I don't know that I consider anyone the authority on DMLs, haha. Many threads hundreds of pages and thousands of pages deep and patents and products going back decades and nobody has nailed the formula yet. The best we have are some "pretty good" designs that may be more a product of luck than skill. There are tons of people with invaluable tribal knowledge and engineering understanding way over my head, and plenty of pioneers and passionate people sharing their successes and failures and I appreciate all of you, and hope to be able to contribute something of value to the zeitgeist soon.

I don't really know what you mean by this,but parts express sell the exciter negativeghostrider has ordered and they have a FR plot of the xps material he is thinking of using ,I just thought this might be helpful.

Steve.

Check, who owns which company, where they are situated and so on. Parts Express sells Dayton Audio, which is owned by Parts Express.

The best we have are some "pretty good" designs that may be more a product of luck than skill.

That's what it exactly is, a product of luck than skill.

Most manufacturers of "high-end" DMLs or BMRs or whatever sometimes are good at marketing, rather than giving the world a acceptable product. The "high-end" equal to exorbitant prices, but no one appears to have "high-end" ears!

Instruments hear, and the graphs are drawn, but no high-end ears.

Here's something to experiment on. If you have an unused tweeter, a mid/low driver and a bass driver, just connect them together without XOs and hear what kind of sound the system would give.

Last edited:

If anyone wants to read about a BMR driver, where you can gleam some interesting facts you can use in your DML experiment.

By the way, I just heard the best news few minutes ago.

By the way, I just heard the best news few minutes ago.

Check, who owns which company, where they are situated and so on. Parts Express sells Dayton Audio, which is owned by Parts Express.

And the problem is ?

Steve

And the problem is ?

Steve

Oh, don't worry, if it is not obvious.

Anyway, I am very happy. Got the best news in four years, few minutes ago. And, I am not even an American.

Hope the link on a BMR driver would give some ideas on the DML matter. TK!

Last edited:

Standard assumptions:

1) "A normal speaker driver relies on the cone diaphragm attached to the voice coil to modulate air and make sound."

2) "Exciters, instead, rely upon the voice coil being coupled directly to the inside surface of an object, transforming that object’s outer surface into an invisible, protected speaker by imparting vibration from the exciter’s moving mass into the surface. The vibration of the surface modulates air in such a way that sound is created in planar-wave fashion."

The 1st assumption is that the cone moves air to make sound by the pistonic action, but doesn't consider the vibrations along the surface of the cone diaphragm.

The 2nd assumption is that, the exciter would transfer the vibrations to the outer surface, and on that surface "modulates" air. It doesn't take into account that, there's no reason for the vibrations to go through the thickness of the object first, before modulating the air on the side the the exciter is attached. This is the biggest problem of all flat panel + exciter DML systems. They disregard the backside of the panel. The modulations comes first on the side the exciter is attached, than on the outer surface, whatever the thickness of the panel.

Now, considering the cone drivers, you box the backside of it and place a transmission line or a tube(s) to get low sounds out of it. What if you consider the backside as the main side, and box the front side? Or, what if you box both sides with calculated openings? The standard bass-reflex box shows that the best sound comes from back of the driver, transmitted out through some sort of a tube. More mellow and nicer. (A kind of an example.)

I mentioned few posts earlier about boxing the backside of the DML and make a bass-reflex or transmission line. High-end Manger speakers are doing just that, by the way.

1) "A normal speaker driver relies on the cone diaphragm attached to the voice coil to modulate air and make sound."

2) "Exciters, instead, rely upon the voice coil being coupled directly to the inside surface of an object, transforming that object’s outer surface into an invisible, protected speaker by imparting vibration from the exciter’s moving mass into the surface. The vibration of the surface modulates air in such a way that sound is created in planar-wave fashion."

The 1st assumption is that the cone moves air to make sound by the pistonic action, but doesn't consider the vibrations along the surface of the cone diaphragm.

