Make sure you follow the instructions on how to add padding on the front and rear chambers. It is important with a wooden cabinet to treat it or you will get a reverberant sound.

https://www.diyaudio.com/forums/ful...onator-0-53x-dual-tc9fds-296.html#post5577990

This is also linked at the bottom of Post 1 in Karlsonator thread. It is known as the wooden "Karlsonator Kurse" if not dealt with properly.

if not dealt with properly.

https://www.diyaudio.com/forums/ful...onator-0-53x-dual-tc9fds-296.html#post5577990

This is also linked at the bottom of Post 1 in Karlsonator thread. It is known as the wooden "Karlsonator Kurse"

xrk971, well it's too late for changes :/ I have no access to the inside of the speakers...

I have already added 20mm melamine pads behind the speakers, on the back of the curtain there will be BASF Basotect 10mm as well, I have used 12mm Poroso felt anywhere else, hope it will be sufficient. There are no dividers anywhere. I have done it based on the project I got over 2 years ago

I have already added 20mm melamine pads behind the speakers, on the back of the curtain there will be BASF Basotect 10mm as well, I have used 12mm Poroso felt anywhere else, hope it will be sufficient. There are no dividers anywhere. I have done it based on the project I got over 2 years ago

Last edited:

That's correct, the Re is actually 12.3ohms. Drivers are often a bit lower than their impedance rating. Like 8ohm drivers are many times 6.8ohms or even 6ohms.

https://www.parts-express.com/pedocs/specs/294-1105-faitalpro-3fe25-16-specifications.pdf

https://www.parts-express.com/pedocs/specs/294-1105-faitalpro-3fe25-16-specifications.pdf

I have spent a few hours listening to them, in a short: awesome speakers! Very detailed, punchy bass, with brilliant 3D scene, I don't feel tired after hours of listening. Definitely worth building them.

The only thing that I am not sure if I like are the highs, a bit noisy and too much to my taste. For female vocales I still prefer EMI 92390BP but stil these are really brilliant speakers. I need to check with a different amp. They could be a bit more efficient. Tried them with Soren dac and F5.

The only thing that I am not sure if I like are the highs, a bit noisy and too much to my taste. For female vocales I still prefer EMI 92390BP but stil these are really brilliant speakers. I need to check with a different amp. They could be a bit more efficient. Tried them with Soren dac and F5.

adding mass to a panel to damp it will only lower the panel resonance and increase the Q of the new lower resonance due to the additional mass. Lighter and stiffer is the way to go, brace work is also a good option where the intention is to push the resonance up out beyond the pass band of the driver then the problem then becomes non existent. This then is a win win situation.

I see, I thought it would be the other way around, by adding lead I would lower the resonance frequency and its Q. Thank for that. So... has anyone tried a better material than 12mm plywood, I guess lightweight material with high Young module? Has anyone tried bracing?

BTW will this harsh high frequency sound of 3FE25 be gone after burning in?

BTW will this harsh high frequency sound of 3FE25 be gone after burning in?

Last edited:

well adding the lead will lower the resonance but it will still resonate and at the new lower resonant frequency you will now have more mass resonating and that will be harder to stop, same as with stopping a truck which is going to stop in a shorter distance the empty truck or the fully loaded truck?

The most popular method to prevent the tapers from resonating had been some threaded rod but you can just as easily make a wood standoff and use wood screw to fix the taper to it a section of hardwood dowel would be excellent just make sure you pre tap the hole for the wood screw so the dowel does not crack (the hole will be in the end grain). I hope this helps.

The most popular method to prevent the tapers from resonating had been some threaded rod but you can just as easily make a wood standoff and use wood screw to fix the taper to it a section of hardwood dowel would be excellent just make sure you pre tap the hole for the wood screw so the dowel does not crack (the hole will be in the end grain). I hope this helps.

Yes - foam core.So... has anyone tried a better material than 12mm plywood, I guess lightweight material with high Young module?

I would say yes, to a certain extent. I base it on fellow member Skylar88’s build. He was the first to make dual 3FE25-16 mini Karlsonators way back in November 2017. They are made with foam core. Initially he tried to tame the harshness with BSC, but did not like the results. Eventually the drivers became much smoother and currently he is using a little EQ. They sound absolutely amazing now (with a little toe-in and tilted backwards slightly) he told me just yesterday – powered by a B1 + H2 + ACA. But I have heard them many times myself.BTW will this harsh high frequency sound of 3FE25 be gone after burning in?

Thank you Jerry. Happy to hear that

Just two words about these speakers. I mentioned about the harshness, yes it is present, but TBH I never listened to the speakers that with some specific recordings... when I close my eyes, I feel that I am in front of the orchestra, this is unbeliavable. 3D effects is also great, especially with Yosi Horikawa work, "Letter" or "Bubbles".

