Hello,

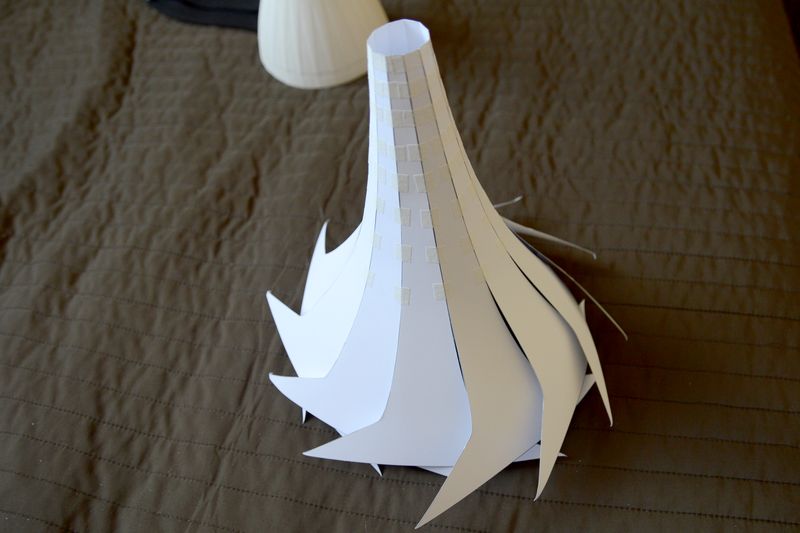

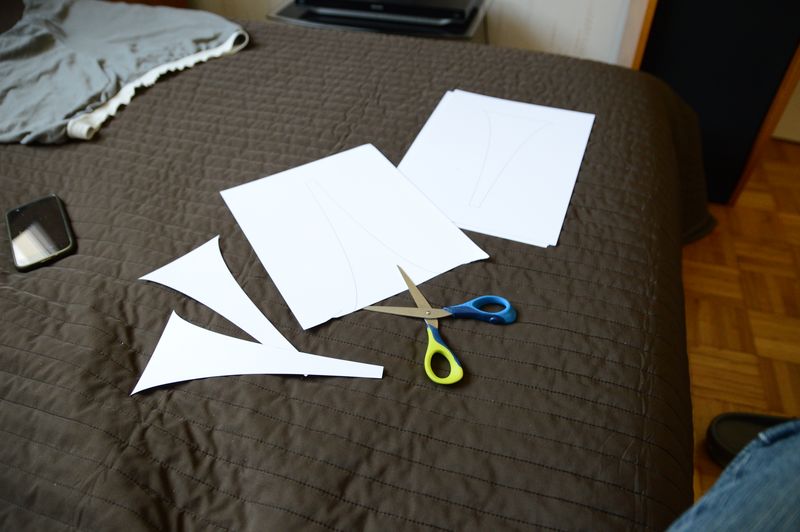

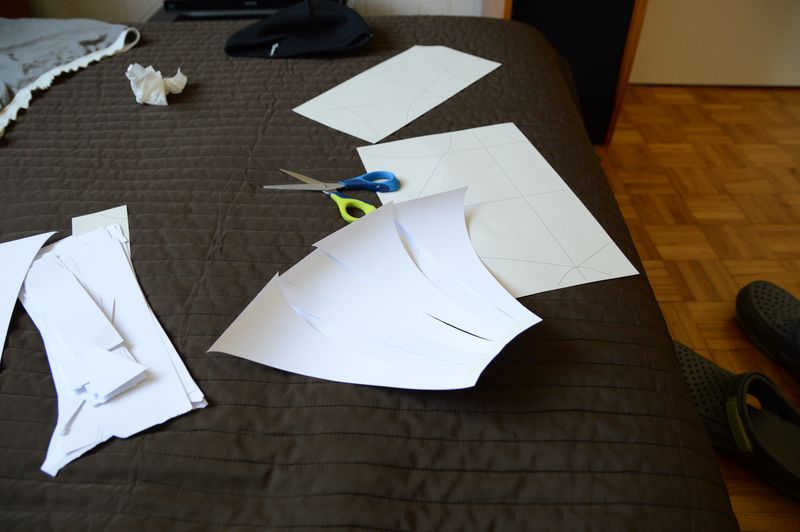

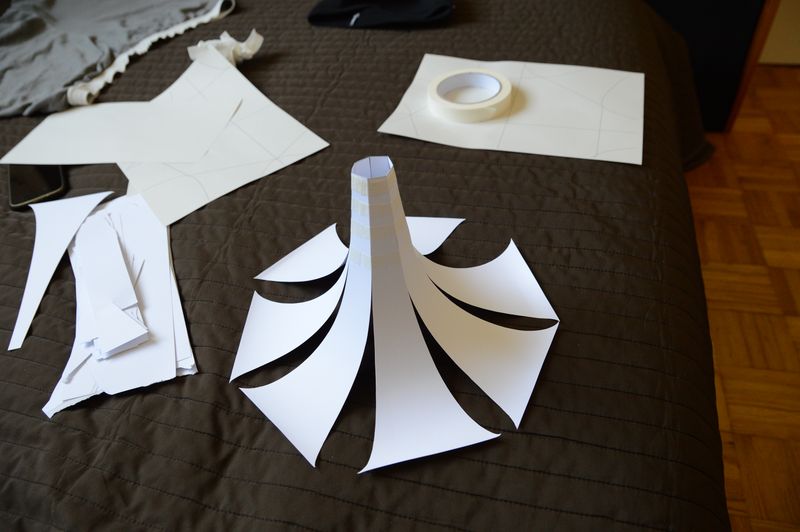

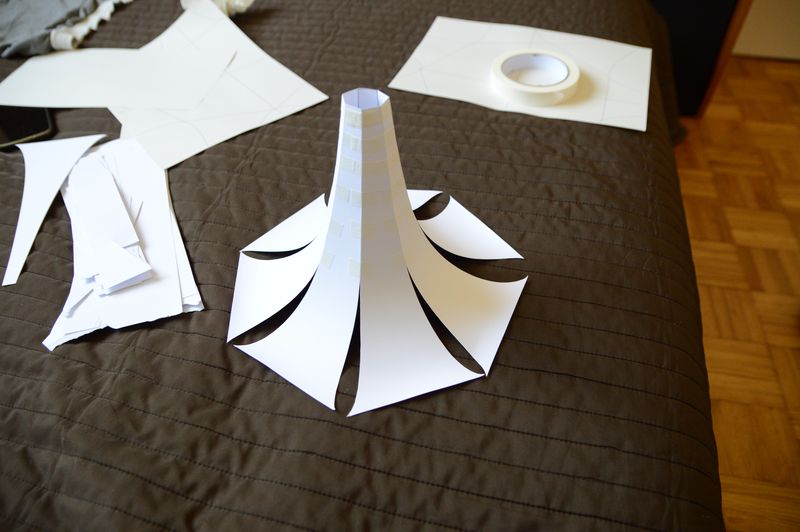

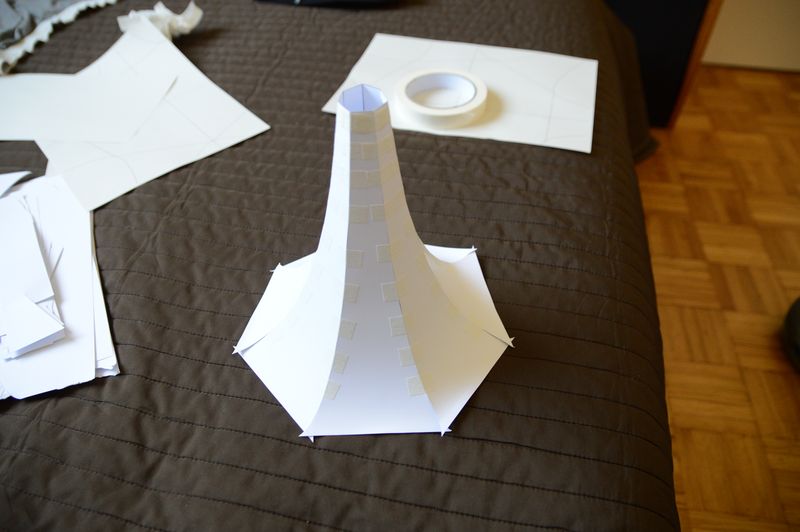

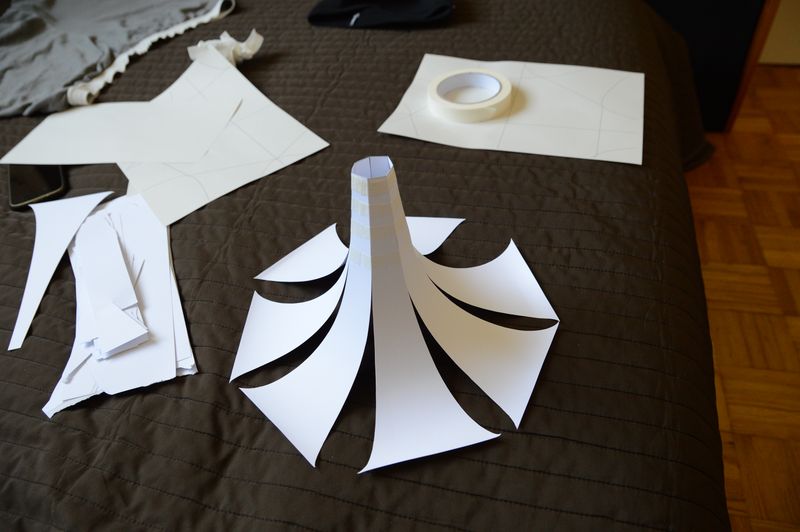

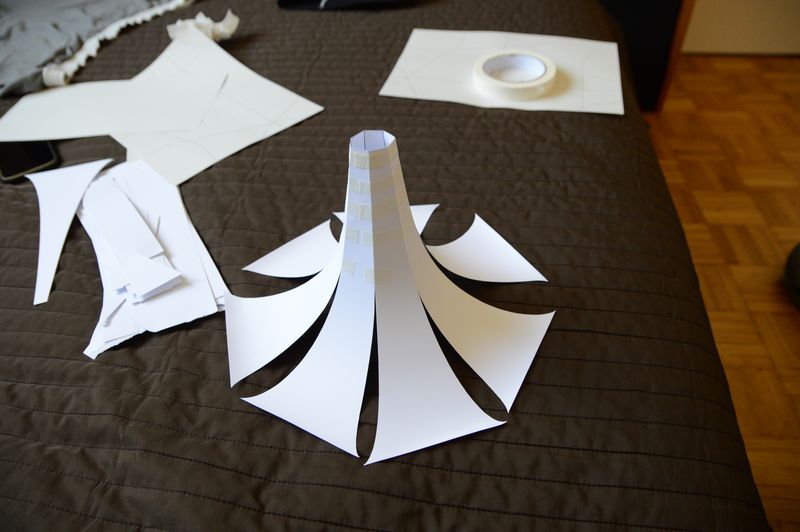

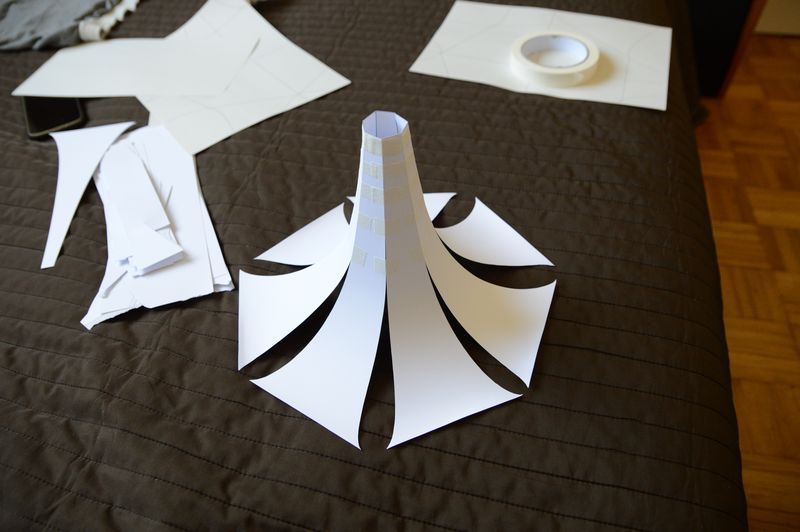

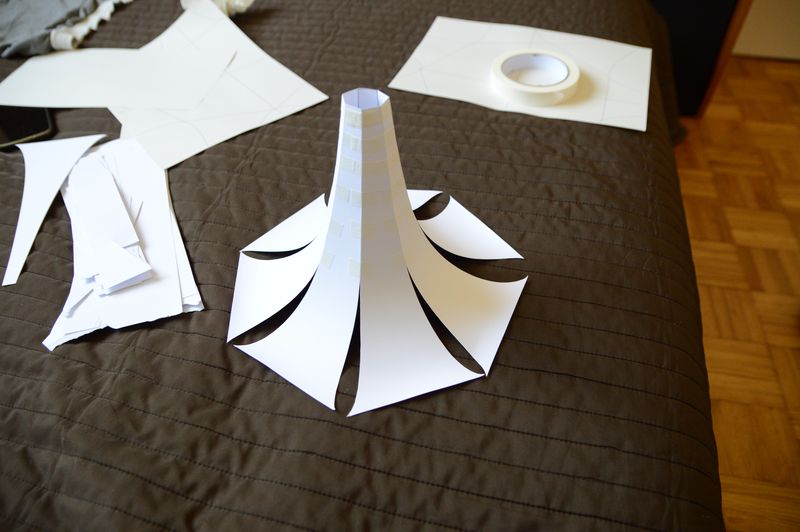

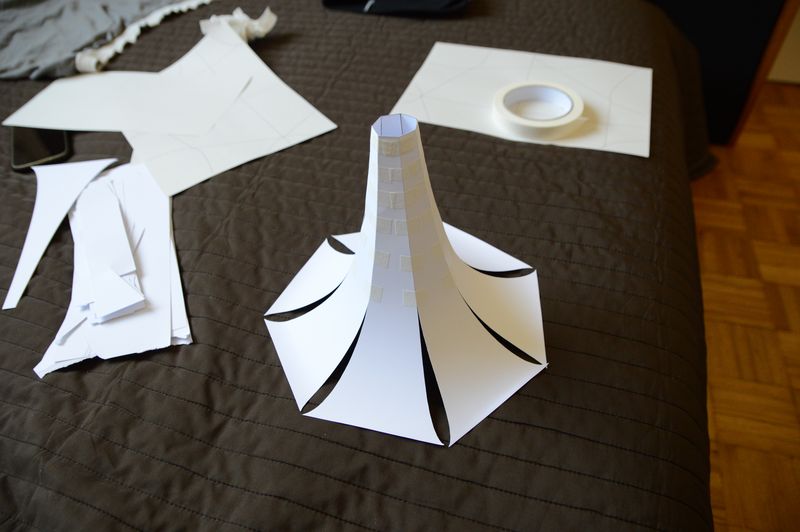

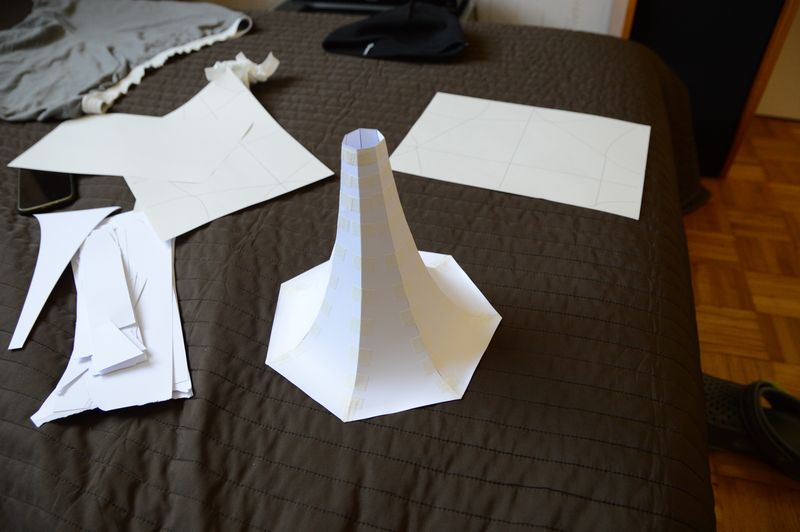

No comments, just photos, you can build all the horns you want for less than 2$.

Do not use candle paraffin, use edible solid paraffin (much more rigid), allow to reach the needed rigidity for a big horn.

You need :

1 hour

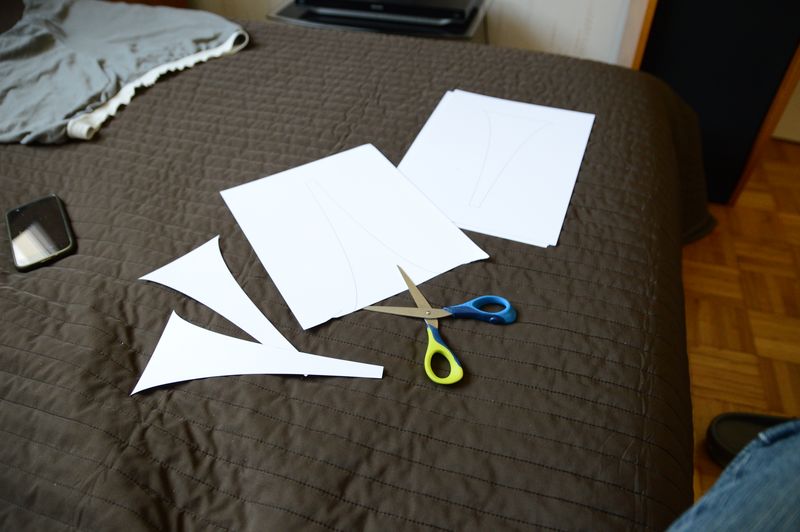

1 scissors

7 paper sheets (inkjet)

1 scotch roller

1 paintbrush (paraffin application)

1 saucepan (from the kitchen)

Some paraffin

No comments, just photos, you can build all the horns you want for less than 2$.

Do not use candle paraffin, use edible solid paraffin (much more rigid), allow to reach the needed rigidity for a big horn.

You need :

1 hour

1 scissors

7 paper sheets (inkjet)

1 scotch roller

1 paintbrush (paraffin application)

1 saucepan (from the kitchen)

Some paraffin

Last edited:

heavier paper horns

Hi there: I experimented with paper horn construction using red temporary floor paper used by contractors to protect finished floors while other trades completed work. A big roll costs about $25 at the depot. I was using the cheapest white glue from Michals craft/art supply. The sections were wetted in glue and were overlapped at the edges. The horn was rather stiff after drying. However, I was not able to control warping, so I abandoned the project. Your edge gluing process gives a smooth finished product. My wife is using the red paper as covering or her work table while painting miniature houses on rocks, so I still have plenty of material to try out your process. Note that other experiments using foam core to construct traxt type horns worked well and sound good, so I'd expect horns made by your process will also sound good. Hope you will post listening results and measurements if possible. ...regards, Michael

Hi there: I experimented with paper horn construction using red temporary floor paper used by contractors to protect finished floors while other trades completed work. A big roll costs about $25 at the depot. I was using the cheapest white glue from Michals craft/art supply. The sections were wetted in glue and were overlapped at the edges. The horn was rather stiff after drying. However, I was not able to control warping, so I abandoned the project. Your edge gluing process gives a smooth finished product. My wife is using the red paper as covering or her work table while painting miniature houses on rocks, so I still have plenty of material to try out your process. Note that other experiments using foam core to construct traxt type horns worked well and sound good, so I'd expect horns made by your process will also sound good. Hope you will post listening results and measurements if possible. ...regards, Michael

Last edited:

I suggest to use 'modge podge' soaked paper layers...instead of paraffin, it hardens to light but strong material.

Yup. Use wood glue or wallpaper glue, the former is stronger, the latter is a lot cheaper.

Yup. Use wood glue or wallpaper glue, the former is stronger, the latter is a lot cheaper.

Wood glue:water 1:5-1:2 is a good idea.

Hello,

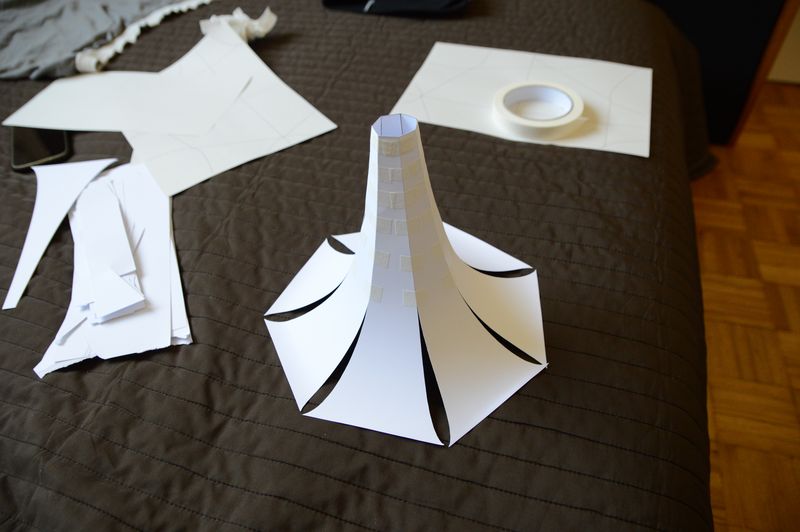

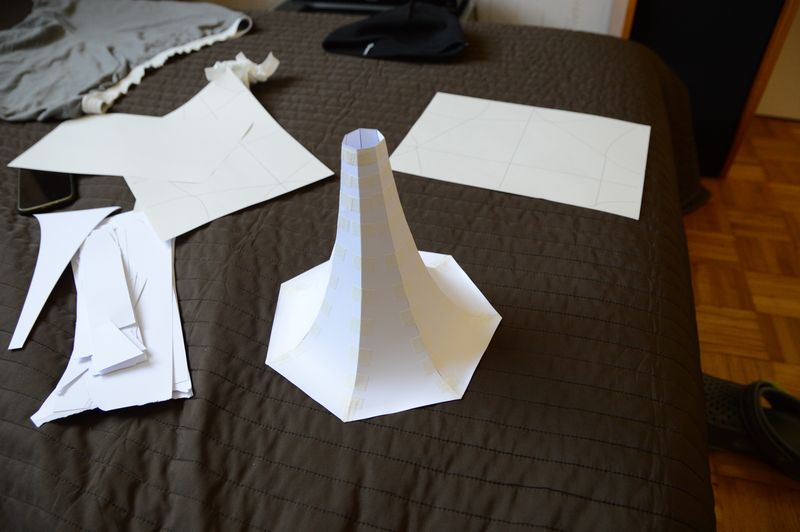

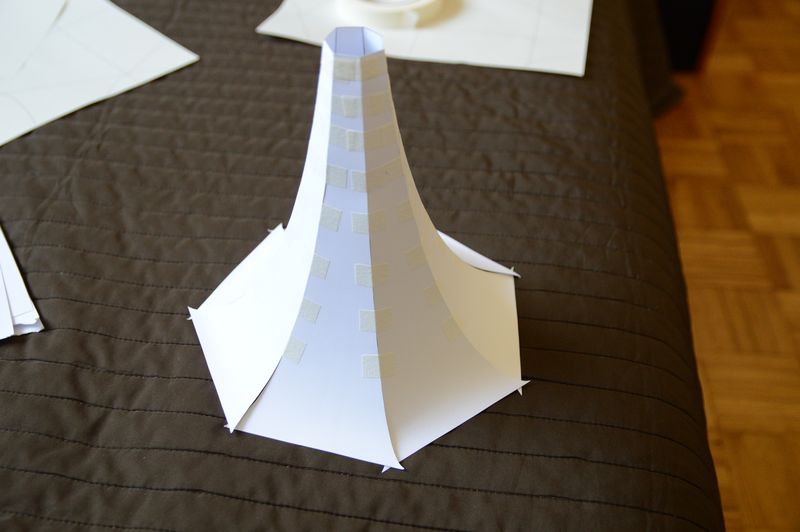

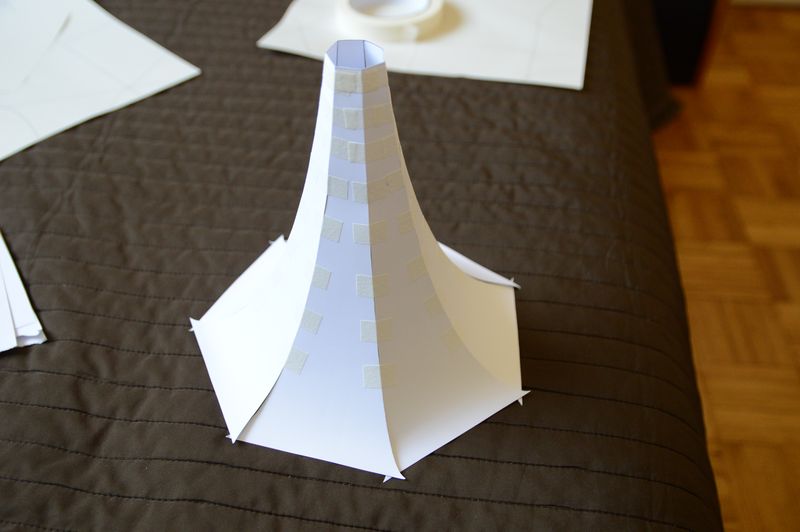

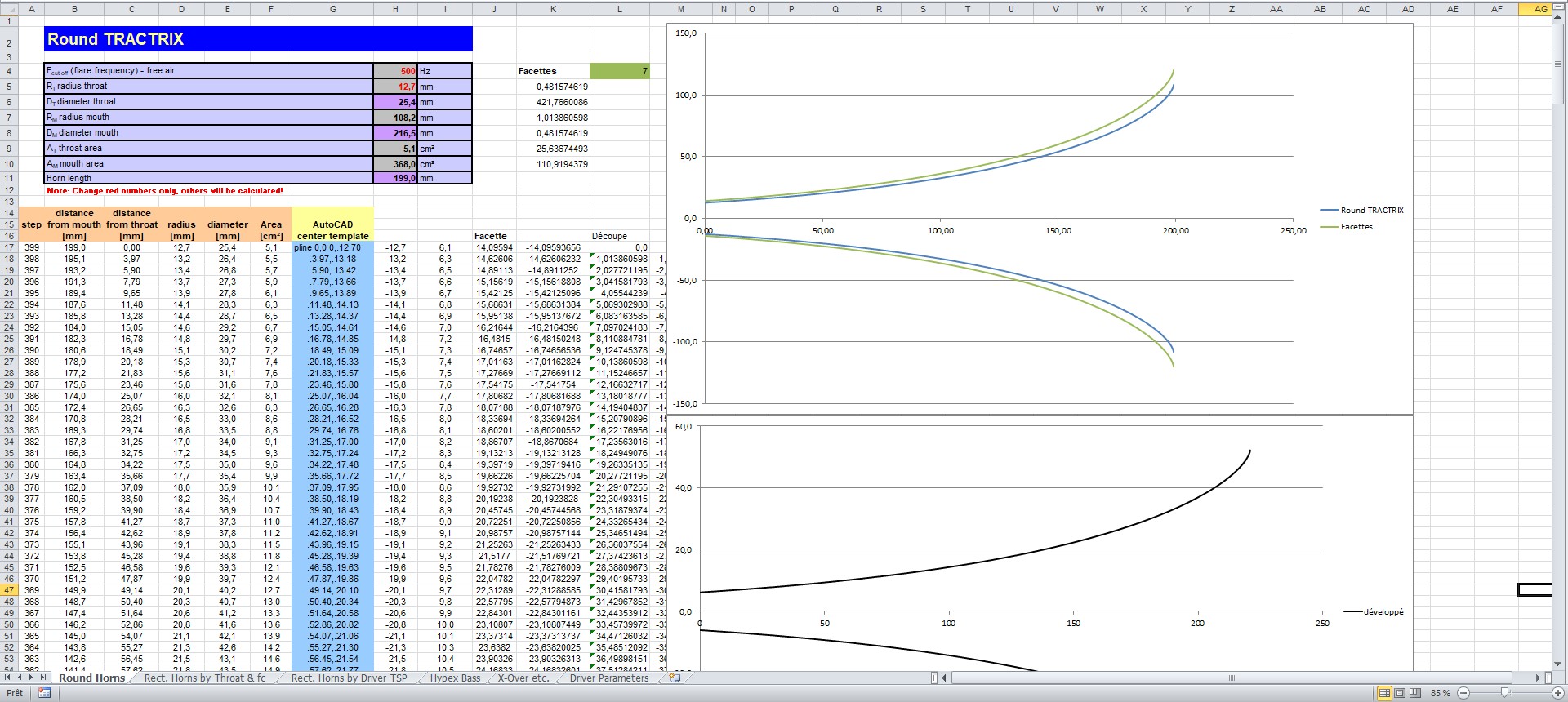

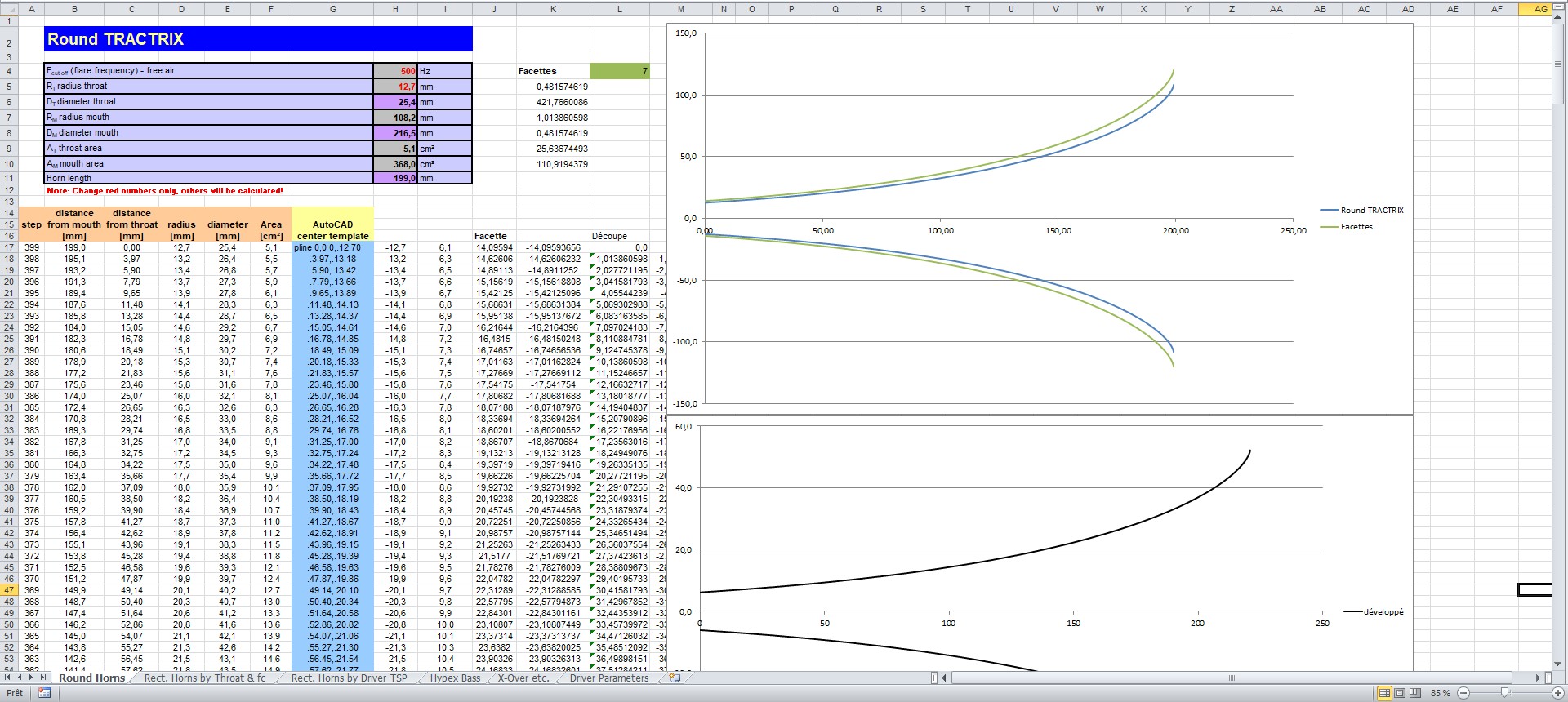

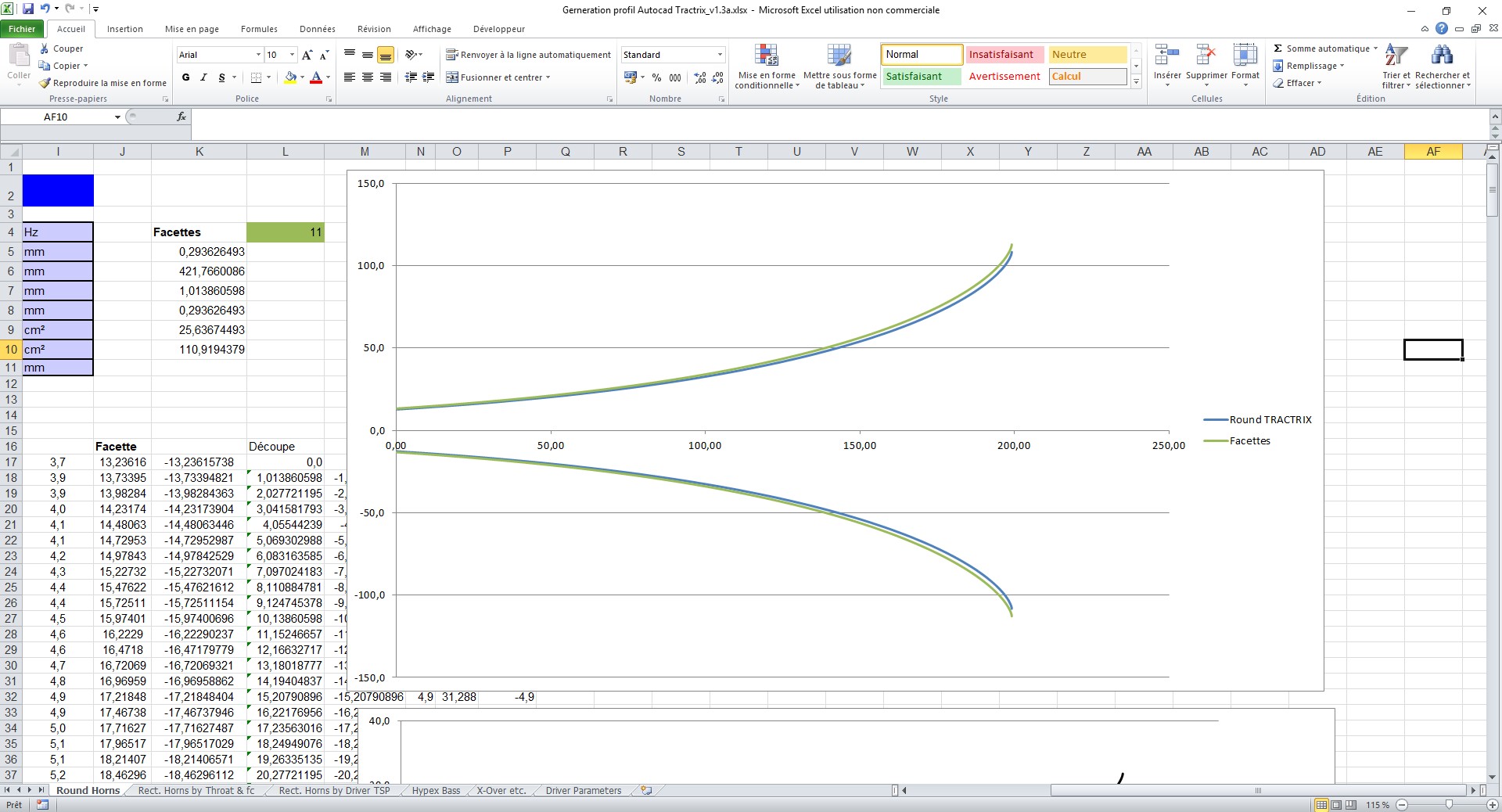

The data is coming from an existing internet excel datasheet, i’ve added a petal generator, you need a CAD drawing software in order to trace and print accurately the contours with this tool.