The 2nd assumption is that, the exciter would transfer the vibrations to the outer surface, and on that surface "modulates" air. It doesn't take into account that, there's no reason for the vibrations to go through the thickness of the object first, before modulating the air on the side the the exciter is attached. This is the biggest problem of all flat panel + exciter DML systems. They disregard the backside of the panel. The modulations comes first on the side the exciter is attached, than on the outer surface, whatever the thickness of the panel.

Now, considering the cone drivers, you box the backside of it and place a transmission line or a tube(s) to get low sounds out of it. What if you consider the backside as the main side, and box the front side? Or, what if you box both sides with calculated openings? The standard bass-reflex box shows that the best sound comes from back of the driver, transmitted out through some sort of a tube. More mellow and nicer. (A kind of an example.)

I mentioned few posts earlier about boxing the backside of the DML and make a bass-reflex or transmission line. High-end Manger speakers are doing just that, by the way.

Here's something to experiment on. If you have an unused tweeter, a mid/low driver and a bass driver, just connect them together without XOs and hear what kind of sound the system would give.

You'll hear garbage for a while, until your tweeter and woofer burn up their VCs trying to operate beyond their range. LOL. That's why DML's are so fascinating to me, or at least one of the reasons - the broad range of frequencies they can replicate from a single panel. And at the same time it makes perfect sense that you can't a clean, powerful, and linear sound from 20-20k from a single panel. Not that it should stop us from getting as close as we can.

You'll hear garbage for a while, until your tweeter and woofer burn up their VCs trying to operate beyond their range. LOL.

It is a question of the current that goes in. You can resist and/or slow the current by resistors and coils, supply any missing with capacitors. Anyway, that's an XO. The "voice" coil in any of the drivers are also there to slow the current, and create an electro magnet, which opposes the polarity of the permanent magnet, so the to and fro movement of that coil. Tweeters have quite small coil, whereas the woofer has a larger one. You can't hear more than your ears can stand. So, around 10-20% of the amp volume nothing is going to burn. It is the area of the cone that's being moved, makes one a tweeter, and the other a woofer. The current is the same at the given moment. The woofer won't tweet, while the tweeter won't ever give out bass sound.

Anyway, have you ever tried? :

I've seen few 2-way boxes with only one small capacitor at the tweeter, and nothing else. Some of them are more than 30 years old and still working.

Ah, by the way, the signal from the amp comes through one pair of wires, not 3 pairs of wires one each to a tweeter, mid/low or to woofer.

Last edited:

That's what it exactly is, a product of luck than skill.

Most manufacturers of "high-end" DMLs or BMRs or whatever sometimes are good at marketing, rather than giving the world a acceptable product. The "high-end" equal to exorbitant prices, but no one appears to have "high-end" ears!

Instruments hear, and the graphs are drawn, but no high-end ears.

Here's something to experiment on. If you have an unused tweeter, a mid/low driver and a bass driver, just connect them together without XOs and hear what kind of sound the system would give.

It is a question of the current that goes in. You can resist and/or slow the current by resistors and coils, supply any missing with capacitors. Anyway, that's an XO. The "voice" coil in any of the drivers are also there to slow the current, and create an electro magnet, which opposes the polarity of the permanent magnet, so the to and fro movement of that coil. Tweeters have quite small coil, whereas the woofer has a larger one. You can't hear more than your ears can stand. So, around 10-20% of the amp volume nothing is going to burn. It is the area of the cone that's being moved, makes one a tweeter, and the other a woofer. The current is the same at the given moment. The woofer won't tweet, while the tweeter won't ever give out bass sound.

Anyway, have you ever tried? :

I've seen few 2-way boxes with only one small capacitor at the tweeter, and nothing else. Some of them are more than 30 years old and still working.

Ah, by the way, the signal from the amp comes through one pair of wires, not 3 pairs of wires one each to a tweeter, mid/low or to woofer.

Mine was a rushed and facetious statement in an attempt to be funny. There are a number of destructive potentials there besides large and small mass speakers trying to oscillate way outside their mass will allow. I haven't personally tried running three drivers full range simultaneously but I have heard and see the results of subs and tweeters being run at full range and it isn't pretty so I can't imagine that combining them with a third mid driver improves things. Not sure what wiring the trio in series or parallel would do in that scenario, though.

