Hi all...

I can see this thread is heading toward a discussion on tghe sonic properties of heatsink materials. That's fine, but before it wanders too far of Peter's original post, I would like to ask:

Peter: The amp you have shown looks great - up to your usual level of design and execution. I am very interested in the stepping-motor volume control. Could you provide some detail (maybe a schematic), either here or on another thread?

Eddog: To melt spun bronze (your cymbals) you will need a furnace that can sustain 2,200C, a crucible that can hold liquid amorphous amalgams (Bronze is brass and tin, remember) and a cooling chanber for the molten metal which will allow cooling to occur over about 18 hrs. Otherwise, oxydation will cause your ingots to break (explode) when they drop thru 1,250 - 1,200C, unless you can cool it in an oxygen-free, inert-gass environment. This project is extremely delicate and hazardous and should proovide you and your friends with a fun-filled weekend

Jess

I can see this thread is heading toward a discussion on tghe sonic properties of heatsink materials. That's fine, but before it wanders too far of Peter's original post, I would like to ask:

Peter: The amp you have shown looks great - up to your usual level of design and execution. I am very interested in the stepping-motor volume control. Could you provide some detail (maybe a schematic), either here or on another thread?

Eddog: To melt spun bronze (your cymbals) you will need a furnace that can sustain 2,200C, a crucible that can hold liquid amorphous amalgams (Bronze is brass and tin, remember) and a cooling chanber for the molten metal which will allow cooling to occur over about 18 hrs. Otherwise, oxydation will cause your ingots to break (explode) when they drop thru 1,250 - 1,200C, unless you can cool it in an oxygen-free, inert-gass environment. This project is extremely delicate and hazardous and should proovide you and your friends with a fun-filled weekend

Jess

For that amp, I used the board from Bentaudio. It is exactly the same as one presented here: http://www.diycable.com/main/product_info.php?products_id=532

Banned

Joined 2002

tade said:That is a sweet volume control. Too bad it is 450 bucks though...

I love the amp.

I am considering making gainclone. Does it feel strange to spend way more work on the case than the electronics, the gainclone being reasonably simple?

Wonderful job.

It's 450$ but well worth it.

From Peter

For that amp, I used the board from Bentaudio. It is exactly the same ...

Thanks, Peter. I had found that offering from DIYCable. It is rather pricey and it set me off on a hunt for a circuit I could DIY. I am playing with some floppy disk drive stepper motors and a cute little IC from Texas Instruments. When I have something, be sure I will post it.

Also, I just finished my 4766 stereo chipamp. Works great at 40wpc. I posted it here:

http://www.diyaudio.com/forums/showthread.php?s=&threadid=75358&highlight=

Not up to your exacting enginerering standards, Peter, but have a look - the case and heatsink are interesting.

Jess

JesseG said:

Thanks, Peter. I had found that offering from DIYCable. It is rather pricey and it set me off on a hunt for a circuit I could DIY.

Jess

You may actually be interested in this...

http://www.diyaudio.com/forums/showthread.php?postid=848119#post848119

JesseG said:Thanks, Peter. I had found that offering from DIYCable. It is rather pricey and it set me off on a hunt for a circuit I could DIY. I am playing with some floppy disk drive stepper motors and a cute little IC from Texas Instruments. When I have something, be sure I will post it.

The $450 is for the stepper motor assembly/control board AND the DACT attenuator. Without DACT attenuator, the price is about 50% of that. The Elma switch is needed to control setting on the transformers and it's about $60 from Percy.

It definitely can be done much cheaper, but at that time I didn't want to be bothered with developing another circuit.

Peter Daniel said:

Comparison between all those heatsinks isn't certainly an easy one. Maybe you remember that my first monoblock amp was using large copper piece acting as heatsink and structural bar. Initially, I liked the sound, but after CES, we came to conlusion that the air was somewhat missing in that amp. I was also using a clamping bar to attach the chip to the heatsink. After removing that calmp and replacing it with a regular screw things improved, but eventually we decided for aluminum heatsink as it provided more air extention, with copper it was a bit less. Those are not only my observations, but also from the people who worked with me while developing the amp.

