Spedge,

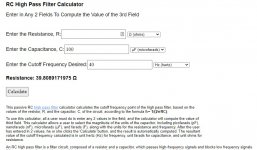

I got these 100uf capacitors from a pair of Sony cubes used as the satellite speakers for a high-end receiver. The sub I'm using provided the bass. I'm guessing these capacitors were blocking the below-40 Hz frequencies to the 3.5x4.5" speakers in the cubes. Here is the high-pass calculator I got the values from. Since the Sony speakers did not use a resistor, do you think it would be ok to not use one with the DMLs, too? No matter how rusty you think you may be with this, you are light-years ahead of me on it.

I got these 100uf capacitors from a pair of Sony cubes used as the satellite speakers for a high-end receiver. The sub I'm using provided the bass. I'm guessing these capacitors were blocking the below-40 Hz frequencies to the 3.5x4.5" speakers in the cubes. Here is the high-pass calculator I got the values from. Since the Sony speakers did not use a resistor, do you think it would be ok to not use one with the DMLs, too? No matter how rusty you think you may be with this, you are light-years ahead of me on it.

Attachments

Thin Thermo-Acoustic panels

IMO using vibrating panels have so many issues that it's time to get back to the basics and generate sound with Thermo-Acoustic (TA) panels. With the current technologies being developed one can have a standard letter size 8" x 11" TA film generate sounds in a very linear range from 500 Hz to ~1.5 MHz.

With the acoustic range one would have to use a sub woofer to complete the full human hearing range of 20-20K Hz. Thermo-Acoustics panels are not suitable for low frequency range since low sound frequencies favor pressure as oppose to thermal methods of generating longitudinal sound waves in air.

Pervious work in TA has been with thin film metals and wire with limited good results since these are not the best material. University of Texas and several Korean groups have started to use carbon nanotube and graphene foam with better results. The reason for this is carbon nanotubes and graphene foam have ideal thermal properties for heating and cooling gases (i.e. air). Their biggest issues are thickness since sound pressure is a function of the reciprocal of the thickness of the film. So to make the speaker loud one wants a very thin film on the order of 1 to 10 nanometers thick. To make graphene foam that thickness is difficult and expensive.

My experience and method is to make graphene film that is large on the order of letter page size and on the order of 25 to 20 nanometers thick with the current process. This gives sound pressure 80-85 dB at 1 meters distance from the film at the frequency range of 500Hz to 550KHz (with the current microphones that I have access to). If my next tweaks work and get the thickness down to 1 to 5 nanometers the sound pressure would go up to 115 dB at 1 meters distance from the film at the frequency range of 500Hz to 1,550KHz. The beauty of thin graphene is it optically transparent and robust even at such thickness of a few nanometers.

Now for the down side for the wonder film is the cost of fabrication. It's running about $2K to $1K per sheet. This limits it appeal to the DIY community since most want to have things cheap. If the current teaks to the process are doable to make thin pinhole free 1 to 5 nanometer films could get the cost down to $50 to $25 in small quantities and below $1 in large quantities due to cost scales in quantities. This opens up a board audio market as well as from the main market solid state batteries which this film has been developed for.

is the cost of fabrication. It's running about $2K to $1K per sheet. This limits it appeal to the DIY community since most want to have things cheap. If the current teaks to the process are doable to make thin pinhole free 1 to 5 nanometer films could get the cost down to $50 to $25 in small quantities and below $1 in large quantities due to cost scales in quantities. This opens up a board audio market as well as from the main market solid state batteries which this film has been developed for.

IMO using vibrating panels have so many issues that it's time to get back to the basics and generate sound with Thermo-Acoustic (TA) panels. With the current technologies being developed one can have a standard letter size 8" x 11" TA film generate sounds in a very linear range from 500 Hz to ~1.5 MHz.

With the acoustic range one would have to use a sub woofer to complete the full human hearing range of 20-20K Hz. Thermo-Acoustics panels are not suitable for low frequency range since low sound frequencies favor pressure as oppose to thermal methods of generating longitudinal sound waves in air.

Pervious work in TA has been with thin film metals and wire with limited good results since these are not the best material. University of Texas and several Korean groups have started to use carbon nanotube and graphene foam with better results. The reason for this is carbon nanotubes and graphene foam have ideal thermal properties for heating and cooling gases (i.e. air). Their biggest issues are thickness since sound pressure is a function of the reciprocal of the thickness of the film. So to make the speaker loud one wants a very thin film on the order of 1 to 10 nanometers thick. To make graphene foam that thickness is difficult and expensive.

My experience and method is to make graphene film that is large on the order of letter page size and on the order of 25 to 20 nanometers thick with the current process. This gives sound pressure 80-85 dB at 1 meters distance from the film at the frequency range of 500Hz to 550KHz (with the current microphones that I have access to). If my next tweaks work and get the thickness down to 1 to 5 nanometers the sound pressure would go up to 115 dB at 1 meters distance from the film at the frequency range of 500Hz to 1,550KHz. The beauty of thin graphene is it optically transparent and robust even at such thickness of a few nanometers.

Now for the down side for the wonder film

I had not thought of making, or taking a pre-made, composite panel and then having the photographic image printed on it. I will look to see if there is a suitable printing service here in Melbourne.

Welcome to the board Chris.

I am also based in Melbourne and trying to make my own DMLs.

You can try this local mob that does printing on metal.

Also photographic prints can be 'laminated' or enclosed in epoxy that can be poured at whatever thickness you want.

Good luck.

Hope to catch up sometime and exchange our experiences.

Last edited:

aagas,

You certainly make it sound feasible for me to construct composite Al+foam panels. I might visit the hardware store and get a feel for the materials available there.

The idea of whipping up your own foam is something I never would have thought of. I don't have a workshop to do that kind of stuff in, so I would have to think carefully about what level of mess I might make on my desk before trying it. I also don't have much in the way of sophisticated tools, mostly just a few handtools, etc.

Have you tried using foaming urethane for the foam layer using the same method?

Chris

You certainly make it sound feasible for me to construct composite Al+foam panels. I might visit the hardware store and get a feel for the materials available there.

The idea of whipping up your own foam is something I never would have thought of. I don't have a workshop to do that kind of stuff in, so I would have to think carefully about what level of mess I might make on my desk before trying it. I also don't have much in the way of sophisticated tools, mostly just a few handtools, etc.

Have you tried using foaming urethane for the foam layer using the same method?

Chris

Hi Sonnar,

How has your build turned out? Are you happy with the result?

Re: local printing, I have had a print on Al sheet made by that crowd once before; turned out beautifully. I had not considered whether they might be able to print on user supplied substrates, but I can find out. They are more expensive than the other print-to-metal service that supplied to me the picture I'm going to experiment with. I'm pretty sure the cheaper mob has them produced in asia and then delivered though.

Cheers,

Chris

How has your build turned out? Are you happy with the result?

Re: local printing, I have had a print on Al sheet made by that crowd once before; turned out beautifully. I had not considered whether they might be able to print on user supplied substrates, but I can find out. They are more expensive than the other print-to-metal service that supplied to me the picture I'm going to experiment with. I'm pretty sure the cheaper mob has them produced in asia and then delivered though.

Cheers,

Chris

Jaxboy.

The coil resistance for your exciter at 45hz is unknown?

You could just try attaching the cap only to the + terminal and see what happens?

It's not going to do any harm but might not be the roll off you want?

This is the cap that came on my exciter,but for two exciters,so is for 8ohms aprox?

It's 60uf 63v and I believe it xo is much higher up?

Give it a go

Steve.

The coil resistance for your exciter at 45hz is unknown?

You could just try attaching the cap only to the + terminal and see what happens?

It's not going to do any harm but might not be the roll off you want?

This is the cap that came on my exciter,but for two exciters,so is for 8ohms aprox?

It's 60uf 63v and I believe it xo is much higher up?

Give it a go

Steve.

Attachments

Spedge,

In the calculator, you put in 2 knowns, and it gives you the third, so I put in 40 Hz and 100 uf, and below, it gave me 39.8089 ohms in the dark print. I took 32 ohm resistors, which is what I had on hand, and put them across the DMLs and the 100uf capacitors in line, which gave me a high-pass for 50Hz. I tried it with Neil Diamond's 'Stones", which has a very strong bass thump at the beginning. That had totally bottomed out the panels before, and with the filter, they very slightly bottomed in a way that I could very easily live with, so I'm a happy camper. Thanks for worrying about it for me. Now I just need to find a way to hang/mount them that doesn't just look totally ugly.

In the calculator, you put in 2 knowns, and it gives you the third, so I put in 40 Hz and 100 uf, and below, it gave me 39.8089 ohms in the dark print. I took 32 ohm resistors, which is what I had on hand, and put them across the DMLs and the 100uf capacitors in line, which gave me a high-pass for 50Hz. I tried it with Neil Diamond's 'Stones", which has a very strong bass thump at the beginning. That had totally bottomed out the panels before, and with the filter, they very slightly bottomed in a way that I could very easily live with, so I'm a happy camper. Thanks for worrying about it for me. Now I just need to find a way to hang/mount them that doesn't just look totally ugly.

Jaxboy.

Did you try using without the resistor?

Without knowing the voice coil resistance at your chosen frequency it's all a bit hit and miss.

I presume that the resistor will lower the output of your exciter,which could be good if it was a bass driver.

Sorry I've got to go!!!

Steve.

Did you try using without the resistor?

Without knowing the voice coil resistance at your chosen frequency it's all a bit hit and miss.

I presume that the resistor will lower the output of your exciter,which could be good if it was a bass driver.

Sorry I've got to go!!!

Steve.

jaxboy.

i will moan no more .

.

a bit of a torcher track from chasing the dragon cd ,ive chopped out the bass solo to shorten the track ,which was too long for this site.

ive done a recording of one of my test dome panels on the left in this recording.

the right side is the 5mm xps about 2ft with dome.

the test panel size is only about 6inches so i xo both at 300hz.

i think i might have stumbled onto something to improve the performance quite a bit more.

but ill have to do more tests first ,just to make sure .

please take into consideration that converting and upload totally destroys and flattens the sound stage .

but hopefully the detail on the left is coming through?

this was playing at realistic levels

.

.

hope you like it.

steve

i will moan no more

a bit of a torcher track from chasing the dragon cd ,ive chopped out the bass solo to shorten the track ,which was too long for this site.

ive done a recording of one of my test dome panels on the left in this recording.

the right side is the 5mm xps about 2ft with dome.

the test panel size is only about 6inches so i xo both at 300hz.

i think i might have stumbled onto something to improve the performance quite a bit more.

but ill have to do more tests first ,just to make sure .

please take into consideration that converting and upload totally destroys and flattens the sound stage .

but hopefully the detail on the left is coming through?

this was playing at realistic levels

hope you like it.

steve

Attachments

jaxboy.

Don't forget that the microphones only go up to about 10k, so you're only missing a few khz.

I must roll off my system at 8k to get an idea of what you can hear.

A lot of live acoustic cds I have don't have much above 8k either.

I did another recording of a violin track,but the computer is stuck doing another update ,so I'll have to post it tomorrow.

Going to bed now.

Steve.

Don't forget that the microphones only go up to about 10k, so you're only missing a few khz.

I must roll off my system at 8k to get an idea of what you can hear.

A lot of live acoustic cds I have don't have much above 8k either.

I did another recording of a violin track,but the computer is stuck doing another update ,so I'll have to post it tomorrow.

Going to bed now.

Steve.

jaxboy.

i tried to upload at 256kb but it was too large a file, so im back to 128kb again !!!

i will make shorter recordings on the higher rate in future as the quality is so much better, reduces the mushy dumpy flat sound .

.

although i have not listened to it down loaded yet?

hope this sounds ok though.

steve.

ps.

after a very hectic fathers day with grandchildren , which totally wiped me out, i spent most of the night staring at the ceiling, with my brain unable to turn off

what a day

i tried to upload at 256kb but it was too large a file, so im back to 128kb again !!!

i will make shorter recordings on the higher rate in future as the quality is so much better, reduces the mushy dumpy flat sound

although i have not listened to it down loaded yet?

hope this sounds ok though.

steve.

ps.

after a very hectic fathers day with grandchildren , which totally wiped me out, i spent most of the night staring at the ceiling, with my brain unable to turn off

what a day

Attachments

Spedge,

What frequency did that go up to? That was a good recording. I tried it with just the DMLs, and they played it quite well. One of my DMLs came crashing down last night! The spine came unglued, so I ran a screw through each side into the frame. I didn't think I would have needed to have done that before, but I guess so.

I want to try running the box speakers along with the DMLs. Everything is 4 ohm. I have connected the boxes in series as 8 ohm. Should I just put everything in series (as 12 ohm), or put 4 ohm resistors in series with the DMLs (as 8 ohm) and then put the DMLs with the resistors in parallel with the boxes (8 ohm), to make everything 4 ohm? I am running this with a class D amp, which will handle 4 ohms ok, but I am not so sure about 2 ohms or so. I have had such poor luck with my amps that I am not willing to risk blowing my amp by experimenting.

What frequency did that go up to? That was a good recording. I tried it with just the DMLs, and they played it quite well. One of my DMLs came crashing down last night! The spine came unglued, so I ran a screw through each side into the frame. I didn't think I would have needed to have done that before, but I guess so.

I want to try running the box speakers along with the DMLs. Everything is 4 ohm. I have connected the boxes in series as 8 ohm. Should I just put everything in series (as 12 ohm), or put 4 ohm resistors in series with the DMLs (as 8 ohm) and then put the DMLs with the resistors in parallel with the boxes (8 ohm), to make everything 4 ohm? I am running this with a class D amp, which will handle 4 ohms ok, but I am not so sure about 2 ohms or so. I have had such poor luck with my amps that I am not willing to risk blowing my amp by experimenting.

Jaxboy.

I presume you mean that your box speaker has two 4ohm drivers in series ,making 8ohms plus the exciter in series will make 12ohms?

The capacitor will be in series too,maybe removing this and resistor?

This will work fine but the the volume levels of the exciter and box speaker could be very different?

Steve.

I presume you mean that your box speaker has two 4ohm drivers in series ,making 8ohms plus the exciter in series will make 12ohms?

The capacitor will be in series too,maybe removing this and resistor?

This will work fine but the the volume levels of the exciter and box speaker could be very different?

Steve.

Jaxboy.

Good question what did the frequency go up to ?

Surprisingly playing the track using peak hold on my daq produced this picture.

At least 20db down by 8k and 25db by 10k which is my microphones limit.

The roll off starting at about 2.5k.

So you didn't miss much of anything realy.

Just confirmed this by rolling off the frequencies at 8k on my daq.

You learn something new every day .

.

By the way I did say sometime ago ,that I wasn't doing any more experimenting with small panels and was going to concentrate on LPs and my larger eps panels !

yesterday I suddenly realised that I'm doing it AGAIN

I'm going to have to make lots of similar panels to test this new idea (of sorts)for comparisons.

Hopefully for use with larger panels as well,if possible?

Luckily small panels are easy to make and throw away,just got to eat more pizzas and corn flakes

Steve.

Good question what did the frequency go up to ?

Surprisingly playing the track using peak hold on my daq produced this picture.

At least 20db down by 8k and 25db by 10k which is my microphones limit.

The roll off starting at about 2.5k.

So you didn't miss much of anything realy.

Just confirmed this by rolling off the frequencies at 8k on my daq.

You learn something new every day

By the way I did say sometime ago ,that I wasn't doing any more experimenting with small panels and was going to concentrate on LPs and my larger eps panels !

yesterday I suddenly realised that I'm doing it AGAIN

I'm going to have to make lots of similar panels to test this new idea (of sorts)for comparisons.

Hopefully for use with larger panels as well,if possible?

Luckily small panels are easy to make and throw away,just got to eat more pizzas and corn flakes

Steve.

Attachments

Spedge,

I don't understand this. I just put an ohm meter across the DMLs, and with the non-polarized capacitor in series with the exciter and the 32 ohm resistor in parallel with the 4 ohm exciter (after the capacitor), the ohm meter reading was 1 ohm. That was for each DML. What gives? Should I take the 32 ohm resistor off? It would be easy enough. 1 little snip.

I don't understand this. I just put an ohm meter across the DMLs, and with the non-polarized capacitor in series with the exciter and the 32 ohm resistor in parallel with the 4 ohm exciter (after the capacitor), the ohm meter reading was 1 ohm. That was for each DML. What gives? Should I take the 32 ohm resistor off? It would be easy enough. 1 little snip.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker