I have just designed and built this phono stage:-

https://www.diyaudio.com/forums/ana...x7-phono-stage-susceptible-surface-noise.html

To my ears its sounds really good and worth investing a bit more on. Being a well planned out prototype it has still ended up being a little messy due to all the changes and tweaks in order to get it where it is.

The problem I am having is that the circuits are very sensitive to 50Hz EMI. There seems to be no issues with RF but this things just seems to suck 50Hz out of the ether. Prone to picking up switching noise when appliances around the home turn on or off (boiler, washing machine, dishwasher, etc.).

I changed the linear regulated HT PSU to an regulated inverter based supply with no change in noise. Also added additional regulation to the already regulated DC heater supplies.

The phono stage in in a grounded aluminium enclosure with screening cans around the valves and has a separate PSU, also in a grounded aluminium enclosure. However, despite this if you move the phono stage close to the PSU it will pick up the EMI which can be heard through the speakers.

Any info out there that would be helpful? I don’t want to just shotgun new enclosures, metal boxes and screens for circuits etc, as I would rather have a plan.

https://www.diyaudio.com/forums/ana...x7-phono-stage-susceptible-surface-noise.html

To my ears its sounds really good and worth investing a bit more on. Being a well planned out prototype it has still ended up being a little messy due to all the changes and tweaks in order to get it where it is.

The problem I am having is that the circuits are very sensitive to 50Hz EMI. There seems to be no issues with RF but this things just seems to suck 50Hz out of the ether. Prone to picking up switching noise when appliances around the home turn on or off (boiler, washing machine, dishwasher, etc.).

I changed the linear regulated HT PSU to an regulated inverter based supply with no change in noise. Also added additional regulation to the already regulated DC heater supplies.

The phono stage in in a grounded aluminium enclosure with screening cans around the valves and has a separate PSU, also in a grounded aluminium enclosure. However, despite this if you move the phono stage close to the PSU it will pick up the EMI which can be heard through the speakers.

Any info out there that would be helpful? I don’t want to just shotgun new enclosures, metal boxes and screens for circuits etc, as I would rather have a plan.

Can you take some pics of the device and its enclosure? Perhaps we can suggest a better way to do the job, perhaps no.

Take into account that a phono stage usually has high gain, so a well screening/shielding may not be sufficient, lay out, position, proximity to cables/cords, etc. Also, a good line filter may give some improvements. But, again, a pic may be of help to us to help you.

Take into account that a phono stage usually has high gain, so a well screening/shielding may not be sufficient, lay out, position, proximity to cables/cords, etc. Also, a good line filter may give some improvements. But, again, a pic may be of help to us to help you.

I suspect it's a different problem:

The stages should use the valves differently so that you can have floating filaments that you can independently elevate with a dc bias .for 12ax7 you need about 50vdc bias over the cathode voltage to cancel the hum completely.

I never need any shielding to get no audible hum at max volume with no cartridge connected!

The stages should use the valves differently so that you can have floating filaments that you can independently elevate with a dc bias .for 12ax7 you need about 50vdc bias over the cathode voltage to cancel the hum completely.

I never need any shielding to get no audible hum at max volume with no cartridge connected!

Attachments

I'll try elevating the heater supplies although I am not sure how DC heater supplies effect mains EMI pickup. Easy to float the heater supply, so not a problem to try it.

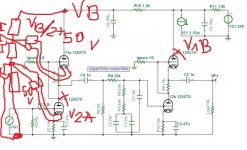

Here is a pic of the phono stage and the external PSU.

Both chassis are grounded but if I move the phono stage to within about 100mm of the PSU it starts to pick up noise from it. Moving it away further or in other locations around the house there is always a residue amount of hum.

Here is a pic of the phono stage and the external PSU.

Both chassis are grounded but if I move the phono stage to within about 100mm of the PSU it starts to pick up noise from it. Moving it away further or in other locations around the house there is always a residue amount of hum.

Side question, how good is your tone arm and arm lead shielding? Your noise might not be getting in where you think it is, just saying.

I took a paradise phono to a clients, utterly silent at mine, signal grounds floated from chassis, earthing meticulously taken care of. Huge 50hz hum at his. Tried everything internally, made no difference.

Fitted a double shielded tonearm lead and xlr sockets using pin1 to chassis from the shield. Zero noise.

I took a paradise phono to a clients, utterly silent at mine, signal grounds floated from chassis, earthing meticulously taken care of. Huge 50hz hum at his. Tried everything internally, made no difference.

Fitted a double shielded tonearm lead and xlr sockets using pin1 to chassis from the shield. Zero noise.

Its pretty good, I’ve check continuity of the shield and there was no problem with my other phono stage. Also the hum is the same with the inputs grounded.

Gain is not massively high (actually around 39 dB @ 1khz) and I can’t understand how it manages to pick up stray EMI through a shielded PSU case and the shielded case of the phono stage itself.

Gain is not massively high (actually around 39 dB @ 1khz) and I can’t understand how it manages to pick up stray EMI through a shielded PSU case and the shielded case of the phono stage itself.

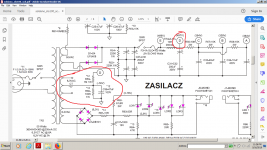

Try to keep the loop area from the input connector via R12 to V1b to C7 and back to the input connector as small as you can. Low-frequency magnetic fields are almost impossible to shield, so keeping loop areas small, increasing distances, putting loops at right angles to each other and twisting are all you can do against low-frequency magnetic coupling.

I'll try elevating the heater supplies although I am not sure how DC heater supplies effect mains EMI pickup. Easy to float the heater supply, so not a problem to try it.

.

This is an usual misconception, that the dc supply of the heater is getting you any low noise unless it is filtered and regulated down to microvolts level which is kinda hard to be honest.Most of the noise come from the cathode-filament induced hum through capacitive coupling and the ripple current can be as low as picoamps (depending on the gm and gain of that stage/tube) and still produce significant noise.The lower the noise of a tube, the higher capacitance between cathode and filament and subsequently the lower Vkf Max breakdown unfortunately.

By elevating the filament over the cathode you fight the intrinsic capacitive leakage between them and you find that you don't even need dc supply if you lift both taps of the filament to 30...50v.You can do it to the filament in both ac or dc .In ac its even simpler if you have mid tap like soldano amp does , but you can do it with no mid tap, just two resistors from the +50v tap to both ends of the filament.

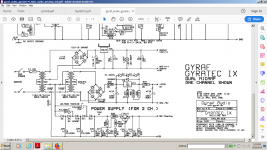

Look at Soldano Slo 100 schematic which is one of the highest gain amp for guitar pick-up where the hum is even more problematic than in normal phono preamps.Actually if you study some of the best guitar amps or preamps wiring you can easily do noiseless phono preamps with no shielding at all:

SOLDANO SLO100 SCH Service Manual download, schematics, eeprom, repair info for electronics experts

Read this post and the whole article if you want as they talk about all the techniques used to kill hum:

Any advantage using DC for filament?

I used to clone Mesa boogie dual rectifier amps and do the dc filtering trick they do, until i found that the original Soldano design that they used had no such thing and had even better hum removal than the Mesa...

Study both, Soldano and Dual Rectifier wiring and grounding techniques and you know almost everything it is to know to get low noise valve preamps.

Attachments

Last edited:

A 50Hz magnetic field will go straight through thin aluminium. You need several inches thickness to stop it, which is usually not practical. You need to ensure low loop area and use either twisting or coax for signal wiring - both twisting and coax reduce magnetic pickup, although they do it in different ways.primalsea said:I can’t understand how it manages to pick up stray EMI through a shielded PSU case and the shielded case of the phono stage itself.

Started to solve most of the noise issues. Elevated the heaters and rerouted some of the wiring. Also discovered that I didn’t have continuity all the way through the psu case, which has now been fixed.

Still have some noise but this is down to the PSRR of only 6dB on SRPPs and the gain at 50 hz is huge, being a phono stage.

Still have some noise but this is down to the PSRR of only 6dB on SRPPs and the gain at 50 hz is huge, being a phono stage.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Best Screening / Shielding Practice for Sensitive Phono Stage?