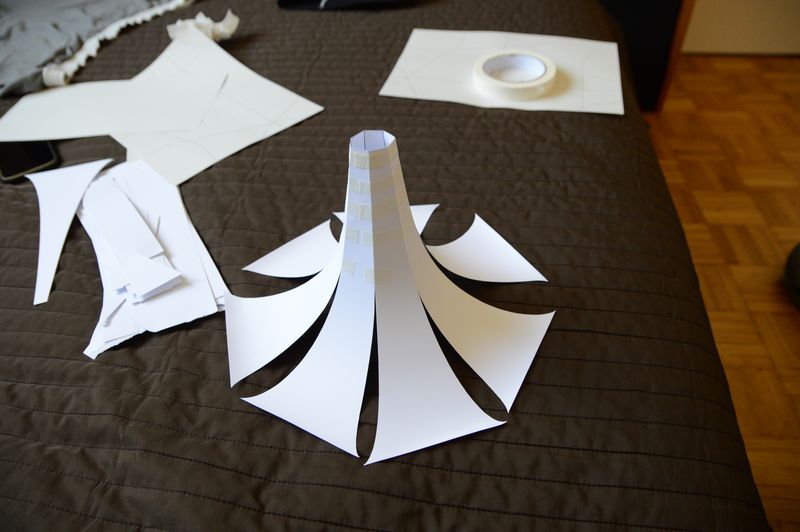

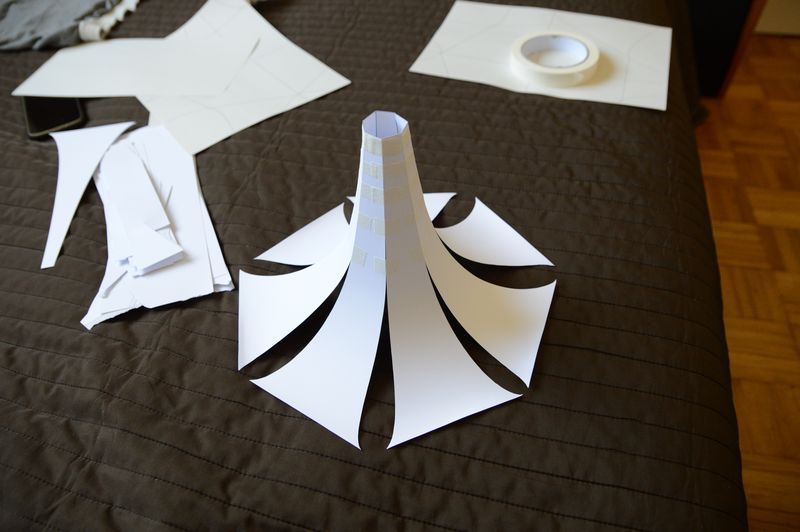

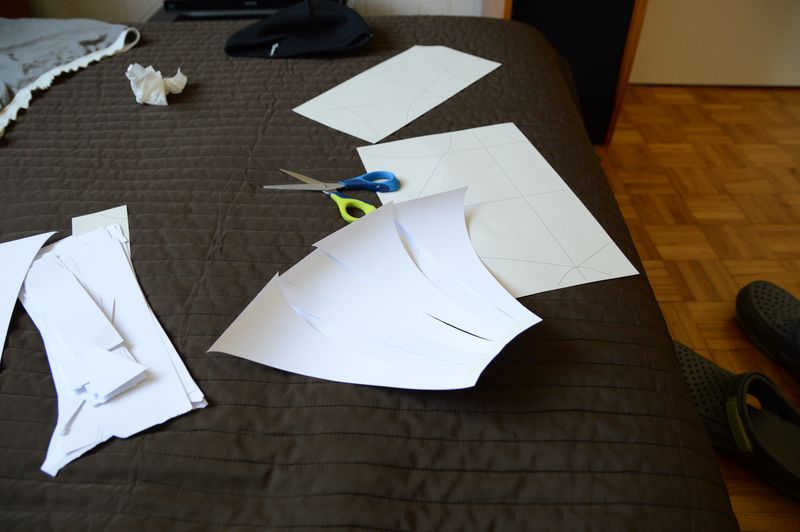

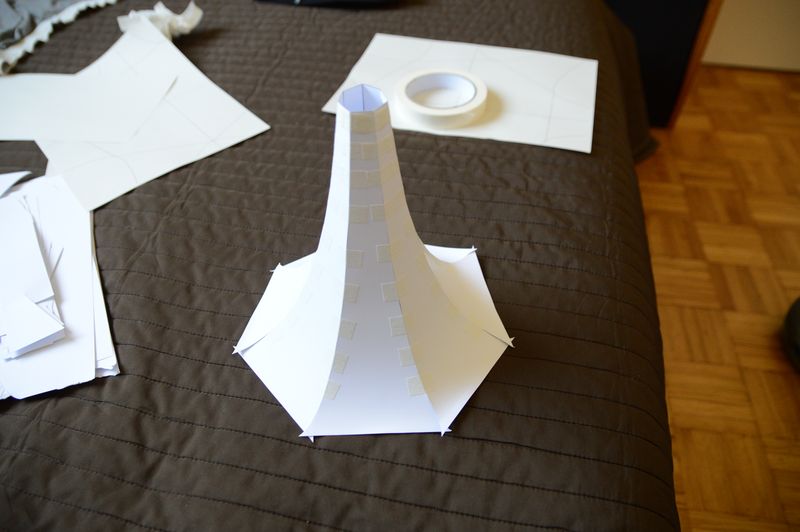

There are many better solutions than mine but it is a fast prtotyping process, the paraffin hardens immediately and is cheap as butter. Moreover the childrens safety scissors cost around two buck and can make many prototypes.

The paper mache process is the second part of the conception process IMHO, the cost is raising seriously (5€) and the quality of the final part is very high, my last ptototype uses whool/cellulose black paper and a cotton mesh on the surface to mimic the loudspeakers drivers paper cones like this one :

The data is coming from an existing internet excel datasheet, i’ve added a petal generator, you need a CAD drawing software in order to trace and print accurately the contours with this tool.

There are many better solutions than mine but it is a fast prtotyping process, the paraffin hardens immediately and is cheap as butter. Moreover the childrens safety scissors cost around two buck and can make many prototypes.

The paper mache process is the second part of the conception process IMHO, the cost is raising seriously (5€) and the quality of the final part is very high, my last ptototype uses whool/cellulose black paper and a cotton mesh on the surface to mimic the loudspeakers drivers paper cones like this one :

This is the core of one of two ways most phonograph (and early radio) speaker horns were made.

Tin and brass were done. But many were paper-fiber cut-outs finished with Bakelite resin or "Japan". "Japan" was shellac and other resins used on small Japanese snuff-boxes and such, very fashionable (as a fad, and as a small-craft material).

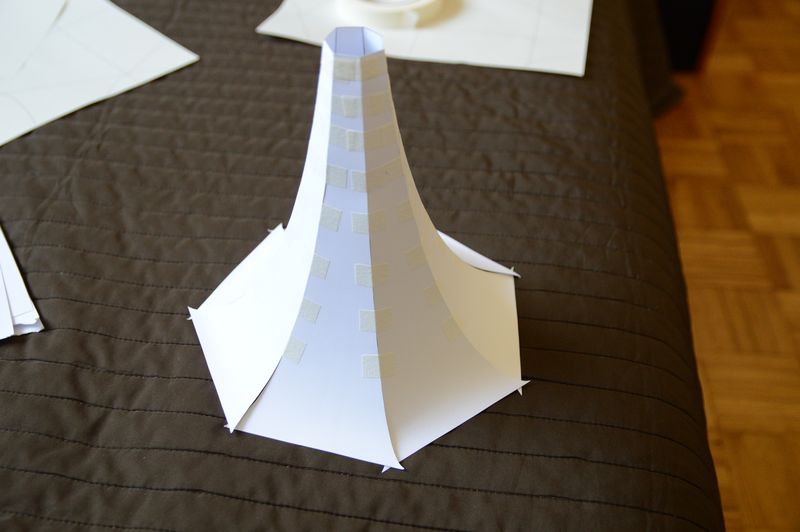

You do not need a computer to generate the pattern. Draw your horn cross-section full-size. Hold your ruler along the line and mark every inch along the *horn*, not the horn-axis. Find those diameters.

