Those are used a lot in LED lights, details there.

The aluminum is bonded on the insulated side of the board, it is there for heat dissipation. The tracks are usually copper, as in surface mount PCBs, and masked except at soldering points.

The insulating layer is thin for better heat transfer to the aluminum, which is a structural support too.

Not very useful in a DAC unless you use the aluminum as a ground plane or something. Or you have heating issues.

The aluminum is bonded on the insulated side of the board, it is there for heat dissipation. The tracks are usually copper, as in surface mount PCBs, and masked except at soldering points.

The insulating layer is thin for better heat transfer to the aluminum, which is a structural support too.

Not very useful in a DAC unless you use the aluminum as a ground plane or something. Or you have heating issues.

Last edited:

How do you make a PCB out of a conductor? It's usually an insulator with conductive traces.

Single sided board only. CIA = copper-insulator-aluminum.

The cheap offerings are all functionally single sided, less then ideal for most RF applications (And a DAC IS an RF application), especially as you cannot really via thru to the ally substrate to use it as the system ground plane.

What would actually be more useful would be a core manufactured and then bonded to the ally, as that way you could have a ground plane.

What would actually be more useful would be a core manufactured and then bonded to the ally, as that way you could have a ground plane.

Not worse than in a 4 layers board with the second layer from top a ground plane.

Never tried Al boards, but I would expect soldering to be a big problem, in particular for fine pitched parts. These boards are best to be reflowed rather than soldered manually, but reworking is still going to be a mess.

Never tried Al boards, but I would expect soldering to be a big problem, in particular for fine pitched parts. These boards are best to be reflowed rather than soldered manually, but reworking is still going to be a mess.

Last edited:

Of course traces are copper... but the presence of the aluminum sheet will dissipate the soldering heat, so you will either need to increase the temperature (and face the possibility of exfoliating the pads/traces), or use a powerful soldering iron (which will make soldering fine pitch parts difficult), or a hot air station with very hot air flow (which will make local soldering very difficult).

It is possible to pre-heat the entire board before and during the soldering, but then the soldering operation will become a quite unpleasant hot experience.

Better to reflow the board, but this requires a stencil, paste, and experience with a frying pan or oven.

And no, it is not a regular PCB bonded on aluminum, is a thin dielectric, with the copper traces patterned, bonded to aluminum. Otherwise, the heat transmission of a regular PCB is very low, cooling would be totally ineffective.

It is possible to pre-heat the entire board before and during the soldering, but then the soldering operation will become a quite unpleasant hot experience.

Better to reflow the board, but this requires a stencil, paste, and experience with a frying pan or oven.

And no, it is not a regular PCB bonded on aluminum, is a thin dielectric, with the copper traces patterned, bonded to aluminum. Otherwise, the heat transmission of a regular PCB is very low, cooling would be totally ineffective.

Last edited:

These are intended for machine soldering, with screen position of solder, machine placement of components and a single pass through a wave solder machine, or its equivalent.

After that there are automatic testing machines, and maybe skilled rework facilties.

It is not intended to be repaired.

And cost has to be low.

In short, a disposable item.

It is only us who repair those things...

After that there are automatic testing machines, and maybe skilled rework facilties.

It is not intended to be repaired.

And cost has to be low.

In short, a disposable item.

It is only us who repair those things...

There is no electrical connection between the copper traces and the aluminium sheet, so it cannot be used as a ground plane. If the MCPCB is single layer, this means no high frequency capabilities, so it is unsuitable for DACs.

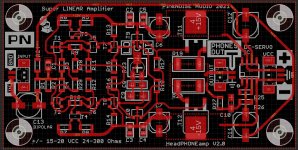

Aluminium MCPCB could be used to make SMD discrete opamps with a bit of power for a headphone amp though, for example. You can also get tight thermal coupling between a power transistor and a temperature sensor for bias regulation. But it would be preferable to make them as modules and mount them vertically on a base PCB, so they act as their own mini meat sinks. But then, dissipated power in a headphone amp should suit a normal FR-4 PCB, so, meh...

Maybe to use many fast SMD transistors in an output stage, then mounting the thing on a big heat sink...

4 layer has become cheap enough to be the default choice for hobby audio projects. For a board with enough components, time saved on routing is well worth the small extra cost... and you get extra performance.

Aluminium MCPCB could be used to make SMD discrete opamps with a bit of power for a headphone amp though, for example. You can also get tight thermal coupling between a power transistor and a temperature sensor for bias regulation. But it would be preferable to make them as modules and mount them vertically on a base PCB, so they act as their own mini meat sinks. But then, dissipated power in a headphone amp should suit a normal FR-4 PCB, so, meh...

Maybe to use many fast SMD transistors in an output stage, then mounting the thing on a big heat sink...

4 layer has become cheap enough to be the default choice for hobby audio projects. For a board with enough components, time saved on routing is well worth the small extra cost... and you get extra performance.

The dielectric between traces and aluminium is usually thinner than between layer 1 and 2 of a 4 layer board, so the stray capacitances are typically higher, but not grossly so - though it is available to custom thicknesses if you have the money.

Secondly the aluminium can be used as a ground plane, albeit very awkwardly by using bolts or rivets wherever a connection is needed - agreed this is not practical for most situations, but for high power components there's often bolt-through hardware. This at least means you can screen the circuit on one side, and even use the Al as a free busbar.

Soldering IMS is easy, its done by standard SMT reflow (definitely not wave soldering!), the difference in (volume) specific heat capacity is negligible(*) between FR4 and Al, heat capacity is not thermal conductivity, and conductivity isn't important if you heat the entire board at once. Just pick&place then cook!

(*) 10% different or so by my calculations.

Secondly the aluminium can be used as a ground plane, albeit very awkwardly by using bolts or rivets wherever a connection is needed - agreed this is not practical for most situations, but for high power components there's often bolt-through hardware. This at least means you can screen the circuit on one side, and even use the Al as a free busbar.

Soldering IMS is easy, its done by standard SMT reflow (definitely not wave soldering!), the difference in (volume) specific heat capacity is negligible(*) between FR4 and Al, heat capacity is not thermal conductivity, and conductivity isn't important if you heat the entire board at once. Just pick&place then cook!

(*) 10% different or so by my calculations.

- Home

- Source & Line

- Digital Line Level

- Aluminium PCB for DAC?