A chinese driver i posted on 1558, long time to receive them and no time to work... So just now i finish my speaker, i don't try other speakers but what i listen from them is not so bad, actually the other channel loudpeaker is coming from main system and is a tannoy driver.

In comparison the sound of cornu lose some body in low frequencies , but is incredible how low is the difference compared to a more big and expensive speaker.

Last think is that drivers needs a burning time, as long sa they work the sound will better in particular in the extremes. Maybe people in this forum know that but i'm happy to share my esperience. Thanks a lot again xrk, your project is very fun to build and sound very nice

In comparison the sound of cornu lose some body in low frequencies , but is incredible how low is the difference compared to a more big and expensive speaker.

Last think is that drivers needs a burning time, as long sa they work the sound will better in particular in the extremes. Maybe people in this forum know that but i'm happy to share my esperience. Thanks a lot again xrk, your project is very fun to build and sound very nice

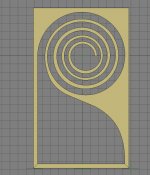

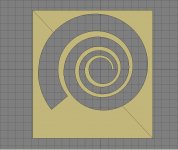

Spiral BLH boom box version 3

My latest design iteration -

Now based on a 3" driver. I am thinking the Tang band W3-1878. The overall dimension is 12" x 20". The horn is 90" long down the middle. The narrow end is 0.5" nearest the driver, and the spiral grows to about 2" before widening out to the biggest mouth I can fit in the overall box. Grid is 1".

Is this good enough to try to build, or should I make refinements first?

I have a pretty good technique down for making these now in my computer software, so new versions are not hard to make.

My hunch is that the horn does not expand enough in with as it spirals around. There is an exponential function in there, but scaled and manipulated to make it fit.

xrk971, what do you think?

My latest design iteration -

Now based on a 3" driver. I am thinking the Tang band W3-1878. The overall dimension is 12" x 20". The horn is 90" long down the middle. The narrow end is 0.5" nearest the driver, and the spiral grows to about 2" before widening out to the biggest mouth I can fit in the overall box. Grid is 1".

Is this good enough to try to build, or should I make refinements first?

I have a pretty good technique down for making these now in my computer software, so new versions are not hard to make.

My hunch is that the horn does not expand enough in with as it spirals around. There is an exponential function in there, but scaled and manipulated to make it fit.

xrk971, what do you think?

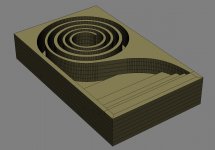

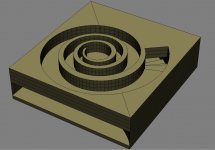

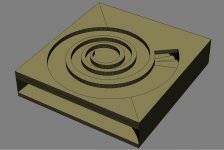

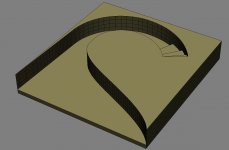

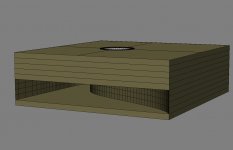

OK -

After fighting to keep the overall size low and weight down, I came up with a way to push the horn down through the layers and emerge from the side in lower layers so I still get a big mouth without a big baffle. This is about 15" square, and uses a 3" driver.

The horn goes from 0.5" in the middle to almost 15" at the mouth. The midline of this horn is about 90" long.

xrk971, is this better?

Other thoughts?

Colin

After fighting to keep the overall size low and weight down, I came up with a way to push the horn down through the layers and emerge from the side in lower layers so I still get a big mouth without a big baffle. This is about 15" square, and uses a 3" driver.

The horn goes from 0.5" in the middle to almost 15" at the mouth. The midline of this horn is about 90" long.

xrk971, is this better?

Other thoughts?

Colin

Attachments

-

stair_step_persp_horn_mouth.jpg163.5 KB · Views: 101

stair_step_persp_horn_mouth.jpg163.5 KB · Views: 101 -

stair_step_persp_05.jpg399.4 KB · Views: 113

stair_step_persp_05.jpg399.4 KB · Views: 113 -

stair_step_persp_04.jpg355.7 KB · Views: 105

stair_step_persp_04.jpg355.7 KB · Views: 105 -

stair_step_persp_03.jpg230 KB · Views: 100

stair_step_persp_03.jpg230 KB · Views: 100 -

stair_step_persp_02.jpg283.3 KB · Views: 469

stair_step_persp_02.jpg283.3 KB · Views: 469 -

stair_step_persp_01.jpg250.8 KB · Views: 490

stair_step_persp_01.jpg250.8 KB · Views: 490 -

stair_step_persp_spiral.jpg262 KB · Views: 75

stair_step_persp_spiral.jpg262 KB · Views: 75

XRK -

There is enough room in all the layers of plywood for the cylindrical opening behind the driver to be deeper and higher volume.

In my current design this open space is ~3" in diameter, and the spiral section is 1.5" deep - 3 layers of 1/2" plywood.

All of the open areas of the the lower layers are outside of this area, so it would be possible to extend the depth of this cylindrical area behind the driver up to 6".

Is there an advantage to making this chamber directly behind the driver have higher volume? I can make this volume 2x bigger without changing the design, the horn dimensions would stay the same.

Make sense? Thoughts?

There is enough room in all the layers of plywood for the cylindrical opening behind the driver to be deeper and higher volume.

In my current design this open space is ~3" in diameter, and the spiral section is 1.5" deep - 3 layers of 1/2" plywood.

All of the open areas of the the lower layers are outside of this area, so it would be possible to extend the depth of this cylindrical area behind the driver up to 6".

Is there an advantage to making this chamber directly behind the driver have higher volume? I can make this volume 2x bigger without changing the design, the horn dimensions would stay the same.

Make sense? Thoughts?

- Home

- Loudspeakers

- Full Range

- Ever think of building a Cornu Spiral horn? Now you can!