I think jean-paul is describing the commonly-cited example here, in a roundabout way, just without the diodes:Let's see: in a 230V circuit with a 13A breaker, a short circuit would require a 10 Ohm resistor to deal with about 5000 Watts of power until the circuit breaker gets around to tripping.

The 10 Ohm resistor should be placed between the audio circuit common (aka ground) and the chassis. The PE/SG must be connected directly to the chassis.

Earthing (Grounding) Your Hi-Fi - Tricks and Techniques (which synonymous already linked to in this thread)

As shown, the chassis is still directly connected to PE, but 0V / audio ground is connected through the loop breaker. The diodes are intended to protect the resistor from the very situation you are worried about.

Yes it isis the source device balanced?

Yes it is

If you have analogue and digital circuits keeping the grounding separate it critical to limit digital noise in the audio.

I agree with the analogue grounding via a circuit breaker to earth, this creates screening needed to improve hum immunity.

Digital can float from the case as this is sensitive to power spikes which can come from earth.

Where to connect digital and analogue grounds is a big question.

I have an ADC and DAC so I have arranged the grounds to be connected very close to the chip. All analogue grounds go back to a common analogue star ground at the circuit breaker.

I still have noise issues from the switching currents in a large OLED display and plan to galvanically isolate that with a DC-DC converter and SPI isolator.

Any other thoughts on how to do this?

Personally I favour a single 'Ground plane', with the analogue and digital doings kept well separate and careful consideration of where I connect reference nodes to the plane (Hierarchical grounding), in particular the 'ground that forms the common with the two opamp decoupling caps is surprisingly dangerous if you want low THD.....

A slit or two can help as well, but NO nets should cross the slit, and in a balanced or differential IO scenario the board should only be connected to chassis at one point (Difficult if USB <Spit> is involved).

The trick is to remember that currents flow in loops, and you generally wish to minimise loop areas, so that I2S bus should really be above a ground plane connecting the analogue and digital doings.

4 Layer boards are your friends, who got time for two layer these days?

A slit or two can help as well, but NO nets should cross the slit, and in a balanced or differential IO scenario the board should only be connected to chassis at one point (Difficult if USB <Spit> is involved).

The trick is to remember that currents flow in loops, and you generally wish to minimise loop areas, so that I2S bus should really be above a ground plane connecting the analogue and digital doings.

4 Layer boards are your friends, who got time for two layer these days?

Just a few points:

a] 'earth' has many different meanings and in a thread like this, different posters may have different meanings.

b] AC in this type of thread, power line Alternating Current.

c] PE/SG = Protective Earth/Safety Ground. This is the path from a component chassis back to the Neutral connection at the building entrance. While it does have continuity to the Planet Earth connection, this is far from it's primary purpose.

d] a shield does not require a path to the PE/SG or to Planet Earth to function as a shield.

e] in a XLR interconnect, pin #1 is the shield it is not the audio circuit common (aka ground). It should be attached to the chassis at the connector.

a] 'earth' has many different meanings and in a thread like this, different posters may have different meanings.

b] AC in this type of thread, power line Alternating Current.

c] PE/SG = Protective Earth/Safety Ground. This is the path from a component chassis back to the Neutral connection at the building entrance. While it does have continuity to the Planet Earth connection, this is far from it's primary purpose.

d] a shield does not require a path to the PE/SG or to Planet Earth to function as a shield.

e] in a XLR interconnect, pin #1 is the shield it is not the audio circuit common (aka ground). It should be attached to the chassis at the connector.

the abbreviation 'gnd' comes under point [a]D and E seem in conflict. A shield not connected to gnd is an aerial.

Think about electronic equipment in cars and airplanes.

I managed to get the amp built and working thanks to the advice in this thread, chassis seems safely grounded (as per the approach outlined by @sq225917) and no audible noise issues.

By audible I mean, I can connect a 110dB CD to it and if I put that next to my ear then the noise is consistent across every channel, this is inaudible at maybe a foot or so away. Whether this is a good result or not I don't know but it doesn't seem to be an issue for me.

A pic of the interior for reference, if there is anything that could be improved then appreciate any tips. Hindsight says I should have cut the signal cables a bit shorter & used separate heatsinks for the 3 amps so I could run power cables between the heatsinks.

I had bought the parts already before this thread so decided to build it as is but the bit I still don't understand is why I don't have a problem with hum. The XLR connectors are grounded to the chassis and the chassis is earthed so why no noise problem? (which I was expecting given comments in the thread). I am clearly missing something.

By audible I mean, I can connect a 110dB CD to it and if I put that next to my ear then the noise is consistent across every channel, this is inaudible at maybe a foot or so away. Whether this is a good result or not I don't know but it doesn't seem to be an issue for me.

A pic of the interior for reference, if there is anything that could be improved then appreciate any tips. Hindsight says I should have cut the signal cables a bit shorter & used separate heatsinks for the 3 amps so I could run power cables between the heatsinks.

I had bought the parts already before this thread so decided to build it as is but the bit I still don't understand is why I don't have a problem with hum. The XLR connectors are grounded to the chassis and the chassis is earthed so why no noise problem? (which I was expecting given comments in the thread). I am clearly missing something.

Last edited:

It looks OK but using "open" fuse blocks is unsafe. This while a fused terminal block is also used. Please rewire to the existing fused terminal block and click in the black part with a suitable fuse in it.

I see you used a double pole switch which is good. Also completely insulated AMP connectors, hurray! The mains wiring to the on/off switch was too short hence the "dangling in the air" solution. I would use a terminal block there.

So you are unsatisfied not having hum? I don't know if you connected audio GND to PE?! I am not hindered by any knowledge of XLR systems but connecting the outer shield to PE is not the same as connecting the audio GND pin to PE in the connector is it?

I don't know if you connected audio GND to PE?! I am not hindered by any knowledge of XLR systems but connecting the outer shield to PE is not the same as connecting the audio GND pin to PE in the connector is it?

Problems occur when using unbalanced stuff and every device has audio GND connected to PE directly. Please use the search function on any anglosaxon audio forum for "hum problems" as they come for free with that direct audio GND - PE connection system when used in every available device. They call it ground loop problems. When using an FM tuner with centralised antenna system it will occur as the shield of the coax cable is normally connected to PE.

Please let us not use the term "earthed" and "earth" as some do mean connecting chassis to audio GND with that. It is already hard enough in English to describe the differences and "ground" and "earth" are mixed up very very often. Please let us use "audio GND" and "PE". Or "GND" and "PE".

I see you used a double pole switch which is good. Also completely insulated AMP connectors, hurray! The mains wiring to the on/off switch was too short hence the "dangling in the air" solution. I would use a terminal block there.

I had bought the parts already before this thread so decided to build it as is but the bit I still don't understand is why I don't have a problem with hum. The XLR connectors are grounded to the chassis and the chassis is earthed so why no noise problem? (which I was expecting given comments in the thread). I am clearly missing something.

So you are unsatisfied not having hum?

Problems occur when using unbalanced stuff and every device has audio GND connected to PE directly. Please use the search function on any anglosaxon audio forum for "hum problems" as they come for free with that direct audio GND - PE connection system when used in every available device. They call it ground loop problems. When using an FM tuner with centralised antenna system it will occur as the shield of the coax cable is normally connected to PE.

Please let us not use the term "earthed" and "earth" as some do mean connecting chassis to audio GND with that. It is already hard enough in English to describe the differences and "ground" and "earth" are mixed up very very often. Please let us use "audio GND" and "PE". Or "GND" and "PE".

Last edited:

BTW I recently saw a few high end tube amplifiers from the Far East that had audio GND connected to the chassis (why?) but no PE is used?!?! Some even did not have an IEC inlet but just a non detachable mains cable entering the chassis through a rubbed ring. I have to admit this device was quite old but still from a period that PE was already common. This specific device had a severe hum problem which only went away when connecting the chassis to PE which goes to show

I don't understand how these can be imported?! I got a story in return that not many people have PE in their living room which seems odd as PE is used in homes for many decades... And why would a manufacturer produce expensive gear that does not comply to legislation? Just to please the few people that don't have PE in their homes?

Questions that came up:

1. Why is PE omitted?

2. How can such a device be called safe?

3. What is the use to connect audio GND to chassis (especially when not having a connection of the chassis to PE)?

It again is a kind of proof that self regulation is not working. IMHO every device should be checked by an independent company for safety and only after approval it can be imported.

I don't understand how these can be imported?! I got a story in return that not many people have PE in their living room which seems odd as PE is used in homes for many decades... And why would a manufacturer produce expensive gear that does not comply to legislation? Just to please the few people that don't have PE in their homes?

Questions that came up:

1. Why is PE omitted?

2. How can such a device be called safe?

3. What is the use to connect audio GND to chassis (especially when not having a connection of the chassis to PE)?

It again is a kind of proof that self regulation is not working. IMHO every device should be checked by an independent company for safety and only after approval it can be imported.

Last edited:

Thanks for the advice, I'll change the fuse.

The dangling in the air bit is a terminal block which splits the wire from the switch to the 2 power supplies, the wire is a bit short so I change it if the block dangling in the air is unsafe/inadvisable.

I think this goes to show that I don't know what audio ground actually is specifically, at least not in reference to some of the other docs I've read anyway. For example, is it the same as the "signal reference" from Audio Component Grounding and Interconnection ?

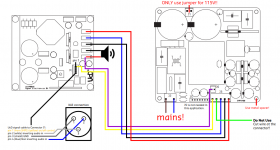

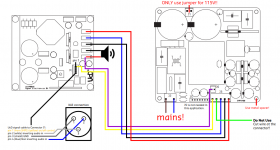

My wiring is basically as per the hypex docs so you can see 2 things called GND in this scheme, one connected to the shield (and hence pin 1 & the chassis) and another connected to the power supply (the thicker black line).

The dangling in the air bit is a terminal block which splits the wire from the switch to the 2 power supplies, the wire is a bit short so I change it if the block dangling in the air is unsafe/inadvisable.

I think this goes to show that I don't know what audio ground actually is specifically, at least not in reference to some of the other docs I've read anyway. For example, is it the same as the "signal reference" from Audio Component Grounding and Interconnection ?

My wiring is basically as per the hypex docs so you can see 2 things called GND in this scheme, one connected to the shield (and hence pin 1 & the chassis) and another connected to the power supply (the thicker black line).

Audio Component Grounding and Interconnection

Never knew this, this saves a lot of explaining. It is a long read but it is good someone took the effort of writing such a necessary document.

The Hypex drawing is illogical to me as you need specific module info with it.

Never knew this, this saves a lot of explaining. It is a long read but it is good someone took the effort of writing such a necessary document.

The Hypex drawing is illogical to me as you need specific module info with it.

Last edited:

Earthing Modushop Slimline Chassis

I have built with 3 or 4 Modushop cases and they are great. When I saw the anodising along the edges of the panels I realised earthing would be a problem.

I stripped the anodising along internal edges that would not be seen on all the side panels and the corresponding surfaces where they met . When assembled I checked with continuity testing with a multimeter to ensure everything was connected.

For the slimline cases I strip the anodizing off the back panel counter sink holes, used a bright bolt, none anodized and this gives you continuity across the back, sides and front panel. I then strip off a small bit of anodizing on inside of top and bottom panels and countersink it from with a 6mm m3 stainless screw and connect this with a 3mm wire to the front panel brackets. This gives continuity across the whole case.

.

I have built with 3 or 4 Modushop cases and they are great. When I saw the anodising along the edges of the panels I realised earthing would be a problem.

I stripped the anodising along internal edges that would not be seen on all the side panels and the corresponding surfaces where they met . When assembled I checked with continuity testing with a multimeter to ensure everything was connected.

no offense to Mr Davenport but there's still some incorrect information in that article that will lead to noise and loops but as i've been put in the sin bin before for such discussions i'll leave it to you to peruse the article and make your own determination.Audio Component Grounding and Interconnection

Never knew this, this saves a lot of explaining. It is a long read but it is good someone took the effort of writing such a necessary document.

feel free to PM me for further discussion.

This is incorrect, you have never been binned for discussion of grounding related topics.i've been put in the sin bin before for such discussions

Any further enquiries please use the proper channels (Rule 11).

Any further enquiries please use the proper channels (Rule 11).- Home

- Design & Build

- Construction Tips

- Safely grounding a modushop slimline chassis