its tougher to cut small wings than large - I did ok freehand for an 18" klam - it would be a hassle to make a compass jig for a jigsaw or template for router but those might be of use.

wings which go to the top would: let out more "highs", tune a bit higher. Somewhere in-between could be using a narrow inverted "V" slit tapering to zero width near the cabinet top or extend the slot to right below the Karlsonator's vent. If you had some cheap scrap (or even two layers of good cardboard) then might be worth making two sets of wings so you can pick and possibly tweak.

assuming your drivers play reasonably flat in the, either should sound very good. I'm mainly familiar with old-school Karlson at this point but will have Karlsonator12s within a week.

I have a regularly vented K-coupler not too much different in frontal aspect from the Karlsonator8 and FWIW, measured best

with a somewhat truncated height aperture - but it seemed to sound as good or better with full height aperture. It probably

would have been better if the aperture tapered towards zero at the top. This cabinet probably behaves different than

the Karlsonator8 as there's a reflector panel at top which alters the cross section quite a bit.

Carl is the first HAK type builder - here's one of his high aspect K-8's apertures

wings which go to the top would: let out more "highs", tune a bit higher. Somewhere in-between could be using a narrow inverted "V" slit tapering to zero width near the cabinet top or extend the slot to right below the Karlsonator's vent. If you had some cheap scrap (or even two layers of good cardboard) then might be worth making two sets of wings so you can pick and possibly tweak.

assuming your drivers play reasonably flat in the, either should sound very good. I'm mainly familiar with old-school Karlson at this point but will have Karlsonator12s within a week.

I have a regularly vented K-coupler not too much different in frontal aspect from the Karlsonator8 and FWIW, measured best

with a somewhat truncated height aperture - but it seemed to sound as good or better with full height aperture. It probably

would have been better if the aperture tapered towards zero at the top. This cabinet probably behaves different than

the Karlsonator8 as there's a reflector panel at top which alters the cross section quite a bit.

An externally hosted image should be here but it was not working when we last tested it.

Carl is the first HAK type builder - here's one of his high aspect K-8's apertures

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

For cutting the wings what I did was to draw the radius onto a piece of hardboard, cut out as close to the line as possible on the bandsaw, and then sand down to the line on a stationary belt sander. I finished up the edge by hand with a flexible sanding block.

Now that you have your hardboard template it easy to cut as many as you want with a router and a flush trim bit. If you could cut the radius directly with a router that would be the most accurate, but its a big radius so you would have to make a really big circle jig for your router.

Now that you have your hardboard template it easy to cut as many as you want with a router and a flush trim bit. If you could cut the radius directly with a router that would be the most accurate, but its a big radius so you would have to make a really big circle jig for your router.

I thought about just enlarging the drawing to full scale and tracing directly onto the wings, then cutting just outside the lines and rasping and sanding to the lines. That's kinda what I did with my K12s except I did a pencil rubbing of a factory wing (I didn't know it was a radius at that time).

Ok guys, I finally have a bit of time this weekend to make some sawdust!

A few question for those more experienced...

1.) Any advice on how to best cut the front wings so they don't look like a visually challenged third grader did them? I have a router and a jigsaw at my disposal.

2.) I know it has been covered in the thread but what would the main differences be between the wings that stop 3/4 the way up and those that go to the top?

3.)Any opinions on using the SEAS FA22RCZ instead of the Fostex FE203En-S?

XRK, maybe you could run it through your sim?

1) Cutting the wings: As Jesse has already suggested, a good method is to use hardboard/'masonite' to make a template, and then use a router to cut the wings with a template bearing bit. I would suggest cutting just outside the line with a jigsaw (or bandsaw) first, to make things easier on the router.

Yeah, a router on a long compass arm would probably be ideal. It would be like a homemade giant 'Jasper' type jig. I would not suggest this unless you are extremely familiar with this power tools and jigs. There's potential for extreme injury, and it's too much trouble for a single pair of speakers IMO.

My usual quick and dirty method: If you don't have a router, use a jigsaw to cut very close to the line. Save a piece of the cutoff from a particularly well cut section, and make a curved sanding block from it. Glue some 60 grit sandpaper to the inside to refine the curve of the wings. You will need to stick some sandpaper to thin plastic or something to do the narrow portion of the slot. This method yields very good results if you are patient.

The line itself is best marked with a long stick compass, though for the mini-karlsonator I simply printed out the plans and glued them to the wing board. To make a compass, take a flat stick, put nail through a drilled hole in one end, and jab a knife through the other. You can use a pencil instead of a knife, but it's less accurate.

2) RE: length of the slot - First, understand that this is not well understood. You get to be part of the research team.

