Bingo

The only issue I ever ran into with wooden chassis/ cabinets was cracking of veneer on a tube phono stage that I designed with insufficient ventilation for the hottest valve in the circuit - the 5AR4 rectifier. Thermal loads on underrated multiple secondary power transformers can also get them toasty enough to accelerate pyrolysis of wood in immediate contact, but unless unprotected by AC mains fuse, I’d imagine risk of combustion to be rare?

The only issue I ever ran into with wooden chassis/ cabinets was cracking of veneer on a tube phono stage that I designed with insufficient ventilation for the hottest valve in the circuit - the 5AR4 rectifier. Thermal loads on underrated multiple secondary power transformers can also get them toasty enough to accelerate pyrolysis of wood in immediate contact, but unless unprotected by AC mains fuse, I’d imagine risk of combustion to be rare?

With the concern around working with ac line potential as large as it is on this site, I am surprised that placing that kind of energy into a wooden box, assumably inside one’s living quarters, hasn’t had the same diligence.

So besides risking your home value, or well being is it not worth the time and effort spared to make a proper enclosure, or is cheaper always better?

I have seen lower powered equipment in lesser enclosures, however they have had been given a ul rating. I would think that a little overkill might be a good thing with diy equipment in the event of any issue.

I use dead amplifier cases for amp projects, I seem to have a few of those.

While your comments seem to make sense, I would suggest that you have a quick look inisde a modern Marshal amp. Simple metal chassis/framework inside an MDF (or sometimes a plywood) box.

best regards

Mike

Well if you haven’t had a problem, then by all means...

And if you can’t differentiate the risks between household wiring and an appliance, I don’t know what to tell you!

Good luck I suppose.

Just try and imagine yourself as an insurance company talking with a fire inspector after a fire.

How are you going to respond to something so obviously hand made with a wire attached to an outlet?

I don’t give a crap about what other products that are out there, they have paid the ul fees and are all insured.

And if you can’t differentiate the risks between household wiring and an appliance, I don’t know what to tell you!

Good luck I suppose.

Just try and imagine yourself as an insurance company talking with a fire inspector after a fire.

How are you going to respond to something so obviously hand made with a wire attached to an outlet?

I don’t give a crap about what other products that are out there, they have paid the ul fees and are all insured.

Last edited:

I'm always willing to learn. Please post any examples of fires caused by wood used in an amplifier (or any electronic device) case.Well if you haven’t had a problem, then by all means...

The most likely scenario I can imagine for a DIY amplifier causing a fire is somebody throwing a jacket or blanket over the amplifier when it's powered up, and the heat from the heatsinks or exposed tubes causing it to catch fire. Unlikely as that situation may be, it will happen as certainly with a 'full metal jacket' chassis as with one with wood or MDF sides.Just try and imagine yourself as an insurance company talking with a fire inspector after a fire.

How are you going to respond to something so obviously hand made with a wire attached to an outlet?

BTW, I find your confidence in the UL labels to be charming but fanciful. All the cheap junk light fixtures and appliances from 'overseas' that I see have the full set of UL/CSA/etc stickers on them. And, of course, a 'repurposed' chassis won't have a valid UL sticker either.

Attachments

that wording or word choice actually makes no sense.placing that kind of energy into a wooden box

You don´t seem to know what "energy" means and apparently use the word the way non Tech (anti Technology in fact) New Age and similar people do.

As in:

"I feel full of Energy"

"I am connected with the Energy of the Universe"

"his speech/sermon/poem/book/song is full of Energy"

and so on.

Sadly, we bored square unimaginative Engineering/Tech type guys have a very different meaning for "Energy".

AgreeAll chassis was done from recycled materials .......

The last amplifier pic. It looks like a tin of sardines the way it is packed. Every millimeter in the box has been used. Quite some task to fit everything so well.

I would like to remark something. The boxes are beautifully made and have a good finish. From what I have seen on this tread is that they all lack front panel marking.

I would like to give an idea how these can be made. As for myself I use microsoft publisher. I grid the page in 0.5cm boxes. I would measure the front panel and take measurements where all the holes slots etc would be and transfer these measurements on the page on the computer. I will design the art work according to my needs.

I will transfer the Publisher file to PDF so that nothing will move. I save the file to a pen drive and go to my local stationery an make a transparent sticker of the artwork. This will be stuck to the front panel.

Below is a picture of my Audio dummy load under assembly which I recently built.

Attachments

Last edited:

You don´t seem to know what "energy" means...

I’m not going to get into what I do on this forum, it’s R&D, but I can say that when a large truck ripped the power line completely out of my house, the utility company asked who had done the repair, and wanted to see paperwork prior to reconnecting the power. I told them what I did and what I did for work, and they just said “oh”, and promptly reconnected the power.

