable. You proved you can get a flat frequency response from the upper range of human hearing all the way down to Schroeder with a 1x2 panel.

Does your frequency response remain flat as you rotate the speaker off-axis? Do you get good intelligibility (human voices spoken at frequencies above Schroeder - female voices or children) as you walk around the room?

I need to take measurements off-axis. It does respond very well to EQ (I use a MiniDSP HD). I do try focus on the quality of female singers and it's very good. That's kind of what I meant by detail, along with separation of instruments and stereo image. The dispersion appears to be very wide, My room is rather small (9'x10'). I need to move it into the family room and try (assuming my wife let's me).

Thanks, Dave

this is a test.

just downloaded some software to produce and apply mp4 ,what a nightmare.

this hopefully is from my laptop comuter mono mic !! its all i have at the moment.its lying on a chair about 10ft from two small panels plus sub.i hope!

i know its basic but like burntcoil and others who have posted recordings ,it gives an idea of whats going on,i hope.

just downloaded some software to produce and apply mp4 ,what a nightmare.

this hopefully is from my laptop comuter mono mic !! its all i have at the moment.its lying on a chair about 10ft from two small panels plus sub.i hope!

i know its basic but like burntcoil and others who have posted recordings ,it gives an idea of whats going on,i hope.

Attachments

I glued (spray adhesive) CF fabric to heavy-duty two-ply cardboard. Then applied a two-part epoxy coating on the CF.

Thanks, Dave

I don't know if I could bring myself to put my CF on cardboard, but your results look great! How thick is your heavy duty two ply cardboard? Is this corrugated cardboard you are talking about? Any pics of the cardboard itself?

I'd be interested to see the frequency response without the sub and dsp.

As far as adding more carbon, my guess would be that it wouldn't do much if any good. Probably just make it too stiff and push the resonant frequencies higher, making it cut out at something higher than the 140 Hz you already have. How heavy/thick is your carbon? Is it 3K, 6K or other?

Eric

I don't know if I could bring myself to put my CF on cardboard, but your results look great! How thick is your heavy duty two ply cardboard? Is this corrugated cardboard you are talking about? Any pics of the cardboard itself?

I'd be interested to see the frequency response without the sub and dsp.

As far as adding more carbon, my guess would be that it wouldn't do much if any good. Probably just make it too stiff and push the resonant frequencies higher, making it cut out at something higher than the 140 Hz you already have. How heavy/thick is your carbon? Is it 3K, 6K or other?

Eric

Eric, I will try to take measurements without sub and DSP. The CF is 3K and the corrugated cardboard is about 1/4" thick (presentation board from Staples). Thanks for the feedback regarding adding CF.

Dave

Attachments

Eric, I will try to take measurements without sub and DSP. The CF is 3K and the corrugated cardboard is about 1/4" thick (presentation board from Staples). Thanks for the feedback regarding adding CF.

Dave

Thank you. I see why you made the panel 12 inches wide now. It's the width of your fabric, it looks like.

I recently made a small 8" x 12" prototype with 3K fabric over 1/16" balsa. I like it and plan to make some larger ones with the same or similar construction.

Eric

I need to take measurements off-axis. It does respond very well to EQ (I use a MiniDSP HD). I do try focus on the quality of female singers and it's very good. That's kind of what I meant by detail, along with separation of instruments and stereo image. The dispersion appears to be very wide, My room is rather small (9'x10'). I need to move it into the family room and try (assuming my wife let's me).

Thanks, Dave

Yes, I don't know the proper terminology. I'm not from the audio world. When you say detail I might say intelligibility or clarity: female and child spoken voices sound extremely crisp and clear. Deep male voices run into room mode problems so they aren't helpful for quality checking your speaker performance. Which is curious, because some of the popular spoken voice tests (a BBC test?) are deep male radio voices. IMO, they should used children's voices. Luckily, we can easily find high quality child spoken voice recordings on TV and movie streaming services like Amazon/Netflix.

I watched a YouTube video of Floyd Toole discussing speakers. He said after 40 years of studying the subject he was dumbfounded and amazed at how good humans can objectively measure speaker performance *IN BLIND TESTING*. If humans see the speakers they screw up ratings because their perception biases kick in.

Consequently, since we can't blind test our own speakers, I think a combination of off-axis frequency measurements in conjunction with high frequency range spoken voice testing will give you a good basis to quality check your speakers.

I've heard audio people say you should audition speakers using familiar music. I think that's wrong. Music is emotional. Why would one want to bias their judgement with a soundtrack that is designed to evoke emotion?

Yes, I don't know the proper terminology. I'm not from the audio world. When you say detail I might say intelligibility or clarity: female and child spoken voices sound extremely crisp and clear. Deep male voices run into room mode problems so they aren't helpful for quality checking your speaker performance. Which is curious, because some of the popular spoken voice tests (a BBC test?) are deep male radio voices. IMO, they should used children's voices. Luckily, we can easily find high quality child spoken voice recordings on TV and movie streaming services like Amazon/Netflix.

I watched a YouTube video of Floyd Toole discussing speakers. He said after 40 years of studying the subject he was dumbfounded and amazed at how good humans can objectively measure speaker performance *IN BLIND TESTING*. If humans see the speakers they screw up ratings because their perception biases kick in.

Consequently, since we can't blind test our own speakers, I think a combination of off-axis frequency measurements in conjunction with high frequency range spoken voice testing will give you a good basis to quality check your speakers.

I've heard audio people say you should audition speakers using familiar music. I think that's wrong. Music is emotional. Why would one want to bias their judgement with a soundtrack that is designed to evoke emotion?

I'm never sure how to describe sound either but clarity is a good word to describe the sound of these panels. The methods you describe for accessing sound quality make a lot of sense! I will take off axis measurements and spend more time listening to female and child vocals.

Eric, the CF/balsa is an interesting combination. Looking forward to feedback on your larger panels. Can you take measurements? I found 12"W by 5'L CF fabric on Amazon for $24, plus the panel size is more aesthetically acceptable.

In my opinion the best DML "system" requires EQ (DSP) and low end help (pair of subs).

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker