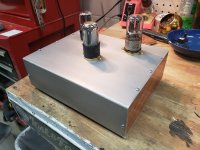

I am making a chassis for a tube phono preamp power supply and am using 22 gauge steel sheet. I want to have a "brushed aluminum" look so I was thinking of doing the appropriate sanding, etching it with glacial acetic acid and spraying it with clear coat. The open sides will be filled with hardwood flooring remnants I have.

I have done this with aluminum several times but I have never painted steel without priming first.

Will this work?

I have done this with aluminum several times but I have never painted steel without priming first.

Will this work?

Attachments

Probably should use a rust inhibitor as primer. Rustoleum sells one.

Thanks, just googled that. Seems cheap enough that I can try it on a piece of scrap to see what it looks like.

Yes.

Aluminum is easy, but steel RUSTS.

Problem is that even if your clear coast keeps oxygen away, any scratch will let it in and rust is both self catalyzed, so you need some kind of inhibitor.

If you dare, ($$$$$) your best option would be to steel brush finish it the way you like and chrome it, there is matte chrome available which combined with brushing is killer, *or* make it out of stainless steel , also brushed.

In any case, shine and tint will be superb, plain steel and even more if you pickle it in acid will be greyish by comparison.

Not sure bout Rustoleoum "transparency", I expect it to carry some solids, although I never used it.

Steel is a b*tch, personally I always use Aluminum, even if I need double thickness for strength.

But of course it´s your choice.

Aluminum is easy, but steel RUSTS.

Problem is that even if your clear coast keeps oxygen away, any scratch will let it in and rust is both self catalyzed, so you need some kind of inhibitor.

If you dare, ($$$$$) your best option would be to steel brush finish it the way you like and chrome it, there is matte chrome available which combined with brushing is killer, *or* make it out of stainless steel , also brushed.

In any case, shine and tint will be superb, plain steel and even more if you pickle it in acid will be greyish by comparison.

Not sure bout Rustoleoum "transparency", I expect it to carry some solids, although I never used it.

Steel is a b*tch, personally I always use Aluminum, even if I need double thickness for strength.

But of course it´s your choice.

Yes.

Aluminum is easy, but steel RUSTS.

Problem is that even if your clear coast keeps oxygen away, any scratch will let it in and rust is both self catalyzed, so you need some kind of inhibitor.

If you dare, ($$$$$) your best option would be to steel brush finish it the way you like and chrome it, there is matte chrome available which combined with brushing is killer, *or* make it out of stainless steel , also brushed.

In any case, shine and tint will be superb, plain steel and even more if you pickle it in acid will be greyish by comparison.

Not sure bout Rustoleoum "transparency", I expect it to carry some solids, although I never used it.

Steel is a b*tch, personally I always use Aluminum, even if I need double thickness for strength.

But of course it´s your choice.

I am not prepared to spend much on this, I know that "chrome" spray paint is available and that I could prime this and use that but I have never seen what chrome paint actually looks like. I have doubts that it looks like chrome. Not really looking for shiny, I usually go for matte finishes.

Yeah I have always used aluminum but wanted to try this and see what I could do with it, keeping it inexpensive and DIY.

This is an enclosure I made last year and I was wanting to get a "similar" look:

Attachments

Nice finish.

You can first protect iron with any "conventional" primer, any colour (not dissing transparent Rustoleum suggested above, simply never used it and can´t imagine what transparent inhibitor they use) and final paint with any silver coloured car type paint.

Won´t look like polished or brushed sheet metal surface of course, silver colour pigment is usually fine aluminum dust, a different texture.

But your picture above sort of suggests that.

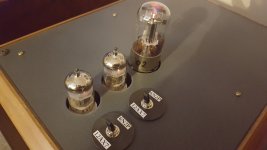

I see 3 different variations of "silver" surfaces there: neutral "painted look" main surface, bluish zinc plated screw heads and yellowish chrome or nickel plated socket rings.

Hues I mention are subtle, of course, only noticeable when side by side as in that picture.

You *might* brush or polish steel panel to your liking, send it to a zinc plater (it´s incredibly cheap, cheaper than paint, go figure) and have it zinc plated, basic process is always the same, but then ask for "blue passivation", they´ll know what you are talking about, is same as those screw heads (the alternative being "gold passivation", actually yellow-greenish, not really gold hue by any means)

Plain zinc is whitish or opaque silver, final passivation can give it very good shine (if you want that) as long as you do your homework and polish it before. (it hides nothing).

I make my own chassis, panels and speakers, so I was forced to explore and experiment all kinds of finishing.

PS:you might also sand blast your steel, since you like matte finish.

You can first protect iron with any "conventional" primer, any colour (not dissing transparent Rustoleum suggested above, simply never used it and can´t imagine what transparent inhibitor they use) and final paint with any silver coloured car type paint.

Won´t look like polished or brushed sheet metal surface of course, silver colour pigment is usually fine aluminum dust, a different texture.

But your picture above sort of suggests that.

I see 3 different variations of "silver" surfaces there: neutral "painted look" main surface, bluish zinc plated screw heads and yellowish chrome or nickel plated socket rings.

Hues I mention are subtle, of course, only noticeable when side by side as in that picture.

You *might* brush or polish steel panel to your liking, send it to a zinc plater (it´s incredibly cheap, cheaper than paint, go figure) and have it zinc plated, basic process is always the same, but then ask for "blue passivation", they´ll know what you are talking about, is same as those screw heads (the alternative being "gold passivation", actually yellow-greenish, not really gold hue by any means)

Plain zinc is whitish or opaque silver, final passivation can give it very good shine (if you want that) as long as you do your homework and polish it before. (it hides nothing).

I make my own chassis, panels and speakers, so I was forced to explore and experiment all kinds of finishing.

PS:you might also sand blast your steel, since you like matte finish.

A metallic silver/grey paint would look good and any future scratches (unlikely I know as you will take care) could be repainted. Plenty of shades including gunmetal, champagne and plain silver.

If clear coat was scratched you might end up repainting in metallic anyway.

Plain zinc plating can and will dull. Passivation helps.

I wouldn't use zinc plate on a large surface where it shows. 'Commercial finish' is how it would be described.

Unless you are going for steampunk?

If clear coat was scratched you might end up repainting in metallic anyway.

Plain zinc plating can and will dull. Passivation helps.

I wouldn't use zinc plate on a large surface where it shows. 'Commercial finish' is how it would be described.

Unless you are going for steampunk?

If you consider using a clear varnish keep in mind that they aren‘t suitable for outdoor uses (for steel applications that is)...

The easiest method I know of is cellulose laquer (we call it „Zaponlack“), but it is glossy, and not really resilient.

Better are PUR laquers, which you get as color or clear, glossy or mat (and everything between)

I personally don’t like steel that much because of it‘s blueish tint. But you could alter it with a very very thin glaze which you can apply with a brush, a spray-gun or even with a cloth (beware of a cloudy appearance though)

If you do that in many (very thin) coats, the tint becomes more intense, and may end in a very „deep“ appearance (a bit like urushi)—you literally look through the color with the steel shining through... gorgeous. this doesn‘t work well with hues containing white pigment.

The easiest method I know of is cellulose laquer (we call it „Zaponlack“), but it is glossy, and not really resilient.

Better are PUR laquers, which you get as color or clear, glossy or mat (and everything between)

I personally don’t like steel that much because of it‘s blueish tint. But you could alter it with a very very thin glaze which you can apply with a brush, a spray-gun or even with a cloth (beware of a cloudy appearance though)

If you do that in many (very thin) coats, the tint becomes more intense, and may end in a very „deep“ appearance (a bit like urushi)—you literally look through the color with the steel shining through... gorgeous. this doesn‘t work well with hues containing white pigment.

I know someone who bough an expensive brazed steel bike, he chose the clear " paint " as he presumed they'd do the brazing neater, however it rusted. Removing rust from bare steel is much much easier that removing clear coat and rust. Some people just use bees wax on steel. How about taking it to some chrome platers and having it copper plated - cool. You could heat it and dip in oil, repeat until it goes black - in an open well ventilated space.

Auto parts stores have all kinds of wheel paint. Many of these colors are shades of silver or grey, to kind of match OEM wheel colors. Because honestly, priming and painting it is your best bet for a durable finish and corrosion protection.

I used some Eastwood wheel paint on some wheels. They're charcoal grey. That was over 15 years ago and they still clean up and look custom.

Spray thin coats and you won't dull the look of the metal. I think you want a dull matte finish but that's up to you.

I used some Eastwood wheel paint on some wheels. They're charcoal grey. That was over 15 years ago and they still clean up and look custom.

Spray thin coats and you won't dull the look of the metal. I think you want a dull matte finish but that's up to you.

I decided not try clear coat directly on the steel. Going to prime it and spray it with some type of silver or aluminum paint.

Then I might use a matte clear coat over the paint, I used a matte clear coat over paint a long time ago and it came out nice. This is a top plate I did that way, the matte clear coat is over flat black. The plate is aluminum but I don't think that will make much difference.

Then I might use a matte clear coat over the paint, I used a matte clear coat over paint a long time ago and it came out nice. This is a top plate I did that way, the matte clear coat is over flat black. The plate is aluminum but I don't think that will make much difference.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Clear coat over steel?