Lingwendil, not the PC-83's that I know of, but I did a portable foam core speaker with the PC-65's (2-1/2" little brother to the PC-83) paired with a Tang Band W3-1876S and I'm VERY happy and impressed by the sound. And that's only being powered by an ebay TPA3118 plate amp. I can see the PC-83's would have potential for sure.

Last edited:

Thanks X! I spent 5 years cutting foam core in architecture school so I hope I can meet expectations there.Looking forward to first sound!

Hah! That explains why your work looks so neat.

Very cool that you are an architect by day. Any big projects we know of?

Please excuse my ignorance regarding foam core board. What glue is used to put the speaker together?

Usually hot melt glue for quick tacking or to use like caulking to seal. Also PVA glue for the final panel "capping" process where you need more time to dry.

Please read this thread and you will get more info on technique.

Foam Core Board Speaker Enclosures?

Also, low volatile "Liquid Nails" construction adhesive works too as well as PL Premium, or Gorilla glue (expanding polyurethane).

In addition to X's post, I've been using good old Elmer's white school glue for all the visible seams on my foam core builds. It takes forever to dry but is pretty much invisible against the white foam core. Also, being able to re-position parts from time to time isn't a bad thing either. I also used Titebond III wood glue on the non-visible interior parts of my latest mini-k's. Super strong stuff and sets a little faster than the Elmers. I also remember back in the day people were fans of "tacky glue" and "sobo". It comes down to which ever glue you're comfortable working with and has the ability to fill gaps between pieces. Mini-k's are very dependent on leak-free joints.

Hello, I just build a slightly modified Karlsonator to fit Tb W6-658E out of 12mm (shitty) plywood.

X-max:4.10 mm

Vas:28.31 Litr

Qts:0.44

Qms:4.49

Qes:0.49

Complete speaker data here: W6-658I - 6.5" PPM. Woofer - TB SPEAKER CO., LTD.

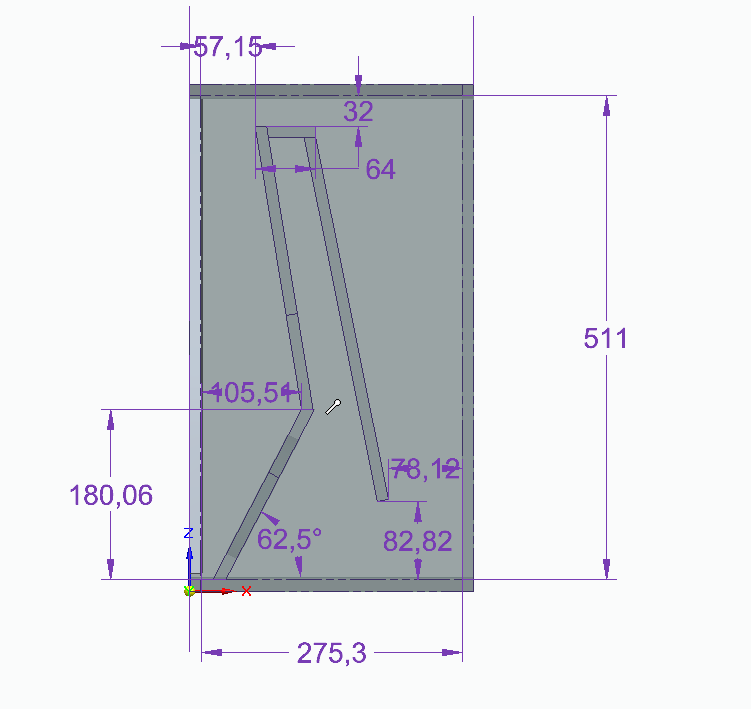

The dimensions i ended up with was something close to this:

So far it does its job but i expect a more refined version sound better. The final version will probably be 16mm MDF.