Wow . . .

The op amp chip must be a great magician . . .

On what color of the chip, the sound could be the best . . . ?

"Eddog: To melt spun bronze (your cymbals) you will need a furnace that can sustain 2,200C, a crucible that can hold liquid amorphous amalgams (Bronze is brass and tin, remember) and a cooling chanber for the molten metal which will allow cooling to occur over about 18 hrs. Otherwise, oxydation will cause your ingots to break (explode) when they drop thru 1,250 - 1,200C, unless you can cool it in an oxygen-free, inert-gass environment. This project is extremely delicate and hazardous and should proovide you and your friends with a fun-filled weekend "

Hahahaha!! More confirmation that I should just hit my cymbals less hard, then I wouldn't feel compelled to do something with the damn things when they break. At upwards of$200 each you just hate to have them hanging in the garage collecting dust!

Hahahaha!! More confirmation that I should just hit my cymbals less hard, then I wouldn't feel compelled to do something with the damn things when they break. At upwards of$200 each you just hate to have them hanging in the garage collecting dust!

Banned

Joined 2002

Peter Daniel said:

The $450 is for the stepper motor assembly/control board AND the DACT attenuator. Without DACT attenuator, the price is about 50% of that. The Elma switch is needed to control setting on the transformers and it's about $60 from Percy.

It definitely can be done much cheaper, but at that time I didn't want to be bothered with developing another circuit.

Id do it but i don't want to step on any one's toe's. Is any one interested in such a device ? 450$ is a little steep.

From jleaman

Id do it but i don't want to step on any one's toe's. Is any one interested in such a device ? 450$ is a little steep.

I for one would be VERY interested in a remote volume setup that I could DIY for less that the known kits - hopefully LOTS less.

Jess

jleaman said:

Id do it but i don't want to step on any one's toe's. Is any one interested in such a device ? 450$ is a little steep.

yes

It's not only steep, but DACT attenuator is nothing really special either.

I already mentioned that the better volume control is under development: http://www.diyaudio.com/forums/showthread.php?postid=839425#post839425

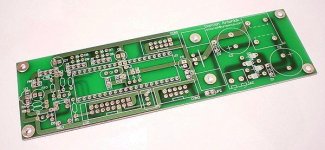

I'm working on it with Veteran, who does programing and development of control board, pictured below.

This setup should be able to compete with any currently available attenuator kit on a market, the price will reflect it, but as usually, it will be still affordable.

I already mentioned that the better volume control is under development: http://www.diyaudio.com/forums/showthread.php?postid=839425#post839425

I'm working on it with Veteran, who does programing and development of control board, pictured below.

This setup should be able to compete with any currently available attenuator kit on a market, the price will reflect it, but as usually, it will be still affordable.

Attachments

From Peter Daniel

This setup should be able to compete with any currently available attenuator kit on a market, the price will reflect it, but as usually, it will be still affordable.

I am very interested in this type of control, as I said before. I have this vision of being able to touch a button from the comfort of my chair to adjust the volume on my chipamp. But, I like the sound of my chipamp and I don't want to loose it to the innards of a volume control chip.

I have seen some very simple motorized pot setups that didn't cost much, but the weak point was, of course, the pot.

The other 'but' is that I got in to chip amps because of they are phenomenally inexpensive. If I wanted to spend hundreds of dollars, I would buy something with a warranty so I had someone to yell at if it didn't work properly. However, for me, the fun of building a working amp with descent preformance from junk-bin parts and a couple of hours is right up my alley. $200 for a volume control would be more than double what all 3 of my chipamps cost - $450 would probably exceed my entire investment in hifi.

So, guys, I am looking for a good, CHEAP remote stepped attenuator solution - probably an oxymoron, but then so am I.

Jess

Peter Daniel said:Yes, there will be LED numeric display, as well a volume knob and remote control. No options here, it will be standard.

nice

Peter Daniel said:

This setup should be able to compete with any currently available attenuator kit on a market, the price will reflect it, but as usually, it will be still affordable.

How much ?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- More Vendors...

- Audio Sector

- The most advanced GainClone amp yet