Those building Electronic Equipment on wooden chassis are just following an old and revered technology without which Electronics would have never developed, or veeeeryyy sloooowwwlllyyyy at best.

Experimenters built their stuff on, *literally*, breadboards.

Technique was safe and practical enough to be used later in expensive *commercial* stuff.

A few examples of 1920´s Technology, built on polished oak, brass, and that wonderful invention: Bakelite!!!!!

Reminding again that none of these are experimenter´s kludges but expensive commercial products.

An Atwater Kent "breadboard" Radio sold in 1923 for 325 U$ ... some u$5000 today.

In fact, WAY more, Inflation is cronically under reported or "rounded down" ever year.

But ... didn´t so much "Energy" coupled to wooden chassis and cabinets bring trouble?

Wood is no barrier for Electromagnetism!!!!

Well, yes, it did cause trouble.

Women listening to radio became uncontrolled hotheads who even ... smoked !!!!!!!

and Men ... we all know men don´t share their problems but become more and more isolated inside themselves.

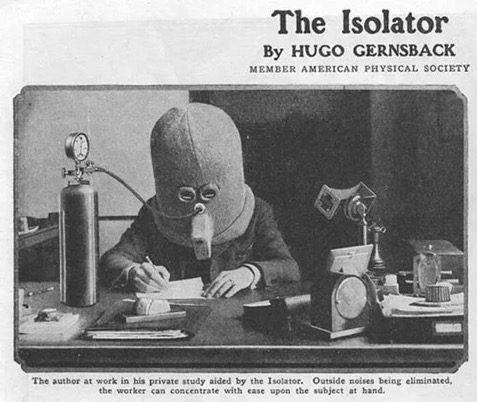

Hugo Gernsback, a famous Radio (and Science Fiction) pioneer, had to go this far to experiment without people bothering him and weakening his focus and concentration:

Experimenters built their stuff on, *literally*, breadboards.

Technique was safe and practical enough to be used later in expensive *commercial* stuff.

A few examples of 1920´s Technology, built on polished oak, brass, and that wonderful invention: Bakelite!!!!!

Reminding again that none of these are experimenter´s kludges but expensive commercial products.

An Atwater Kent "breadboard" Radio sold in 1923 for 325 U$ ... some u$5000 today.

In fact, WAY more, Inflation is cronically under reported or "rounded down" ever year.

But ... didn´t so much "Energy" coupled to wooden chassis and cabinets bring trouble?

Wood is no barrier for Electromagnetism!!!!

Well, yes, it did cause trouble.

Women listening to radio became uncontrolled hotheads who even ... smoked !!!!!!!

and Men ... we all know men don´t share their problems but become more and more isolated inside themselves.

Hugo Gernsback, a famous Radio (and Science Fiction) pioneer, had to go this far to experiment without people bothering him and weakening his focus and concentration:

I like the handles and the spikes!

Thanks Victoria.

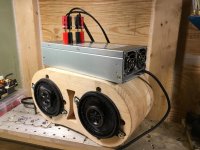

I have no qualms whatsoever with the intelligent use of wood in a DIY chassis. Most of mine are of what I call the typical "hamburger" type, comprised of a mitered wooden box between two aluminum plates. Easy, cheap and safe. To that last point, I employ a variety of methods to engineer safety in each of my builds.

First, I use fused and filtered IEC power entry modules exclusively. This simplifies/minimizes exposed mains wiring, makes for a neater installation, and has the added benefit of eliminating the need for a power cord strain relief. Best of all they give me the chance to use up all those old computer power cords I've accumulated through the years! During initial testing I make certain that the fuse is properly matched to the load current - just enough to withstand the initial power-up surge and no more.

Next, I've begun using those LED-illuminated vandal-proof switches for the mains. They're rated at ~25,000 cycles at 3A, made of stainless steel, and provide a positive visual indication of the unit's state. I'll note here that I always purchase them from a reputable supplier (e.g. Mouser) even though they're more expensive than the ones sold through online auction sites. Why? Because I can view a proper manufacturer spec sheet; I have confidence in what I'm buying.

During the build itself I make absolutely certain that all - and I mean ALL - of the various exposed metal plates are tied to a proper ground. This is just good practice. No sense tempting fate by leaving this stuff floating.

I also make certain the inside of the box is properly ventilated. Again, this is just good practice. For instance, surrounding power output tubes with a ring o' holes helps harness the convective currents on the tubes' exterior, pulling air through the inside of the box and keeping the contents cool. One additional benefit (one I've rarely seen discussed) is that it helps make internal failures more apparent; a blown or overheated component is more easily seen, heard or smelled. To further protect against fire, I just use a little common sense and avoid placing high-heat components on or near the wooden sides. Chassis-mount resistors are great in this regard as they can be mounted directly on the underside of the top plate, thus using it as a heat sink and further enhancing chassis convection.

Finally, I employ a master power switch on my audio rack, which is in turn plugged into a GFI outlet. By using this multi-faceted approach I've managed to avoid literally "firing 'em up" every time I've, um, fired 'em up.

Below is a picture of a pair of monoblocks I built last year that incorporate all the techniques described above. Instead of drilling ventilation holes around the tube sockets, I simply bored the holes oversize and mounted the sockets from below. Also note that the B+ choke is mounted on the chassis side, but its connections are soldered well away from the wood itself. To set that wood on fire, the choke is going to have to short out for long enough to reach ignition temperature without blowing the mains fuse or tripping the GFI outlet - which ain't going to happen (I've tested this!).

BTW, these pictures were taken during testing, before the upper and lower plates were permanently mounted.

@djn: Yours are among the most creative chassis designs I've seen. Truly "outside the box" thinking. Great work!

First, I use fused and filtered IEC power entry modules exclusively. This simplifies/minimizes exposed mains wiring, makes for a neater installation, and has the added benefit of eliminating the need for a power cord strain relief. Best of all they give me the chance to use up all those old computer power cords I've accumulated through the years! During initial testing I make certain that the fuse is properly matched to the load current - just enough to withstand the initial power-up surge and no more.

Next, I've begun using those LED-illuminated vandal-proof switches for the mains. They're rated at ~25,000 cycles at 3A, made of stainless steel, and provide a positive visual indication of the unit's state. I'll note here that I always purchase them from a reputable supplier (e.g. Mouser) even though they're more expensive than the ones sold through online auction sites. Why? Because I can view a proper manufacturer spec sheet; I have confidence in what I'm buying.

During the build itself I make absolutely certain that all - and I mean ALL - of the various exposed metal plates are tied to a proper ground. This is just good practice. No sense tempting fate by leaving this stuff floating.

I also make certain the inside of the box is properly ventilated. Again, this is just good practice. For instance, surrounding power output tubes with a ring o' holes helps harness the convective currents on the tubes' exterior, pulling air through the inside of the box and keeping the contents cool. One additional benefit (one I've rarely seen discussed) is that it helps make internal failures more apparent; a blown or overheated component is more easily seen, heard or smelled. To further protect against fire, I just use a little common sense and avoid placing high-heat components on or near the wooden sides. Chassis-mount resistors are great in this regard as they can be mounted directly on the underside of the top plate, thus using it as a heat sink and further enhancing chassis convection.

Finally, I employ a master power switch on my audio rack, which is in turn plugged into a GFI outlet. By using this multi-faceted approach I've managed to avoid literally "firing 'em up" every time I've, um, fired 'em up.

Below is a picture of a pair of monoblocks I built last year that incorporate all the techniques described above. Instead of drilling ventilation holes around the tube sockets, I simply bored the holes oversize and mounted the sockets from below. Also note that the B+ choke is mounted on the chassis side, but its connections are soldered well away from the wood itself. To set that wood on fire, the choke is going to have to short out for long enough to reach ignition temperature without blowing the mains fuse or tripping the GFI outlet - which ain't going to happen (I've tested this!).

BTW, these pictures were taken during testing, before the upper and lower plates were permanently mounted.

@djn: Yours are among the most creative chassis designs I've seen. Truly "outside the box" thinking. Great work!

Attachments

Last edited:

BTW, these pictures were taken during testing, before the upper and lower plates were permanently mounted.

Very nice! 6CB5's?

jeff

Thank you, Sir! You're correct; they're a twist on Thomas Mayer's "economy" design, but there's certainly nothing cheap about the sound. I've heard them next to a 300B amp, and frankly I can't tell the difference. My only regret is that I can't plug in a pair of the old ST-bulb 6CB5's. Poo.

I lugged them to Burning Amp last year. It was like hauling a pair of steam locomotives on my back... It was worth it, though.

It was worth it, though.

I lugged them to Burning Amp last year. It was like hauling a pair of steam locomotives on my back...

For my TGM8 amps I used some surplus steel boxes that I found, 8" x 10" x 3 3/4". I believe they were coin boxes from some kind of vending machine. With a couple of bent panels, toroid and rectifiers mounted inside, Rustoleum dark bronze hammer tone paint, they became a chassis.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Low Cost Amplifier Chassis Ideas