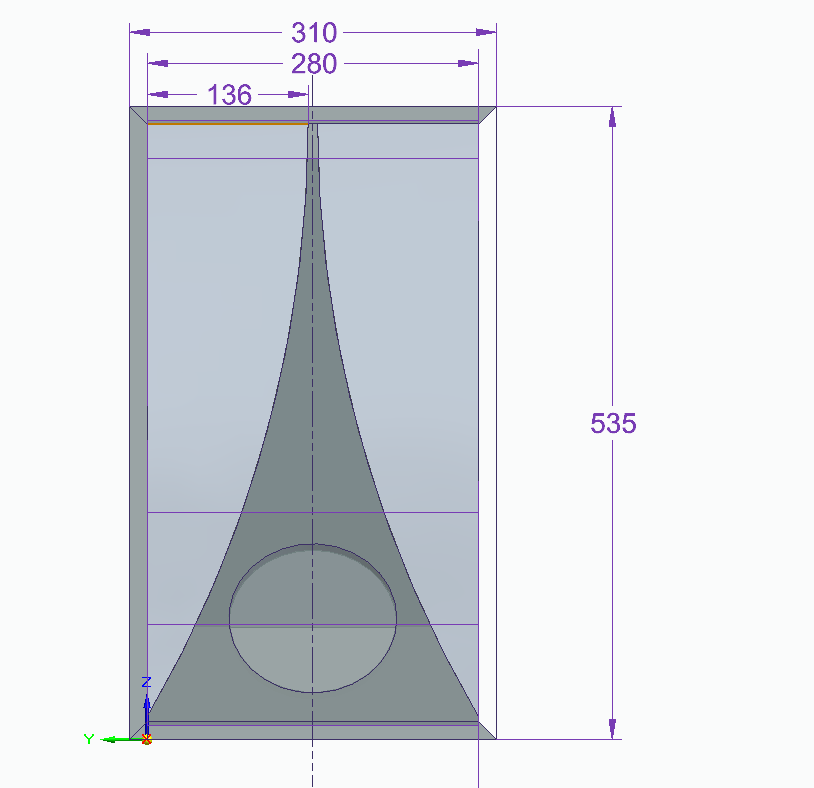

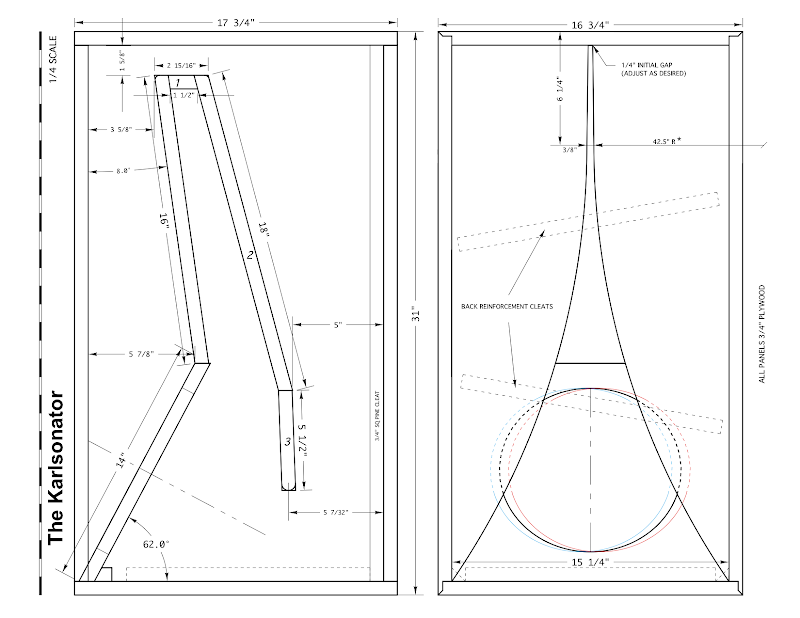

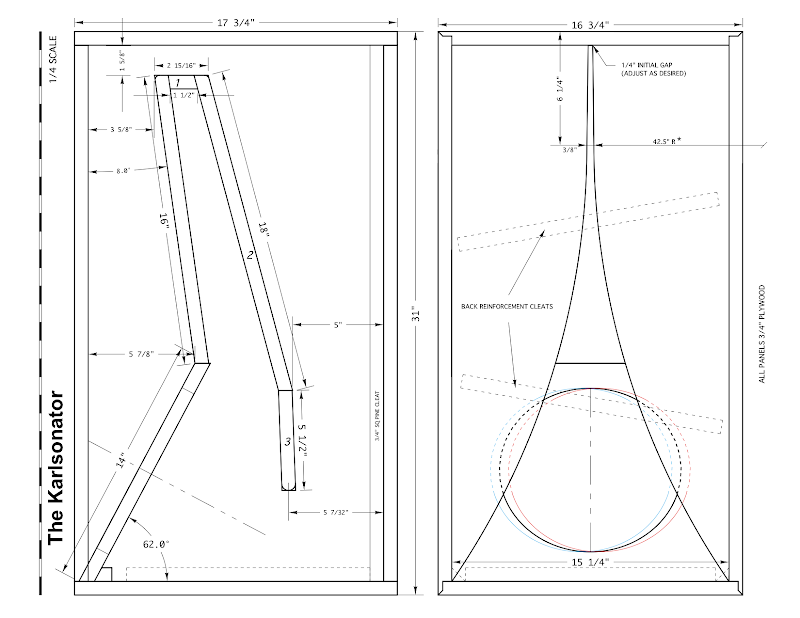

The "original" karlsonator dimensions i have found seems to be this:

And the 6" version has more changes than just scaling:

Are the W6-658E suited for a Karlsonator at all and what would be the correct way to scale?

In more general terms, what different options would be usable to be able to scale individually? I am thinking of making an parametrisation/automation where it will generate new plans according to new conditions, so any input regarding what dimensions you would like to modify and i will be happy to automate plans for you.

X-max:4.10 mm

Vas:28.31 Litr

Qts:0.44

Qms:4.49

Qes:0.49

Complete speaker data here: W6-658I - 6.5" PPM. Woofer - TB SPEAKER CO., LTD.

The dimensions i ended up with was something close to this:

So far it does its job but i expect a more refined version sound better. The final version will probably be 16mm MDF.

The "original" karlsonator dimensions i have found seems to be this:

And the 6" version has more changes than just scaling:

Are the W6-658E suited for a Karlsonator at all and what would be the correct way to scale?

In more general terms, what different options would be usable to be able to scale individually? I am thinking of making an parametrisation/automation where it will generate new plans according to new conditions, so any input regarding what dimensions you would like to modify and i will be happy to automate plans for you.

Attachments

Thank you XKR,

So when you simulate, what dimensions do you generate? I put out A-Z on the attached PDF and if you could point out what you would like to be "driving" i could make everything else adjust accordingly. Also If there is some other relations or so please try to explain what should relate and i will try to make the whole thing automatic.

So when you simulate, what dimensions do you generate? I put out A-Z on the attached PDF and if you could point out what you would like to be "driving" i could make everything else adjust accordingly. Also If there is some other relations or so please try to explain what should relate and i will try to make the whole thing automatic.