3) Both drivers seem like they would work, but sound different subjectively. Eventually, xrk will come through with a sim for the seas, or did he already? I'd expect the Fostex to have more detail. The Seas might be better with rock.

xrk971 - if you are ever bored and looking for something to do...

Perhaps you could try the SEAS full range in your Karlsonator model? (8 or 12)

Perhaps you could try the SEAS full range in your Karlsonator model? (8 or 12)

Seas FA22RCZ specs

Nominal Impedance 8 Ohms

Voice Coil Resistance 5.7 Ohms

Recommended Frequency Range 30 - 20000 Hz

Voice Coil Inductance 0.09 mH

Force Factor 6.4 N/A

Long Term Power Handling * 40 W

Free Air Resonance 30 Hz

Characteristic Sensitivity (2,83V, 1m) 94 dB

Moving Mass 12.6 g

Voice Coil Diameter 26 mm

Air Load Mass In IEC Baffle 1.92 g

Voice Coil Height 12 mm

Suspension Compliance 2.2 mm/N

Air Gap Height 6 mm Suspension Mechanical Resistance 0.63 Ns/m

Linear Coil Travel (p-p) 6 mm

Effective Piston Area 222 cm^2

Maximum Coil Travel (p-p) 14 mm

VAS 134 Litres

QTS 0.35

QMS 4.36

QES 0.38

Magnetic Gap Flux Density 1.1 T

Magnet Weight 0.6 kg

Total Weight 2.05 kg

Seas FA22RCZ specs

Nominal Impedance 8 Ohms

Voice Coil Resistance 5.7 Ohms

Recommended Frequency Range 30 - 20000 Hz

Voice Coil Inductance 0.09 mH

Force Factor 6.4 N/A

Long Term Power Handling * 40 W

Free Air Resonance 30 Hz

Characteristic Sensitivity (2,83V, 1m) 94 dB

Moving Mass 12.6 g

Voice Coil Diameter 26 mm

Air Load Mass In IEC Baffle 1.92 g

Voice Coil Height 12 mm

Suspension Compliance 2.2 mm/N

Air Gap Height 6 mm Suspension Mechanical Resistance 0.63 Ns/m

Linear Coil Travel (p-p) 6 mm

Effective Piston Area 222 cm^2

Maximum Coil Travel (p-p) 14 mm

VAS 134 Litres

QTS 0.35

QMS 4.36

QES 0.38

Magnetic Gap Flux Density 1.1 T

Magnet Weight 0.6 kg

Total Weight 2.05 kg

Last edited:

GregB,

Sure, I will run the SEAS as soon as I get to my computer and have time. Regarding the slot and how far up it goes - my model seems to indicate that this part is really critical to the bass extension and shape of the bass shelf. A wider slot gives higher bass amplitude and a little overshoot but less extension. A narrow slot or cusp gives deeper extension and smoother roll-of. It makes sense that this part is important because it is the first part of the mouth that lets the sound pressure out. Velocities here at the top slot can be very high - 50 to 60 m/s on 115 dB peaks with an 8 inch 95 dB driver. Definitely enough to blow a candle out if not spray molten wax everywhere. Someone should make some measurements with both and see if this is true. Regarding the smoothness of the shape of the aperture: below the top third, the smoothness probably doesn't matter for sound quality it is mostly aesthetics. In fact, I think you could have 9 to 12 step staircase edged K-aperture and it will still sound good. Another experiment to try with measurements.

Sure, I will run the SEAS as soon as I get to my computer and have time. Regarding the slot and how far up it goes - my model seems to indicate that this part is really critical to the bass extension and shape of the bass shelf. A wider slot gives higher bass amplitude and a little overshoot but less extension. A narrow slot or cusp gives deeper extension and smoother roll-of. It makes sense that this part is important because it is the first part of the mouth that lets the sound pressure out. Velocities here at the top slot can be very high - 50 to 60 m/s on 115 dB peaks with an 8 inch 95 dB driver. Definitely enough to blow a candle out if not spray molten wax everywhere. Someone should make some measurements with both and see if this is true. Regarding the smoothness of the shape of the aperture: below the top third, the smoothness probably doesn't matter for sound quality it is mostly aesthetics. In fact, I think you could have 9 to 12 step staircase edged K-aperture and it will still sound good. Another experiment to try with measurements.

Last edited:

X- much appreciated.

RE slot velocity: Yep. Anyone that has played with Karlsons can tell you that, in fact, there are very high velocities near the top of the slot. No molten wax though.

Maybe I will try to experiment with tightening the initial aperture on my test mule mini karlsonators, and see what happens.

Believe it or not, I've always assumed if anyone ever made a computer model of the Karlson, it would be with a stepped approximation of the aperture. Thinking ahead from that, I always imagined that a stepped/staircase K-aperture might be an interesting aesthetic feature - a sort of Aztec meets Flash Gordon kind of a thing. One issue: my most recent experiments seem to indicate that diffraction from the wings right in front of the driver may be significant. I'm not sure if stair steps would make this better or worse.

