I having been having a play with 16mm PSU filter caps and I am struggling to fit them on nicely. I can maybe cram them onto the board with a small change in dimensions but at the expense of the 5mm gab in between the filter caps that allows screw driver access to the chip. This board is somewhat designed for a specific implementation that I am planning.

Perhaps I should make a 2nd more universal board with the fuse rails removed and larger filter caps allowed. Or simply a larger board. I'd be happy to release the Gerber files if people were interested and wanted to order their own.

Perhaps I should make a 2nd more universal board with the fuse rails removed and larger filter caps allowed. Or simply a larger board. I'd be happy to release the Gerber files if people were interested and wanted to order their own.

For the 22uF cap use a good quality BP like the Nichicon ES (green suckers). I've never seen a film cap used in this location. Dump the fuses and if required, add them on the power supply PCB.

Digi-Key is a good supplier of stuff and free shipping over AU$60.

I haven't tried digikey before, I typically use Element 14 and RS components. Strangely, they can reliably deliver quicker from Syndey to Auckland than I can reliable deliver across Auckland.

I've read on multiple LM1875 threads that the 22uF feedback cap is the most important part on the whole board.

As far as my limited understanding goes; a film cap is superior to an electrolytic. So it makes sense to me to use a large film cap since the extra cost is only a few $ extra on such a cheap fitout.

Something like $25 to populate a board with genuine and name brand parts makes these hilariously good bang for buck.

Another possibility is to simply shortcut the feedback cap.

Its sole purpose is to block dc amplification (if a dc voltage would be present at the input it would be amplified, resulting in a huge dc offset at the output, which might kill your speaker)

If you're using a quality foil type for the input cap there is no chance of a dc voltage at the input of the LM1875, so it could be ommitted.

When googling for gainclone i noticed many people do that actually without problems.

Of course you should check and recheck the offset voltage in a test setup before actually connecting your speakers.

If you wish to avoid any capacitor in your signal path another option would be to use a professional mini audio transformer 10k:10k.

These little transformers linear from eg 20Hz-80kHz or even 200 kHz.

The advantage is also, that you isolate you amplifier from the input, so it will effectively block "hum" groundloops.

Widely used in studios, but they are somewhat expensive (good quality about 25$ for a pair)

Its sole purpose is to block dc amplification (if a dc voltage would be present at the input it would be amplified, resulting in a huge dc offset at the output, which might kill your speaker)

If you're using a quality foil type for the input cap there is no chance of a dc voltage at the input of the LM1875, so it could be ommitted.

When googling for gainclone i noticed many people do that actually without problems.

Of course you should check and recheck the offset voltage in a test setup before actually connecting your speakers.

If you wish to avoid any capacitor in your signal path another option would be to use a professional mini audio transformer 10k:10k.

These little transformers linear from eg 20Hz-80kHz or even 200 kHz.

The advantage is also, that you isolate you amplifier from the input, so it will effectively block "hum" groundloops.

Widely used in studios, but they are somewhat expensive (good quality about 25$ for a pair)

Probably prudent really. I was planning to use some 10mm 470uf Panasonic FC caps I have on hand but a brief search on RS components suggests that 16mm diameter 7.5mm pitch is the more common size for 1000uF caps

I decided to remove the ground lift resistor as from what I have read around these forums it is probably unnecessary and doesnt feature on the spec sheet design.

What would be the advantage of a 100uF cap instead of the 22uF? I am guessing the answer is a lower frequency rolloff?

Both the spec sheet and the schoolies design use 22uF.

The disadvantage would be cost. A 22uf film cap is around $7 on RS components however a 100uF film cap costs $25. This would necessitate going back to an elco cap. Which then begs the question as to whether a 100uF alco or a 22uF film cap would be superior.

You should use a high quality bipolar electrolytic for input and feedback coupling, if you make them large enough to keep the corner frequency at about 2 Hz it will cause no audible degradation at all. Take a look at what Tomchr said in post #3, he also has a LOT of good info posted on his own site regarding the use of these chips.

Mike

Last edited:

Another way to do it is to use a film cap for input coupling and an electrolytic bipolar for the feedback cap. The film cap value is chosen to set the corner frequency for the whole amp. The feedback cap is then chosen for a corner frequency an octave lower, so that it barely sees any voltage variation and its quality becomes pretty much irrelevant.

Another way to do it is to use a film cap for input coupling and an electrolytic bipolar for the feedback cap. The film cap value is chosen to set the corner frequency for the whole amp. The feedback cap is then chosen for a corner frequency an octave lower, so that it barely sees any voltage variation and its quality becomes pretty much irrelevant.

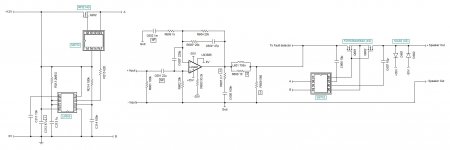

I routinely use a 100 uF cap at the input, and a 1000 uf for the feedback, they are smaller and less expensive. The down side to using such high values is that it takes a little more time for the amp to stabilize when first turned on. I get around that by delaying the connection to the speakers through a MOSFET switch.

Mike

I routinely use a 100 uF cap at the input, and a 1000 uf for the feedback, they are smaller and less expensive. The down side to using such high values is that it takes a little more time for the amp to stabilize when first turned on. I get around that by delaying the connection to the speakers through a MOSFET switch.

Mike

Hi Mike!

Could you tell us a little more about the MOSFET switch and how to set it up?

I have been looking for something like that but not sure how to execute it.

Regards

/Hilding

Thanks!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Chip Amps

- Yet another LM1875 amp - review request