Attachments

Thanks X! I spent 5 years cutting foam core in architecture school so I hope I can meet expectations there.Looking forward to first sound!

Been there, done that!

So many evenings trying to finish a model...

But I was never really good at the drawing part, so I switched to computers.

At that time, I was the only one doing so in my class, on the "wicked fast" Mac IIfx at first, then a Quadra 660AV.

One word of caution using hot glue....

If you live in a hot climate (gets up to 38C over here), and bring your speakers along in your car, they will fall apart!

Went back home, tacked pieces together with spots of hot glue, then made some paper bands, and kinda like "papier-mâché", glued all sides with paper bands dipped in PVA .

Since then, the little mini-Ks have been going strong at the beach and hot weather all around!

Thank you XKR,

So when you simulate, what dimensions do you generate? I put out A-Z on the attached PDF and if you could point out what you would like to be "driving" i could make everything else adjust accordingly. Also If there is some other relations or so please try to explain what should relate and i will try to make the whole thing automatic.

I adjust scale in two dimensions: the height and depth at same time, and width independently. Sometimes all dimensions together like the 0.40x and 0.53x are scaled globally.

I adjust scale in two dimensions: the height and depth at same time, and width independently. Sometimes all dimensions together like the 0.40x and 0.53x are scaled globally.

Alright, I made a template that spits out a drawing. I don't know if it will be to use for anyone but just let me know and i can make one according to your needs. if you would like other dimensions visible or another format please let me know.

I attached how it would look like based on a 1:1 scale in mm.

It can scale independently in all directions and adjust according to material thickness. You can enter custom thickness to every piece.

Attachments

looks like the tuning of the old Karlsonator 6 prototype was around 60Hz

(Karlsonator8 ~41Hz tuning)

Do you know why more changes than just scaling was done on those two?

