Dependent on the size of the panels. The larger the piece the thicker it has to be. What size are they?

You mean the size of whatever I end up building, right?

I dunno yet, just thinking this would be fun material to build with, much stiffer and maybe better insulating than the cheap Dollar Store foam board I've been using.

At the moment, I have no specific projects in mind, but likely it would be smaller things like the uFonken, or Bloodhounds, things of that nature.

The foam boards works well in things like the Cornu because it's only about 3-5" wide and the pressure is equal on either side of it. In a more regular box, the panels are prone to flexing so need to be stiffer. For a 1/2" board I wouldn't go more than about 6-8" by 10 or maybe 12". Doubling the baffles is always a good idea.

So I destroyed some more XPS boards and some hot glue. Playing quite nice. Better half said that even they not have same response as my other speakers this speakers doesnt irritate her. Other speakers are Sonus Faber Signum and Monitor Audio Gold 100 connected with Straight Wire Virtuoso to Denon PMA 2010.

This is Mark Audio CHP 70 connected to Kenwood micro system...what to say

This is Mark Audio CHP 70 connected to Kenwood micro system...what to say

Attachments

Final Product

This is how the final iteration of the 0.53x K's turned out for my daughter.

- Dayton PA-130's

- 2 coats of HVLP sprayed Latex bathroom paint

- Rustoleum Stone texture paint

- 1/4" cherry plywood with Boiled Linseed Oil and Wax finish

- Black drywall screws

They sound great and look not half bad. Now my brother wants a pair for his garage! I said OK. Waiting on backordered Vifas......

This is how the final iteration of the 0.53x K's turned out for my daughter.

- Dayton PA-130's

- 2 coats of HVLP sprayed Latex bathroom paint

- Rustoleum Stone texture paint

- 1/4" cherry plywood with Boiled Linseed Oil and Wax finish

- Black drywall screws

They sound great and look not half bad. Now my brother wants a pair for his garage! I said OK. Waiting on backordered Vifas......

Hi Gecko.

You know how to make foam core look classy! Nice work!

BLO and wax is one of my favorite finishes and it looks fantastic on cherry. Don't they sound great!? Not bad for a $18 "PA driver".

You may have found a new second career if these orders for more speakers keeps up? Could you make me a pair like this?

You know how to make foam core look classy! Nice work!

BLO and wax is one of my favorite finishes and it looks fantastic on cherry. Don't they sound great!? Not bad for a $18 "PA driver".

You may have found a new second career if these orders for more speakers keeps up? Could you make me a pair like this?

Sanity

Hey X,

I certainly owe you! This little hobby has kept me engaged and sane during lock down. Plus, I'm finding ways to use leftover stuff in the garage to make them look nice!

Many thanks!

Hey X,

I certainly owe you! This little hobby has kept me engaged and sane during lock down. Plus, I'm finding ways to use leftover stuff in the garage to make them look nice!

Many thanks!

Hi Gecko.

You know how to make foam core look classy! Nice work!

BLO and wax is one of my favorite finishes and it looks fantastic on cherry. Don't they sound great!? Not bad for a $18 "PA driver".

You may have found a new second career if these orders for more speakers keeps up? Could you make me a pair like this?

Homage to LS3/5A in Foamcore

I have not posted a speaker build here for a while, but I got to urge to make another set of foamcore speakers, and this time wanted to try something very conventional: a 12in tall x 7.5in wide x 6.5in deep compact 2-way sealed monitor with 5.25in woofer and 1in dome tweeter. Sound familiar? Well it's an homage to the venerable LS3/5A. It started as a question of whether or not I could try to make an inexpensive speaker that mimics the response curve of the LS3/5A over in this thread.

Here is the target response of a typical LS3/5A:

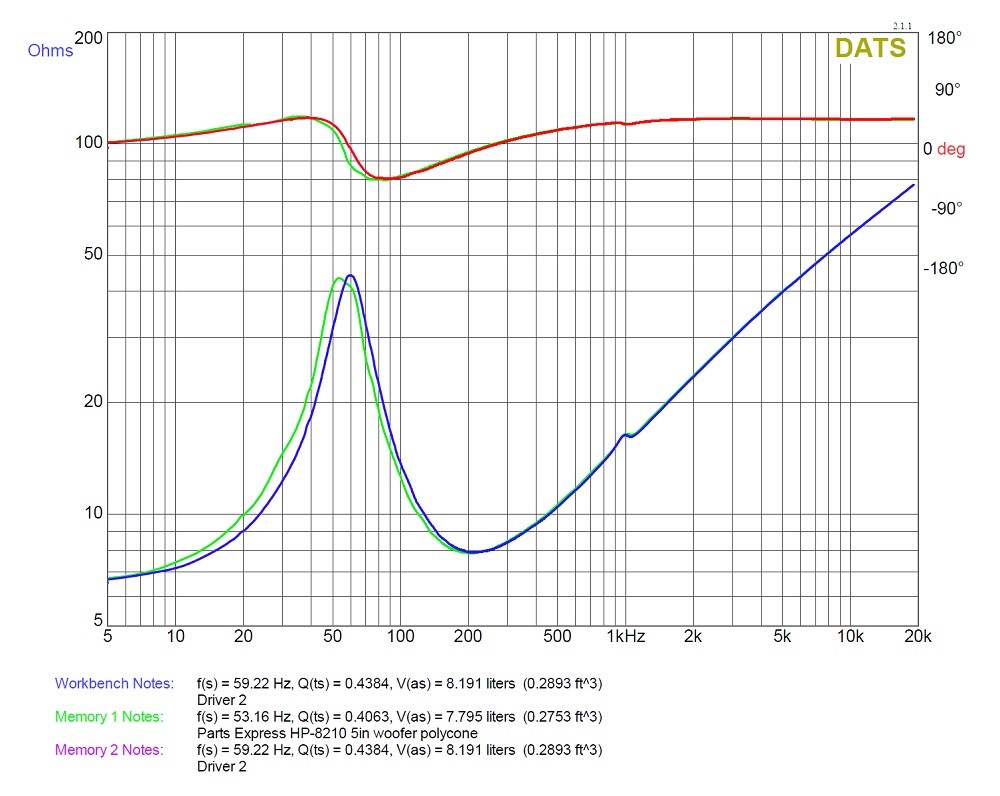

I am using a polycone 5.25in blowout driver from Parts Express, the HP-5210 and the Dayton RST28F-4 dome tweeter. Here is how the woofer measured on DATS:

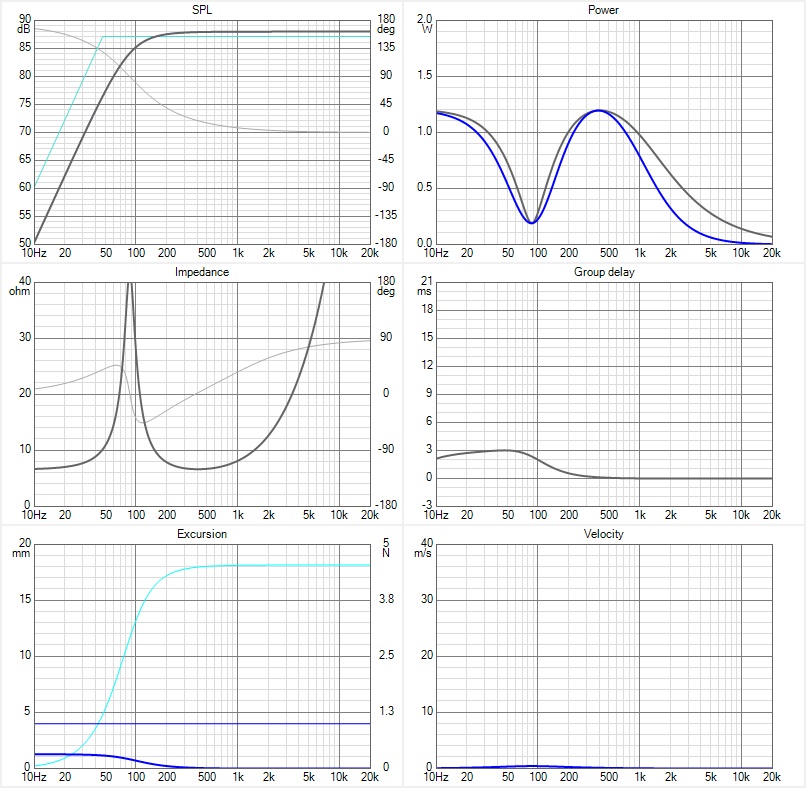

Since I am using foamcore (3/16in thick), there is a bit more than 5L in volume compare to using 1/2in BB ply. For 7.5L, the simulation in VituixCAD for this driver's TS parameters shows a -3dB of about 95Hz - consistent with the goal of replicating the bass response of the LS3/5A - predicted response curve here:

I started by cutting out the panels using a Starrett aluminum meter stick and utility knife:

The drivers have a nice look and will fit well:

Construction proceeded with adding Noico mass loaded butyl sheets to the inside to dampen panel vibrations, then strategically located melamine foam pads plus 1/2in thick grey acoustic eggcrate foam. Of course, lots of bracing. This whole speaker went together using hot melt glue. I did things differently this time in that I glued the bottom panel on last.

Lots of bracing on the front baffle and extra pads for the screw mounts:

Noico damping:

Melamine foam and grey acoustic foam application:

Adding two sets of wires so that the XO can be developed externally first. Once the XO is finalized, it will be installed inside and the wires replaced with a terminal cup:

First test with an existing XO I had from another speaker - sounds pretty good actually:

I will measure the driver raw responses tomorrow and then develop the XO in Xsim. I might try VituixCAD if I can get past the learning curve.

I have one built - and if all goes well, will make the second one on another night.

I have not posted a speaker build here for a while, but I got to urge to make another set of foamcore speakers, and this time wanted to try something very conventional: a 12in tall x 7.5in wide x 6.5in deep compact 2-way sealed monitor with 5.25in woofer and 1in dome tweeter. Sound familiar? Well it's an homage to the venerable LS3/5A. It started as a question of whether or not I could try to make an inexpensive speaker that mimics the response curve of the LS3/5A over in this thread.