Lots of OB towers use arrays of light midranges with whizzers to cover the entire top range with nothing but a high pass cap for protection and they sound great. Complex is not always better.

I am reading some of the earlier posts in the thread and I see numerous mentions about how to test a panel/find nodes/resonant areas by supporting it horizontally at the corners and moving the exciter around to find the optimal sound. The MO for this seems to be for it to be "step 1", then people just affix their exciter and treat it like it's static from that point on. But then you move on to modifying, damping, framing, etc. to chase down and resolve unwanted qualities, all the while leaving the exciter put. Pardon my ignorance here but don't all of those further steps change the harmonics of the panel overall, and maybe shift the locations of the good and bad nodes on the substrate? Wouldn't you want to reconduct the same test after each modification step, and probably even try other exciters? Otherwise it seems like you're missing or ignoring possibly critical secondary/tertiary effects of your changes. Sure, you added more damping and checked your REW and now you see improvements in some areas overall but consequential reductions or lack of change in others. Why not play around with the exciter and see what happens rather than just being like "Well, I picked my exciter and it's location. Nothing I can do about it now" and convincing yourself that whatever negative side effects that occur in the process of improving other issues just have to be taken for granted? I mean, it's worth a shot, and if nothing good comes of it, put it back where it was right? I guess I am just surprised I haven't seen more people posting about doing this.

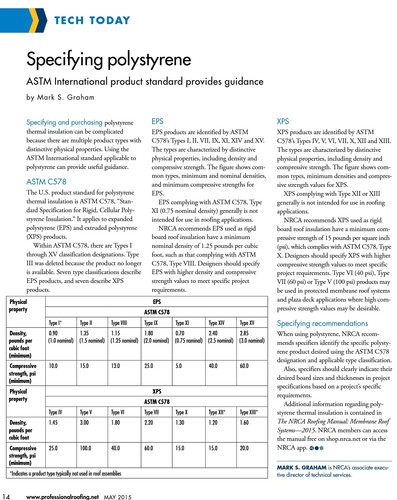

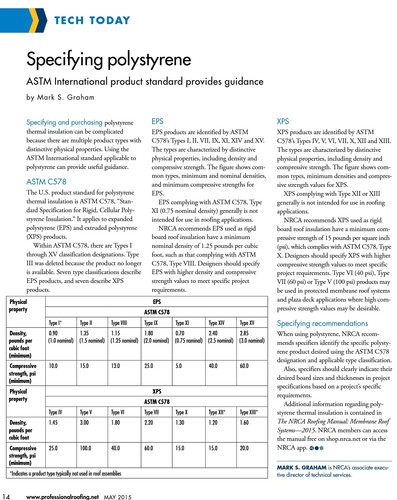

EPS vs XPS observation. I was looking at differences between the two after reading old posts. DMLBES talked a lot about his preference for EPS, especially kinds with high compression strength, because it had higher output and broader range. He often opined that XPS was too dense (at least in the thicknesses that people seemed to use). Anyhow, this got me wondering about what constitutes "high compression strength" so I could more effectively look for products. I found this document (well I found lots but this was at a level of reading comprehension and attention span on my level) and found the ratings interesting. I figured that XPS like foamular 150 would have a fairly high compression strength, but it is only rated at 15 PSI, putting it as a Type X (or XII) with a density of 1.3 lb/ft^3. That's the bottom of the xps compression strength scale and density, with the peak being 100 PSI and 3lb/ft^3 for Type V. Conversely, a high compression strength EPS is 40-60 PSI with a 2.4-2.85 lb/ft^3 density for types XIV and XV.

Now DMLBES didn't specify what he considered "High" but I just found it surprising and interesting that a substrate with a higher compression strength and greater density would have the better output qualities. I know that the composition and air content differences between the two play a role, but by the numbers I would think the higher weight and density per ft^3 would be an overarching influencer. I'm no materialologist though, obviously. My surprise presumes a lot, though - Like that DMLBES was expressing his preference based on equal panel dimensions between the 2 materials.

