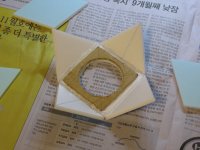

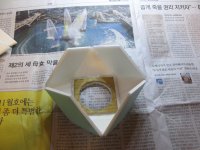

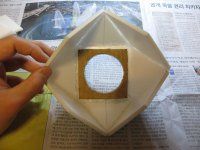

Here is another little something for you to contemplate xrk971 : the tetrahedral version of our design, known to regular geometry as the Triakis Tetrahedron:

That which we call a pentahedroid Futiquity

You can get the 12 pieces for this by cutting 6 rhombi in half along their longer diagonals.

Actually, you need only 9 pieces and an equilateral triangle with a hole in it for the baffle plate. So that's 10 pieces instead of 13 fewer pieces than the truncated rhombic dodecahedron.

If you truncate this back all the way on one of the 3-edge corners the baffle plate is an equilateral triangle. You can obtain the Triakis Tetrahedrom by starting with a regular tetrahedron. Then connect the 4 outer corners to the center like the 4 bonds of a carbon atom. An easy way to do this is to take a wire frame tetrahedron (Like this one made with the 4 pieces of a tootsie roll and 6 qtips) and dip it in a soap film. To equalize surface tensions the bubble that tends to form first is the projection of a 5-cell onto 3-space, that is the planes that join to make the 4 lines connecting the 4 corners to a new point in the middle.

http://www.matthewrkennedy.com/pent1medium.jpg

Now turn this inside out and you get the Triakis Tetrahedron.

That which we call a pentahedroid Futiquity

You can get the 12 pieces for this by cutting 6 rhombi in half along their longer diagonals.

Actually, you need only 9 pieces and an equilateral triangle with a hole in it for the baffle plate. So that's 10 pieces instead of 13 fewer pieces than the truncated rhombic dodecahedron.

If you truncate this back all the way on one of the 3-edge corners the baffle plate is an equilateral triangle. You can obtain the Triakis Tetrahedrom by starting with a regular tetrahedron. Then connect the 4 outer corners to the center like the 4 bonds of a carbon atom. An easy way to do this is to take a wire frame tetrahedron (Like this one made with the 4 pieces of a tootsie roll and 6 qtips) and dip it in a soap film. To equalize surface tensions the bubble that tends to form first is the projection of a 5-cell onto 3-space, that is the planes that join to make the 4 lines connecting the 4 corners to a new point in the middle.

http://www.matthewrkennedy.com/pent1medium.jpg

Now turn this inside out and you get the Triakis Tetrahedron.

BTW here is the movie of dong the pentahedroid bubble trick with pencils and pingpong balls:

Painting a Pentahedroid Futiquity

it is cool that it forms naturally.

Painting a Pentahedroid Futiquity

it is cool that it forms naturally.

My idea for getting a nice tilt with this design is to make a stand it will nestle into. The stand would be like a shallow 3-sided pyramid where halfway up the pyramid, the ascent folds over into a descent -- to form a shallow-tetrahedron concavity in the middle of the stand. The triakis then sits in this with the baffle plate, an upwardly-pointing equilateral triangle, tilted back from vertical to give an upward tilt of the driver.

Who here listed these on ebayy??? LOL

Magnavox Foam Speaker System 12" Woofer 1000 Cycle Horn from Totl Console | eBay

Magnavox Foam Speaker System 12" Woofer 1000 Cycle Horn from Totl Console | eBay

Who here listed these on ebayy??? LOL

Magnavox Foam Speaker System 12" Woofer 1000 Cycle Horn from Totl Console | eBay

Wow those look like OEM injection molded foam enclosures from Magnavox. Interesting.

i like the side firing horn for those "spatial like"effects...

foamcore's got nothin' on injected molded foam!!(i should be quiet and finish my cornu's)

i was looking at the other pic's foam cab's would make lightweight boom boxes wouldn't they

Here is a foam box with a lot of boom.

http://www.diyaudio.com/forums/subwoofers/258433-light-air-slot-loaded-band-pass-sub.html

Just following in the footsteps of xrk971...

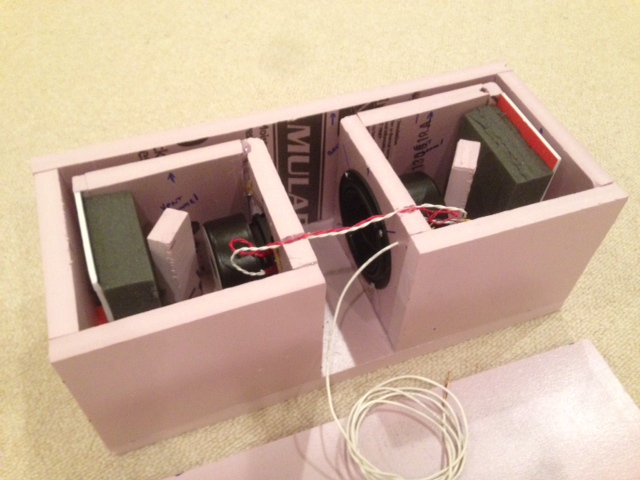

Hypercube speakers made with foamboard.

