Just to show the crack after the emergency repair:

(did not fully clean up the enclosure after gluing)

Am I convinced it will stay that way? Sadly, no...

But one can hope, right?

Now if I could find something as balanced as this:

Magic Body Control

(did not fully clean up the enclosure after gluing)

Am I convinced it will stay that way? Sadly, no...

But one can hope, right?

Now if I could find something as balanced as this:

Magic Body Control

Last edited:

Everyone wants to help but...

You guys ought to read through the thread a little more thoroughly. If you had, you'd know the rods cannot be removed and driving the point home is doing what now?

Wesayso, you're being very patient.

Hey cal, i read the entire thread before commenting. The fact that he was able to tighten up the rods to close the gap which appears to be near the middle of the stack means that the rods are in fact moving in the stack. I'm not there but he may very well be able to remove the rods given enough effort. Silicon and other rubbery glues exhibit a property called creep, a stretching under continuous load. I'd experiment by loosening the bottom nuts and tightening the uppers. See if a 2mm tightening on the top transfers to 2mm of motion in the opposite end of the rod after a period of time; say overnight. If it does, give it a few millimeters a day until the glue breaks, releasing the rods.

Just a thought.

kuroguy,

What you're suggesting is quite reasonable and had crossed my mind these past few days (actually while I was repairing the broken one, even figured welding a nut on top might influence the glue enough to come undone due to the heat applied). But the enclosures are "relaxed" right now (knocking on them will tell you that) and I won't risqué anything yet.

What you're suggesting is quite reasonable and had crossed my mind these past few days (actually while I was repairing the broken one, even figured welding a nut on top might influence the glue enough to come undone due to the heat applied). But the enclosures are "relaxed" right now (knocking on them will tell you that) and I won't risqué anything yet.

As I was reading the thread, I was thinking about trying to use the screw action of the threaded rod to spin them out (as you were discussing). The other idea I had is a bit crude, but an air hammer, the kind used to remove pesky rusted exhaust, might help in giving those rods the proper motivation to start moving.

I think your finish could be fine if you get those rods out and the inside of the cabinets coated with something.

It is a bummer to see such nice work turn on you like that. But I've been there as well. If you do this long enough, everyone has one of these moments.

I think your finish could be fine if you get those rods out and the inside of the cabinets coated with something.

It is a bummer to see such nice work turn on you like that. But I've been there as well. If you do this long enough, everyone has one of these moments.

That could work nicely for a new build I guess. Not ready to do that to this one but it is nice looking and could solve some problems I have now.

It created a few new ones but nothing that couldn't be solved.

Not a bad idea at all, mount the front baffle from behind...

It created a few new ones but nothing that couldn't be solved.

Not a bad idea at all, mount the front baffle from behind...

Last edited:

I looked clode into the picture you posted showing the crack- split on the cabinet.I see the crack-split is on one piece layer raising to the upper level.This is what I had experienced

This photo shows what happened only after 24hrs after I recieved them from the person who assembled these.

If you look it was only a few that split on the bond joint but rather the material split.

Also the photo shows the compression of the bolts.If you look you can see the bend.This all had a lot to do with the cabinets could not be bolted on the front (which is this side) as this is where I had to cut out a 21" hole for the driver.

Over all I am seeing you experience the same thing with the bond joint failing from stress from the material bond as well as your glue joint..

This photo shows what happened only after 24hrs after I recieved them from the person who assembled these.

If you look it was only a few that split on the bond joint but rather the material split.

Also the photo shows the compression of the bolts.If you look you can see the bend.This all had a lot to do with the cabinets could not be bolted on the front (which is this side) as this is where I had to cut out a 21" hole for the driver.

Over all I am seeing you experience the same thing with the bond joint failing from stress from the material bond as well as your glue joint..

Space frame alternative?

Hiya,

Looks like you have some really good advice on how best to solve the problem, Phew!

Re future ideas for towers, I agree with the modular approach for future builds if you need / want high mass.

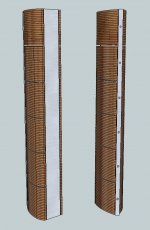

An alternative is the Formula 1 approach ie strong chassis with light weight curved panels... See attached pics

But you need to mount them on the wall as the will suffer from some degree of " cabinet rocking" if used on the floor.

All the best

D

Hiya,

Looks like you have some really good advice on how best to solve the problem, Phew!

Re future ideas for towers, I agree with the modular approach for future builds if you need / want high mass.

An alternative is the Formula 1 approach ie strong chassis with light weight curved panels... See attached pics

But you need to mount them on the wall as the will suffer from some degree of " cabinet rocking" if used on the floor.

All the best

D

Attachments

Que at your door...!

Good point!

Some times the fun / nightmare / challenge of the engineering side is so intense we forget its all about the music.

Please put me down on your list of " new best friends" cause I would love to visit and hear your speakers when ever you feel they are ready for prime time!