Anyway, just thought I'd share my findings, because sharing is caring.

Now DMLBES didn't specify what he considered "High" but I just found it surprising and interesting that a substrate with a higher compression strength and greater density would have the better output qualities. I know that the composition and air content differences between the two play a role, but by the numbers I would think the higher weight and density per ft^3 would be an overarching influencer. I'm no materialologist though, obviously. My surprise presumes a lot, though - Like that DMLBES was expressing his preference based on equal panel dimensions between the 2 materials.

Anyway, just thought I'd share my findings, because sharing is caring.

Last edited:

Mine was a rushed and facetious statement in an attempt to be funny.

Oh, that's OK.

There are a number of destructive potentials there besides large and small mass speakers trying to oscillate way outside their mass will allow.

But, you'd want the tiny "exciter" with its tiny coil and the tiny magnet move a large surface and give out a full range of sound?

You see, its all about surfaces. The tweeter practically doesn't have a surface, the "mid/low" has a small cone, so small surface, while the woofer has a massive surface and a massive coil and a massive magnet.

Lots of OB towers use arrays of light midranges with whizzers to cover the entire top range with nothing but a high pass cap for protection and they sound great. Complex is not always better.

They, who like OBs have quite sensitive ears, I believe.

EPS vs XPS observation. I was looking at differences between the two after reading old posts. DMLBES talked a lot about his preference for EPS, especially kinds with high compression strength, because it had higher output and broader range. He often opined that XPS was too dense (at least in the thicknesses that people seemed to use).

EPS is made from tiny polystyrene balls that get expanded with temperature and pressure in a large pressure box, and when they become larger, the surface tension between the expanded polystyrene ball surfaces and hold them together. I've seen this happening in a factory. Once cut, the panel is not good at bending, it cracks. You can also pull out the tiny balls out, one by one, but they tend to hold on to your hand, the surface tension is still there.

Now DMLBES didn't specify what he considered "High" but I just found it surprising and interesting that a substrate with a higher compression strength and greater density would have the better output qualities. I know that the composition and air content differences between the two play a role, but by the numbers I would think the higher weight and density per ft^3 would be an overarching influencer. I'm no materialologist though, obviously. My surprise presumes a lot, though - Like that DMLBES was expressing his preference based on equal panel dimensions between the 2 materials.

Anyway, just thought I'd share my findings, because sharing is caring.

He was right in many things he said, only his way of saying was somewhat tough. He also wanted to have a patent or so.

OK, when you glue a disk, balsa or whatever, and then glue the disk to the EPS panel, you have 2 materials on the back and one material on the front. The vibrations transferred to the surface through the disk are different than, what you'd get, if you glue the exciter straight to one of those 2 materials separately. On the disk + EPS panel, sound emitting from the area just over the disk and adjoining area are different than the ones you get from further away.

Maybe, you could carve an area deeper in the middle of the EPS panel, then carve another area (radially, of course) further away less deep, and leave the rest, fix the exciter in the middle, you'd get different sounds from the three areas, thinner to deeper, or high to low.

Or, you can use the thinnest possible EPS panel you can get, try with the thin one first, the add another on top of it and test,and another on top of that and test. Of course, test with your own ears. You may find the composition, which suits your ears.

After all kinds of testing, you'd have to find an aesthetic solution, or otherwise the wife would give you a hard time.

Last edited:

NXT.......rubbish??....THINK AGAIN!

EPS is still my favourite dml material, further down in this link i talk about eps(2010).

HD grades have a much better hf response ,I have only used a 40cm panel as large single panels are very expensive

Lower grades(25mm) have a lower shelf above 10k,I will post a link to some pics.

Steve

EPS is still my favourite dml material, further down in this link i talk about eps(2010).

HD grades have a much better hf response ,I have only used a 40cm panel as large single panels are very expensive

Lower grades(25mm) have a lower shelf above 10k,I will post a link to some pics.

