Hi Tom,

Sorry, I meant we are all trying to extract respectable bass from them but it is possible that the HF will be over-represented, the highs shouting to us...I own a regular AN super10 which has a climbing frequency response. This AN cast speaker's membrane has a lower mass for the same magnet weight. This could make a more detailed reproduction but maybe with even more HF sensitivity?

Applying some kind of filter afterwards is IMHO against the purist's spirit of full-range

Comments will be much appreciated.

Regards,

M

In theory, if the horn is designed right, the driver is doing all the work right out the front. The horn in the case of a BLH is only reinforcement for the lower registers from around 15-200 down. Everything above is up to the driver itself.

Sorry, I meant we are all trying to extract respectable bass from them but it is possible that the HF will be over-represented, the highs shouting to us...I own a regular AN super10 which has a climbing frequency response. This AN cast speaker's membrane has a lower mass for the same magnet weight. This could make a more detailed reproduction but maybe with even more HF sensitivity?

Applying some kind of filter afterwards is IMHO against the purist's spirit of full-range

Comments will be much appreciated.

Regards,

M

The ANSuper8 has a similar issue. I have not found it intrusive though I will mention why in a second. I suppose it is up to the ears of the listener though. One way around it is through a BSC (Baffle Step Compensation) circuit. You will lose some sensitivity but with high quality components (inductors and resistors) you shouldn't lose any quality. One way I have dealt with the rising response in my home is to listen off axis about 20 degrees. This in my situation effectively deals with the rising response and harshness that can come with it in certain musical passages.

Tom

Tom

One method I use to limit HF beaming with a FR driver, is to mount a finger of foam from below, as close to the driver as is possible and until it covers up approximately half of the dust cap or phase plug. Sometimes two fingers of foam work better from opposite directions.

I obtain this foam by soaking 4" foam rollers in boiling water until their internal adhesive goes soft, and then work the foam off the roller shaft whilst wearing heat insulating gloves.

This foam disperses a portion of the cone focussed HF beam thus reducing axial HF and improving the radiation pattern. It also assists in suppressing the main cone diameter related peak, circa 3>4kHz with an 8" driver.

I must comment that these 'fingers' look odd and somewhat phallic, but they DO work !

Cheers ......... Graham.

I obtain this foam by soaking 4" foam rollers in boiling water until their internal adhesive goes soft, and then work the foam off the roller shaft whilst wearing heat insulating gloves.

This foam disperses a portion of the cone focussed HF beam thus reducing axial HF and improving the radiation pattern. It also assists in suppressing the main cone diameter related peak, circa 3>4kHz with an 8" driver.

I must comment that these 'fingers' look odd and somewhat phallic, but they DO work !

Cheers ......... Graham.

Remember guys, a horn is unlikely to suffer from this issue to the same extent as some other cabinets.

One of the reasons low Q units are generally (though not invariably) prefered for horns is because their greater motor-power & typically rising IB response to some extent counters the horns relatively high damping & concomitant HF roll-off. How severe the latter is depends on the size of the horn of course, but the larger things get, the greater the damping.

One of the reasons low Q units are generally (though not invariably) prefered for horns is because their greater motor-power & typically rising IB response to some extent counters the horns relatively high damping & concomitant HF roll-off. How severe the latter is depends on the size of the horn of course, but the larger things get, the greater the damping.

Thanks for the comments.

Dear Graham, would you mind posting a photo or a diagram?

If I understood correctly, and "inverted phase plug" should work...

You may know I am mono-thematic; if indeed bass and highs were prominent (usually the later more than the former) I would mount a front horn to increase midrange. Bass horn could be extended a little to reach the end of the midhorn (for aesthetic reason) . This would need more calculations but I bet it would sound better.

IMHO one thing is frequency response and another one is perception of sound propagation or emission (for lack of better term). I think sound is perceived differently if coming from a direct radiator or a from a horn. Maybe due to efficiency or radiation pattern... I don't know but I can tell that when using front and back loaded horns it just feels "right"...

The truth is that I feel sad that so few seem to be interested in this approach

Regards,

M

PS: a little wood is cheaper than good quality inductors...

Dear Graham, would you mind posting a photo or a diagram?

If I understood correctly, and "inverted phase plug" should work...

You may know I am mono-thematic; if indeed bass and highs were prominent (usually the later more than the former) I would mount a front horn to increase midrange. Bass horn could be extended a little to reach the end of the midhorn (for aesthetic reason) . This would need more calculations but I bet it would sound better.

IMHO one thing is frequency response and another one is perception of sound propagation or emission (for lack of better term). I think sound is perceived differently if coming from a direct radiator or a from a horn. Maybe due to efficiency or radiation pattern... I don't know but I can tell that when using front and back loaded horns it just feels "right"...

The truth is that I feel sad that so few seem to be interested in this approach

Regards,

M

PS: a little wood is cheaper than good quality inductors...

Compound horns are fine & can be less of a compromise than pure BLHs. They're a bit trickier to design though, and unfortunately, there isn't any software available (AFAIK) that can model the things, which makes life awkward if you don't have the ability, for whatever reason, to build multiple prototypes.

Hi M.

This is the only photo I have at the moment - helping out on a test baffle with the rising charactersistic of a B200.

Not easy to tell from the photo, but the 'foam fingers' are angled inwards.

This method helps counter driver shape related dynamically induced air side resonances, ie. circular cone, and would apply for front radiation no matter what type of baffle, waveguide or horn a wide range driver is mounted upon.

Cheers ....... Graham.

PS. The replacement centre dome on this driver is glued to the voice coil former, not to the cone as is supplied by Visaton.

This is the only photo I have at the moment - helping out on a test baffle with the rising charactersistic of a B200.

Not easy to tell from the photo, but the 'foam fingers' are angled inwards.

This method helps counter driver shape related dynamically induced air side resonances, ie. circular cone, and would apply for front radiation no matter what type of baffle, waveguide or horn a wide range driver is mounted upon.

Cheers ....... Graham.

PS. The replacement centre dome on this driver is glued to the voice coil former, not to the cone as is supplied by Visaton.

Attachments

Scottmoose said:Compound horns.........there isn't any software available (AFAIK) that can model the things..........

With just a quick browse through the manual it looks like Akabak can, though as always YMMV.

GM

Yes, one of the advantages of horns is that BSC is almost non-existant. (closed circuit acoustic resonator that doesn't rely on the room for (much) support, correct?). That is neither here nor there. I have found with my model 1 enclosure that the only place I notice the rising frequency is at higher frequencies. Hasn't been that much of a problem because it doesn't rise too high up until much higher freqs. So, I imagine this contributes to the high-hat sounding a bit out of place in the sound stage, but other than that, all good.

Akabak looks really interesting. I was playing last night a bit with it and the depth and breadth is astounding. Man, I need to find a solid manual for it. Anyone know where I can find one? Greg? Scott? Compound horns have been one of my desires for a while. I was thinking of just creating two designs, both front and back and estimating back-pressure for the front load to get similar FR's (DB wise).

Tom

Akabak looks really interesting. I was playing last night a bit with it and the depth and breadth is astounding. Man, I need to find a solid manual for it. Anyone know where I can find one? Greg? Scott? Compound horns have been one of my desires for a while. I was thinking of just creating two designs, both front and back and estimating back-pressure for the front load to get similar FR's (DB wise).

Tom

No, the main advantage of a BLH is that no BSC is required. Of course the room's effect must be factored into the design for best performance if no outboard EQ is planned.

??? You can print out the manual, though at 285 pages I imagine you'll need a commercial printer to do it all at once.

GM

??? You can print out the manual, though at 285 pages I imagine you'll need a commercial printer to do it all at once.

GM

GM said:No, the main advantage of a BLH is that no BSC is required. Of course the room's effect must be factored into the design for best performance if no outboard EQ is planned.

??? You can print out the manual, though at 285 pages I imagine you'll need a commercial printer to do it all at once.

GM

The manual. Where is it? I must be missing something. hehe. This is like a wheres Waldo game isn't it. hehe. Ok, the manual is there somewhere. I will find it. Thanks Greg!

Tom

cut sheet errata for EZ10??

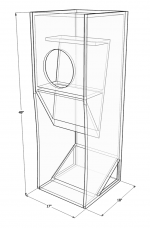

looking at the cut sheet: https://app.box.com/shared/fbnx0ij28k referenced from https://spqracoustics.wordpress.com/

is the cut sheet ok?

mainly pieces B and D (i dont know about the others)

piece B = 18" - 3/4" - 3/4" = 16 1/2 " (here i'm missing 1 1/2 " cut sheet says 15" )

piece D = 18" - 3/4" = 17 1/4" but is 16 1/2" in the cut sheet

its late night here, i'm drinking whiskey and scratching my head. i can smell the plywood all over my living room and i really need to hear i can not read the blueprints, because i'm living in the lands with cursed metric measures. all i was about before i got plywood cut was rescaling from inches to millimeters. i know it's been ages. anyone... @Harderror?

i dont know if the other distances are correct

looking at the cut sheet: https://app.box.com/shared/fbnx0ij28k referenced from https://spqracoustics.wordpress.com/

is the cut sheet ok?

mainly pieces B and D (i dont know about the others)

piece B = 18" - 3/4" - 3/4" = 16 1/2 " (here i'm missing 1 1/2 " cut sheet says 15" )

piece D = 18" - 3/4" = 17 1/4" but is 16 1/2" in the cut sheet

its late night here, i'm drinking whiskey and scratching my head. i can smell the plywood all over my living room and i really need to hear i can not read the blueprints, because i'm living in the lands with cursed metric measures. all i was about before i got plywood cut was rescaling from inches to millimeters. i know it's been ages. anyone... @Harderror?

i dont know if the other distances are correct

Member

Joined 2009

Paid Member

The manual. Where is it?

Just saw this

Anyway, he's been MIA for nearly a year now, so wonder if he's done here or just plain 'done'.........

GM

Member

Joined 2009

Paid Member

Pity.

Whilst we’re here, anybody know what’s inside this box in terms of structure ?

Auditorium 23 Hommage

Loudspeakers | Don Better Audio

Whilst we’re here, anybody know what’s inside this box in terms of structure ?

Auditorium 23 Hommage

Loudspeakers | Don Better Audio

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- S.P.Q.R. EZ10 for the AN Cast 10