A turtle doesn't need to order ANY gear with or without any measurements, but we are human beings and can predict the results, right?Well, without the beef measurements given, why a turtle would order your gear

Hp

You can roll your eyes as many times as you need, but does this action solve anything?

It seems that the RMS-to-DC converter chip, the AD536, gets harder to find and more expensive. Digikey wants $ 20 for one.

So I will redesign the attenuator board for a currently available RMS-to-DC converter (which will most probably be SMD anyway). But that will take me some time and to accommodate the current situation I will include an AD536 for free in any kits ordered from today. Saves you up to $ 20

Jan

So I will redesign the attenuator board for a currently available RMS-to-DC converter (which will most probably be SMD anyway). But that will take me some time and to accommodate the current situation I will include an AD536 for free in any kits ordered from today. Saves you up to $ 20

Jan

It seems that the RMS-to-DC converter chip, the AD536, gets harder to find and more expensive. Digikey wants $ 20 for one.

So I will redesign the attenuator board for a currently available RMS-to-DC converter (which will most probably be SMD anyway). But that will take me some time and to accommodate the current situation I will include an AD536 for free in any kits ordered from today. Saves you up to $ 20

Jan

Hi Jan,

Can you PM me with current price and ordering details? Thanks!

Cheers!

Howie

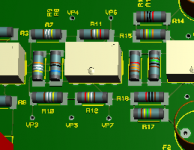

BTW, what do you guys think about the use of MELF resistors? Would you be comfortable to solder those? For me it became a no-brainer once I tried a couple, but what do you guys think?

MELFs are generally a bit more linear and less expensive than through-hole film R's, although the differences are not huge.

Jan

MELFs are generally a bit more linear and less expensive than through-hole film R's, although the differences are not huge.

Jan

Attachments

It shouldn't, if you use a tweezer. Really simple, look here:

Master Soldering: IPC J-STD-001 Chip & MELF soldering - YouTube

The guy shakes a bit but there's a technique to keep your hand rock-steady.

Most people try to do this 'from the shoulder' as it were, and that causes trembling.

What I do is support the wrist area on the bench or board so the lever is only a few inch instead of two feet of the arm.

I wish I could film it ..

Jan

Master Soldering: IPC J-STD-001 Chip & MELF soldering - YouTube

The guy shakes a bit but there's a technique to keep your hand rock-steady.

Most people try to do this 'from the shoulder' as it were, and that causes trembling.

What I do is support the wrist area on the bench or board so the lever is only a few inch instead of two feet of the arm.

I wish I could film it ..

Jan

BTW, what do you guys think about the use of MELF resistors? Would you be comfortable to solder those? For me it became a no-brainer once I tried a couple, but what do you guys think?

MELFs are generally a bit more linear and less expensive than through-hole film R's, although the differences are not huge.

Jan

Hi Jan,

I honestly see no value in going to MELF resistors. Resistors are cheap, whether they are MELF or high quality through-hole metal film. The latter offer more than adequate performance to achieve extremely good results. Victor did not need to use MELFs to achieve his astounding performance.

Cheers,

Bob

True, but Viktor used thin film SMD's, much harder to solder than MELF's.

And in the AR potentially you have to cope with 100V+ signal levels.

Attached example, those Vishays are $ 20 in singles, the MELF's between $ 0.50 and $ 1.50.

Jan

And in the AR potentially you have to cope with 100V+ signal levels.

Attached example, those Vishays are $ 20 in singles, the MELF's between $ 0.50 and $ 1.50.

Jan

Attachments

Last edited:

Yep. You can't solder small stuff "from the shoulder." You've got to brace yourself to work with the small stuff.

MELF is about as easy to solder as the flat SMD parts, except for rolling away when you drop them. That is to say, MELF and flat SMDs are both pretty danged easy to solder.

I can't speak to the differences between MELF, through hole, or regular SMD in terms of noise or other aspects of performance.

MELF is about as easy to solder as the flat SMD parts, except for rolling away when you drop them. That is to say, MELF and flat SMDs are both pretty danged easy to solder.

I can't speak to the differences between MELF, through hole, or regular SMD in terms of noise or other aspects of performance.

Last edited:

True, but Viktor used thin film SMD's, much harder to solder than MELF's.

And in the AR potentially you have to cope with 100V+ signal levels.

Attached example, those Vishays are $ 20 in singles, the MELF's between $ 0.50 and $ 1.50.

Jan

Hi Jan,

I was referring to quality through-hole metal film resistors. I doubt that Victor paid $20 apeice for the SMT resistors he used.

I could be wrong, but I think quality through-hole metal film resistors are every bit as good as SMT resistors like the ones Victor used in his oscillator. Very true that SMT resistors save an enormous amount of space, so I am not necessarily advocating the use of through-hole in all locations, since many locations are quite uncritical.

In my evaluation circuit for Victor's oscillator, I used through-hole metal film resistors throughout. The front end was a passive twin-T, where most of the passive component distortion will originate, and it was implemented with these rather ordinary through-hole resistors. Whatever distortion there was, be it from Victor's oscillator or my measurement circuit, was buried in the noise at -150 or better.

Cheers,

Bob

Hi Bob,

Yes all good points, and I think excellent circuits can be constructed with either type. It does seem though that the available variety of values, TC and tolerances have been shifting in favor of SMD, in whatever guise, for some time now, at least at Mouser where I get most of my parts.

I still have a lot of through-hole stock, but soldering a MELF or SMD (I use 1206 resistors and caps a lot) becomes so easy, that bending leads, inserting, turning over, soldering, cutting excess wiring, turning back, seems, I don't know, tiring maybe?

OTOH, through hole is generally more robust and mechanically less finicky than SMD, although for some reason the dissipation of those relatively small resistors is still easily 0.4 or 0.5W. Must have to do with material.

But again, I am ready to admit that excellent performing circuits can be designed and build with either. You need to pick your poison carefully.

Jan

Yes all good points, and I think excellent circuits can be constructed with either type. It does seem though that the available variety of values, TC and tolerances have been shifting in favor of SMD, in whatever guise, for some time now, at least at Mouser where I get most of my parts.

I still have a lot of through-hole stock, but soldering a MELF or SMD (I use 1206 resistors and caps a lot) becomes so easy, that bending leads, inserting, turning over, soldering, cutting excess wiring, turning back, seems, I don't know, tiring maybe?

OTOH, through hole is generally more robust and mechanically less finicky than SMD, although for some reason the dissipation of those relatively small resistors is still easily 0.4 or 0.5W. Must have to do with material.

But again, I am ready to admit that excellent performing circuits can be designed and build with either. You need to pick your poison carefully.

Jan

I could be wrong, but I think quality through-hole metal film resistors are every bit as good as SMT resistors like the ones Victor used in his oscillator.

You are, in general. Through hole resistors, unless specially designed, are much more inductive compared to thin film SMD, and it's not only because of having leads. Most metal film through hole resistors are trimmed on a spiral, there are only a very few vacuum deposition thicknesses and compositions.

Another issue with through hole components is the much larger loop area (between the body and the back ground plane) waiting to collect stray magnetic fields and EMI.

Of course, one may not care about these for audio applications.

Don't know about MELF, though, but I would not use them for ultimate applications. I don't think 1206 SMD are much more difficult to solder compared to MELF.

There's some info here:

What is a MELF Resistor >> Electronics Notes .

Note that MELFs are also laser-trimmed with a helical groove.

PS and I also like the pretty colors ;-)

Jan

What is a MELF Resistor >> Electronics Notes .

Note that MELFs are also laser-trimmed with a helical groove.

PS and I also like the pretty colors ;-)

Jan

soldering a MELF or SMD (I use 1206 resistors and caps a lot) becomes so easy, that bending leads, inserting, turning over, soldering, cutting excess wiring, turning back, seems, I don't know, tiring maybe?

Not to mention the difficulty of pulling and replacing from plated through holes, during development and repair jobs.

You are, in general. Through hole resistors, unless specially designed, are much more inductive compared to thin film SMD, and it's not only because of having leads. Most metal film through hole resistors are trimmed on a spiral, there are only a very few vacuum deposition thicknesses and compositions.

Another issue with through hole components is the much larger loop area (between the body and the back ground plane) waiting to collect stray magnetic fields and EMI.

Of course, one may not care about these for audio applications.

Don't know about MELF, though, but I would not use them for ultimate applications. I don't think 1206 SMD are much more difficult to solder compared to MELF.

I think it is better to say that I am wrong, specifically, not in general, and perhaps only in regard to the particular characteristics you mentioned.

Bruce Hofer probably knows best in all of these issues.

Cheers,

Bob

In all my years doing pcb layout, I have never used MELF packaged devices. Imo they were a transistion package from THT to SMT. I do not recall ever seeing a MELF capacitor. In deciding on a package, it is best to consider availability, second sourcing, cost. Unless a component is unique and the package has clear advantages, they should be discouraged esp for the DIY community.

When I sourced parts for soldering up Victors oscillators, I chose Susumi thin films in the 0805. For amateur’s, 1206 is best, but not used as much as 0805 and smaller. Of course power dissipation has to be factored into consideration.

Rick

When I sourced parts for soldering up Victors oscillators, I chose Susumi thin films in the 0805. For amateur’s, 1206 is best, but not used as much as 0805 and smaller. Of course power dissipation has to be factored into consideration.

Rick

Last edited:

- Home

- Design & Build

- Equipment & Tools

- Autoranger for soundcards