Back to the hmn...

I'm struggling to find suitable connectors to get between the psu and phono stage.

I obviously want to make sure that the psu can't have exposed pins with HT on them if not connected.

I did find a 5 pole connector that looked OK but as it had a plastic body I couldn't connect protective earth through that. At least that's what it looks like sy did in the pictures.

The 6 pole version isn't stocked any more.

I don't know how I feel about having a 5 pole cord and then a totally separate earth bond wire connected by screw down binding posts. I would use the crimp type connector that looks like an earth tag that goes over the bolt that gets screwed down so it can only come off it the nut comes completely off too.

I'm struggling to find suitable connectors to get between the psu and phono stage.

I obviously want to make sure that the psu can't have exposed pins with HT on them if not connected.

I did find a 5 pole connector that looked OK but as it had a plastic body I couldn't connect protective earth through that. At least that's what it looks like sy did in the pictures.

The 6 pole version isn't stocked any more.

I don't know how I feel about having a 5 pole cord and then a totally separate earth bond wire connected by screw down binding posts. I would use the crimp type connector that looks like an earth tag that goes over the bolt that gets screwed down so it can only come off it the nut comes completely off too.

I ran an 18 gauge stranded through plastic connectors between my separate psu and phono stage on my EO phono stage build. I know that 18 gauge doesn't sound that big in the event of a failure, but it will pass 16 Amps which should be enough to blow the fuse in the event of a failure. 600 V wire, of course.

I agree with kevinkr, there a lots of connector options at digikey, mouser, etc. A lot of the industrial connectors are good for high voltage and reasonably priced.

I agree with kevinkr, there a lots of connector options at digikey, mouser, etc. A lot of the industrial connectors are good for high voltage and reasonably priced.

cheers. In the end i got an ampehnol c16 3 which is really strudy and the female contacts are well recessed with a dedicated protected earth contact which is more prominent so it would lose contact last.

Ended up getting some 7 core rather than 6 core wire. Could find anything suitable that they would sell per meter. I really dont need a reel of it! 16awg and fits the amphenol and the gland on the other end perfectly.

A bit more than i wanted to spend but this is definitely not going to fall apart or get tugged out leaving either one chassis ungrounded or 300+volts on a pin!

Cheers

Ended up getting some 7 core rather than 6 core wire. Could find anything suitable that they would sell per meter. I really dont need a reel of it! 16awg and fits the amphenol and the gland on the other end perfectly.

A bit more than i wanted to spend but this is definitely not going to fall apart or get tugged out leaving either one chassis ungrounded or 300+volts on a pin!

Cheers

My next question is about strip board/perf board. I need to construct the HT supply and HT regs old school.

What do people find best/easiest?

1. perf board, which i think it just single pads that you solder connecting wires along,

2. Strip/Varioboard.

3. Groups of three padboard. I usually find myself wishing these were in strips of 4 or 5 holes.

Ive built a few things on strip and groups of three but usually takes a while (more than a while sometimes) to work out how to lay it out.

Do i also need to worry about high voltages on these things? I cant find any voltage ratings on the datasheets.

I did find some nice strip board in maplin a while back which was fibreglass rather than the cardboardy orange stuff and tinned strips.

What do people find best/easiest?

1. perf board, which i think it just single pads that you solder connecting wires along,

2. Strip/Varioboard.

3. Groups of three padboard. I usually find myself wishing these were in strips of 4 or 5 holes.

Ive built a few things on strip and groups of three but usually takes a while (more than a while sometimes) to work out how to lay it out.

Do i also need to worry about high voltages on these things? I cant find any voltage ratings on the datasheets.

I did find some nice strip board in maplin a while back which was fibreglass rather than the cardboardy orange stuff and tinned strips.

I used some group of 5 padboard that I found at Mouser or Farnell. You can see a picture of it in post 223 of the Equal Opportunity MM Pre thread. The regulators are on another of the same board. Happily, the EO doesn't use quite as high a voltage as the HMN, but I was probably pushing it because the gap between pads isn't that big. I did manage to keep unconnected pads between high voltage and ground on the high voltage circuits.

Given the high voltages in the HMN, I might be tempted to use perf board and high voltage insulated wire from point to point.

Jac

Given the high voltages in the HMN, I might be tempted to use perf board and high voltage insulated wire from point to point.