Steve

Uploaded Pictures

The pictures show some of my panels I'd tested.

The 5x2ftx1inch probably 70 grade? Response is shown in three pics at 1ft, and 10ft into the room,with and without the transmission line LF units.

As can be seen ,a pretty flat response can be achieved without eq.

Steve

The pictures show some of my panels I'd tested.

The 5x2ftx1inch probably 70 grade? Response is shown in three pics at 1ft, and 10ft into the room,with and without the transmission line LF units.

As can be seen ,a pretty flat response can be achieved without eq.

Steve

EPS70, 50mm x 1000mm x 500mm pack of 12 price is £33 in UK. £2.75 per sheet.

EPS70, 50mm x 2400mm x 1200mm pack of 6, Kay-Metzeler or Jablite is £97. £16.16 per sheet. You can get white and grey sheets. 25mm, 40mm are cheaper.

EPS100 is twice the price.

Sundolitt (and other brands) XPS300, 50mm x 1200mm x 600mm pack of 8 is £56. £7 per sheet.

You can get them from any online insulation products shops. You'd have to pay delivery charges. If you can find Encon, Johnsons, Travis Parkins etc, near your area, you can get them even cheaper. You can always buy 1 or 2 sheets.

EPS/XPS can also be found quite frequently behind furniture shops, malls etc for free.

There's also multi-layer insulation material, such as Thinsulex Silver, Thinsulex Gold and Low-E reflective foils, or breather membranes. They are not stiff, but can be pasted with wet-dry paper or other thin material on one side or on both and create a panel. All are freely available in building material/Insulation shops, online and stationary.

EPS70, 50mm x 2400mm x 1200mm pack of 6, Kay-Metzeler or Jablite is £97. £16.16 per sheet. You can get white and grey sheets. 25mm, 40mm are cheaper.

EPS100 is twice the price.

Sundolitt (and other brands) XPS300, 50mm x 1200mm x 600mm pack of 8 is £56. £7 per sheet.

You can get them from any online insulation products shops. You'd have to pay delivery charges. If you can find Encon, Johnsons, Travis Parkins etc, near your area, you can get them even cheaper. You can always buy 1 or 2 sheets.

EPS/XPS can also be found quite frequently behind furniture shops, malls etc for free.

There's also multi-layer insulation material, such as Thinsulex Silver, Thinsulex Gold and Low-E reflective foils, or breather membranes. They are not stiff, but can be pasted with wet-dry paper or other thin material on one side or on both and create a panel. All are freely available in building material/Insulation shops, online and stationary.

Last edited:

I have no problem getting 70 grade from wickes diy for about £8 for a 1200x2400x25mm sheet, no transport costs.

It had to be trimmed to get it in the house,let alone the car.

You can buy higher grades in large quantity to reduce each pane cost,but what do you do with 20 or so room filling panels,slipping them behind the curtains won't work this time

Steve

It had to be trimmed to get it in the house,let alone the car.

You can buy higher grades in large quantity to reduce each pane cost,but what do you do with 20 or so room filling panels,slipping them behind the curtains won't work this time

Steve

You can buy higher grades in large quantity to reduce each pane cost,but what do you do with 20 or so room filling panels,slipping them behind the curtains won't work this time

Steve

What about any building sites nearby, or someone repairing his house?

Chdsl - Yeah, DMLBES definitely had an abrasive way of communicating, and a little bit of a blue collar napoleon complex. He was right about a lot of things, though.

Spedge - I like the story of the large sheet trying to take you to the Land of Oz ��

On the subject of thinner panels, do either of you gents have advice for cleanly cutting a piece along it's thin axis? I got some 1" xps sheets that I'd like to get it down to 1/2" without having to sand them and make a mess.

Spedge - I like the story of the large sheet trying to take you to the Land of Oz ��

On the subject of thinner panels, do either of you gents have advice for cleanly cutting a piece along it's thin axis? I got some 1" xps sheets that I'd like to get it down to 1/2" without having to sand them and make a mess.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker