Not from alternator and I hear it when no RCA or speaker is hooked up. It's coming from a component but I can't isolate it. Usually when it first powers on for a second or two. Then it comes and goes while just sitting idle. Not super loud and I don't think you would even notice when playing music. I'm just curious if this is something a certain component might do if it was failing or out of spec.

Thanks,

Steve

Thanks,

Steve

Attachments

I’ve seen this in other older Rockford amps. Most likely the transformer. You can use some medium CA glue or silicone to lock loose windings in place.

Following Perry’s prodding’s will certainly help you understand things better than you ever thought possible. He wrote the book on amp repair.

Just my two cents,

David

Following Perry’s prodding’s will certainly help you understand things better than you ever thought possible. He wrote the book on amp repair.

Just my two cents,

David

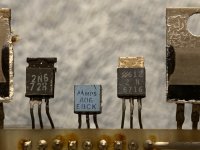

Definitely the transformer. I put the faintest pressure on it and it goes away. The windings feel pretty solid, though. The pads near the edge look a bit crusty so I think I'm going to give the board a little alcohol toothbrush scrub and maybe re-flow some of the solder joints. I didn't measure the frequency because I didn't know where to probe. The only dips are 2 NE5532P's and a single TL072CP and they were on the opposite end from the power supply. I even read your basic amp repair guide looking for clues before getting back here. I suspect the 2 GE D40D8's might have that duty but they're so close to board I can't probe the legs unless I remove from the heat sink and get to the back side. This amp and my 45's both use the BYV27-100's. Could I replace with them with MUR810's? I saw you used MUR820's in your punch 45 BYV28-150 replacement. Or should I up it to 815's? Is there any benefit(or detriment) to a higher voltage limit? My gut tells me that higher won't hurt or benefit but the better current rating and heat dissipation of the 220 package is why you used them.

Thanks,

Steve

Thanks,

Steve

You read the frequency on the center leg of the power supply transistors (the ones clamped to the heatsink).

You can simply move one or two of the smaller windings over a fraction of an inch to stop the noise but if it's operating at an acceptable frequency and you couldn't hear it with the amp assembled and mounted in the trunk, I wouldn't be concerned about it.

You can simply move one or two of the smaller windings over a fraction of an inch to stop the noise but if it's operating at an acceptable frequency and you couldn't hear it with the amp assembled and mounted in the trunk, I wouldn't be concerned about it.

You read the frequency on the center leg of the power supply transistors (the ones clamped to the heatsink).

You can simply move one or two of the smaller windings over a fraction of an inch to stop the noise but if it's operating at an acceptable frequency and you couldn't hear it with the amp assembled and mounted in the trunk, I wouldn't be concerned about it.

Basically what I was thinking. I might move them and put a couple dabs of hot glue on them(like I've seen on other transformers).

I'd like to try running this or maybe one of my 45's at 2ohm mono for an 8" speaker I have. The 8 is rated at 180 or 200 rms. I want to build a t-line for it. This is in my work commute car so only about 25 minutes, twice a day. Is there anything I should upgrade while I've got it apart? Rectifiers?

Attachments

I wouldn't put anything on the transformer. It will only serve to prevent it from cooling.

I'd never use hot glue for anything in an amp. Amp components get hotter than the melting point of the glue.

If the ringing won't be audible, I'd suggest leaving it alone.

If you have to do something just move the smaller windings slightly. Often just pulling them over, on top of another winding is enough.

From page 18 of my site (only for this model 45):

Modified Punch 45

I'd never use hot glue for anything in an amp. Amp components get hotter than the melting point of the glue.

If the ringing won't be audible, I'd suggest leaving it alone.

If you have to do something just move the smaller windings slightly. Often just pulling them over, on top of another winding is enough.

From page 18 of my site (only for this model 45):

Modified Punch 45

Last edited:

From page 18 of my site (only for this model 45):

Modified Punch 45

I've probably read this 20 times over the past year! That's why I asked. Should I replace the rectifiers as you mention them being the weak link? Or maybe just send it as is and see what happens? If they smoke, replace them at that time?

Thanks,

Steve

The rectifiers are a weak point that often fail under normal operating conditions.

When they fail, they will generally cause the PS to fail which can also cause damage.

The heat they produce (abusive operation) can damage the board. If you intend to drive the amp hard, I'd replace the rectifiers while you have it apart.

When they fail, they will generally cause the PS to fail which can also cause damage.

The heat they produce (abusive operation) can damage the board. If you intend to drive the amp hard, I'd replace the rectifiers while you have it apart.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Car Audio

- 1st Gen RF Punch 75 High Pitched Ring from component.