A good day to you at DiyAudio; this is out of the ordinary, I have an electronic flue gas analyser, made by Colwick Instruments Ltd (they are no longer around), it’s called Anagas. The sensor fitted detects CO carbon dioxide only, yet the manufacturer successfully managed to achieve detecting CO² carbon dioxide; I am guessing this was achieved by adding a adjustable resistor?

It would be good to know more about how this was achieved, detecting CO².

You can see the components on my Microsoft OneDrive

https://1drv.ms/i/s!AuQDAPiShOjc2Sru5HJEJIdT1oRK

I am in the process of fitting a new battery pack and a new CO sensor.

It would be good to know more about how this was achieved, detecting CO².

You can see the components on my Microsoft OneDrive

https://1drv.ms/i/s!AuQDAPiShOjc2Sru5HJEJIdT1oRK

I am in the process of fitting a new battery pack and a new CO sensor.

I assume you mean carbon monoxide CO which would be a flue gas combustion byproduct? CO2 is carbon dioxide. (Also a combustion byproduct)

I have no idea, and would assume that the sensor was either specially selected or different in some way from what you think it is.

This isn't exactly the right forum for these sorts of questions either.

I have no idea, and would assume that the sensor was either specially selected or different in some way from what you think it is.

This isn't exactly the right forum for these sorts of questions either.

The sensor fitted detects CO carbon dioxide only, yet the manufacturer successfully managed to achieve detecting CO² carbon dioxide

just a guess, probably using math. If there is no co, then it is all co2 and vice versa. Is it only for one fuel or are there settings for particular fuels?

I assume you mean carbon monoxide CO which would be a flue gas combustion byproduct? CO2 is carbon dioxide. (Also a combustion byproduct)

Yes; CO carbon monoxide, just testing

This isn't exactly the right forum for these sorts of questions either.

Well I have googled searched; made various searches for a forum related to "CO and CO2 test equipment forum" there just doesn't seem to be one and any possible ones were in 2010. If you know of one Kevin; a link to the forum would be helpful,

I use this instrument for setting-up oil burners.

Last edited:

Yes; I would say that comes into the equation.just a guess, probably using math.

The selector switch selects either CO or CO2.If there is no co, then it is all co2 and vice versa.

Is it only for one fuel or are there settings for particular fuels?

The instrument has a probe which in inserted through a access/test point in the flue to sample the gases of; 28 second kerosene, 35 second gas oil, LPG, natural gas.

Last edited:

It will be, for a flue, CO sensor. Carbon Monoxide and they have a 5 year life before the sensor no longer works properly.

For your safety, replace it.

This has drifted off my initial question; "It would be good to know more about how this was achieved, detecting CO²".

This has drifted off my initial question; "It would be good to know more about how this was achieved, detecting CO²".

Make it easy. For methane:

2x CH4 + 4x O2 = 2x CO2 + 4x H2O under ideal stoichiometric conditions.

Say you have this instead:

2x CH4 + 3.5x O2 = CO2 + CO + 4x H2O

When you don't have enough oxygen, some of that CO2 will become CO instead. So if the detector detects CO, it knows there is less CO2, some sort of logic could be programmed to figure it out. That is what I meant by 'using math'.

More importantly, when you replace a sensor in an obsolete device, how do you calibrate the device? How can you be confident in it?

http://international.go-dove.com/en...-instruments-limited-Anagas-Flue-Gas-Analyser

Last edited:

Jon, it's not an alarm, it's a tool for verifying that the fuel mixture ratio is correct for setting up or servicing various types of heating equipment.

If the manufacturer is out of business there is a good argument for replacing the tool with one that is supported. Should someone still offer a calibration service for it that would be a good start for determining whether the instrument is still serviceable.

I can't guess whether or not math is used to determine the % CO2, it seems plausible however.

If the manufacturer is out of business there is a good argument for replacing the tool with one that is supported. Should someone still offer a calibration service for it that would be a good start for determining whether the instrument is still serviceable.

I can't guess whether or not math is used to determine the % CO2, it seems plausible however.

Make it easy. For methane:

2x CH4 + 4x O2 = 2x CO2 + 4x H2O under ideal stoichiometric conditions.

Say you have this instead:

2x CH4 + 3.5x O2 = CO2 + CO + 4x H2O

When you don't have enough oxygen, some of that CO2 will become CO instead. So if the detector detects CO, it knows there is less CO2, some sort of logic could be programmed to figure it out.

