Parallel alignment with platter :

I am not posting with confidence but I thought with multiple bearings the horizontal balance would need to be looked at differently as resistance would be greater. Secondly we have three plane to balance. The tonearm base + the linkeages which move horizontally + tonearm which moves horizontally. So if the base is perfectly balanced and tonearm is also balanced the linkages assembly if not perfectly horizontal/balanced (And which will be difficult to adjust with bubble level) would probably give a little different balance at different positions.

Simply put. It has to be balanced 360 degrees.

Friction :

It is natural that the horizontal friction would be more than typical tonearm. But it would be nice to compare. I suppose 2wice tonearm will have comparatively less friction. If both designs does not have much friction and effective mass within limit compared to the friction it posses, what we would have is a very very well made tonearm.

Regards

Bearing friction for PT arms is non-issue at all. Effective mass isn't a problem. As long as the resonant frequency is under 20 Hz, ideally 15 Hz, it will be fine. All tonearms designs are the same with resonant frequency, not only PT arms.

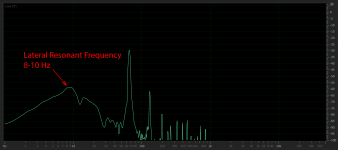

I did resonant frequencies test today. Please see attached images.

The test tracks I used are from Cardas Frequency Sweep and Burn-in Record. Track 8a is 49 Hz lateral modulation and track 8b is 49 Hz vertical modulation. The results indicate that both vertical resonant frequency and lateral resonant frequency are within 8-10 Hz, which are very good. This is exactly what I expected.

The test tracks I used are from Cardas Frequency Sweep and Burn-in Record. Track 8a is 49 Hz lateral modulation and track 8b is 49 Hz vertical modulation. The results indicate that both vertical resonant frequency and lateral resonant frequency are within 8-10 Hz, which are very good. This is exactly what I expected.

Attachments

I did some tests to see how the tonearm performs. Here are the results.

Right channel square wave

The right channel is excellent. I couldn’t ask for more.

Left channel square wave

The left channel can be improved. Its peaks are cut off.

Right channel toneburst

Again, I couldn’t ask for more. It is excellent.

Left channel tone burst

Same again. I couldn’t ask for more as well. It is excellent.

All things indicate that the ball pen bearings are working very well.

Right channel square wave

The right channel is excellent. I couldn’t ask for more.

Left channel square wave

The left channel can be improved. Its peaks are cut off.

Right channel toneburst

Again, I couldn’t ask for more. It is excellent.

Left channel tone burst

Same again. I couldn’t ask for more as well. It is excellent.

All things indicate that the ball pen bearings are working very well.

Last edited:

Bon raised an interesting question that the lateral resonant frequency may change across the surface of the record. In order to confirm his view, I run three tests.

The tracks I used are from Hifi News Test LP. There are three 300 Hz tracks on the LP. The 1st one is on the most outer groove. The 2nd one is in the middle of the groove, and the 3rd one is on the most inner groove. Bon was talking about lateral resonant frequency. But I don’t know if these three tracks are lateral modulation.

On the most outer groove

In the middle of the groove

On the most inner groove

These tests did confirm that the resonant frequency of my 6B tonearm is 9-10 Hz.

The resonant frequency decreases from 10 Hz to 6 Hz, then it increases from 6 Hz to 10 Hz. I can’t explain the reasons underlying the pattern of changes. In addition to that, I don’t know if the tracks are lateral modulation. Therefore, I think these tests are inconclusive.

In any cases, as I said it before, it doesn't matter too much because from 6 Hz to 10 Hz, the resonant frequency is well under 20 Hz. It is completely fine.

The tracks I used are from Hifi News Test LP. There are three 300 Hz tracks on the LP. The 1st one is on the most outer groove. The 2nd one is in the middle of the groove, and the 3rd one is on the most inner groove. Bon was talking about lateral resonant frequency. But I don’t know if these three tracks are lateral modulation.

On the most outer groove

In the middle of the groove

On the most inner groove

These tests did confirm that the resonant frequency of my 6B tonearm is 9-10 Hz.

The resonant frequency decreases from 10 Hz to 6 Hz, then it increases from 6 Hz to 10 Hz. I can’t explain the reasons underlying the pattern of changes. In addition to that, I don’t know if the tracks are lateral modulation. Therefore, I think these tests are inconclusive.

In any cases, as I said it before, it doesn't matter too much because from 6 Hz to 10 Hz, the resonant frequency is well under 20 Hz. It is completely fine.

Last edited:

The resonant frequency decreases from 10 Hz to 6 Hz, then it increases from 6 Hz to 10 Hz. I can’t explain the reasons underlying the pattern of changes. In addition to that, I don’t know if the tracks are lateral modulation. Therefore, I think these tests are inconclusive.

In any cases, as I said it before, it doesn't matter too much because from 6 Hz to 10 Hz, the resonant frequency is well under 20 Hz. It is completely fine.

The HFN tracks are lateral. This can be checked by looking at L-R. It should be much smaller than L+R. I recall tonearm resonance should also lie above around 5 Hz to avoid typical LP warp and ripple. 6 Hz is cutting it too fine.

Hi Super10018.

I have a question about the Birch/Thales tangential alignment and you might be able to answer. Looking at the Reed 5A Youtube video description of the geometric principle seems to suggest it is based on tangential alignment at inner, outer and mid-groove positions. This allows for unique circles to pass through three points. Also the text on the Reed 5A web-page and supporting graphs refer to minimising tangential tracking error (in the the usual sense), not zero tracking error at each position. Is the Birch alignment tangential at a only a finite number of radii or truly tangential everywhere with the reported tracking error due to construction tolerances?

I have a question about the Birch/Thales tangential alignment and you might be able to answer. Looking at the Reed 5A Youtube video description of the geometric principle seems to suggest it is based on tangential alignment at inner, outer and mid-groove positions. This allows for unique circles to pass through three points. Also the text on the Reed 5A web-page and supporting graphs refer to minimising tangential tracking error (in the the usual sense), not zero tracking error at each position. Is the Birch alignment tangential at a only a finite number of radii or truly tangential everywhere with the reported tracking error due to construction tolerances?

Thanks. Saved me trawling years of the thread.

A Birch-style arm isn't truly tangential everywhere. This is why Frank's LT arm uses a non-circle guide in the rear. However, a non-circle guide is complicated and is difficult to make for DIYers. I had made many attempts to reduce tracking errors using a circle guide. A circle guide has its advantage over a non-circle guide. All you need is only one pivot.Hi Super10018.

I have a question about the Birch/Thales tangential alignment and you might be able to answer. Looking at the Reed 5A Youtube video description of the geometric principle seems to suggest it is based on tangential alignment at inner, outer and mid-groove positions. This allows for unique circles to pass through three points. Also the text on the Reed 5A web-page and supporting graphs refer to minimising tangential tracking error (in the the usual sense), not zero tracking error at each position. Is the Birch alignment tangential at a only a finite number of radii or truly tangential everywhere with the reported tracking error due to construction tolerances?

In order to reduce tracking errors, I did the following.

Limit the tracking area. I only need to consider the playable area of a record.

Expend the Thales circle. The Thales is 400 mm for my 6B.

Expend the movements. The arm length is 185 mm for my 6B. As I said before, I treated the 6B as a linear arm and didn't compress the movements around the arm base.

I also strategically placed the errors on the outer groove.

After all the efforts, the maximum tracking error on my 6B is less than 0.1 degrees and the tracking errors only exist within about 1/3 of the trajectory across the surface of a record.

Last edited:

I would like to add additional comments about the playable area of LP in the above post.

According to RIAA's LP standard, the minimum inside diameter of an LP is 4.75". But I used 4.25". Furthermore, the minimum inside diameter of the actual playable area is about 5.75". In the beginning, I thought to measure about 100 LPs to determine the playable area of an LP. However, I gave it up without measuring. If I used 5.75", I could even reduce the tracking errors more. Does this make any difference? Probably not. In theory, it might help to reduce tracking errors more.

According to RIAA's LP standard, the minimum inside diameter of an LP is 4.75". But I used 4.25". Furthermore, the minimum inside diameter of the actual playable area is about 5.75". In the beginning, I thought to measure about 100 LPs to determine the playable area of an LP. However, I gave it up without measuring. If I used 5.75", I could even reduce the tracking errors more. Does this make any difference? Probably not. In theory, it might help to reduce tracking errors more.

Is this correct? IEC give minimum recording radius as 57.5mm which is 4.53" diameter.Furthermore, the minimum inside diameter of the actual playable area is about 5.75".

Thanks. This is just the info I was seeking.A Birch-style arm isn't truly tangential everywhere. This is why Frank's LT arm uses a non-circle guide in the rear. However, a non-circle guide is complicated and is difficult to make for DIYers. I had made many attempts to reduce tracking errors using a circle guide. A circle guide has its advantage over a non-circle guide. All you need is only one pivot.

In order to reduce tracking errors, I did the following.

Limit the tracking area. I only need to consider the playable area of a record.

Expend the Thales circle. The Thales is 400 mm for my 6B.

Expend the movements. The arm length is 185 mm for my 6B. As I said before, I treated the 6B as a linear arm and didn't compress the movements around the arm base.

I also strategically placed the errors on the outer groove.

After all the efforts, the maximum tracking error on my 6B is less than 0.1 degrees and the tracking errors only exist within about 1/3 of the trajectory across the surface of a record.

Please see the photo. Actually, I should use 4.75" instead of 4.25". The actual playable area is another option as I haven't seen an LP that has the groove up to 4.75.Is this correct? IEC give minimum recording radius as 57.5mm which is 4.53" diameter.

I just measured every side of my Solti Mahler boxed set of symphonies 5-7.Please see the photo. Actually, I should use 4.75" instead of 4.25". The actual playable area is another option as I haven't seen an LP that has the groove up to 4.75.

View attachment 1004087

Diameters of recorded inner groove in inches :

5.2, 5.4, 5.2, 5.9, 5.6, 5.3, 5.1, 4.8, 5.5, 5.4

Random sides of pop LP's inner recorded groove diameters:

4.60, 5.00, 4.9, 4.8, 5.2, 5.3

Only the one inner groove measures more than 5.75"

In general non-classical have inner recorded grooves closer to the RIAA standard or even further in.

The 4.75" seems closer to the mark but the 5.75" figure does not appear to be useful in modelling.

Well, I might not state it clearly. I just took an LP randomly to illustrate my point. It doesn't mean I think 5.75" is a proper dimension to do the model. As I said in my previous post, I thought to measure about 100 LPs to get an estimate of the average dimension. In some cases, the actual dimension may be larger than the dimension I chose to design the tonearm, it really doesn't matter too much since the tracking errors are just starting. The tracking errors are very small anyhow.

Sorry, haven't spent much time here for a while... at the risk of being boring:I studied Schröder LT again. LT has one fixed mount screw in the back and two adjustable set screws in the front. It is clear that Frank thinks the adjustments need to be left and right side only, not front and back. In my opinion, the adjustments should be all way around. On my 6B, I added three set screws. The level can be adjusted 360 degrees. I am also trying to modify 6C to have an easy adjustment mechanism. Frank, if you are reading this thread, please correct me if I miss anything.

directdriver is correct. You only need two adjustment screws for 360° level adjustment if the third, nonadjustable "foot"(screw tip) is "sticking out" sufficiently so that either or both screws can be adjusted to be sticking out more or less then said third foot. No problem to make the third foot height adjustable as well, just not necessary

The washer underneath the fixing screw has vertical flex(it is slightly conical and corrugated), so one has a bit of adjustment range...

All the best,

Frank

Frank,

Since I know you are reading this thread, may I ask you a question? If you don't feel comfortable answering, I understand it completely.

My 6B has the same geometry as your LT. However, you said that your LT has a small skating force, but my 6B doesn't, at least, the skating force doesn't act up. Can I ask you why you think your LT has a small skating force? And, how do you detect the existence of the skating force?

Thank you in advance!

Jim

Since I know you are reading this thread, may I ask you a question? If you don't feel comfortable answering, I understand it completely.

My 6B has the same geometry as your LT. However, you said that your LT has a small skating force, but my 6B doesn't, at least, the skating force doesn't act up. Can I ask you why you think your LT has a small skating force? And, how do you detect the existence of the skating force?

Thank you in advance!

Jim

- Home

- Source & Line

- Analogue Source

- Building a Tuthill/Reed 5A Tangential Tracking Pivot Tonearm