Nice work man! I can't wait to hear your listening impressions...but keep in mind, it's all about room placement, especially until you get those deflectors installed. I'm looking forward to your deflector build as I might have to follow your lead.

BTW, I installed these terminals on my frugel because they were easy and have a nice gasket. Didn't realize they were a good choice for sonic reasons.

Oh, and btw, I can't hear any wire rattling inside the horn. If you're concerned about that, just wrap the wire with some foam weather stripping similar to what they do inside the doors of cars.

BTW, I installed these terminals on my frugel because they were easy and have a nice gasket. Didn't realize they were a good choice for sonic reasons.

An externally hosted image should be here but it was not working when we last tested it.

Oh, and btw, I can't hear any wire rattling inside the horn. If you're concerned about that, just wrap the wire with some foam weather stripping similar to what they do inside the doors of cars.

chuyler1 said:

Oh, and btw, I can't hear any wire rattling inside the horn. If you're concerned about that, just wrap the wire with some foam weather stripping similar to what they do inside the doors of cars.

well, as he said, the boxes are already glued up, so access gets a bit tricky for anything other than a short direct path, but for future reference, I'd embed the wire in either silicone or hot melt glue.

The CSS Trio8 was suggested to me for use as a subwoofer as well. It's power handling is more in line with what my amp has to offer and it has the advantage in cone area as well. It's also cheaper than the SDX7....which is always a frugal plus

It's not likely that these will be corner loaded but i'll certainly try.

It's not likely that these will be corner loaded but i'll certainly try.

italynstylion said:The CSS Trio8 was suggested to me for use as a subwoofer as well. It's power handling is more in line with what my amp has to offer and it has the advantage in cone area as well. It's also cheaper than the SDX7....which is always a frugal plus

It's not likely that these will be corner loaded but i'll certainly try.

If not corner loaded you lose ultimate bass extension (ie probably from 50-80 Hz or so) and the deflector becomes more important for the bass (but i figure the ripple reduction is the most important).

The Trio8 is a fairly recent addition to Bob's stable. I just got 4 to play with/ For many of the things we are doing, the SDX7s extension to near 1kHz and then a smooth fall-off is important... Firing into a wall that is moot, and the Trio8 should have sufficient extension to integrate well. The Trio8 seems to be able to move about twice as much air, but needs almost twice the volume... somewhere between 20 & 30 litres per box (sealed). If you are out from the corner, the increased depth of the deflector becomes less of an issue. Sealed is an asset with this kind of loading but you do need to get the system Q down below 0.6. Attached is a sim of a 25 litre sealed box with Trio8. With driver loading the corner/wall junction, mirroring gives you close to an effective 4 8" drivers and should be flat to below 25 Hz.

I'd recommend a stereo amplifier and not a plate amp. This one has caught our eye -- i have a deal going to get one, but haven't yet. <http://www.parts-express.com/pe/showdetl.cfm?Partnumber=300-812>

An externally hosted image should be here but it was not working when we last tested it.

At an estimated 40 W into 8 ohms stereo, you'd probably want 2. For most situations with a push-push pair of woofers running 4 ohms, the 75 w is probably sufficient -- good current capability more important then ultimate power. The built in low pass (and a useful 3rd order) is nice.

The frugal-phile approach would be to scare up the cheap 70s/80s japanese receiver or integrated and use it's power amp with a PLLXO, or build a set of high voltage chip amps with lots of capacitance (ie for 8 ohms, bass only duty).

Trying to find room in the deflector to properly mount a plate amp is an attractive notion, but uses up already precious volume (and besides the inside of a loudspeaker is not the best environs for an amplifier)

And if you already have a 500 w plate amp, keep in mind that too much power is better than too little when it comes to speaker survival.

dave

Attachments

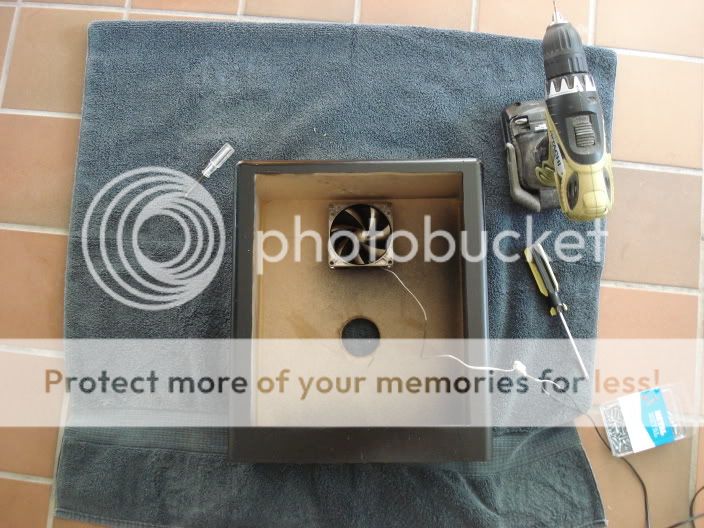

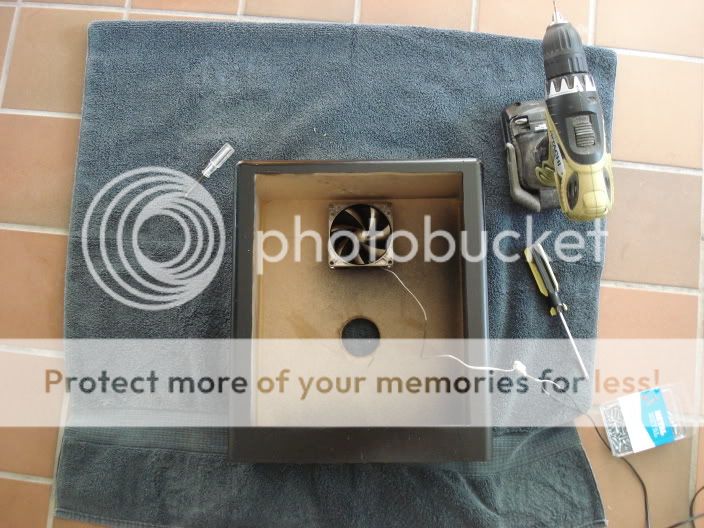

Dave, thanks for the response. I already have the O-Audio 500watt plate amp. I decided when I got it that i wanted to mount it in it's own free standing little box so it wasn't integrated into any speaker enclosure.

I did this for a couple reasons. It runs a pair of Peerless XXLS 12" subs that each have their own enclosures. Since they are in separate enclosures, putting the amp in it's own little unit allowed me to make the sub enclosures absolutely identical. It also allows me to use the amp to power whatever I want. It's portable and i even integrated a small computer fan to help keep it cool. It sucks in cool air from the bottom and blows the hot air out the top.

Keeping all this in mind, I'm really not planning to buy another amp. Since I wont have to mount a plate amp, I plan on making the deflectors/sub enclosures perfectly identical. I believe I could squeeze 30L of sealed enclosure space out of each of the deflectors easily. Both of the Trio8's wired in parallel would produce a final load of 4 ohms on my amp and provide 250RMS to each sub. I think this would be the best approach for the sub stage. Do you agree?

I did this for a couple reasons. It runs a pair of Peerless XXLS 12" subs that each have their own enclosures. Since they are in separate enclosures, putting the amp in it's own little unit allowed me to make the sub enclosures absolutely identical. It also allows me to use the amp to power whatever I want. It's portable and i even integrated a small computer fan to help keep it cool. It sucks in cool air from the bottom and blows the hot air out the top.

Keeping all this in mind, I'm really not planning to buy another amp. Since I wont have to mount a plate amp, I plan on making the deflectors/sub enclosures perfectly identical. I believe I could squeeze 30L of sealed enclosure space out of each of the deflectors easily. Both of the Trio8's wired in parallel would produce a final load of 4 ohms on my amp and provide 250RMS to each sub. I think this would be the best approach for the sub stage. Do you agree?

italynstylion said:Do you agree?

Given the current set of resources, sounds like the best plan.

dave

Today I stained the cabinets and the suprabaffles. I think I'm going to use the poyacrilic sealer/finish on them individually before mounting the supra baffle. I think it will be easier to paint on this way and will yield a much better finish. That's what I'm hoping anyway...

Terry Cain would have machined the pictured piece in a large wood turning lathe, but lacking that, if you have access to a large (as in the Porter Cable 7518 3 1/2 HP production ) router, you can get pretty close to the desired profile with a table edge bit

Attach the suprabaffle workpiece to secure worksurface with flush mounted screws through the driver mounting holes (I recess the drivers, so that's easy to do ) and "give 'er" slowly, with at least 2 passes of increasing depth.

Then follow with random orbit power sander.

Attach the suprabaffle workpiece to secure worksurface with flush mounted screws through the driver mounting holes (I recess the drivers, so that's easy to do ) and "give 'er" slowly, with at least 2 passes of increasing depth.

Then follow with random orbit power sander.

^that's a $70 bit that I'd have to mail away for. Will changing the radius of the round over make it sound $80 better in your opinion? That's kind of defeating the purpose of the "frugal" horn for me. If I had the bit already I'd have used that for sure. I do already have the random orbit sander though.

italynstylion said:^that's a $70 bit that I'd have to mail away for. Will changing the radius of the round over make it sound $80 better in your opinion? That's kind of defeating the purpose of the "frugal" horn for me. If I had the bit already I'd have used that for sure. I do already have the random orbit sander though.

Well, yeah when you build 20 or so pairs of different designs in a year, you get used to amortizing tool costs - and of course a router safe enough* to use with a bit this size is over $300.

*Not only do you want to be able to spin the bit without wearing out motor bearings, but it certainly helps if the router has substantial mass to damp vibrations from a 1 1/2" + diameter bit spinning at over 20,000 RPM, to reduce chatter marks, tearout, and fatigue. I find it al lot easier to push / pull the heavier tool than to fight the smaller one.

I have this Bosch router. I don't know how it stacks up against the best stuff but I love it and couldn't be happier. Would my router do fine with a bit like that?

If someone would be willing to loan me one of these router bits I'd alter the baffles. I'd pay for shipping both ways and I'd be eternally grateful

If someone would be willing to loan me one of these router bits I'd alter the baffles. I'd pay for shipping both ways and I'd be eternally grateful

Oh Lord NO!

I have a comparable size Porter Cable and it is just barely adequate for a 3/4" round-over bit. I personally would never try to free hand a bit the size in question. That's router table sized, but to be truly save, you need a shaper to swing bits this size.

IMO and I still have all of my fingers.

Bob

I have a comparable size Porter Cable and it is just barely adequate for a 3/4" round-over bit. I personally would never try to free hand a bit the size in question. That's router table sized, but to be truly save, you need a shaper to swing bits this size.

IMO and I still have all of my fingers.

Bob

how bout using a pre-fab suprabaffle

http://www.hofcraft.com/woodenbowls-flat.htm

...aka, salad bowl

http://www.hofcraft.com/woodenbowls-flat.htm

...aka, salad bowl

chuyler1 said:how bout using a pre-fab suprabaffle

http://www.hofcraft.com/woodenbowls-flat.htm

...aka, salad bowl

Those are really a nice shape... they would be a good starting point...

When i said rasp, the attached is what i had in mind... $10 at home despot. A very useful tool to have.

dave

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- My Frugel-Horn Build