Good; yes that will be that part of the equation; the next step would of been to use certain components, to use (that would combine and work) in-conjunction with the Figaro sensor?

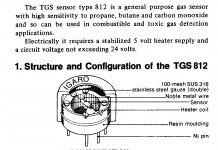

I guess the manufacture (Colwick) knew that this avalible long life sensor could only identify/had sensitivity to as indicated in the specifications see the picture below and devised a complementary way to abstract a measurement from the presents of CO² carbon dioxide.

The Figaro sensor; it’s worth a look at the Figaro PDF to gain more insight on my Microsoft OneDrive. https://1drv.ms/f/s!AuQDAPiShOjc2RPG-X10IL1vNeG7

It took quite some time to find someone who could re-calibrate this instrument; a small company called Environmental Calibration Services is where I send it. Welcome to Environmental Calibration ServicesMore importantly, when you replace a sensor in an obsolete device, how do you calibrate the device? How can you be confident in it?

Attachments

Metal oxide semiconductor: When the silica chip's circuitry detects carbon monoxide, it lowers the electrical resistance, and this change triggers the alarm.

Yes a very good reply too; Metal Oxide Semi-Conductor Gas Sensors see the PDF below this does imply sensing CO² carbon dioxide (the link is for the full size file, too large to post).

http://www.mdpi.com/1424-8220/10/6/5469/pdf-vor

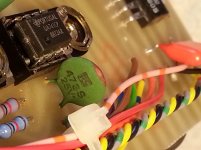

The picture below shows these green components RS 473S 25v- they are on the main PC board can anyone recognise?

Attachments

The search results for 473 capacitor came up with this; the nearest match: 47nF (473) - 50v Ceramic Disc Radial Capacitors. Not what I had hoped for.

On the main PC board component; BD131 S M (could be a STMicroelectronics BD131/BD132 NPN+PNP Bipolar Transistor, 3 A, 45 V, 3-Pin)

I’m thinking this could be component to assist with detecting CO² carbon dioxide?

I searched for; metal oxide semiconductor field effect transistor, the results I’ve chosen this YouTube video for insight. https://www.youtube.com/watch?v=tz62t-q_KEc

On the main PC board component; BD131 S M (could be a STMicroelectronics BD131/BD132 NPN+PNP Bipolar Transistor, 3 A, 45 V, 3-Pin)

I’m thinking this could be component to assist with detecting CO² carbon dioxide?

I searched for; metal oxide semiconductor field effect transistor, the results I’ve chosen this YouTube video for insight. https://www.youtube.com/watch?v=tz62t-q_KEc

Attachments

I’m thinking this could be component to assist with detecting CO² carbon dioxide?

BC131 is a transistor with a small heat sink on it. 7805 is a 5V regulator

555 is a timer, the ua741s are op amps, the green things are definitely caps. THe orange and purple things are caps. The black and silver things are diodes. The silver and brown things with slots are trimmers.

There are no gas sensors on that board.

I hope you are playing with it for personal use and you aren't intending on repairing people's furnaces with it...

Greetings, I was the Chairman and Managing Director of Colwick Instruments Limited and did much of the original development and design work on the Anagas. We sold the instrument in 40 countries over a thirty year period. The comment above about the CO (combustibles) sensor having a 5 year life is nonsense. The sensor has an almost unlimited life provided that it is treated correctly, unlike electrochemical sensors used by most competitors. Many more modern instruments use infrared sensors, now that technology is somewhat simpler to implement. As for the guess that we calculate CO@ from the CO reading, that is also false. There is a completely different sensor for CO2. We also produced a model which also measured O2 (using a long life electrochemical sensor) and with that unit it was simple to derive the theoretical maximum CO2 for the fuel in use. The probe was fitted with a thermocouple for the measurement of temperature ... actually differential temperature, i.e., the difference in temperature between ambient and flue temperature, as needed for efficiency calculations. The Anagas ran for 5 hours on a battery charge, so could handle a day's work for a combustion engineer and if he was using it absolutely continuously, he could use it on the charger for as long as needed. Rather than be making silly guesses, why not just ask me if there is something you would like to know...I would like to know WHY you want to know too. Kind Regards, David

In response to Michael, the battery pack was originally 7 cells of sub-c size NiCad connected in series. Batteries have improved a lot and it might be possible to use high powered AA size ones now. A battery pack of reasonable quality cells should last you for at least 5 years. The charging circuit in the Anagas is very kind to the cells and it is virtually impossible to overcharge. There is a protective diode which prevents problems when the power supply is wrongly connected, but it doesn't protect from reversal of the battery as far a I recollect.

The CO sensor is a solid state tin oxide semiconductor but it is essential to calibrate the new sensor because they are quite variable one to the next. Also, you will need to run the sensor for a couple of weeks to 'condition' it prior to calibration. The correct calibration gas to use is 100vpm CO plus 3% O2 plus a nitrogen balance. If you don't want to buy that from BOC Special Gasses, you will need to make your own mixture, or perhaps calibrate by comparison against another instrument of known accuracy. We calibrated the low end of the scale with clean air (carefully cleaned !) and then the 100 ppm point two thirds of the way across the meter. The range approximates to logarithmic, so the top end of it is simply ridiculously too high for any combustion appliance. We were mainly concerned to get combustion below 100 vpm which is fairly safe and reasonably efficient for gaseous fuels. Liquid fuels such as oil may produce smoke before producing CO, so a smoke reading must always be taken .. largely it depends on the method of combustion of the oil (as will be known by most combustion engineers).

I would offer to fix it for you, but I don't have any calibration gases now, or the means to make them. Also the quality status died when I closed down the company, so a calibration certificate would hardly be valid. The instrument was designed in the 1970s and I am well into retirement, however, if there is serious interest in people wishing to resurrect these instruments, I am prepared to assist.

The CO sensor is a solid state tin oxide semiconductor but it is essential to calibrate the new sensor because they are quite variable one to the next. Also, you will need to run the sensor for a couple of weeks to 'condition' it prior to calibration. The correct calibration gas to use is 100vpm CO plus 3% O2 plus a nitrogen balance. If you don't want to buy that from BOC Special Gasses, you will need to make your own mixture, or perhaps calibrate by comparison against another instrument of known accuracy. We calibrated the low end of the scale with clean air (carefully cleaned !) and then the 100 ppm point two thirds of the way across the meter. The range approximates to logarithmic, so the top end of it is simply ridiculously too high for any combustion appliance. We were mainly concerned to get combustion below 100 vpm which is fairly safe and reasonably efficient for gaseous fuels. Liquid fuels such as oil may produce smoke before producing CO, so a smoke reading must always be taken .. largely it depends on the method of combustion of the oil (as will be known by most combustion engineers).

I would offer to fix it for you, but I don't have any calibration gases now, or the means to make them. Also the quality status died when I closed down the company, so a calibration certificate would hardly be valid. The instrument was designed in the 1970s and I am well into retirement, however, if there is serious interest in people wishing to resurrect these instruments, I am prepared to assist.

I think Flue Gas Analysers are probably well off the audio topic, but I came across this completely by accident and felt that I could help out a bit. At least the Anagas is an electronic instrument with 'permanent' sensors. I hope I haven't taken up too much space and time with my responses. I am also interested in audio and have built many bespoke pieces of equipment over the years, so I am pleased to have found this place.

Detecting CO² Carbon Dioxide

My model is an AG1 with serial number 9962; I can assure you it has only one gas sensor fitted it is a FIGARO TGS812; which does not detect CO² carbon dioxide.

I am the original owner of this unit who is responsible for its maintenance; would you kindly like to give your answer to this question, how this was achieved, detecting CO² carbon dioxide?

It would be very helpful if I had a service manual for this model?

As for the guess that we calculate CO@ from the CO reading, that is also false. There is a completely different sensor for CO2.

My model is an AG1 with serial number 9962; I can assure you it has only one gas sensor fitted it is a FIGARO TGS812; which does not detect CO² carbon dioxide.

I am the original owner of this unit who is responsible for its maintenance; would you kindly like to give your answer to this question, how this was achieved, detecting CO² carbon dioxide?

It would be very helpful if I had a service manual for this model?

What you have sounds quite different from what the original designer has described. Have you bought a cheap clone/fake, or one which has been 'got at' by an incompetent 'repairer'? The gas sensor you have would seem to be a general sensor for any combustible gas, not CO specifically. As such, it could not detect CO2. Flue gases can be expected to contain large amounts of CO2 and small amounts of CO, so it is unlikely that a reading of one can be inferred from a reading of the other.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Everything Else

- Electronic Flue Gas Analyser