We assume the horn is near-round. Each diameter gets multiplied by 3.14 to get the circumference of a round horn. Now divide by the number of sides. This gives the width of the paper at 1-inch increments. Taking 7 sides:

How many sides? An awful lot of the old horns have 11 sides. There may have been a published pattern for this; or it may have been a standard at some company. Mystic Numerics will suggest other numbers for Divine Properties. Being atheist, I will note that our circular approximation gets poor at 4 sides (however math it as a square and the same approach is perfect). At silverprout's 7 sides, I'd call the pi math perfect for any practical purpose (you *will* scale your horn a bit bigger than your actual passband).

Tin and brass were done. But many were paper-fiber cut-outs finished with Bakelite resin or "Japan". "Japan" was shellac and other resins used on small Japanese snuff-boxes and such, very fashionable (as a fad, and as a small-craft material).

You do not need a computer to generate the pattern. Draw your horn cross-section full-size. Hold your ruler along the line and mark every inch along the *horn*, not the horn-axis. Find those diameters.

We assume the horn is near-round. Each diameter gets multiplied by 3.14 to get the circumference of a round horn. Now divide by the number of sides. This gives the width of the paper at 1-inch increments. Taking 7 sides:

Code:

len -- dia -- *pi -- /7

0 -- 2" -- 6.28 -- 0.9

1 -- 3" -- 9.4 -- 1.34

2 -- 4.6"-- 14.5 -- 2.1

3 -- 6" -- 18.8 -- 2.7

...

7 -- 15.5"-- 48.7 -- 6.96How many sides? An awful lot of the old horns have 11 sides. There may have been a published pattern for this; or it may have been a standard at some company. Mystic Numerics will suggest other numbers for Divine Properties. Being atheist, I will note that our circular approximation gets poor at 4 sides (however math it as a square and the same approach is perfect). At silverprout's 7 sides, I'd call the pi math perfect for any practical purpose (you *will* scale your horn a bit bigger than your actual passband).

