im just assuming on he box size based on the newer sub. im going to try to re contact soundstream tomorrow becuase they claimed the tech support guy was on vacation all last week. i have not used any box programs and im sure the box demensions are not the bost but thats the space i have to work with.

http://www.soundstream.com/manuals/2006/sbw/SPLX SUBWOOF.pdf the SPLX 154 is the one i based off of.

http://www.soundstream.com/manuals/2006/sbw/SPLX SUBWOOF.pdf the SPLX 154 is the one i based off of.

the recondmended port is two circle 4" by 16 long. a 4 inch circle has a area of 12.5". so two at 12.5 comes to 25" shouldnt that be right then?

on this one i built its 2.4 CF per side wit a port 2 by 6 by 11 or something with no port noise http://s227.photobucket.com/albums/...New 12 box/

on this one i built its 2.4 CF per side wit a port 2 by 6 by 11 or something with no port noise http://s227.photobucket.com/albums/...New 12 box/

one of the worse sounding boxes i have mad and one of the worst videos ever but even with small ports this box was loud and had no port noise http://videos.streetfire.net/video/94-Blazer-s10-with-my-12s_97028.htm

here's a box i made for one 15"...it was so loud it gave me heart pains, very sharp, clear tight ,loud and could play VERY VERY WELL below tuning...with authority...louder than a low tuned box for a low note...and way louder on a higher note.

you would'nt think it would because the appearance of the large port area and short length, but this box has crazy airflow with very little turbulence.

You will have to experiment to get it just right...just lay it on your garage floor and mess with the port, i tuned it in my living room.

the port assembly slides back and forth to find the sweet spot, but you have to mess around with the length of the port opening 'inside' the box....the part that is sticking out has to be there, if you cut it off...you will lose db's... it helps to prevent the cancellation between the sub and the port.

panel A and B shoud be the samesize as the side panels.

something happens in this design, that lets it play low, but with the extra volume of higher tuning.

tuning goes by fast because you know if someting sucks, it just sucks...when you find the sweet spot you will know...i used a few screws to secure the test points, then secured them better once i had it.

this box hit every note i threw at it.

you would'nt think it would because the appearance of the large port area and short length, but this box has crazy airflow with very little turbulence.

You will have to experiment to get it just right...just lay it on your garage floor and mess with the port, i tuned it in my living room.

An externally hosted image should be here but it was not working when we last tested it.

the port assembly slides back and forth to find the sweet spot, but you have to mess around with the length of the port opening 'inside' the box....the part that is sticking out has to be there, if you cut it off...you will lose db's... it helps to prevent the cancellation between the sub and the port.

panel A and B shoud be the samesize as the side panels.

something happens in this design, that lets it play low, but with the extra volume of higher tuning.

tuning goes by fast because you know if someting sucks, it just sucks...when you find the sweet spot you will know...i used a few screws to secure the test points, then secured them better once i had it.

this box hit every note i threw at it.

Clipped said:what kind of car? port placement can be very picky...especially in a trunk.

Sub back port side sounds good in many vehicles...usually sound great in trunks. Does well in SUV.s also.

http://www.freeimagehosting.net/uploads/2b09b385a3.jpg

forgot to mention...the opening area under panel 'A' should be atleast the width from the boxes side wall to panel 'A'... or it can be bigger, mine was a little bigger.

forgot to mention...the opening area under panel 'A' should be atleast the width from the boxes side wall to panel 'A'... or it can be bigger, mine was a little bigger.

sorry no pics, i made it about 3 years ago...after i tried a 6" aeroport, then a regular slot port using the 12"-14". sqin rule.

never tried it on a single 10" sub.

i wanted to experiment with port sizes, so made the sliding port...when i found the sweet spot i cut off the overhang sticking out and lost volume...made another overhang and the loudness came back...then tried to make another overhang on the opposite side and lost volume again so removed it.

the overhang works to seperate the mass of air on the face of the enclosure, which is constantly being tugged back and forth between the sub and port...

i also suspect the overhang is extending the range of tuning...as well as equalizing the airflow friction from the inner port wall on the side of the box...which is the reason panel A has to be the same length as the box sides....

regarding the length of panel B, thats what i used...and have had the most consistent results with.

*** ive never been able to get this design to work with a dual sub box with port down the middle.( i just bummed a few people out)

ive never been able to get this design to work with a dual sub box with port down the middle.( i just bummed a few people out)

there needs to be some room between panel B and the inner port mouth...which would make the dual sub box too wide to put in a car...

ive had zero luck with trying to mimick panel B and the overhang in a square box design...it doesnt work effectively with square boxes or boxes with subs 'not' mounted on the longest face ,the air velocity is too fast and localized...do the port first, then adjust panel B.

the box was 18.5" x 18.5" x 37.5"....outer dimensions...5/8"HDF, yes 5/8"....HDF not MDF

use a rap song with QUICK low really really really hard hitting bass around 40-45hz...about two beats a second...the faster the box can breath the louder it will be...for slower songs the extension and detail will be dramatic...this is a very clean design.

btw...use long" drywall screws to test the angles of panel B, screwed down from the inside going through B and just piercing the inner box walls.

good luck if you decide to try it !...and i was serious about the heart pain thing...be careful

never tried it on a single 10" sub.

i wanted to experiment with port sizes, so made the sliding port...when i found the sweet spot i cut off the overhang sticking out and lost volume...made another overhang and the loudness came back...then tried to make another overhang on the opposite side and lost volume again so removed it.

the overhang works to seperate the mass of air on the face of the enclosure, which is constantly being tugged back and forth between the sub and port...

i also suspect the overhang is extending the range of tuning...as well as equalizing the airflow friction from the inner port wall on the side of the box...which is the reason panel A has to be the same length as the box sides....

regarding the length of panel B, thats what i used...and have had the most consistent results with.

***

ive never been able to get this design to work with a dual sub box with port down the middle.( i just bummed a few people out)

ive never been able to get this design to work with a dual sub box with port down the middle.( i just bummed a few people out)there needs to be some room between panel B and the inner port mouth...which would make the dual sub box too wide to put in a car...

ive had zero luck with trying to mimick panel B and the overhang in a square box design...it doesnt work effectively with square boxes or boxes with subs 'not' mounted on the longest face ,the air velocity is too fast and localized...do the port first, then adjust panel B.

the box was 18.5" x 18.5" x 37.5"....outer dimensions...5/8"HDF, yes 5/8"....HDF not MDF

use a rap song with QUICK low really really really hard hitting bass around 40-45hz...about two beats a second...the faster the box can breath the louder it will be...for slower songs the extension and detail will be dramatic...this is a very clean design.

btw...use long" drywall screws to test the angles of panel B, screwed down from the inside going through B and just piercing the inner box walls.

good luck if you decide to try it !...and i was serious about the heart pain thing...be careful

audiobahnkid592

Because I have yet to find a speaker 100% accurate to published T/S, I have to be able to tune.

The port you have designed doesn't seem to allow for that easily.

You can use PVC plumbing and elbows and 45 degree fittings to make a bent port you can adjust easier

Because I have yet to find a speaker 100% accurate to published T/S, I have to be able to tune.

The port you have designed doesn't seem to allow for that easily.

You can use PVC plumbing and elbows and 45 degree fittings to make a bent port you can adjust easier

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Car Audio

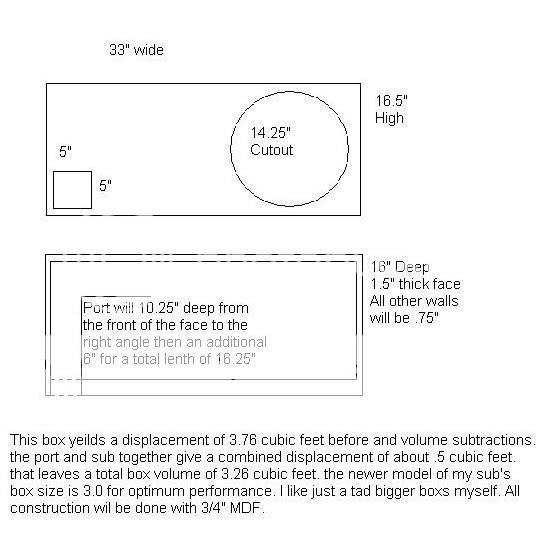

- My Box plans help please