Here is an example of one recording - I know it's just a mobile phone bad quality video - but could not resist posting:

Karlsonator 0.53 with dual 3FE25 16 Ohms - YouTube

The 4 Seasons: Violin Concerto in G Minor, Op. 8, No. 2, RV 315, "L'estate" (Summer): III. Tempo impetuoso d'Estate 1985

Antonio Vivaldi, Nils-Erik Sparf

Just two words about these speakers. I mentioned about the harshness, yes it is present, but TBH I never listened to the speakers that with some specific recordings... when I close my eyes, I feel that I am in front of the orchestra, this is unbeliavable. 3D effects is also great, especially with Yosi Horikawa work, "Letter" or "Bubbles".

Here is an example of one recording - I know it's just a mobile phone bad quality video - but could not resist posting:

Karlsonator 0.53 with dual 3FE25 16 Ohms - YouTube

The 4 Seasons: Violin Concerto in G Minor, Op. 8, No. 2, RV 315, "L'estate" (Summer): III. Tempo impetuoso d'Estate 1985

Antonio Vivaldi, Nils-Erik Sparf

Last edited:

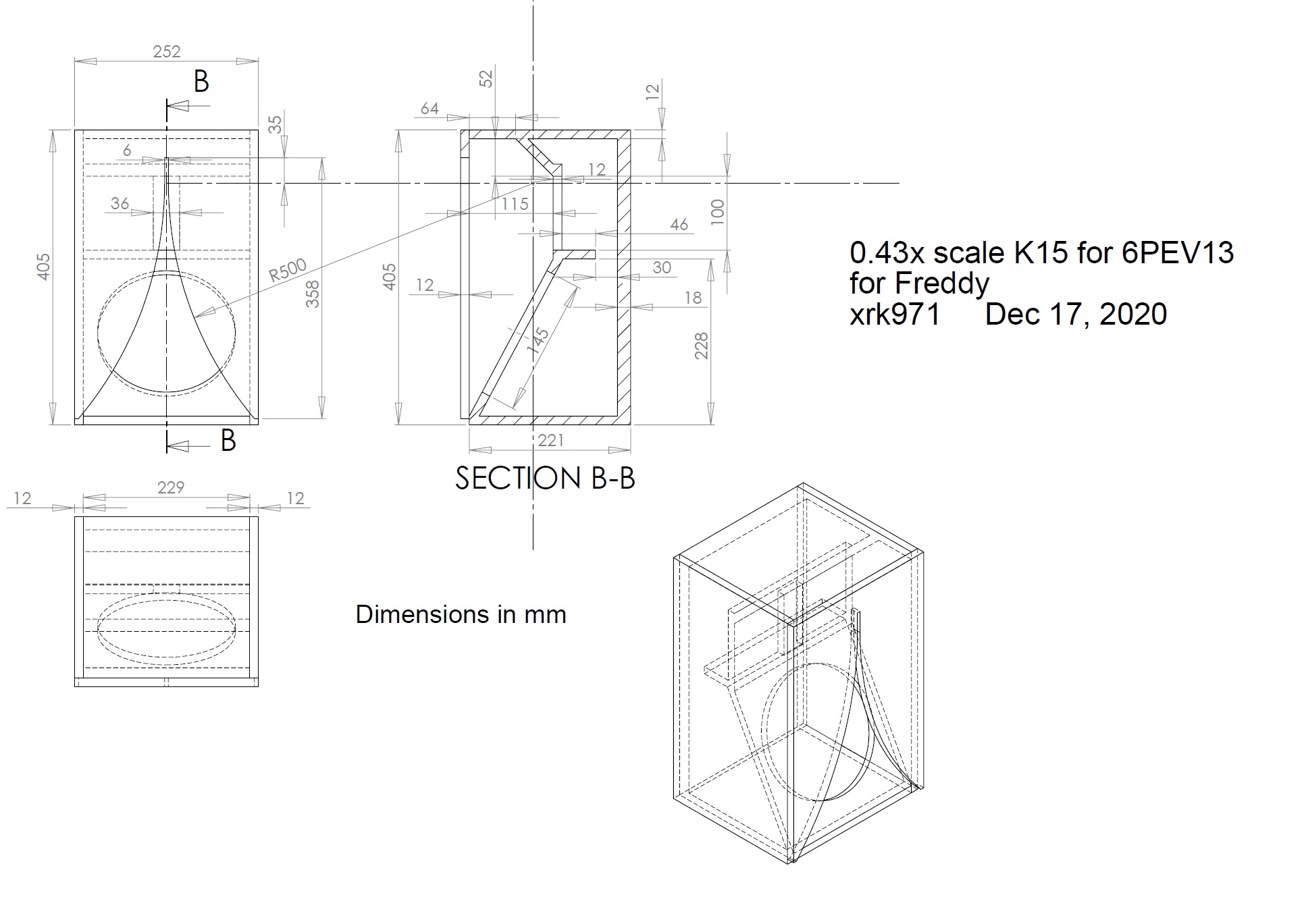

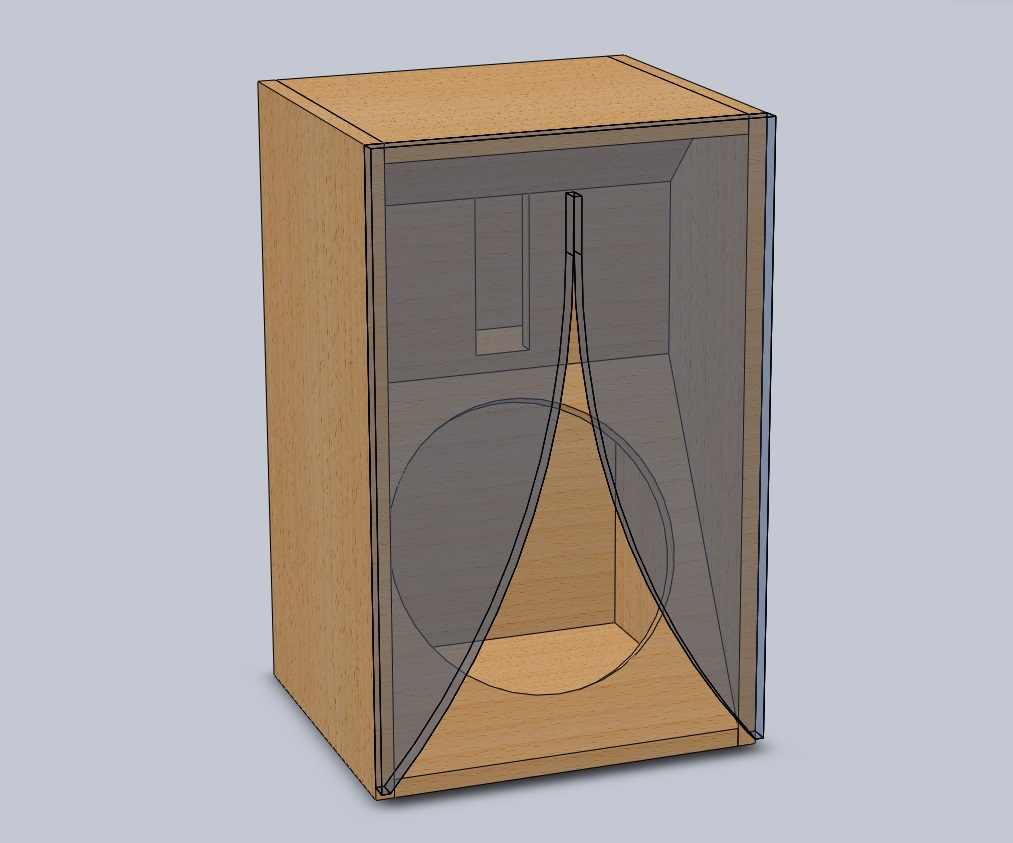

I had a request from Freddy for plans for a 0.43x scaled K15 to use with 6.5in drivers. In particular, an EV 6PEV13. So here is a PDF plan in case anyone else is interested.

Attachments

Last edited:

I recently saw a tip on a woodworking site that I am going to try for attaching the rear panels of my Little K5s. After the holes are threaded I am going to apply a layer of thinned glue and re-thread after the glue sets. I think this will permit the several removals of the panels for padding adjustments w/o damaging threads. When I say threading I only mean inserting screws into pre-drilled holes.

Last edited:

EddieT, why not claw nuts? I have used them for mounting the speakers and the front panel.

BTW I am wondering if making the edges of the curves in the aperture/front panel rounded (like in the bottom internal element) will make any improvements. My speakers makes wind like noise at 60 and 63Hz. I have added 10mm melamine foam to the whole aperture. I am going to try the foam core soon.

BTW I am wondering if making the edges of the curves in the aperture/front panel rounded (like in the bottom internal element) will make any improvements. My speakers makes wind like noise at 60 and 63Hz. I have added 10mm melamine foam to the whole aperture. I am going to try the foam core soon.

- Home

- Loudspeakers

- Full Range

- A Speaker that Kicks Butt in Large Spaces