Jac

there was a post recently regarding heater voltages. I think more to do with the equal opportunity amp but i want to just check Ive understood correctly.

For the HMN,

One output board will have the heaters connected to 65v and 71.3v giving a diff of 6.3v

and the other output board would have 65v and 58.7v also giving a difference of 6.3v

Presumably the positive 6.3v and negative 6.3v is because thats an easy way to elevate the voltage using the transformer.

If i tried to use 65v+/-3.15 V then they would be floating and i would also have major problems trying to stop my regulators overheating.

Does it matter which pin (4 or 5) gets the 65v?

Im assuming not but for my OCD I sort of want

Board A

pin 5 71.3v

pin 4 65v

Board B

pin 5 65v

pin4 58.7v

For the HMN,

One output board will have the heaters connected to 65v and 71.3v giving a diff of 6.3v

and the other output board would have 65v and 58.7v also giving a difference of 6.3v

Presumably the positive 6.3v and negative 6.3v is because thats an easy way to elevate the voltage using the transformer.

If i tried to use 65v+/-3.15 V then they would be floating and i would also have major problems trying to stop my regulators overheating.

Does it matter which pin (4 or 5) gets the 65v?

Im assuming not but for my OCD I sort of want

Board A

pin 5 71.3v

pin 4 65v

Board B

pin 5 65v

pin4 58.7v

Ive also noticed that the pcbs i have specify C5 and C4 as X2 rated.

Ive had a look at the impasse schematics and boards and there are caps doing the same job under more stress but no mention of X2 ratings in these cases. Do they actually need to be X2 or are the standard wima mkp ok?

I managed to order 1uF 250v by mistake for C5 (just to add to a stack of 1uF 250v mks4s i already had!), i appreciate that this probably does need to be 400v as until the HV regs stabilise there could be more than 250v across it.

I do have some 2.2uF 400v MKP4 and some 0.68uF and 0.33uF 600v multicaps. But tbh the 0.68 is a bit on the large side for the board.

Would either of these do or does it really need to be 1uF?

Ive had a look at the impasse schematics and boards and there are caps doing the same job under more stress but no mention of X2 ratings in these cases. Do they actually need to be X2 or are the standard wima mkp ok?

I managed to order 1uF 250v by mistake for C5 (just to add to a stack of 1uF 250v mks4s i already had!), i appreciate that this probably does need to be 400v as until the HV regs stabilise there could be more than 250v across it.

I do have some 2.2uF 400v MKP4 and some 0.68uF and 0.33uF 600v multicaps. But tbh the 0.68 is a bit on the large side for the board.

Would either of these do or does it really need to be 1uF?

Hi peafarmer. I think the cap you are refering to in the psu is across AC mains. I see why that needs to be X2 rated.

C5 on the output board is decoupling the 160v dc rail across the last tube stage. But potentially may see more until stabilized hence 400v rating as raw B+ will be around 350v.

C4 is the output blocking capacitor of the audio. Doesnt an X2 rated cap seem a bit industrial in this position?

Arent film caps self healing as well, with a tendency to fail open?

Thanks

C5 on the output board is decoupling the 160v dc rail across the last tube stage. But potentially may see more until stabilized hence 400v rating as raw B+ will be around 350v.

C4 is the output blocking capacitor of the audio. Doesnt an X2 rated cap seem a bit industrial in this position?

Arent film caps self healing as well, with a tendency to fail open?

Thanks

I admit up front, this is an apples and oranges comment, but at least the design was a phono pre by SY in both cases.

In the EO MM pre, SY uses caps in the same way, decoupling the rail and output blocking cap. In the EO BOM and schematic higher than rail voltages are specified for the caps (but only 125 V B+ rail). However, no mention of X caps. I checked because I know I used an audio cap for the output blocking caps and I think I did for the rail cap as well.

I will leave it to you to infer what you want for that, but I'm glad I used audio caps for blocking because I tried a couple and came away with a preference.

Jac

In the EO MM pre, SY uses caps in the same way, decoupling the rail and output blocking cap. In the EO BOM and schematic higher than rail voltages are specified for the caps (but only 125 V B+ rail). However, no mention of X caps. I checked because I know I used an audio cap for the output blocking caps and I think I did for the rail cap as well.

I will leave it to you to infer what you want for that, but I'm glad I used audio caps for blocking because I tried a couple and came away with a preference.