Here is the target response of a typical LS3/5A:

An externally hosted image should be here but it was not working when we last tested it.

I am using a polycone 5.25in blowout driver from Parts Express, the HP-5210 and the Dayton RST28F-4 dome tweeter. Here is how the woofer measured on DATS:

Since I am using foamcore (3/16in thick), there is a bit more than 5L in volume compare to using 1/2in BB ply. For 7.5L, the simulation in VituixCAD for this driver's TS parameters shows a -3dB of about 95Hz - consistent with the goal of replicating the bass response of the LS3/5A - predicted response curve here:

I started by cutting out the panels using a Starrett aluminum meter stick and utility knife:

The drivers have a nice look and will fit well:

Construction proceeded with adding Noico mass loaded butyl sheets to the inside to dampen panel vibrations, then strategically located melamine foam pads plus 1/2in thick grey acoustic eggcrate foam. Of course, lots of bracing. This whole speaker went together using hot melt glue. I did things differently this time in that I glued the bottom panel on last.

Lots of bracing on the front baffle and extra pads for the screw mounts:

Noico damping:

Melamine foam and grey acoustic foam application:

Adding two sets of wires so that the XO can be developed externally first. Once the XO is finalized, it will be installed inside and the wires replaced with a terminal cup:

First test with an existing XO I had from another speaker - sounds pretty good actually:

I will measure the driver raw responses tomorrow and then develop the XO in Xsim. I might try VituixCAD if I can get past the learning curve.

I have one built - and if all goes well, will make the second one on another night.

Attachments

-

LS3-5A-foamcore-homage-10.jpg201.6 KB · Views: 1,453

LS3-5A-foamcore-homage-10.jpg201.6 KB · Views: 1,453 -

LS3-5A-foamcore-homage-09.jpg290.1 KB · Views: 742

LS3-5A-foamcore-homage-09.jpg290.1 KB · Views: 742 -

LS3-5A-foamcore-homage-08.jpg340.9 KB · Views: 7,250

LS3-5A-foamcore-homage-08.jpg340.9 KB · Views: 7,250 -

LS3-5A-foamcore-homage-07.jpg342.6 KB · Views: 716

LS3-5A-foamcore-homage-07.jpg342.6 KB · Views: 716 -

LS3-5A-foamcore-homage-06.jpg378.5 KB · Views: 7,493

LS3-5A-foamcore-homage-06.jpg378.5 KB · Views: 7,493 -

LS3-5A-foamcore-homage-05.jpg363.8 KB · Views: 724

LS3-5A-foamcore-homage-05.jpg363.8 KB · Views: 724 -

LS3-5A-foamcore-homage-04.jpg396.9 KB · Views: 7,781

LS3-5A-foamcore-homage-04.jpg396.9 KB · Views: 7,781 -

LS3-5A-foamcore-homage-03.jpg384.4 KB · Views: 764

LS3-5A-foamcore-homage-03.jpg384.4 KB · Views: 764 -

LS3-5A-foamcore-homage-11.jpg161.3 KB · Views: 1,438

LS3-5A-foamcore-homage-11.jpg161.3 KB · Views: 1,438

Last edited:

The cheap buyout woofer just isn't going to cut it. I switched to a Dayton DC130A-8, which has a much smoother response and is still in production. Data measured at 0.5m and 2.0Vrms on tweeter axis with6-cycle freq dependent window (FDW) enabled.

@turk182

I have veneered foam core with very thin 3/16in subfloor luan wood ply on a Karlso type baffle and it is very light and rigid. For a tour-grade box, you might consider honeycomb core marine ply. Very light and rigid and will save many pounds from a subwoofer box.

Here is a product with luan ply exteruior abd honeycomb core:

Standard Honeycomb Panels, OEM Product Manufacturing Panels

@turk182

how veneering a foam core build would turn out

I have veneered foam core with very thin 3/16in subfloor luan wood ply on a Karlso type baffle and it is very light and rigid. For a tour-grade box, you might consider honeycomb core marine ply. Very light and rigid and will save many pounds from a subwoofer box.

Here is a product with luan ply exteruior abd honeycomb core:

Standard Honeycomb Panels, OEM Product Manufacturing Panels

its fascinating just to see the bracing technique and sculptured foam ! With one side removed the cabinet could pass as modern art.

Question - is Super Tuff-R 1/2" foam insulation board (~$12.25 per 4' x 8' sheet) too tough/wonky (foil on one side) to cut accurately? That's a lot of board for the money at Home Depot.

https://www.homedepot.com/p/Super-TUFF-R-1-2-in-x-4-ft-x-8-ft-R-3-3-Foam-Insulation-268413/100322369

Question - is Super Tuff-R 1/2" foam insulation board (~$12.25 per 4' x 8' sheet) too tough/wonky (foil on one side) to cut accurately? That's a lot of board for the money at Home Depot.

https://www.homedepot.com/p/Super-TUFF-R-1-2-in-x-4-ft-x-8-ft-R-3-3-Foam-Insulation-268413/100322369

Last edited:

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?