I have some plots of the CD panel.

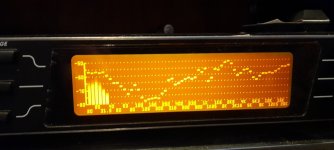

The first two were of the CD with eggshell dome.

The first from the front, probably at about 2ft distance.?

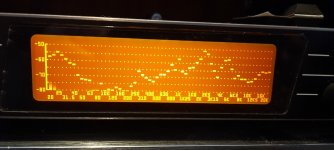

The second from the back.

showing the exciter noise coming through and around the CD.

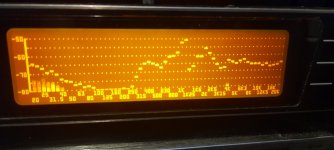

The third is with a paper dome plus in a rigid frame , the response is much better down to about 2.5k at 1m.

I also used a large bluetack ring to reduce the exciter noise.

I am going to try a fabric dome to see if this helps things a little more?

The last two pictures are front and back of the CD panel.

Even with the lumpy response below 2.5k it still sounds pretty good considering.

I will make a recording before continuing.

Steve.

The first two were of the CD with eggshell dome.

The first from the front, probably at about 2ft distance.?

The second from the back.

showing the exciter noise coming through and around the CD.

The third is with a paper dome plus in a rigid frame , the response is much better down to about 2.5k at 1m.

I also used a large bluetack ring to reduce the exciter noise.

I am going to try a fabric dome to see if this helps things a little more?

The last two pictures are front and back of the CD panel.

Even with the lumpy response below 2.5k it still sounds pretty good considering.

I will make a recording before continuing.

Steve.

Attachments

Hi Steve:a very quick recording.

CD on the left crate ply on the right , crate ply turned down a little so as not to drown out the CD.

hope it sounds OK.

not bad for a CD ?

i will get my knife out and replace the paper dome next.

steve.

You've spent a heap of time trying to defeat exciter noise..... Do you think it may be time to try just a few different exciters???

Eucy

Eucy.

Coil drivers have always had mechanical noise problems from the day they were invented.

Do you know of one including cone drivers that is without any problems?

I just point out that this type of exciter is not perfect, and needs careful attention ,if perfection is wanted.

Steve.

Coil drivers have always had mechanical noise problems from the day they were invented.

Do you know of one including cone drivers that is without any problems?

I just point out that this type of exciter is not perfect, and needs careful attention ,if perfection is wanted.

Steve.

Hi SteveEucy.

Coil drivers have always had mechanical noise problems from the day they were invented.

Do you know of one including cone drivers that is without any problems?

I just point out that this type of exciter is not perfect, and needs careful attention ,if perfection is wanted.

Steve.

Yep - OK - I just thought that maybe other types my not be as noisy....and so lessen the issue

Eucy

Eucy.

It depends on the panel material, the proplex for example shows no sign of exciter problems from the front surface.

Some materials such as crate ply are quite noisy and the use of damping is necessary.

The CD panel is very noisy, I intend to try a softer mounting, bluetack or some sort of foam?

The surround I used was not as rigid as it should have been and is affecting the sound as well.

A solid wood ring would probably have been a better choice?

But I'm wondering if a lower frequency could be achieved with the softer mounting?

The CD isn't my material of choice but it is not doing as badly as I had thought.

The CD isn't very efficient sound wise, but my exciters can handle it, it is just trying to get rid of all the bad sounds this combination makes, but hopefully without ruining the good sounds.

Steve.

It depends on the panel material, the proplex for example shows no sign of exciter problems from the front surface.

Some materials such as crate ply are quite noisy and the use of damping is necessary.

The CD panel is very noisy, I intend to try a softer mounting, bluetack or some sort of foam?

The surround I used was not as rigid as it should have been and is affecting the sound as well.

A solid wood ring would probably have been a better choice?

But I'm wondering if a lower frequency could be achieved with the softer mounting?

The CD isn't my material of choice but it is not doing as badly as I had thought.

The CD isn't very efficient sound wise, but my exciters can handle it, it is just trying to get rid of all the bad sounds this combination makes, but hopefully without ruining the good sounds.

Steve.

Hi burnt.

It could be interesting to see what idea's people come up with for improving the motor units.

Little has changed in the last 100 years ?

Having a large exciter motor covering the rear driving surface area is not a good idea.

That is why I have always kept my eye out for flat film piezoelectric drivers, hopefully one day I will put my hand in my pocket 😬 and do some experiments.

Steve.

It could be interesting to see what idea's people come up with for improving the motor units.

Little has changed in the last 100 years ?

Having a large exciter motor covering the rear driving surface area is not a good idea.

That is why I have always kept my eye out for flat film piezoelectric drivers, hopefully one day I will put my hand in my pocket 😬 and do some experiments.

