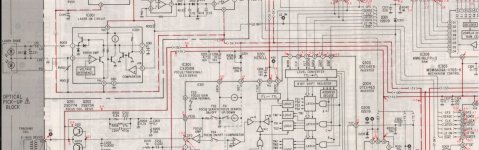

hi. i just had similar problem - mine cdp701es machine after 1 hour started skipping and finally stops. After cooling period it started working and same happens again. Im opened it and found noise from the laser head, also found the lens moves in one directon after power up. It shouldnt happens. Im found guilty stk 6922 and replaced by bx1201 taken from another cdp101 player. After replace i had to adjust tracking gain, focus gain and "jump" to bring the player back to normal operation. my question is where can i buy bx1201, i wish to fix my 101 back to life. also i have the cdp501 bought from flea market but it goes only after about 1hr warm up. I cleaned and replaced greese on gears, still the same happens. Any suggestions about this one?

Google provides still some suppliers of the diodes itself, if you use the key words "KSS-151A" and "ebay". The showed diodes are also suitable for the most other optical pick up devices from SONY (like KSS152, KSS271, KSS150), as mentioned in the previous posting, and this diodes are successors for the used diodes at those days, the SLD-104U.check out the ebay item No

271029488132

and

260834703729

But where is the supplier for the replace performing itself?

Here an example found by Google in Germany:

5 piece Sony KSS-151A Laser Lens LD Laser Diode 780nm 3-5mw 5.6mm | eBay

Unfortunately I am still not able to find those company, which are able to remove the old diode replace the new diode include all necessary mechanical adjustments.

Who can help to find such companies or guys?

any news?

check out post #85 under

http://www.diyaudio.com/forums/digi...l-pickups-sonys-kss-series-9.html#post4803400

check out post #85 under

http://www.diyaudio.com/forums/digi...l-pickups-sonys-kss-series-9.html#post4803400

I would assume there are none.

I am very busy with building this:

http://www.diyaudio.com/forums/digi...-long-gone-let-us-build-one-ourselves-63.html

When I find the time, I will work on replacing the Sharp laser diode in Sony transports. (As far as I remember something like LC22 as designation. Is used by early generation Philips players as well)

As we all know, adjusting diffraction grating is the culprit. I got 10 diodes half a year ago but the other problem is that those

diodes may have suffered damage from ESD. They were packed in material that does not built up static, but conductive foam was completely missing.

Did not have time to check them yet. The only way for me to do is to built them into a laser unit.

I am very busy with building this:

http://www.diyaudio.com/forums/digi...-long-gone-let-us-build-one-ourselves-63.html

When I find the time, I will work on replacing the Sharp laser diode in Sony transports. (As far as I remember something like LC22 as designation. Is used by early generation Philips players as well)

As we all know, adjusting diffraction grating is the culprit. I got 10 diodes half a year ago but the other problem is that those

diodes may have suffered damage from ESD. They were packed in material that does not built up static, but conductive foam was completely missing.

Did not have time to check them yet. The only way for me to do is to built them into a laser unit.

Hi Salar,

Please continue your efforts in learning how to replace the laser diode in the best old Sony transports. I am a huge fan of these great old machines and currently own a 555esd, 2x 337esd and 1x 333esd all with BU-1E or KSS-190a transports.

If you can sucessfully replace the laser diodes in these machines it will be a great service to the classic Hi Fi community. I applaud your efforts!

Please continue your efforts in learning how to replace the laser diode in the best old Sony transports. I am a huge fan of these great old machines and currently own a 555esd, 2x 337esd and 1x 333esd all with BU-1E or KSS-190a transports.

If you can sucessfully replace the laser diodes in these machines it will be a great service to the classic Hi Fi community. I applaud your efforts!

Aahhhh...

(stretches and yawns)

I have not posted in at least a year, so greetings, audiophiles and general audio enthusiasts. First of all, let me start my awakening by saying this:

FOR SALE (OR FREE TO A GOOD HOME)

Harman Kardon HD500 cd player

Will read erratically, has repeat function, cosmetically a bit rough.

I am moving, I don't need this anymore, no time to fix it (much less to replace a laser diode in it)

Secondly, with all this talk about replacing laser diodes, which seems like a grand idea, we must consider the reason for which we are doing this. To read compact discs. Question:

How long does the media last? 30 years? 50 years?

We might be spending lots of time and effort in order to gain very little listening time. CDs will eventually go out of fashion, as did Vinyl.

did I go too far?

cheers,

Gain Wire

(stretches and yawns)

I have not posted in at least a year, so greetings, audiophiles and general audio enthusiasts. First of all, let me start my awakening by saying this:

FOR SALE (OR FREE TO A GOOD HOME)

Harman Kardon HD500 cd player

Will read erratically, has repeat function, cosmetically a bit rough.

I am moving, I don't need this anymore, no time to fix it (much less to replace a laser diode in it)

Secondly, with all this talk about replacing laser diodes, which seems like a grand idea, we must consider the reason for which we are doing this. To read compact discs. Question:

How long does the media last? 30 years? 50 years?

We might be spending lots of time and effort in order to gain very little listening time. CDs will eventually go out of fashion, as did Vinyl.

did I go too far?

cheers,

Gain Wire

Big setback in the moment - the Sharp LT022MC diodes I got from an ebay seller are all dead. I have to deal with diodes I got from Rohm. Mechanically

they have a 5.6mm rim whereas the original Sharp have 9mm.

Does anyone out there has access to a metal 3D Printer?

An adapter could easily be milled from brass but there are notches

for alignment. This is why I would like a printed one.

I also cannot read from the datasheet if astigmatism is different.

Electrical characteristics have to be adapted as well. Anyone out there to do the math?

An APC for Sharp LT022MC diode is attached.

All the best,

Salar

they have a 5.6mm rim whereas the original Sharp have 9mm.

Does anyone out there has access to a metal 3D Printer?

An adapter could easily be milled from brass but there are notches

for alignment. This is why I would like a printed one.

I also cannot read from the datasheet if astigmatism is different.

Electrical characteristics have to be adapted as well. Anyone out there to do the math?

An APC for Sharp LT022MC diode is attached.

All the best,

Salar

Attachments

Update, the diodes seem to be ok. But misalignment of the diffraction grating is

that big that the disc won´t even speed up. Working on the BU-1C, I also recognize

that there seems to be possible misalignment vertically because the diode sits on

a spring and is fixed by a relatively flexible washer.

Also the diffraction grating and the diode seem to sit in a tube that is fixed within

the laser assembly. Did not check this in detail but an allen screw indicates it.

In the moment I assume, that the alignment was done complety outside the assembly and placed in the assembly.

Any ideas and hints about this are welcome. Any contacts to former Sony developers

or technicians familiar with this in factory alignment appreciated.

All the best,

Salar

that big that the disc won´t even speed up. Working on the BU-1C, I also recognize

that there seems to be possible misalignment vertically because the diode sits on

a spring and is fixed by a relatively flexible washer.

Also the diffraction grating and the diode seem to sit in a tube that is fixed within

the laser assembly. Did not check this in detail but an allen screw indicates it.

In the moment I assume, that the alignment was done complety outside the assembly and placed in the assembly.

Any ideas and hints about this are welcome. Any contacts to former Sony developers

or technicians familiar with this in factory alignment appreciated.

All the best,

Salar

Last edited:

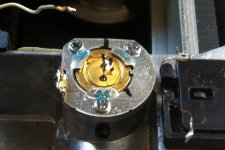

I did tear down a Sony KSS-123A laser some time ago:

http://www.diyaudio.com/forums/digi...et-us-build-one-ourselves-11.html#post4467651

Now I did the same with the BU-1C - please do not forget that this mech was working - in the moment it is sacrificed for good - I hope.

The following images show the assembly of the laser diode Sharp LT022MC.

The diode is being held in place by a washer that is fastened with three screws.

To my surprise, after unfastening the screws, the diode has much play in the washer, around 0.5mm.

If vertical misalignment and some horizontal offset had influence, this would be the first obstacle to overcome besides aligninging the grating.

The spring sits on two washers that hold the diffraction grating in place. The glass of the grating is glued into in a white plastic frame.

I assume two washers give lsser friction to keep the grating movable for adustment. To my knowledge, the adrustment is done by turning the grating.

After removing the grating you sees a little bit of thread locking fluid. But it has no strength, the grating can be easily removed.

It looks like the assembly is placed in a tube that is placed in the die cast casing.

An allen screw indicates that. Even though it looks like that the allen screw holds the diffraction grating in place this is not the fact.

But I have no fitting allen key in the moment to check that.

BTW the brass parts that can be seen in the hole mostly at the lower part of the images belong to the photodiode array.

I assume that the alignment was done before the laser diode & diffraction grating were placed in the laser assembly.

Again, any ideas about this is are appreciated.

If someone knows someone who knows somebody who knows someone who was involved in the manufacturing process - tell me!

http://www.diyaudio.com/forums/digi...et-us-build-one-ourselves-11.html#post4467651

Now I did the same with the BU-1C - please do not forget that this mech was working - in the moment it is sacrificed for good - I hope.

The following images show the assembly of the laser diode Sharp LT022MC.

The diode is being held in place by a washer that is fastened with three screws.

To my surprise, after unfastening the screws, the diode has much play in the washer, around 0.5mm.

If vertical misalignment and some horizontal offset had influence, this would be the first obstacle to overcome besides aligninging the grating.

The spring sits on two washers that hold the diffraction grating in place. The glass of the grating is glued into in a white plastic frame.

I assume two washers give lsser friction to keep the grating movable for adustment. To my knowledge, the adrustment is done by turning the grating.

After removing the grating you sees a little bit of thread locking fluid. But it has no strength, the grating can be easily removed.

It looks like the assembly is placed in a tube that is placed in the die cast casing.

An allen screw indicates that. Even though it looks like that the allen screw holds the diffraction grating in place this is not the fact.

But I have no fitting allen key in the moment to check that.

BTW the brass parts that can be seen in the hole mostly at the lower part of the images belong to the photodiode array.

I assume that the alignment was done before the laser diode & diffraction grating were placed in the laser assembly.

Again, any ideas about this is are appreciated.

If someone knows someone who knows somebody who knows someone who was involved in the manufacturing process - tell me!

Attachments

Last edited:

I think this guy was successful:

A l?atelier... (page 54) - vintage-audio-laser.com

You´ve got to scroll down a bit, until "Sony CDP-502ES - Remplacement de la diode laser".

I contacted him -in english- but he did not reply. My french is very rusty, maybe someone else could try?

If he was successful, I assume that he did not touch the diffraction grating - the diode has some play. But I also assume that he was simply lucky;

the grating is fixed with thread locker. On my KSS-123A, much thread locker was used, the grating was more or less glued into place. A litte bit of force was needed to remove it.

But with the BU-1C, there was only a tiny drop of threadlocker. It had some play immediately when the spring between diode and grating was removed.

I bought some LT022MC diodes from ebay. I do not have a laser power meter

but the beam seems to be weaker than with the original diode

(I make photos because camera sensors "see" the light) Is it normal that diodes can differ from batch to batch in power consumption or is this already a sign of static damage?

(They were not packed well, only wrapped in non - charging plastic, but no conductive foam or ESD-bag)

All the best,

Salar

A l?atelier... (page 54) - vintage-audio-laser.com

You´ve got to scroll down a bit, until "Sony CDP-502ES - Remplacement de la diode laser".

I contacted him -in english- but he did not reply. My french is very rusty, maybe someone else could try?

If he was successful, I assume that he did not touch the diffraction grating - the diode has some play. But I also assume that he was simply lucky;

the grating is fixed with thread locker. On my KSS-123A, much thread locker was used, the grating was more or less glued into place. A litte bit of force was needed to remove it.

But with the BU-1C, there was only a tiny drop of threadlocker. It had some play immediately when the spring between diode and grating was removed.

I bought some LT022MC diodes from ebay. I do not have a laser power meter

but the beam seems to be weaker than with the original diode

(I make photos because camera sensors "see" the light) Is it normal that diodes can differ from batch to batch in power consumption or is this already a sign of static damage?

(They were not packed well, only wrapped in non - charging plastic, but no conductive foam or ESD-bag)

All the best,

Salar

Last edited:

According this various offers there must actually be anywhere special companies or guys, which have appropriate equipment for diode replacing and precision adjustment.Many of us still have first and second generation CD Players, built like tanks,

with linear motors, brushless disc motors, wonderful, heavy pieces of machinery and probably lasting forever - except the laser diodes.

And replacements for the pickups are no longer available or cost as much as a new player.

There are many Sony KSS-XXX Lasres out there, in many brands, with different physical dimensions, maybe different coil assemblies .

But what about the diodes?

Maybe many KSS-Lasers shared the same diode over the years, and maybe, besides the risk of static electrity, these diodes can easily be replaced?

Does anyone have information about this?

All the best,

Sal

2pcs SONY 780nm 3-5mw 5.6mm KSS-151A Laser Lens LD Laser Diode NEW-20 | eBay

SONY KSS-151A 3mw-5mW 780nm 5.6mm TO18 Infrared IR Laser/Lazer Diode LD | eBay

SONY KSS-151A 3mw-5mW 780nm 5.6mm TO18 Infrared IR Laser/Lazer Diode LD | eBay

1pc SONY KSS-151A 3mw-5mW 780nm 5.6mm TO18 Infrared IR Laser/Lazer Diode LD | eBay

Maybe one of the members from Taiwan can find out the addresses and websites.

Hi,

watching this and the other threads with interest. The Laser for my Pioneer is no longer available!!

Can I just ask though, in all the Players you are working on, have they stopped emmiting Light?

In all my years as a Repair Tech I think I can count on one hand the times a CD Laser was not lighting. The cause as I thought was the receiving Diode and the lack of a large enough pk-pk Output waveform.

Continue the good work.

P.

watching this and the other threads with interest. The Laser for my Pioneer is no longer available!!

Can I just ask though, in all the Players you are working on, have they stopped emmiting Light?

In all my years as a Repair Tech I think I can count on one hand the times a CD Laser was not lighting. The cause as I thought was the receiving Diode and the lack of a large enough pk-pk Output waveform.

Continue the good work.

P.

..... bringing the diffraction grating out of adjustment kills the laser...

Moving the Grating shouldn't kill the laser.

The Grating was an alignment to be carried out when replacing a Laser in a Pioneer.

Were you ant-static protected when working on it?

P.

Some important questions about the diffraction grating used in 3-beam lasers:

-When aligned, the "sweet spot" means that the side beams next to the center beam

have the same brightness? And a misaligment does not influence the distance between the beams, only their brightness?

- When being focused on the CD, the distance between the center beam and side beams is about 1.6µm as far as I remember. Not so important right now.

But very important: What is the distance before the beams enter the collimation lenses? Something still visible to the bare eye?

I assume the distance between the photodiodes on the receiving chip could be a reference?

All the best,

Salar

-When aligned, the "sweet spot" means that the side beams next to the center beam

have the same brightness? And a misaligment does not influence the distance between the beams, only their brightness?

- When being focused on the CD, the distance between the center beam and side beams is about 1.6µm as far as I remember. Not so important right now.

But very important: What is the distance before the beams enter the collimation lenses? Something still visible to the bare eye?

I assume the distance between the photodiodes on the receiving chip could be a reference?

All the best,

Salar

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Digital Source

- Dead Laser Pickups - why not replacing the Diode only?