One issue: my most recent experiments seem to indicate that diffraction from the wings right in front of the driver may be significant. I'm not sure if stair steps would make this better or worse.

RE slot velocity: Yep. Anyone that has played with Karlsons can tell you that, in fact, there are very high velocities near the top of the slot. No molten wax though.

Maybe I will try to experiment with tightening the initial aperture on my test mule mini karlsonators, and see what happens.

Believe it or not, I've always assumed if anyone ever made a computer model of the Karlson, it would be with a stepped approximation of the aperture. Thinking ahead from that, I always imagined that a stepped/staircase K-aperture might be an interesting aesthetic feature - a sort of Aztec meets Flash Gordon kind of a thing.

distributed slit-vent K12 have very high internal front chamber velocities around fb and generate distortion if driven by sine wave. A regular, less constricted - less lossy vent combined with the narrow top aperture can exhibit high velocities but seemingly not adversely affect distortion when driven by sine. Do the old school K12 play subjectively well due to music being comprised of ever changing transients? Can some speakers which do well in spots in sine testing fail to pass subjective evaluation with music?

the first few inches of slot seem to affect subjective: "speed", "system damping", thickness of upper bass.

the first few inches of slot seem to affect subjective: "speed", "system damping", thickness of upper bass.

An externally hosted image should be here but it was not working when we last tested it.

xrk971 - if you are ever bored and looking for something to do...

Perhaps you could try the SEAS full range in your Karlsonator model? (8 or 12)

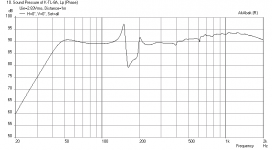

Here is the Seas in a full size Karlsonator 12 - looks pretty good.

Attachments

would a w8-1772 play well either in the Karlsonator 8 or 12?

Yes, I recall doing that sim already at some point. You will know once you put it in your K12 that Jessman built for you. It reaches 40 Hz as I recall but has a rising response that may need some shelf filter or EQ. It may be fine though as is.

www.fullrangedriver.com expired?

I have some potential new K-info to post. Don't know if the domain will be renewed.

I have some potential new K-info to post. Don't know if the domain will be renewed.

I'll post it here:

Wright Sound Systems K-18, an 18" Karlson with Sigma Pro 18.

Untitled Document

I don't remember ever seeing or hearing of this one. If anyone does, it's Freddi - have you?. Very few were apparently built. I came across a copy of "The K-Koppler" hosted on this website. Exchanged a few e-mails with the guy and he sent me that link, otherwise not accessible through the main website. The guy mentioned how Karlson don't scale-down well in his experience. Most people come to that conclusion. Apparently a relative of Wright bros.

Wright Sound Systems K-18, an 18" Karlson with Sigma Pro 18.

Untitled Document

I don't remember ever seeing or hearing of this one. If anyone does, it's Freddi - have you?. Very few were apparently built. I came across a copy of "The K-Koppler" hosted on this website. Exchanged a few e-mails with the guy and he sent me that link, otherwise not accessible through the main website. The guy mentioned how Karlson don't scale-down well in his experience. Most people come to that conclusion. Apparently a relative of Wright bros.

glad to know one is available - appears (?) to be like a 5181 and 77lb loaded is a nice weight -

it might be made a bit lighter with a neo motor 18.

"The subject of much controversy, one listen will convince any skeptic, John Karlson really knew what he was doing in 1951!"

5181 plan direct link http://img72.imageshack.us/img72/825/gaussbracing.jpg

some time ago, Dirk Bladt made scale size K18 - it did not have a front shelf - bet it was powerful

it might be made a bit lighter with a neo motor 18.

"The subject of much controversy, one listen will convince any skeptic, John Karlson really knew what he was doing in 1951!"

5181 plan direct link http://img72.imageshack.us/img72/825/gaussbracing.jpg

An externally hosted image should be here but it was not working when we last tested it.

some time ago, Dirk Bladt made scale size K18 - it did not have a front shelf - bet it was powerful

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

hey IG - does Wright have tips on building K's in the 10" driver size? it would be good to collect as much info as possible on what cavity shape, port arrangement, and chamber sizes worked will in studies. My K10 size has plenty of punch but it could be improved. At that size, a front chamber like the first K12 may be better than a slanted upper port panel. There's the question of aspect - will squeezing the width while raising the height help smooth a potential cavity peak while leveraging a bit more towards the bottom? We know KenL's approach could work but I'd like to stick with the klassic one more time.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

- Home

- Loudspeakers

- Full Range

- Mini Karlsonator (0.53X) with Dual TC9FDs