Steve.

Hello EucySteve:-

I must admit I'm perplexed, because I've never heard any noise which I could attribute to the exciter....Any issues I've had have always been the panel - Maybe I'm deaf to it... (that could be a bonus)

Eucy

I can't say like Steve I have heard it but pretty sure I can say I have measured it. Being in the mid frequencies (some kHz), it might be possible that stopping it makes a difference.

The signature : a peak at some kHz visible in the rear wave and not in the front? You can refer to my reply to a Steve's post where Steve posted a record of a panel front and rear side. More in the past, I think I posted something about my plywood panel measuring it outdoors. At this time I thought having a kind of horn effect due to the piece of wood that is around the exciter but in fact the root cause seems more the air flow coming from the area inside of the voice coil (see a previous post with a drawing of pistonic speaker)

Christian

Eucy.

I used to think it was just a panel problem , but it can be both the panel and the exciter, exciters can make mechanical noises if pushed too hard.

but the other sounds are more subtle , a slight harshness now and again that show up on certain tracks.

I am sorry if I have led you into thinking that I am suffering from rattling exciters 😁

But when these small problems are corrected they give a cleaner and clearer sound .

the problems with cone drivers is well documented and exciters are exactly the same, using the same drive motor design.

It is made more difficult for us because we are running these pretty much full range , it is a lot to ask, especially from a lump of wood or a small CD !

I am still surprised that DML actually works.

I have given up trying to tell audiophiles how good they sound, they seem to have a look on their faces of disbelief and disgust as they are trying reverse out of the room , and conversation 😱

Steve.

I used to think it was just a panel problem , but it can be both the panel and the exciter, exciters can make mechanical noises if pushed too hard.

but the other sounds are more subtle , a slight harshness now and again that show up on certain tracks.

I am sorry if I have led you into thinking that I am suffering from rattling exciters 😁

But when these small problems are corrected they give a cleaner and clearer sound .

the problems with cone drivers is well documented and exciters are exactly the same, using the same drive motor design.

It is made more difficult for us because we are running these pretty much full range , it is a lot to ask, especially from a lump of wood or a small CD !

I am still surprised that DML actually works.

I have given up trying to tell audiophiles how good they sound, they seem to have a look on their faces of disbelief and disgust as they are trying reverse out of the room , and conversation 😱

Steve.

Hello BurntMorning all. Just a thought, as there is much experimentation to do on exciters, I am having thoughts myself on how to optimise the design, is it worth starting a new thread on exciters?

I don't know what you have in mind. I don't think to do something on the exciter itself but for now I am in the opinion of experimenting around the exciter to panel interface. 2 reasons for that :

- is there a way to cancel or at least reduce what Steve call the exciter noise?

- what about a coupling part for a better matching between the panel mechanical impedance and the voice coil of the exciter? See US20020094095 (especially if there is a way to get lighter material for better efficiency... even if I agree with you that poplar is not a to bad comprise on this aspect)

Christian

@spedge

Exactly Steve, there hasn’t been a significant development of the thinking around exciters that I am aware of, lots of good incremental development by people like Billion for Dayton, but no fundamental experimentation like you do for example. There is much to be considered in alternative coil designs, e.g. flat coils on the panel with the magnet separate, how do we use the reaction force to drive another surface rather than just absorb it, the very interesting paper you found on the problem of large diameter voice coils ‘collapsing’ at high frequency, the exciter noise problem. There is probably a lot of experimentation to do with things like ferrofluid as a possible cure for voice coil noise, extending your thinking on combining tweeter domes with exciter coils. And as you suggest Peizo’s are interesting and they were never designed for DML as far as I am aware. There are lots of people who might be interested as there is some obvious crossover with ’normal’ drivers. It would be very interesting to see what comes up.

@homeswinghome

Yes that’s a good idea, the interface issue is a big one as we just assume it works but I also think it may be possible to investigate better options. After all, commercial units are limited by cost and that don’t apply to us DIYers. I also agree it would be helpful to have a clean start on the topic because this is a very large thread and many of the insights get lost or are difficult to find after a while. The thread looking at DML’s as a PA solution is what I had in mind and it has brought new people into the DML topic and has generated some fresh thinking.

Burnt

Exactly Steve, there hasn’t been a significant development of the thinking around exciters that I am aware of, lots of good incremental development by people like Billion for Dayton, but no fundamental experimentation like you do for example. There is much to be considered in alternative coil designs, e.g. flat coils on the panel with the magnet separate, how do we use the reaction force to drive another surface rather than just absorb it, the very interesting paper you found on the problem of large diameter voice coils ‘collapsing’ at high frequency, the exciter noise problem. There is probably a lot of experimentation to do with things like ferrofluid as a possible cure for voice coil noise, extending your thinking on combining tweeter domes with exciter coils. And as you suggest Peizo’s are interesting and they were never designed for DML as far as I am aware. There are lots of people who might be interested as there is some obvious crossover with ’normal’ drivers. It would be very interesting to see what comes up.

