Strange how some questions don't get an answer while others ramble on & on.

No personal experience here but lacquer aerosol from an auto shop should be ok.

Try an offcut of panel or even the back face to test before committing to the face on view.

Maybe everyone here has their panels engraved?

No personal experience here but lacquer aerosol from an auto shop should be ok.

Try an offcut of panel or even the back face to test before committing to the face on view.

Maybe everyone here has their panels engraved?

Label letters, aka. letter stickers etc., can be bought from just anywhere, you just need a steady hand and accurate eyes to get them in a nice line and spacing.

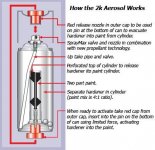

For the clear coat there's a special 2-component available in special spray bottles which comes outfitted with an extra internal chamber containing the hardener which is manually activated through a valve at the bottom of the bottle (see attached picture), when activated the two components starts to mix and cure so the pot life is max 48 hours in ambient temp(!!), the 2-component provides for a much tougher and durable surface.

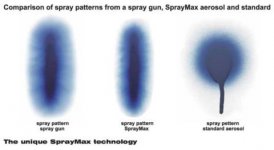

Another advantage buying better quality spray bottle is, they usually come with a special shaped spray nozzle which provides for a much better spray pattern (similar to a real spray gun) and handling (see attached picture).

A good advice is to warm up the spray bottle gently up to ca 35-40 degrees Celsius, the solvents will atomize much better providing for a much better spray fume and result, if the bottle is too cold the tiny droplets are much larger and can even sputter with worse result.

2K Clear coat - SprayMax

Amazon.com: USC Spray Max 2k High Gloss Clearcoat Aerosol: Automotive

For the clear coat there's a special 2-component available in special spray bottles which comes outfitted with an extra internal chamber containing the hardener which is manually activated through a valve at the bottom of the bottle (see attached picture), when activated the two components starts to mix and cure so the pot life is max 48 hours in ambient temp(!!), the 2-component provides for a much tougher and durable surface.

Another advantage buying better quality spray bottle is, they usually come with a special shaped spray nozzle which provides for a much better spray pattern (similar to a real spray gun) and handling (see attached picture).

A good advice is to warm up the spray bottle gently up to ca 35-40 degrees Celsius, the solvents will atomize much better providing for a much better spray fume and result, if the bottle is too cold the tiny droplets are much larger and can even sputter with worse result.

2K Clear coat - SprayMax

Amazon.com: USC Spray Max 2k High Gloss Clearcoat Aerosol: Automotive

Attachments

I'd definitely experiment with materials first.

I've had some bad luck in which it appeared that the oxide layer on the alu seemed to grow months later, clouding the whole thing.

I've always started with a spotless freshly scotch-brighted surface.

Maybe give it a lye bath just before coating? I never tried that.

edit: Oh, it's already anodized, forget the oxide layer comment... Will the clear even stick well without scuffing it?

I've had some bad luck in which it appeared that the oxide layer on the alu seemed to grow months later, clouding the whole thing.

I've always started with a spotless freshly scotch-brighted surface.

Maybe give it a lye bath just before coating? I never tried that.

edit: Oh, it's already anodized, forget the oxide layer comment... Will the clear even stick well without scuffing it?

Last edited:

I made tons of Letraset labelled Guitar amplifiers for years (until I eventually mastered silkscreening)

Front panels could be actually quite impressive, dependes mostly on patience and working slow.

Either black or blue painted with white lettering or brushed/anodized/sandblasted aluminum with black lettering, a clear coat was mandatory , not to protect against scratching but plain removing letters with relative light friction.

Used some kind of another of clear Krylon.

Avoided the matte type because the matting agent causes a whitich hue/veil, just usedb the regular type which is crystal clear.

To avoid it being too bright and easily show fingerprints, I let it dry fully (say 1 or 2 hours) and then applied a single "matting" extra layer, from "too far away" on purpose so solvents partially evaporated while flying, and tiny droplets reached surface keeping their shape and not melying with others.

Try it once and you´ll understand what I mean, easy to control with a little practice.

Now and then I get an old amp for service (years or decades later) and panels hold quite well, although MI amplifiers get knocked around a lot.

Front panels could be actually quite impressive, dependes mostly on patience and working slow.

Either black or blue painted with white lettering or brushed/anodized/sandblasted aluminum with black lettering, a clear coat was mandatory , not to protect against scratching but plain removing letters with relative light friction.

Used some kind of another of clear Krylon.

Avoided the matte type because the matting agent causes a whitich hue/veil, just usedb the regular type which is crystal clear.

To avoid it being too bright and easily show fingerprints, I let it dry fully (say 1 or 2 hours) and then applied a single "matting" extra layer, from "too far away" on purpose so solvents partially evaporated while flying, and tiny droplets reached surface keeping their shape and not melying with others.

Try it once and you´ll understand what I mean, easy to control with a little practice.

Now and then I get an old amp for service (years or decades later) and panels hold quite well, although MI amplifiers get knocked around a lot.

Label letters, aka. letter stickers etc., can be bought from just anywhere, you just need a steady hand and accurate eyes to get them in a nice line and spacing.

For the clear coat there's a special 2-component available in special spray bottles which comes outfitted with an extra internal chamber containing the hardener which is manually activated through a valve at the bottom of the bottle (see attached picture), when activated the two components starts to mix and cure so the pot life is max 48 hours in ambient temp(!!), the 2-component provides for a much tougher and durable surface.

Another advantage buying better quality spray bottle is, they usually come with a special shaped spray nozzle which provides for a much better spray pattern (similar to a real spray gun) and handling (see attached picture).

A good advice is to warm up the spray bottle gently up to ca 35-40 degrees Celsius, the solvents will atomize much better providing for a much better spray fume and result, if the bottle is too cold the tiny droplets are much larger and can even sputter with worse result.

2K Clear coat - SprayMax

Amazon.com: USC Spray Max 2k High Gloss Clearcoat Aerosol: Automotive

Be very, very careful with 2k products as they are extremely harmful if inhaled. I recommend an air fed mask when using these. Look up hazards of isocyanate paints.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Clear coat anodized aluminum panel?