In many, many traverse mechanisms, this motor is used as a spindle motor:

RF-300FA

Used in Sony, Philips, Sanyo Mechanisms.

A cheapo, i. e not suitable for heavy clamps. At least not durable

for decades. (For years, yes)

As far as i know, brushless motors are more reliable and sturdy. Never seen one with shafts thinner than 3mm. They were always the first

choice in first CD-Players and also first generation ROM drives before the companies cut corners.

Replacing a brushed motor with a brushless is not an easy task.

But I would like to give it a try.

As far as I know, in the world of RC-Cars and planes, there are voltage to PWM converters for doing this.

I am good in milling, soldering and buying parts - but very, very bad in designing.

Anone who can help me in designing a converter?

I assume, this mod will be very versatile and could be used in many players, if a small brushless motor (at least in diameter) can be found.

Maybe the Shigaclone guys could also benefit from this...

All the best,

Salar

RF-300FA

Used in Sony, Philips, Sanyo Mechanisms.

A cheapo, i. e not suitable for heavy clamps. At least not durable

for decades. (For years, yes)

As far as i know, brushless motors are more reliable and sturdy. Never seen one with shafts thinner than 3mm. They were always the first

choice in first CD-Players and also first generation ROM drives before the companies cut corners.

Replacing a brushed motor with a brushless is not an easy task.

But I would like to give it a try.

As far as I know, in the world of RC-Cars and planes, there are voltage to PWM converters for doing this.

I am good in milling, soldering and buying parts - but very, very bad in designing.

Anone who can help me in designing a converter?

I assume, this mod will be very versatile and could be used in many players, if a small brushless motor (at least in diameter) can be found.

Maybe the Shigaclone guys could also benefit from this...

All the best,

Salar

If I were to do this I would probably design a linear, sine wave three phase driver. Nothing plucked from the RC field will be like that. Since you're looking at very low output power the loss would hardly be significant, while the noise reduction may be. On the flip side, a better motor is probably a lot easier, even if it had brushes or self contained electronic commutation. If you can machine yourself then shaft size is not too big of a problem. You will probably have to entirely re-tune the servo if the dynamic performance of the new motor is much different, which is probably more complicated than you want. You'd also like a motor with very low torque ripple, like a coreless rotor type or something. Just using a wimpy motor sort of helps that automatically. A lot of CDROM drives use comparitively beefy 3PH brushless spindle motors.

Last edited:

I found this thread @ diyaudio. There is a solution for Philips mechanisms:

http://www.diyaudio.com/forums/digi...ade-board-cdm9-cdm12-transport-cd-player.html

http://www.diyaudio.com/forums/digi...ade-board-cdm9-cdm12-transport-cd-player.html

Hi,

I just finished replacing the worn out motor of my Garrard 35 and it is in a beta test right now. After tried some different motors I decided to see if I can replace it using a stepper motor and a micro. I am using a reflecting sensor, a small reflecting metal strip glued to the platen as a marker and an stepper motor. Used the micro to read the index marker every time the platen do a revolution and calculate the rpm of the platen and display it. Mounting it a bracket used to mount a camera in a Drone Helicopter. I used it to eliminated any vibration coming from the stepper motor. At beginning since the spindle was about 1/4 inches the stepper motor was whining due the high frequency 1000 kHz. Replacing the spindle with a larger pulley I was able to dropped the frequency to 622 KHZ and the whining when away. Now the system it is running very good and it is easy to implement it in any turntable. Attached are some pictures showing the implementation. The only problem it is that you need to know how to program the micro. The software it is in basic using the Zbasic micro. Total cost of the project it is about $75 dollars.

I just finished replacing the worn out motor of my Garrard 35 and it is in a beta test right now. After tried some different motors I decided to see if I can replace it using a stepper motor and a micro. I am using a reflecting sensor, a small reflecting metal strip glued to the platen as a marker and an stepper motor. Used the micro to read the index marker every time the platen do a revolution and calculate the rpm of the platen and display it. Mounting it a bracket used to mount a camera in a Drone Helicopter. I used it to eliminated any vibration coming from the stepper motor. At beginning since the spindle was about 1/4 inches the stepper motor was whining due the high frequency 1000 kHz. Replacing the spindle with a larger pulley I was able to dropped the frequency to 622 KHZ and the whining when away. Now the system it is running very good and it is easy to implement it in any turntable. Attached are some pictures showing the implementation. The only problem it is that you need to know how to program the micro. The software it is in basic using the Zbasic micro. Total cost of the project it is about $75 dollars.

Attachments

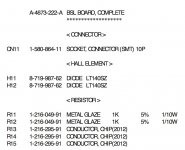

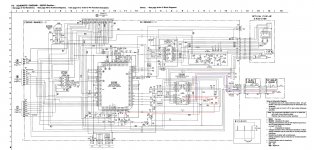

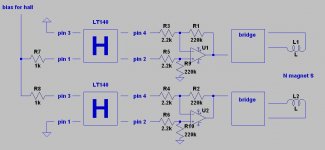

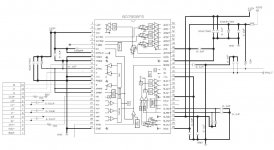

I made a comparison between the Sony CDP-X5000 and CDP-X3000.

The X5000 uses a brushless spindle motor, the X3000 a brushed one.

Could anyone explain the differences in the circuitry? The used almost the same IC´s. Hope I got the signal directions correct. I do not understand the

function of the hall elements LT140SZ. Unfortunately I did not find any datasheets...

The X5000 uses a brushless spindle motor, the X3000 a brushed one.

Could anyone explain the differences in the circuitry? The used almost the same IC´s. Hope I got the signal directions correct. I do not understand the

function of the hall elements LT140SZ. Unfortunately I did not find any datasheets...

Attachments

Hello artegagt

thanks a lot for the proposal and the effort! "Expl.jpeg" is a description

of the CDP-X5000 circuitry? What function does the bridge have?

And how could an IC solution look like?

LT140 Datasheet is attached...

thanks a lot for the proposal and the effort! "Expl.jpeg" is a description

of the CDP-X5000 circuitry? What function does the bridge have?

And how could an IC solution look like?

LT140 Datasheet is attached...

Attachments

Last edited:

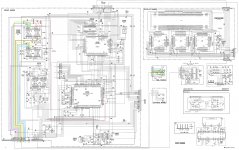

I case anyone wants the X5000 / X3000 circuits in higher resolution:

http://www.filedropper.com/x5000x3000servoboards

Sorry, you´ll have to answer a captcha and it will take some seconds until you can download...

http://www.filedropper.com/x5000x3000servoboards

Sorry, you´ll have to answer a captcha and it will take some seconds until you can download...

Last edited:

Hello artegagt,

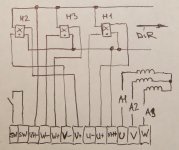

with bridge you mean the driver buffer @outputs 1/2 I guess?

I also have some CD-Rom brushless Motors to play with but the goal is to find a

brushless replacement for common circuitries used today. Again, the Mabuchi RF-300 Motor is used in spindle drives of many players. Here is one example

of a very common servoboard used in many Players from small manufacturers. It can be used with Sanyo and Sony mechanisms, both have RF-300 Motor. Also the Philips CD-Pro2 uses RF-300 and I assume, also the Shigaclones...

with bridge you mean the driver buffer @outputs 1/2 I guess?

I also have some CD-Rom brushless Motors to play with but the goal is to find a

brushless replacement for common circuitries used today. Again, the Mabuchi RF-300 Motor is used in spindle drives of many players. Here is one example

of a very common servoboard used in many Players from small manufacturers. It can be used with Sanyo and Sony mechanisms, both have RF-300 Motor. Also the Philips CD-Pro2 uses RF-300 and I assume, also the Shigaclones...

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Digital Source

- Replacing a Brushed Motor with a Brushless Motor - Advice needed.