Karlson tubes glued to couple of tweeters sitting on top.

Sounds great considering the cheap 3" FR drivers used.

(costs about 3-4 bucks each? )

)

Anyway, thanks to all those at the hypercube thread for the information, inspiration and guidance!

Hypercube speakers made with foamboard.

Karlson tubes glued to couple of tweeters sitting on top.

Sounds great considering the cheap 3" FR drivers used.

(costs about 3-4 bucks each?

Anyway, thanks to all those at the hypercube thread for the information, inspiration and guidance!

Attachments

I know that there have been discussions on other threads about mass loaded constrained layer cabinet damping.It has been noted that the mass of the damping must exceed the mass of the cabinet wall.

It seems to me that having a layer of dynamat or similar bonded between 2 layers of foam core would make an interesting experiment.

I wonder if there is any data about this application available.

It seems to me that having a layer of dynamat or similar bonded between 2 layers of foam core would make an interesting experiment.

I wonder if there is any data about this application available.

I know that there have been discussions on other threads about mass loaded constrained layer cabinet damping.It has been noted that the mass of the damping must exceed the mass of the cabinet wall.

It seems to me that having a layer of dynamat or similar bonded between 2 layers of foam core would make an interesting experiment.

I wonder if there is any data about this application available.

I used a heavier but flexible material between two sheets of foam core and it makes a big difference. I have also added mass between two sheets of foam core via small dabs of heavy plumbers putty and that helps too. Not as much as a thick layer of latex caulking though. More info with measurements here:

http://www.diyaudio.com/forums/multi-way/265957-damping-sheets-constrained-layer-damping.html#post4144674

xrk971,

Thanks! You gave me the inspiration to try making speakers out of FC.

You truly are the 'Godfather of Foamcore Speakers'

The drivers are actually no-name 2-inchers, not 3 inch ones(my mistake).

So the tweeter with Karlson tube helps a lot.

(Not the Hypercube's fault, I might add)

The tweeter is a Korean brand driver. A cheap one.

When I found out that the K-tube really sounds great, I started using the tube in almost every project. But I guess that's for another thread.

(It sounds almost as good as the QSC waveguide Patrick Bateman raves about- he says that the QSC measures best in the group of Econowave waveguides, and the K-tube comes very close - A close second?)

The XO is just a resistor and a capacitor that was from another project,

but it seems to work, so I'm just using it for the time being.

Tesserax,

Thank you for the great design!

Building the Hypercube was a fun and fast project with outstanding results.

I don't understand all the technical discussions you guys are engaging at the other thread, but having made a pair, I feel that the Hypercube concept is very cool, and I'm looking forward to build some more in the near future.

(I hope with better drivers and wood this time - and I'd also love to try 2-way, like xrk's version)

The speaker sounds very natural, and non fatiguing even after long periods of playback. Great for nearfield listening.

Thank you again for sharing your knowledge and design!

Thanks! You gave me the inspiration to try making speakers out of FC.

You truly are the 'Godfather of Foamcore Speakers'

The drivers are actually no-name 2-inchers, not 3 inch ones(my mistake).

So the tweeter with Karlson tube helps a lot.

(Not the Hypercube's fault, I might add)

The tweeter is a Korean brand driver. A cheap one.

When I found out that the K-tube really sounds great, I started using the tube in almost every project. But I guess that's for another thread.

(It sounds almost as good as the QSC waveguide Patrick Bateman raves about- he says that the QSC measures best in the group of Econowave waveguides, and the K-tube comes very close - A close second?)

The XO is just a resistor and a capacitor that was from another project,

but it seems to work, so I'm just using it for the time being.

Tesserax,

Thank you for the great design!

Building the Hypercube was a fun and fast project with outstanding results.

I don't understand all the technical discussions you guys are engaging at the other thread, but having made a pair, I feel that the Hypercube concept is very cool, and I'm looking forward to build some more in the near future.

(I hope with better drivers and wood this time - and I'd also love to try 2-way, like xrk's version)

The speaker sounds very natural, and non fatiguing even after long periods of playback. Great for nearfield listening.

Thank you again for sharing your knowledge and design!

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?