I am always looking for some woodworking projects, and decided that I want to make a few inexpensive speakers.

I have seen your Karlsonator design mentioned MANY times on here as a great build for the TC9FD18 drivers.

I have a few questions though.

I plan to build a set of them to replace the front speakers in my bedroom PC 5.1 setup.

I am a bit confused on your plans though, I see 0.4x and 0.53x and then scaled.

Seems your designs are meant to be built with foam? but I have seen a few done in wood.

I know for the main body I can just work off your internal dimensions, but what about the baffles, since they would be thicker?

Not sure what wood I would be using yet. I want something I can stain, but I can get plywood to look decent and could use 1/4" I think.

Also,

Another project I want to build is an all in one bluetooth and amplified speaker.

But would like to do something "neat" and that has a nice rich deep sound.

At first I thought about taking two 0.4x and just sticking them together, but it ends up being much larger than I would like.

Do you have any designs or recommendations that would work well for something like this?

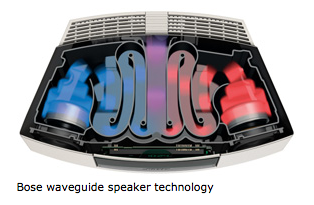

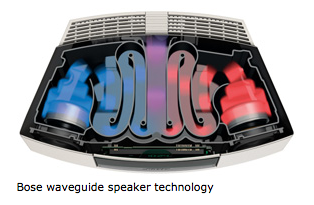

I know there are some compact designs that still get good bass response, and could add something more to the design greater than just a "box".

Below are some examples of what I am wanting to do for this second project.

Though I am also thinking about doing some sort of 360 degree, or bipolar, omni-directional speaker for that also. But thats another thread I suppose. haha

Thanks in advance,

~John

I have seen your Karlsonator design mentioned MANY times on here as a great build for the TC9FD18 drivers.

I have a few questions though.

I plan to build a set of them to replace the front speakers in my bedroom PC 5.1 setup.

I am a bit confused on your plans though, I see 0.4x and 0.53x and then scaled.

Seems your designs are meant to be built with foam? but I have seen a few done in wood.

I know for the main body I can just work off your internal dimensions, but what about the baffles, since they would be thicker?

Not sure what wood I would be using yet. I want something I can stain, but I can get plywood to look decent and could use 1/4" I think.

Also,

Another project I want to build is an all in one bluetooth and amplified speaker.

But would like to do something "neat" and that has a nice rich deep sound.

At first I thought about taking two 0.4x and just sticking them together, but it ends up being much larger than I would like.

Do you have any designs or recommendations that would work well for something like this?

I know there are some compact designs that still get good bass response, and could add something more to the design greater than just a "box".

Below are some examples of what I am wanting to do for this second project.

Though I am also thinking about doing some sort of 360 degree, or bipolar, omni-directional speaker for that also. But thats another thread I suppose. haha

Thanks in advance,

~John

Jtice,

Thanks for your interest and questions. You are correct about maintaining internal dimensions. For the “baffle” or K aperture you can make it out of thin plywood but I would recommend lining the inside of the K aperture with a layer of foam core. The main box similarly, should be made of foam core and covered in thin plywood as a veneer if desired. Several members have built both foamcore and plywood and a common theme was that the plywood did not sound good. It sounded “boxy”. There is some sort of sound dampening going on in foamcore.

The dimensions on the K aperture are not critical - try to make a curve that opens up to at least the surround of the driver. It can all be hand drawn and adjusted and tuned by ear.

Regarding your second question - a compact cabinet with good bass - without resorting a bass reflex, or passive radiators used on 99% of compact BT speakers - the Karlsonator is about as good as it gets. Not super compact, but the sound quality is superior.

I would not recommend building a compact BT speaker. Spend $40 and buy one that has $2M of engineering and tooling behind it. It will be more compact and have deep bass, albeit sound quality overall may not be as good.

DOSS Portable Wireless Bluetooth Speaker 2*6W Drivers 1 Passive Radiator Speakers with Stereo Sound Enhanced Bass For Phone PC-in Portable Speakers from Consumer Electronics on Aliexpress.com | Alibaba Group

If you can spend $500 I recommend a Sonos 5. Very nice sound.