@homeswinghome

Yes that’s a good idea, the interface issue is a big one as we just assume it works but I also think it may be possible to investigate better options. After all, commercial units are limited by cost and that don’t apply to us DIYers. I also agree it would be helpful to have a clean start on the topic because this is a very large thread and many of the insights get lost or are difficult to find after a while. The thread looking at DML’s as a PA solution is what I had in mind and it has brought new people into the DML topic and has generated some fresh thinking.

Burnt

Everyone.

I think it might be helpful to explain the various sounds I have noticed from different areas of the panel and exciter interface.

They all seem to be getting lumped together.

1.

The about 10k peak (on my 25mm coil exciter).

This was the first problem I noticed over 10years ago.

This is caused by the central panel surface area within the coil ring.

This has been called the oil can effect by tectonic.

It is much more complicated than that, but can be easily solved.

2.

The cavity resonance within the coil former and magnet area.

This can give a slight harshness to the sound(but I find as annoying as the rest).

This can be complicated by the type of panel materials or dome used.

I find the harder the surface the harder the sound, more reflective i think?

1, could be making this worse also.

The size of this cavity changes the frequency of this resonance.

3.

As Christian has mentioned, the closeness of the magnet and suspension to the back of the drive area causes what I would call phaseyness , this also could be hampered by the spider being attached to the former? And the reasonace of the coil former and cavity , readily radiating from this area?

4.

The exciter body is also radiating sounds, I am not talking about the mechanical sounds, that are produced by over driving the exciters ,that is a different issue.

The cooling hole in the magnet can also whistle sometimes, this seems to be affected by the panel material chosen?

5.

I have already mentioned coil resonance, but it is also a separate problem.

It is hard to determine which is doing what , and so these tend to all get lumped together .

Off hand, I can't think of any more, but I'm sure some can think of others.

Steve.

I think it might be helpful to explain the various sounds I have noticed from different areas of the panel and exciter interface.

They all seem to be getting lumped together.

1.

The about 10k peak (on my 25mm coil exciter).

This was the first problem I noticed over 10years ago.

This is caused by the central panel surface area within the coil ring.

This has been called the oil can effect by tectonic.

It is much more complicated than that, but can be easily solved.

2.

The cavity resonance within the coil former and magnet area.

This can give a slight harshness to the sound(but I find as annoying as the rest).

This can be complicated by the type of panel materials or dome used.

I find the harder the surface the harder the sound, more reflective i think?

1, could be making this worse also.

The size of this cavity changes the frequency of this resonance.

3.

As Christian has mentioned, the closeness of the magnet and suspension to the back of the drive area causes what I would call phaseyness , this also could be hampered by the spider being attached to the former? And the reasonace of the coil former and cavity , readily radiating from this area?

4.

The exciter body is also radiating sounds, I am not talking about the mechanical sounds, that are produced by over driving the exciters ,that is a different issue.

The cooling hole in the magnet can also whistle sometimes, this seems to be affected by the panel material chosen?

5.

I have already mentioned coil resonance, but it is also a separate problem.

It is hard to determine which is doing what , and so these tend to all get lumped together .

Off hand, I can't think of any more, but I'm sure some can think of others.

Steve.

Ziggy originally posted piezoelectric dml on this site in 2008, before being banned and moving to audiocircle NXT RUBBISH.

https://www.diyaudio.com/community/threads/piezo-nxt-type-panel.133711/

https://www.diyaudio.com/community/threads/piezo-nxt-type-panel.133711/

Well - What do you knowZiggy originally posted piezoelectric dml on this site in 2008, before being banned and moving to audiocircle NXT RUBBISH.

https://www.diyaudio.com/community/threads/piezo-nxt-type-panel.133711/

Nothing new under the sun

Eucy

Attachments

Has anyone explored sandwiching dissimilar materials? I mention that because one study suggested poplar ply was great for certain frequencies and EPS was good for the other. Perhaps combining both into one non-uniform panel (one layer a different size shape than the other)? Or perhaps just sandwiching the same material?

Hello everybody

I recently bought a carbon and nomex panel about the size of the tectonic ones, unfortunately I still can't test everything well, I would like to create a frame to support the panel and the exciters but I don't know what material to use as an alternative to wood or iron, the aim at the moment is to create a structure that is stable without great expense.

Tips?

thank you

I recently bought a carbon and nomex panel about the size of the tectonic ones, unfortunately I still can't test everything well, I would like to create a frame to support the panel and the exciters but I don't know what material to use as an alternative to wood or iron, the aim at the moment is to create a structure that is stable without great expense.

Tips?

thank you

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker