marce, it is explained at length in that article why an SMPS is inherently unsafe and not worth the risk.

Other than that, the same argument that they fed us to ban solder with lead, is, in essence, the same against SMPS: some people make bad use of products with lead-based solder ... ban it! some people misuse linear power supplies ... ban them! I think you can work out the details yourself.

Other than that, the same argument that they fed us to ban solder with lead, is, in essence, the same against SMPS: some people make bad use of products with lead-based solder ... ban it! some people misuse linear power supplies ... ban them! I think you can work out the details yourself.

As he said, he's playing Devils Advocate. SMPS's are used in numerous life critical and high reliability situations. Cheep imports and cheep products will always be desined down to a price.

The reason linear PSU's are being banned is because they are not efficient and for every linear supply we replace with a SMPS we save 0.001 Polar bears, so its got to be a good thing. plus we also need to save power wasted by power supplies to have enough energy left to heat up the lead free solder to the 20-30 degrees it melts at above a good eitectic tin lead solder.

The reason linear PSU's are being banned is because they are not efficient and for every linear supply we replace with a SMPS we save 0.001 Polar bears, so its got to be a good thing. plus we also need to save power wasted by power supplies to have enough energy left to heat up the lead free solder to the 20-30 degrees it melts at above a good eitectic tin lead solder.

The second paragraphis not realy sarcasm but satire.

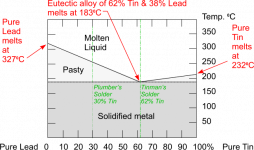

SMPs are used extensivly in medical, millitary and aerospace projects, where high reliability is required, that is a fact, and on that note the failure rates is not as bad as made out, though other safety measures are involved that go above consumer goods. Linear supplies and incandescent lightbulbs are being banned because of their inefficiency and as such they waste power.Lead free solder requires 240-260 deg C reflow compared with 210-235 deg C for tine lead eutectic solder, thus we have to heat the reflow ovens and solder to at least 30 deg C higher for PB free soldering, so we burn extra energy.

I have been heavily involved with the change from leaded solders to lead free, mianly in the build up to PB free day in 2006, and have experience in both the change in PCB design requirements (minimal) and the changes in production departments to cater for lead free solders. As well as being involved in many tests with various combinations of Pb free solder formulations to achieve certain desired goals. I am still heavily involved with designs that have to use tin/lead solder and the problems that incurs when the majority of the components are now terminated with a Pb free compatible terminations (matt tin on passive components etc and Pb free solder balls on BGA's). This brings its own set of problems in creating reliable assemblies with good joints, BGA's have to be re-balled with eutectic tin lead solder balls (at approx 2p per pin) etc etc.

Lead was banned from electronics cos the lentil suckers got a bee in their bonnet about lead in the envoironment, it is almost impossible for lead in tin lead solder to contaninate the envoironment, but banning the lead in solder has increased the amouint of power required to produce electronic assemblies, thus helping global warming.

SMPs are used extensivly in medical, millitary and aerospace projects, where high reliability is required, that is a fact, and on that note the failure rates is not as bad as made out, though other safety measures are involved that go above consumer goods. Linear supplies and incandescent lightbulbs are being banned because of their inefficiency and as such they waste power.Lead free solder requires 240-260 deg C reflow compared with 210-235 deg C for tine lead eutectic solder, thus we have to heat the reflow ovens and solder to at least 30 deg C higher for PB free soldering, so we burn extra energy.

I have been heavily involved with the change from leaded solders to lead free, mianly in the build up to PB free day in 2006, and have experience in both the change in PCB design requirements (minimal) and the changes in production departments to cater for lead free solders. As well as being involved in many tests with various combinations of Pb free solder formulations to achieve certain desired goals. I am still heavily involved with designs that have to use tin/lead solder and the problems that incurs when the majority of the components are now terminated with a Pb free compatible terminations (matt tin on passive components etc and Pb free solder balls on BGA's). This brings its own set of problems in creating reliable assemblies with good joints, BGA's have to be re-balled with eutectic tin lead solder balls (at approx 2p per pin) etc etc.

Lead was banned from electronics cos the lentil suckers got a bee in their bonnet about lead in the envoironment, it is almost impossible for lead in tin lead solder to contaninate the envoironment, but banning the lead in solder has increased the amouint of power required to produce electronic assemblies, thus helping global warming.

As he said, he's playing Devils Advocate. SMPS's are used in numerous life critical and high reliability situations. Cheep imports and cheep products will always be desined down to a price.

The reason linear PSU's are being banned is because they are not efficient and for every linear supply we replace with a SMPS we save 0.001 Polar bears, so its got to be a good thing. plus we also need to save power wasted by power supplies to have enough energy left to heat up the lead free solder to the 20-30 degrees it melts at above a good eitectic tin lead solder.

Good thing is my amps using just for heaters double the max output power.

If I use 10% output in average the global efficiency will be about 3,1%. OUCH,

...

" ... incandescent lightbulbs are being banned because of their inefficiency and as such they waste power...

They are inefficient as light generators. They are quite efficient as heaters.

What happens when the desired output is both heat and light? They are 100% efficient.

In cold climates, switching to non-incandescent bulbs results in increased energy costs, as the lost heat must be replaced by natural gas, other fossil fuels, or increased electrical generation.

BC Hydro (Province of British Columbia, Canada) published a paper that calculated the increased demand and CO2 emissions that a 100% switch to CFL from incandescent would generate. It wasn't trivial, and illustrates the problem with "Global" approaches to problems.

Somewhat back on topic, does anyone know of a lead-free that can sub for tin-lead, taking into consideration reliability of the joint and whisker issues? Is there any that come close ... ie they are simply not as bad as the competition?

Last edited:

I am building a "Counter Pressure Bottling Station" for bottling beer. The last one I made I got rid of about 8 years ago when I quit brewing for a couple of years.

I have since started brewing again and decided to build a new bottling station.

I spent two days looking for my Lenox Sterling Lead free (Tin/Antimony/Copper) solder that I use for all my plumbing copper work, to no avail.

Today I stopped by the local Lowes and they no longer carried it. The only "Lead Free" solder they had was Worthington 331909 WS15031 Rosin Core solder.

4oz for around $10.

Being desperate I bought it.

I must say, "This is the Cats Meow" for soldering copper pipe!

It solders like good Kester 63/37 rosin core solder. It flows beautifully.

The MSDS shows mostly tin with 3-5% copper and 1.5-3% rosin.

https://worthingtonindustries.com/g...in-Core-Lead-Free-Solder-Canada-(English).pdf

I don't know how this would work for electronic work, but it might be worth a try.

I have since started brewing again and decided to build a new bottling station.

I spent two days looking for my Lenox Sterling Lead free (Tin/Antimony/Copper) solder that I use for all my plumbing copper work, to no avail.

Today I stopped by the local Lowes and they no longer carried it. The only "Lead Free" solder they had was Worthington 331909 WS15031 Rosin Core solder.

4oz for around $10.

Being desperate I bought it.

I must say, "This is the Cats Meow" for soldering copper pipe!

It solders like good Kester 63/37 rosin core solder. It flows beautifully.

The MSDS shows mostly tin with 3-5% copper and 1.5-3% rosin.

https://worthingtonindustries.com/g...in-Core-Lead-Free-Solder-Canada-(English).pdf

I don't know how this would work for electronic work, but it might be worth a try.

Hi All,

... Also joining in on reviving an older thread as I soon need to refresh my solder stock and would prefer to switch to lead free solder - IF it is now as good as the leaded types ...

Some years ago I tried different lead free solders, however, experienced that the higher melting temperatures and also a very rapid deterioration of my soldering tips (original Weller) were not feasible side effects of such solders.

Yet, I would prefer to shift to lead-free solder so if it is now available in "as good" quality as leaded solder I'd appreciate hearing about your good experiences ...

Cheers & thanks,

Jesper

... Also joining in on reviving an older thread as I soon need to refresh my solder stock and would prefer to switch to lead free solder - IF it is now as good as the leaded types ...

Some years ago I tried different lead free solders, however, experienced that the higher melting temperatures and also a very rapid deterioration of my soldering tips (original Weller) were not feasible side effects of such solders.

Yet, I would prefer to shift to lead-free solder so if it is now available in "as good" quality as leaded solder I'd appreciate hearing about your good experiences ...

Cheers & thanks,

Jesper

I've written quite a bit on the topic, actually. You can read my thoughts here: Choosing Solder - Navigate the Different Alloys, Types of Flux, etc. – Neurochrome

I've tried SAC305. It's not great but does the job. AIM Sn100C is supposed to be much better. That's available under the generic name "Germanium-doped 99.3/0.7 (Sn/Cu)". Kester has a version called K100LD. Instead of germanium, they dope the 99.3/0.7 Sn/Cu with bismuth. The germanium/bismuth doping reduces bridging. I'll try one of those next.

But unless you have to change to lead-free, I would stay with 60/40 or 63/37 (Sn/Pb) solder.

For leaded solder I'd use 700 ºF (371 ºC) tip temperature. I use 800 ºF (427 ºC) with lead-free solder.

Tom

I've tried SAC305. It's not great but does the job. AIM Sn100C is supposed to be much better. That's available under the generic name "Germanium-doped 99.3/0.7 (Sn/Cu)". Kester has a version called K100LD. Instead of germanium, they dope the 99.3/0.7 Sn/Cu with bismuth. The germanium/bismuth doping reduces bridging. I'll try one of those next.

But unless you have to change to lead-free, I would stay with 60/40 or 63/37 (Sn/Pb) solder.

For leaded solder I'd use 700 ºF (371 ºC) tip temperature. I use 800 ºF (427 ºC) with lead-free solder.

Tom

The reason why there is lead in the solder in the first place:

From Wiki...

Whiskers can cause short circuits and arcing in electrical equipment. The phenomenon was discovered by telephone companies in the late 1940s and it was later found that the addition of lead to tin solder provided mitigation.[4] The European Restriction of Hazardous Substances Directive (RoHS), that took effect on July 1, 2006, restricted the use of lead in various types of electronic and electrical equipment. This has driven the use of lead-free alloys with a focus on preventing whisker formation, see § Mitigation and elimination. Others have focused on the development of oxygen-barrier coatings to prevent whisker formation

From Wiki...

Whiskers can cause short circuits and arcing in electrical equipment. The phenomenon was discovered by telephone companies in the late 1940s and it was later found that the addition of lead to tin solder provided mitigation.[4] The European Restriction of Hazardous Substances Directive (RoHS), that took effect on July 1, 2006, restricted the use of lead in various types of electronic and electrical equipment. This has driven the use of lead-free alloys with a focus on preventing whisker formation, see § Mitigation and elimination. Others have focused on the development of oxygen-barrier coatings to prevent whisker formation

Actually it is...

To prevent the whiskers other metals need to be added and these unfortunately have a higher melting point.

If we could use only tin then this would be much lower.

Tin Whiskers Are Real and Complex - Maxim Integrated

To prevent the whiskers other metals need to be added and these unfortunately have a higher melting point.

If we could use only tin then this would be much lower.

Tin Whiskers Are Real and Complex - Maxim Integrated

Last edited:

The reason why there is lead in the solder in the first place:... it was later found that the addition of lead to tin solder provided mitigation....

???

Wiki has it backward.

Solder had Lead long before any telephone was made. Like 5,000 years ago.

Pure Tin is very expensive and hard to melt. Pure Lead is not too expensive but still hard to melt. Alloys (generally!) have lower melting point than either metal alone. Since Tin is often found mixed with Lead, a Tin/Lead mix was used for jewelry, cookware, sword fittings, glassware, etc.

- Home

- Design & Build

- Equipment & Tools

- Good lead free solder availible yet?