Jac

Hmm. Neither article specified x rated caps. Just was printed on the pcb I received. I can definitely see why you would not want them to fail. It would be ugly. Maybe just covering himself?

The impasse has been fine with a wima. Although that's rated at 630v but it does have a 350v rail. It's only 0.1uf.

Does anyone know how you decide what value to use for decoupling the rails across tubes?

The impasse has been fine with a wima. Although that's rated at 630v but it does have a 350v rail. It's only 0.1uf.

Does anyone know how you decide what value to use for decoupling the rails across tubes?

ht regs

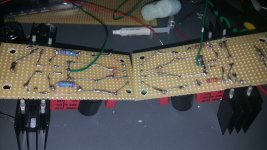

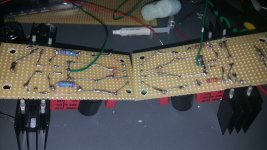

Built my HT regs.

Was wondering if there was a way of testing them without resorting to putting the ht supply on them.

Did continuity check to make sure that input to ground isnt shorted and also ht in to reg out.

Hooked up to bench supply. The outputs match each other, eg, 14v in produces 13.42v at the output on the 160v regs and 13.40v on the 260v regs. both sets match each other perfectly.

First time using perf board. Slightly time consuming but easier to figure out than strip board. Also suspect better for high voltage.

Is this the right idea?

Built my HT regs.

Was wondering if there was a way of testing them without resorting to putting the ht supply on them.

Did continuity check to make sure that input to ground isnt shorted and also ht in to reg out.

Hooked up to bench supply. The outputs match each other, eg, 14v in produces 13.42v at the output on the 160v regs and 13.40v on the 260v regs. both sets match each other perfectly.

First time using perf board. Slightly time consuming but easier to figure out than strip board. Also suspect better for high voltage.

Is this the right idea?

In case anyone thinks ive gone mad, the films have + - marked on them as i was trying the osciloscope noise test when holding them to try and ascertain which way they're coiled. Probably stacked, but hey ho. The transient when i grabbed them did seem slower one way than the other regardless of how theyre actually made.

That's pretty much what my perf board projects look like. I can see you are a belt and suspenders man. I was told that I don't need heat sink grease if I am using a silicone pad.;-)

I have heard of some guys using a Variac to gently increase the input voltage so that they can check there are no surprises. If that's what you did with your bench supply, then it may be time to cross your fingers and go.

Jac

I have heard of some guys using a Variac to gently increase the input voltage so that they can check there are no surprises. If that's what you did with your bench supply, then it may be time to cross your fingers and go.

Jac

Im working on the heater supplies.

Both schematic suggests connecting the D3a first and the PCB also has 2 sets of holes for the D3a and only one for the 6922 also suggesting connecting the heater to the D3a first.

I was under the impression that you should connect the input tube at the end of the chain or is that more for AC supplies?

Both schematic suggests connecting the D3a first and the PCB also has 2 sets of holes for the D3a and only one for the 6922 also suggesting connecting the heater to the D3a first.

I was under the impression that you should connect the input tube at the end of the chain or is that more for AC supplies?

Cool, thanks.

Am now working on riaa network.

Currently I have matched 1 33n on both sides but needed 2 1000pf on one side and 1 1000pf on the other to match. They both measure 33.6nf when combined.

I managed to get the match using the same sort of caps on both channels as the different values I had were a mixture of mkp fkp and fks and didn't want to use a different sort to trim on one side compared to the other.

What do people think about stacking caps to match rather than buying a big bag and matching just 2?

I don't think my multimeter is particularly accurate but there's probably enough precision to get a reasonably close match even if the absolute value is slightly off.

Am now working on riaa network.

Currently I have matched 1 33n on both sides but needed 2 1000pf on one side and 1 1000pf on the other to match. They both measure 33.6nf when combined.

I managed to get the match using the same sort of caps on both channels as the different values I had were a mixture of mkp fkp and fks and didn't want to use a different sort to trim on one side compared to the other.

What do people think about stacking caps to match rather than buying a big bag and matching just 2?

I don't think my multimeter is particularly accurate but there's probably enough precision to get a reasonably close match even if the absolute value is slightly off.

- Home

- General Interest

- diyAudio.com Articles

- His Master's Noise: A Thoroughly Modern Tube Phono Preamp