Or if you want something cheap and sort of looks sort of like your linked images maybe $27 will get you this

XGODY W5 Portable Speaker Wireless Bluetooth Speakers HIFI Stereo Subwoofer Sound Amplifier Speaker for Phone Computer Laptop-in Portable Speakers from Consumer Electronics on Aliexpress.com | Alibaba Group

And if you don’t mind two bookshelf boxes - tough to beat this:

Dayton Audio MK402BT Powered Bluetooth 2-Way Bookshelf Speaker Pair with 3.5mm Aux In

Thanks for your interest and questions. You are correct about maintaining internal dimensions. For the “baffle” or K aperture you can make it out of thin plywood but I would recommend lining the inside of the K aperture with a layer of foam core. The main box similarly, should be made of foam core and covered in thin plywood as a veneer if desired. Several members have built both foamcore and plywood and a common theme was that the plywood did not sound good. It sounded “boxy”. There is some sort of sound dampening going on in foamcore.

The dimensions on the K aperture are not critical - try to make a curve that opens up to at least the surround of the driver. It can all be hand drawn and adjusted and tuned by ear.

Regarding your second question - a compact cabinet with good bass - without resorting a bass reflex, or passive radiators used on 99% of compact BT speakers - the Karlsonator is about as good as it gets. Not super compact, but the sound quality is superior.

I would not recommend building a compact BT speaker. Spend $40 and buy one that has $2M of engineering and tooling behind it. It will be more compact and have deep bass, albeit sound quality overall may not be as good.

DOSS Portable Wireless Bluetooth Speaker 2*6W Drivers 1 Passive Radiator Speakers with Stereo Sound Enhanced Bass For Phone PC-in Portable Speakers from Consumer Electronics on Aliexpress.com | Alibaba Group

If you can spend $500 I recommend a Sonos 5. Very nice sound.

Or if you want something cheap and sort of looks sort of like your linked images maybe $27 will get you this

XGODY W5 Portable Speaker Wireless Bluetooth Speakers HIFI Stereo Subwoofer Sound Amplifier Speaker for Phone Computer Laptop-in Portable Speakers from Consumer Electronics on Aliexpress.com | Alibaba Group

And if you don’t mind two bookshelf boxes - tough to beat this:

Dayton Audio MK402BT Powered Bluetooth 2-Way Bookshelf Speaker Pair with 3.5mm Aux In

Last edited:

xrk971,

Thanks for the input.

Bit of a bummer (for me) that wood is not really recommended for your design, though I guess thats not what it was originally all about anyway.

But I do understand that the foam could be providing alot of dampening. I suppose if one was built form wood that some foam or stuffing could be placed inside,

but that would then change the internal workings of the enclosure.

I want something that of coarse will sound good, but that I can also get to look really nice, hence, wood.

Neat though to see enclosures being made out of foam board,

year ago, last time I was into building enclosures there was alot of influence to make them very solid.

Though, with your designs, its not like any internal pressure is going to be building the walls of the enclosure out.

I have no doubt that a name brand BT speaker is going to sound better than what I can build,

especially if you want something fairly small.

I mainly wanted to do it as a fun project.

Thanks for the input.

~John

Thanks for the input.

Bit of a bummer (for me) that wood is not really recommended for your design, though I guess thats not what it was originally all about anyway.

But I do understand that the foam could be providing alot of dampening. I suppose if one was built form wood that some foam or stuffing could be placed inside,

but that would then change the internal workings of the enclosure.

I want something that of coarse will sound good, but that I can also get to look really nice, hence, wood.

Neat though to see enclosures being made out of foam board,

year ago, last time I was into building enclosures there was alot of influence to make them very solid.

Though, with your designs, its not like any internal pressure is going to be building the walls of the enclosure out.

I have no doubt that a name brand BT speaker is going to sound better than what I can build,

especially if you want something fairly small.

I mainly wanted to do it as a fun project.

Thanks for the input.

~John

You can make it out of wood - just line the inside with foam core - glue with non volatile construction adhesive or even latex caulking. The foam doesn’t have to deal just needs to cover all internal surfaces. Still add felt and foam along back chamber adjacent to driver.

- Home

- Loudspeakers

- Full Range

- Mini Karlsonator (0.53X) with Dual TC9FDs