Can you give me password of cad files?Uploaded to diyaudio as well

Thanks

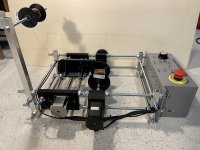

Mono and bifilar transformer winding machine :

This is the version I buid for transformer winding. Particularly, vacuum tube amplifier output transformer. Software and firmware made and modified by ghemml.

ABS printing parts and 10mm rods frame for easy DIY and low cost. All 3D parts are design with Freecad.

I use conventional stepper motors but closed loop are better.

I made it for bifilar as I often need it.

General dimensions without control box (approximately) : 52cm (width), 55cm (length), 40cm (height with reel support)

All STL file and updated PDF on FB group : https://www.facebook.com/groups/804317050166139/?ref=share

This is the version I buid for transformer winding. Particularly, vacuum tube amplifier output transformer. Software and firmware made and modified by ghemml.

ABS printing parts and 10mm rods frame for easy DIY and low cost. All 3D parts are design with Freecad.

I use conventional stepper motors but closed loop are better.

I made it for bifilar as I often need it.

General dimensions without control box (approximately) : 52cm (width), 55cm (length), 40cm (height with reel support)

All STL file and updated PDF on FB group : https://www.facebook.com/groups/804317050166139/?ref=share

Attachments

PDF for more explanations.

All suggestions are welcome!

Link : https://drive.google.com/file/d/1M13W7rKwaKxvFOJ9OENLGPP010BbgLN0/view?usp=sharing

All suggestions are welcome!

Link : https://drive.google.com/file/d/1M13W7rKwaKxvFOJ9OENLGPP010BbgLN0/view?usp=sharing

The wire have a strange color because I use old wire from burnt transformer for testing...

This video show bifilar winding with 2x 0,3mm wire diameter

Updated the file attachments(No password needed to unzip)

- Winding Machine GUI.zip - Visual Basic Source Code(Required Microsoft Visual Studio)

- Winding Machine GUI v0.3.3.zip - Winding Machine GUI exe file

- Winder_Shield_v0.3.1.6.zip - Arduino Firmware

- Wiring Diagram(Due) v0.3.zip - Arduino Due Wiring Diagram in Microsoft Visio

Last edited:

Latest Beta release:

Winding Machine Console v0.3.8 beta download

Winder Shield Firmware v0.3.1.8 download

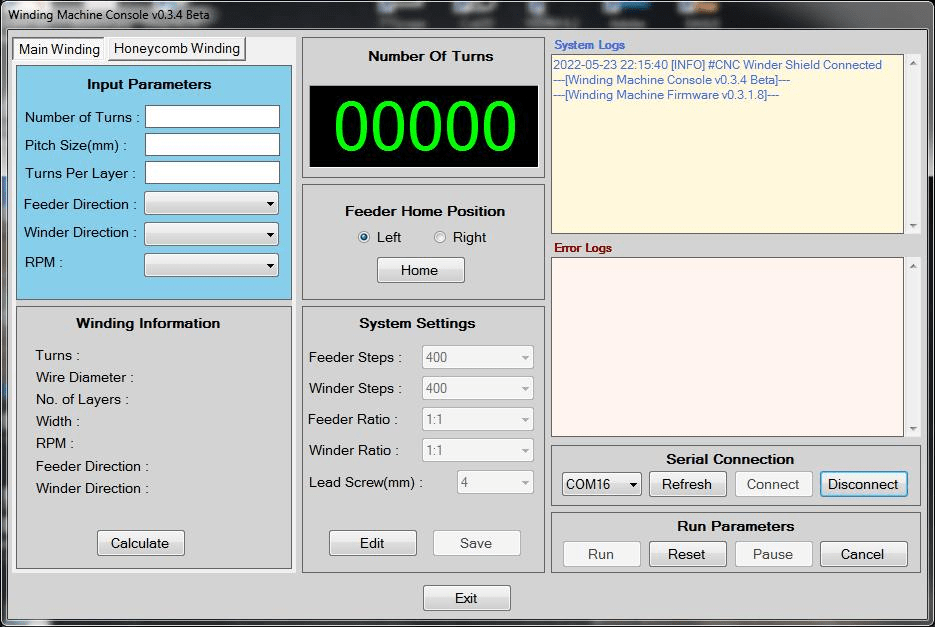

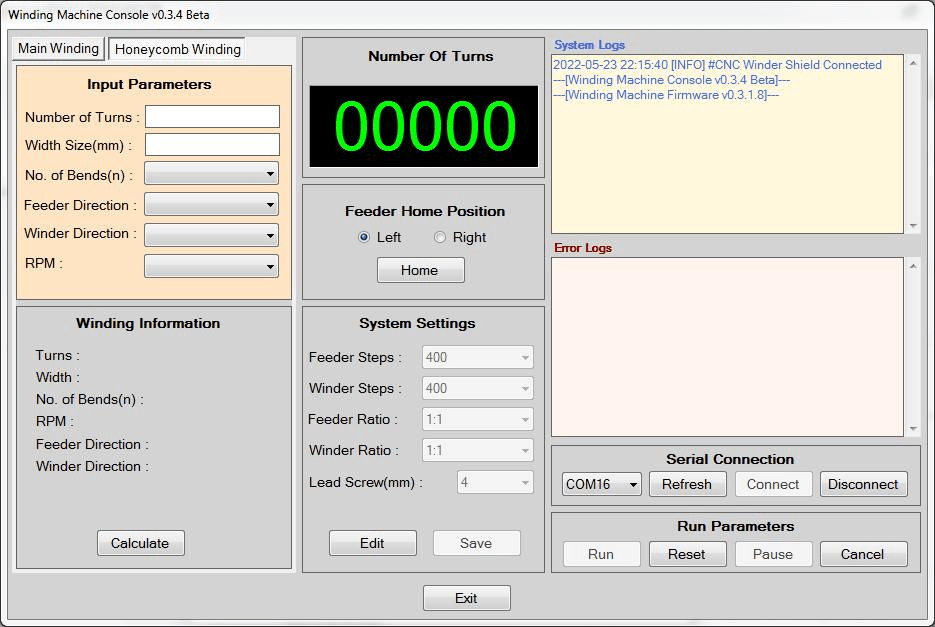

- Winding Machine Console v0.3.4 beta

- Winding Machine Firmware v0.3.1.8

- Added Feature for Honeycomb inductor winding

- Honeycomb winding will now limited to 60rpm max

- Speed selection now changed to RPM

- Microstepping setting been reduced to 200, 400 and 800

- Controller firmware optimized by removing underutilized parameters

- Speed ratio setting now reflect as 1:1, 2:1, 4:1

- Lead screw setting now allow user to select 1, 2, 3, 4, 5(mm)

Winding Machine Console v0.3.8 beta download

Winder Shield Firmware v0.3.1.8 download

Update on the project coding and uploaded to Arduino Project Hub as well

https://www.diyaudio.com/community/threads/diy-voice-coil-winding-machine.320505/post-5381060

https://www.diyaudio.com/community/threads/diy-voice-coil-winding-machine.320505/post-5381060

Thank you for the impressive work & sharing. Of all your videos I have not seen any build demonstrating winding of thick 1.2 mm or more in multiple layers, like 11 or more. I intend to build one such machine but would like to know whether your software is capable of laying out all neatly wound upto 11 or more layers? Also are acceleration & deceleration parameters controllable?

Hi Ghemml, do the actual aluminum/stainless steel parts that make up the machine have to be made or is it a kit that can be bought? I'm very interested in making one of these as I've been building subwoofers for years and with the price of voice coils going up over time, this might actually save me a buck. Thank you for posting thisPhoto of the winding machine and the user interface.

- Home

- Design & Build

- Equipment & Tools

- DIY Voice Coil Winding Machine