It's been a vast conspiracy. Finally yesterday afternoon, I found some foam board at the dollar store farthest away from my house. I'm convinced they all got together to thwart my efforts.

Anyhoo - the two additional Vifa's were delivered Wednesday so I'm ready to go. Before I start I wanted to ask about a couple options. In the interest of time, what do you suggest is the top of several paths:

A. Single driver in foam.

B. Dual drivers in foam.

C. A or B in 1/4" plywood.

D. A or B in foam with plywood baffle and wings.

As I read I get the impression you feel the single driver build provides the most impressive results considering size and number of components. Do I have that right.

Bob,

For sheer speed of build and bang for the buck entertainment value and instant gratification... I would go with the 0.4x single driver in foam core. You can dress it up with a wood K-slot glued on top of the foam K-slot very easily and it will look good with a wood front and white sides and top. You can go one more step and add a wood driver cutout panel for the driver to mount securely on and still go with foam otherwise. Djn is right, 1/4in ply is tough to glue without lots of braces or internal supports. If size is not a constraint and you need deeper bass to reach 60 Hz or so, go with the dual-driver 0.534 scale. Sounds like the option D is what will work for you, but you can start with A and mod it to be a D.

X

The driver build quality is fully consistent with the first pair I bought - great metal basket and super clean construction.

The Vifa TC9FD is a glass-filled polymer (polycarbonate is my guess?) basket. It is a nice quality driver with features normally only found in pricier offerings: vented spider, vented pole piece, copper shorting ring, gold plated terminals, very nice finish and quality treated paper cone - looks like matte black plastic but is really paper. My only gripe is that the foam gasket it comes with is glued on front for OEM install in TV sets. If you remove foam gasket to place at back, it leaves glue residue on bezel and gasket often breaks. You need to re-glue to back with rubber cement because it is so thin fragile, it cannot be self supported. These are durable drivers too: I accidentally put full-rail 12 volts DC for 10 seconds on it and the cone moved like 10 mm and no permanent damage resulted. IMO, this driver is one of the best sounding drivers for the price (and even in the $30 price range) and able to compete with some tweeters yet able to provide a nice smooth sound for mids and vocals and also has some bass when used in a good cabinet designed so.

Last edited:

Thanks, I'll start cutting the foam in a few.

Awesome! Don't forget what I said in post 233 re adding open cell foam or felt around driver back chamber area to reduce reflections.

The Vifa TC9FD is a glass-filled polymer (polycarbonate is my guess?) basket.

Sure fooled me but I didn't look that closely.

Sorry X, It's been one of those "Life keeps happening while you'r making other plans" kind of day. I won't bore anyone with the details, but another saw that seems to get truer as I get older... "You can pick your friends but you can't pick your family"

Hopefully by tomorrow.

Hopefully by tomorrow.

Or the other saying, "If you can't make the speaker you love, love the one you have"  Yeah, I know how life gets in the way of the most well laid plans. Good luck on the build.

Yeah, I know how life gets in the way of the most well laid plans. Good luck on the build.

I am gearing up for a micro Karlsonator at 4/15x - or 4 in wide x 8 in tall. Should be really cute.

I am gearing up for a micro Karlsonator at 4/15x - or 4 in wide x 8 in tall. Should be really cute.

Bob,

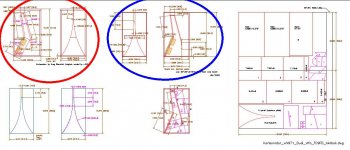

There is a version on left that is a scaled down Karlsonator per original dimensions by GregB. The one on the right appears to be the plans as I adapted them to be optimized for foam core sheets. I did not make these drawings so you will have to double check what the cut sheet is for. If you go with my hand drawn plan on post 1 that will work. I make a long strip of the width and then cut pieces to length to match the plan drawn on one side panel. Sort of like how we built the Cornus.

Hope that helps.

X

There is a version on left that is a scaled down Karlsonator per original dimensions by GregB. The one on the right appears to be the plans as I adapted them to be optimized for foam core sheets. I did not make these drawings so you will have to double check what the cut sheet is for. If you go with my hand drawn plan on post 1 that will work. I make a long strip of the width and then cut pieces to length to match the plan drawn on one side panel. Sort of like how we built the Cornus.

Hope that helps.

X

Bob,

Cool. I usually start at the bottom and work my way around. Use a square piece to brace initial pieces so that they form a 90 deg angle to ensure box is square when done. I just finished the second speaker and waiting for the PVA glue to dry on the final side.

So you are going for 0.53x with dual drivers then? This one sounds really nice with plenty of bass. Also is nice with 91dB sensitivity so that should help things for your ACA amp.

Good luck!

X

Cool. I usually start at the bottom and work my way around. Use a square piece to brace initial pieces so that they form a 90 deg angle to ensure box is square when done. I just finished the second speaker and waiting for the PVA glue to dry on the final side.

So you are going for 0.53x with dual drivers then? This one sounds really nice with plenty of bass. Also is nice with 91dB sensitivity so that should help things for your ACA amp.

Good luck!

X

Last edited:

Hi bcmbob,

Just noticed your question in Post #249, the one you circled in blue is xrk971's version, and all the cutsheet stuff belongs to it. It is based on the scaled original, a material thickness of 3/16" and on xrk971's notes. When you scale an existing drawing the material thickness will more often than not be incorrect, etc., so you have to make adjustments, same for going from a hand drawing with generally close dimensions to a cad drawing; e.g.: the shape and dimensions of the Karlson slot. The one circled in red is just the straight scaled Greg B. original. Either plan could be redrawn for wood (different thicknesses), xrk971's (blue circle) is correct for the 3/16" material thickness.

These drawings are just part of my personal notes, and as you have noticed life can get in the way....

Regards,

Just noticed your question in Post #249, the one you circled in blue is xrk971's version, and all the cutsheet stuff belongs to it. It is based on the scaled original, a material thickness of 3/16" and on xrk971's notes. When you scale an existing drawing the material thickness will more often than not be incorrect, etc., so you have to make adjustments, same for going from a hand drawing with generally close dimensions to a cad drawing; e.g.: the shape and dimensions of the Karlson slot. The one circled in red is just the straight scaled Greg B. original. Either plan could be redrawn for wood (different thicknesses), xrk971's (blue circle) is correct for the 3/16" material thickness.

These drawings are just part of my personal notes, and as you have noticed life can get in the way....

Regards,

Padding plan

Here is how I am adding open cell foam on the inside surfaces near the driver and on flat ends to reduce internal reflections.

The second 0.4x is done and awaits the K wing panel. Listening to it in stereo actually sounds pretty good. You can tell the bass is not as deep as the one with the wing installed.

Here is how I am adding open cell foam on the inside surfaces near the driver and on flat ends to reduce internal reflections.

The second 0.4x is done and awaits the K wing panel. Listening to it in stereo actually sounds pretty good. You can tell the bass is not as deep as the one with the wing installed.

Attachments

- Home

- Loudspeakers

- Full Range

- Mini Karlsonator (0.53X) with Dual TC9FDs