Cheers

Derek.

Good point!

Some times the fun / nightmare / challenge of the engineering side is so intense we forget its all about the music.

Please put me down on your list of " new best friends" cause I would love to visit and hear your speakers when ever you feel they are ready for prime time!

Cheers

Derek.

Hey cal, i read the entire thread before commenting.

Fair enough. I guess I was feeling a little protective of our member. I thought he had been shot at enough times and it was time to give it a rest. In retrospect, no one was saying anything that bad, it was just my instincts kicking in.

There a reason people use the word Mother when describing me.

I must say, this is a cool project and i sincerely hope it turns out nicely. Let me throw this out there. The wood will continue to contract as the moisture content in the air drops which will hit a minimum sometime in january. If you can tighten the bolts enough to prevent/remove any cracks that form at that point you're half way there. Remember, as the moisture content rises the wood will once again expand. If it doesn't have anywhere to expand one of 2 things will occur: the wood will crush under the load of the bolts and kinda get squeezed out of the stack or the bolts will break. come january, you may get away with just installing fender washers and springs at the top of the stack to give the stack a place to expand into.

Hi wesayso

The split was a result of a dimensional change in the wood. This change will probably mean that the baffle mounting holes will be misaligned. If these holes are not well aligned you will run the risk of breaking the captured nuts free within the cabinet, you REALLY don't want to do this and I speak from experience. I recommend holding fire on any further repair work on the cabinet until you get the baffles and can check this alignment. If the alignment is off you may find that the solution to one problem dictates the solution to the other and some good solutions to one problem will make solving the other impossible.

If the allignment is good I would proceed with fitting the drivers to the baffles and fitting them to the towers. This isn't just because I want to see them with drivers mounted as I'm sure you do too. This will enable you to assertain if the split has introduced any sonic nasties by comparing the two towers.

I am in agreement that it is preferable to keep the baffle as a single unit.

Good luck

The split was a result of a dimensional change in the wood. This change will probably mean that the baffle mounting holes will be misaligned. If these holes are not well aligned you will run the risk of breaking the captured nuts free within the cabinet, you REALLY don't want to do this and I speak from experience. I recommend holding fire on any further repair work on the cabinet until you get the baffles and can check this alignment. If the alignment is off you may find that the solution to one problem dictates the solution to the other and some good solutions to one problem will make solving the other impossible.

If the allignment is good I would proceed with fitting the drivers to the baffles and fitting them to the towers. This isn't just because I want to see them with drivers mounted as I'm sure you do too. This will enable you to assertain if the split has introduced any sonic nasties by comparing the two towers.

I am in agreement that it is preferable to keep the baffle as a single unit.

Good luck

Hi niffy,

The baffles aren't made yet. I was actually holding off on having them made to wait for dimensional changes in the towers. Let them acclimate so to speak.

After the emergency repair the length in both towers it off a bit more. They used to be within 2 mm of each other for weeks on end. Now it's a 5 mm difference after some massaging today of the second unbroken tower. (it was a 1 cm difference right after the repair)

The decision to hold off on the baffles being made was because I expected a change in length. The snapping of one of the towers wasn't part of my plan though .

.

All bolt holes for the baffle are oversized and the nuts are mounted in a way to have some play.

The biggest gamble is how much play do I actually need...

The baffles aren't made yet. I was actually holding off on having them made to wait for dimensional changes in the towers. Let them acclimate so to speak.

After the emergency repair the length in both towers it off a bit more. They used to be within 2 mm of each other for weeks on end. Now it's a 5 mm difference after some massaging today of the second unbroken tower. (it was a 1 cm difference right after the repair)

The decision to hold off on the baffles being made was because I expected a change in length. The snapping of one of the towers wasn't part of my plan though

All bolt holes for the baffle are oversized and the nuts are mounted in a way to have some play.

The biggest gamble is how much play do I actually need...

Q1: there will be mass loaded vinyl glued to the back of the aluminum baffle. Between that and the wood will be a thin neoprene strip or a more flexible joint (can't remember the name, it's used in cars for sealing blinking lights etc made by M3.

Q2, only 52 fixing points per speaker...

The baffle holding the speakers will float between the front plate and the enclosure. Mass loaded vinyl below and on top of it. It will have bigger holes than the M6 bolts coming trough. The nuts in the enclosure have play build in as does the front plate. They can move a bit without much worry.

Q2, only 52 fixing points per speaker...

The baffle holding the speakers will float between the front plate and the enclosure. Mass loaded vinyl below and on top of it. It will have bigger holes than the M6 bolts coming trough. The nuts in the enclosure have play build in as does the front plate. They can move a bit without much worry.

Last edited:

- Home

- Loudspeakers

- Full Range

- The making of: The Two Towers (a 25 driver Full Range line array)

could maybe be pivoted at top and bottom

could maybe be pivoted at top and bottom