I'm lying a little bit, because i moved to a custom designed carbide ball slipper that offer a better consistency than conventional friction slippers.Hello, On my nano coil winding machine

So, here is a solution : Polyclutch Slip-Ease RK-EAO12

Polyclutch Slip-Ease RK-EAO12

Last edited:

Those motors are enormous, why chose a stepper for the winding spindle? Surey you want torque control and steppers cannot provide that.

It is a closed loop hybrid motor not a stepper motor.

Hello,

On my nano coil winding machine, i use a Losi hydra-drive hydro coupler, it is extremely smooth and adjustable.

Looks interesting, any more information about it?

https://nsa40.casimages.com/img/2019/04/27/190427070723828493.jpg

Winding Demo

Winding video

Wire diameter: 0.1mm

Turns: 30

Pitch: 0.12mm

Speed: 60 rpm, 240 rpm, 300 rpm

CNC Winding Machine

Winding video

Wire diameter: 0.1mm

Turns: 30

Pitch: 0.12mm

Speed: 60 rpm, 240 rpm, 300 rpm

CNC Winding Machine

Really?? I scoff in your general direction.Quite a project. Well done.

VB is out of my league, I am a C# and C++ man.

Me: 25 years vb on two 11 axis motion platforms.

On the other hand...C# and C++ are out of my league.

Jn

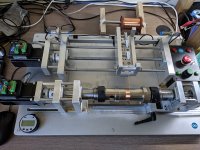

Photo of the winding machine and the user interface.

Hmm. If you modulate the winding pitch of an overhung VC.....

Food for thought.

Jn

Ps..excellent work.

Hmm. If you modulate the winding pitch of an overhung VC.....

Food for thought.

Jn

Ps..excellent work.

The winding machine is capable but largely depends well the bobbin design is.

*Latest update*

Youtube Video: CNC Winding @300 rpm

Youtube Video: CNC Winding @300 rpm

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

I use the DRV8825 with a 3.8v 1.8d Nema stepper running into a 100:1 planetary gearbox for my telescope focuser - hanging off it is a filter wheel, of-axis guider and multiple heavy cameras. Plenty of torque, so much that I have limit and stops on it.

Resolution is over 1.6 million steps For the focuser travel, making it very hi res with very low backlash of gears. Focusing if Astro equipment is probably far higher resolution than winding copper strands.

The stepper system runs at 12v with the DRV current chopping means the stepper remains cold in use for hours on end.

Just be careful of a couple of things;

* switching stepping only Synchronises once at a specific step on each stepping.

* using sleep mode and higher stepping doesn’t guarantee restoring micro stepping alignment. From what I can see you only use it for emergency stop.

Resolution is over 1.6 million steps For the focuser travel, making it very hi res with very low backlash of gears. Focusing if Astro equipment is probably far higher resolution than winding copper strands.

The stepper system runs at 12v with the DRV current chopping means the stepper remains cold in use for hours on end.

Just be careful of a couple of things;

* switching stepping only Synchronises once at a specific step on each stepping.

* using sleep mode and higher stepping doesn’t guarantee restoring micro stepping alignment. From what I can see you only use it for emergency stop.

A device that can only be appreciated but cannot be modified

Everything depends on a person willingness to try modding it or just sit there and watch.

The files I uploaded in my previous reply contain AutoCAD file and parts list. It is up to your imagination, and individual effort to mod it.

I use the DRV8825 with a 3.8v 1.8d Nema stepper running into a 100:1 planetary gearbox for my telescope focuser - hanging off it is a filter wheel, of-axis guider and multiple heavy cameras. Plenty of torque, so much that I have limit and stops on it.

Resolution is over 1.6 million steps For the focuser travel, making it very hi res with very low backlash of gears. Focusing if Astro equipment is probably far higher resolution than winding copper strands.

The stepper system runs at 12v with the DRV current chopping means the stepper remains cold in use for hours on end.

Just be careful of a couple of things;

* switching stepping only Synchronises once at a specific step on each stepping.

* using sleep mode and higher stepping doesn’t guarantee restoring micro stepping alignment. From what I can see you only use it for emergency stop.

Clearly you do not understand what type motor I am using now.

Using stepper motor drivers like AD4988, DRV8825 or even the trinamic tmc2130 are just crappy and lousy way of designing a CNC winder. Overheating, lots of noise and vibration except for trinamic drivers.

And probably you do not understand what is C5 grade means on a ball screw. I can achieve 10 micron accuracy based on my current design.

Using your telescope as your example is a totally different situation, it only critical on the RA Motor and how many teeth you have on your worm gear. Because you do not wind your own voice coil, it means you haven't encounter or understand wire gauge that is 0.01mm thick wires and precision it needed along with the tension requirements.

Modding a EQ3 mount to a fully GOTO mount is just past old project that I did before. My question is have you done any closed loop motor design for you telescope mount and modify the wormgears size and increase the thrust bearing diameter?

Probably I suggest you read up on my facebook page to understand what kind of mechanical engineering business I work on.

Gamut Magnetic Laboratories - GML Loudspeakers - Home | Facebook

Last edited:

- Home

- Design & Build

- Equipment & Tools

- DIY Voice Coil Winding Machine