Attachments

How many sides? An awful lot of the old horns have 11 sides. There may have been a published pattern for this; or it may have been a standard at some company. Mystic Numerics will suggest other numbers for Divine Properties. Being atheist, I will note that our circular approximation gets poor at 4 sides (however math it as a square and the same approach is perfect). At silverprout's 7 sides, I'd call the pi math perfect for any practical purpose (you *will* scale your horn a bit bigger than your actual passband).

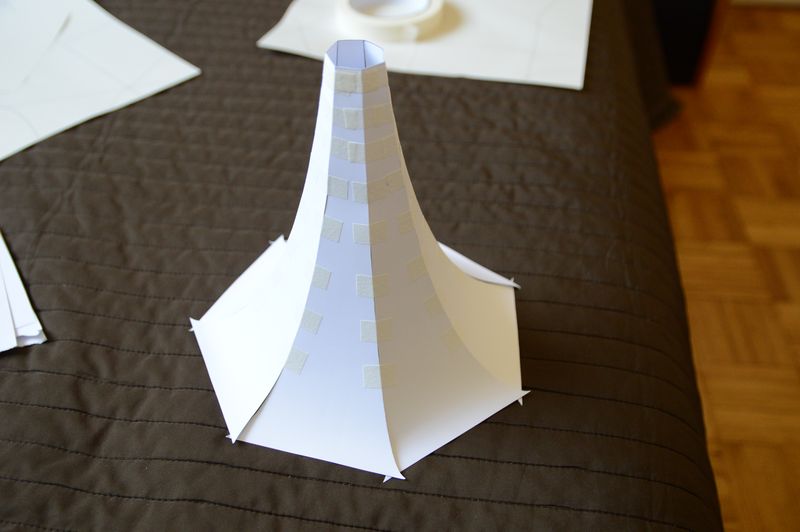

11 sides seems to be a good approximation IMHO, grandaddy was right.

I like the idea of wax or shellac and the quick dry. I made a pair of papier mâché horns from 100% cotton heavy art paper and wall-paper glue. Took forever for each layer to dry. Sounded amazingly good, tho.

The unpressed version of the "champagne jeroboam hom generator prototype" is 4mm thickness, dry completely within 8 hours and have enough rigidity to avoid any doping.

One polymer textile layer really accelerate the drying process, i must thanks the womens feet.

Last edited:

Flange added (laser cut plywood) pieces are entering the mass production phase, i will produce a lot of horns !How are the CD's attached. Is there a reusable threaded piece or flange added ?

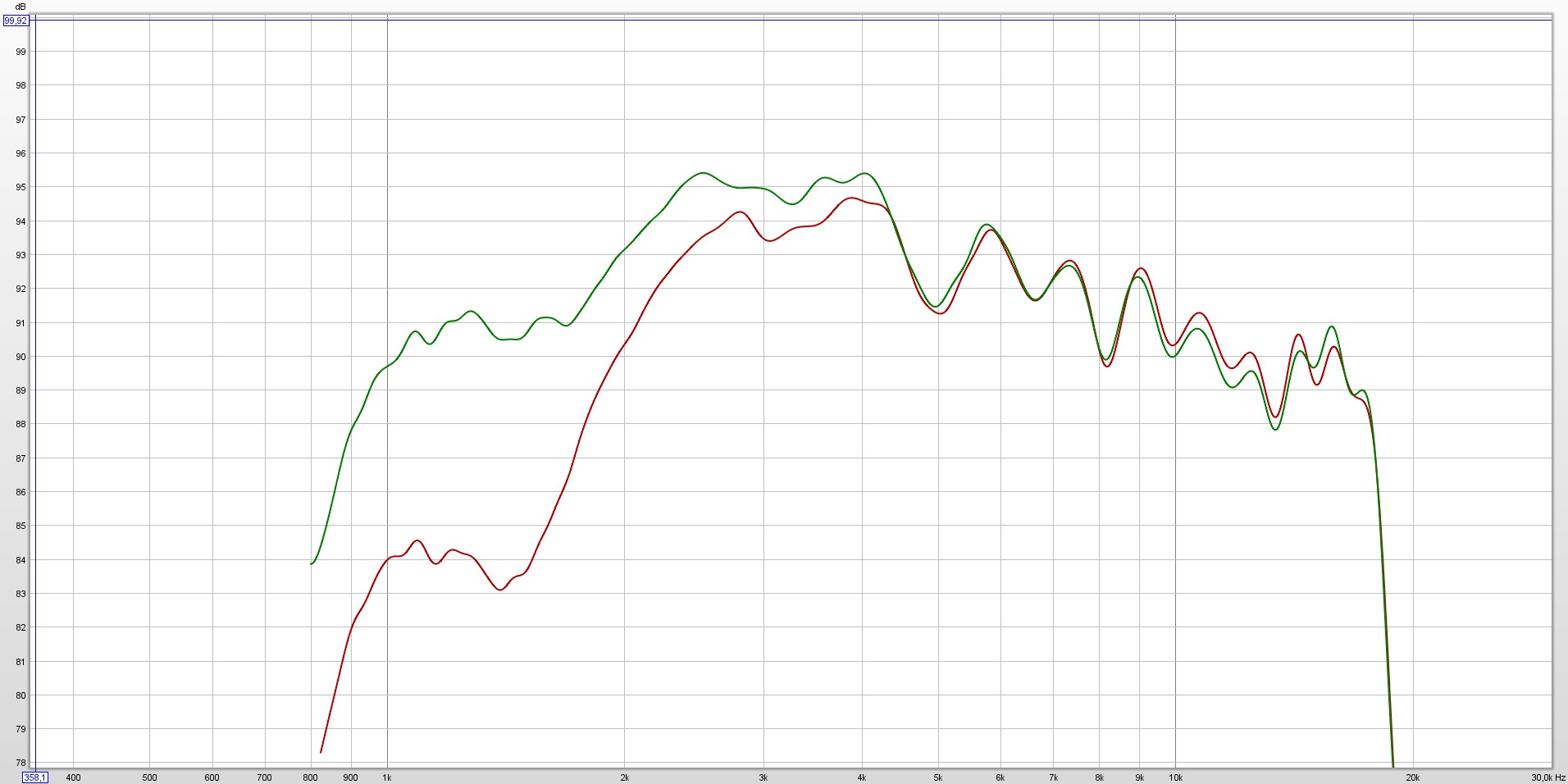

The first one will be the HOM generator that gives a huge resonance of 10 dB at 1000 Hz

I was thinking of a pipe fitting for a screw on CD. Both could be reused on the next horn. Since the horns are paper they could be recycled as well.

I do enjoy the pleasing sound of a resonant 1Khz tone. Maybe I could make a paper "ear trumpet" so that I'll be able to hear it as well.

I do enjoy the pleasing sound of a resonant 1Khz tone. Maybe I could make a paper "ear trumpet" so that I'll be able to hear it as well.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Paper Horn constuction