each motor have its own brushless controller, I have checked their individual speed and they are pretty synchro.

It is an area worth investigating. Even small differences in the speed may render the idea of the two motors useless.

I don't know much about stepper motors but is it not possible to use a single controller for both?

HI,

@ Hiten: Interesting concept of bearing. It reduce the contact point therefore the friction, but reducing much the surface may wear sooner. My bearing of the fly wheel has some basic mistake, but at the present I will live with it. The shaft diameter was made too big, it is 19mm; in my opinion 15 mm would be more appropriate and would also provide the good mechanical stability and less friction. Anyhow for now I keep as it is.

Bushes also might be too long so again increase the friction. Good part is that this bearing will last a life.

@ Analog sa: these are not stepper motor, are brushless similar to what produce the Swiss company Maxon. I cannot have one controller for both, but my problem is not the speed between the 2 motors. Later I shall make some pictures and post.

Today I disassembled the fly wheel bearing and changed the oil with the same brand of oil but adding 6% of Cera Tec from Liqui Moly. I just checked the RPM of the fly wheel in cold ( room temperature ) and immediately it is faster than before, almost the speed that reach when is warm. Seems that this additive it is a good product ( once mixed with the oil have a pink colour like the thousand island dressing ) and perhaps shall reduce a lot th warming up time that is my goal.

However I cannot check my turntable yet since its bearing need thrust plate made, hope my lathe man tomorrow answer me and shall take this small order.

I will post more after I have the whole TT reassembled. Now I am making some running in of the fly wheel bearing and the Cera Tec needs it before can reach the best performance.

Rgds

Adelmo

@ Hiten: Interesting concept of bearing. It reduce the contact point therefore the friction, but reducing much the surface may wear sooner. My bearing of the fly wheel has some basic mistake, but at the present I will live with it. The shaft diameter was made too big, it is 19mm; in my opinion 15 mm would be more appropriate and would also provide the good mechanical stability and less friction. Anyhow for now I keep as it is.

Bushes also might be too long so again increase the friction. Good part is that this bearing will last a life.

@ Analog sa: these are not stepper motor, are brushless similar to what produce the Swiss company Maxon. I cannot have one controller for both, but my problem is not the speed between the 2 motors. Later I shall make some pictures and post.

Today I disassembled the fly wheel bearing and changed the oil with the same brand of oil but adding 6% of Cera Tec from Liqui Moly. I just checked the RPM of the fly wheel in cold ( room temperature ) and immediately it is faster than before, almost the speed that reach when is warm. Seems that this additive it is a good product ( once mixed with the oil have a pink colour like the thousand island dressing ) and perhaps shall reduce a lot th warming up time that is my goal.

However I cannot check my turntable yet since its bearing need thrust plate made, hope my lathe man tomorrow answer me and shall take this small order.

I will post more after I have the whole TT reassembled. Now I am making some running in of the fly wheel bearing and the Cera Tec needs it before can reach the best performance.

Rgds

Adelmo

HI,

@ Hiten: Interesting concept of bearing. It reduce the contact point therefore the friction, but reducing much the surface may wear sooner. My bearing of the fly wheel has some basic mistake, but at the present I will live with it. The shaft diameter was made too big, it is 19mm; in my opinion 15 mm would be more appropriate and would also provide the good mechanical stability and less friction. Anyhow for now I keep as it is.

Bushes also might be too long so again increase the friction. Good part is that this bearing will last a life.

@ Analog sa: these are not stepper motor, are brushless similar to what produce the Swiss company Maxon. I cannot have one controller for both, but my problem is not the speed between the 2 motors. Later I shall make some pictures and post.

Today I disassembled the fly wheel bearing and changed the oil with the same brand of oil but adding 6% of Cera Tec from Liqui Moly. I just checked the RPM of the fly wheel in cold ( room temperature ) and immediately it is faster than before, almost the speed that reach when is warm. Seems that this additive it is a good product ( once mixed with the oil have a pink colour like the thousand island dressing ) and perhaps shall reduce a lot th warming up time that is my goal.

However I cannot check my turntable yet since its bearing need thrust plate made, hope my lathe man tomorrow answer me and shall take this small order.

I will post more after I have the whole TT reassembled. Now I am making some running in of the fly wheel bearing and the Cera Tec needs it before can reach the best performance.

Rgds

Adelmo

I still don't see how temperature affects the speed. I am not saying you are wrong. If you say it's true, I believe you. However, if your bearing isn't binding, your motor has proper torque, and your belt isn't stretching, your motor SHOULD be able to spin the platter at a constant speed regardless of the situation.

Now it could actually be that your bearing is sticking or that oil is not flowing as nicely around your bearing as it should be. Heat will solve both those problems and give you a more stable and ideal speed.

I find this kind of stuff interesting, so keep us posted on what you find.

I still don't see how temperature affects the speed.....

Car starter-motor runs slower on very cold days. The oil gets thick when cold. "Cold" can be relative, most oils thicken/thin over a very b-r-o-a-d range of temperature (usually from pour-point to flash-point).

Cars used in cold weather are often switched to a thinner oil. In the extreme case, WWII airplanes injected gasoline in the oil line for unexpected interceptions to thin the cold/thick oil and get more useful power for climbing.

IF this slow-down is oil related, a thinner oil could be tried. Does a too-thin oil allow metal-metal scuffing when warm? Improved bearing design has allowed today's cars to run much thinner oil than in my youth, with savings in economy, and little risk of damage.

However russel recently re-oiled with a ceramic additive and probably is not interested in basic hydrodynamics.

And there is still the question: is this thick oil? Or is it differential thermal expansion? A steel shaft in an aluminum bushing, the Al expands more than the iron. It could be loose when hot and bound-up when cold, and only accidentally "OK" at in-between temps.

@PRR

That's all true, but I would counter by saying that oil viscosity will only lengthen the time it takes for the motor to achieve a steady operating speed. So long as the motor has sufficient torque and is somehow controlled to run at a fixed rpm, the final speed of the motor shouldn't change. It just takes more energy to get it to that speed and keep it there.

I would also add that the temperature differential we are talking about is pretty small. Worst case scenario is probably something like 25 degrees F above or below room temp. So I can't see the affecting the actual performance of the bearing.

Unless of course the oil really is THAT thick.

That's all true, but I would counter by saying that oil viscosity will only lengthen the time it takes for the motor to achieve a steady operating speed. So long as the motor has sufficient torque and is somehow controlled to run at a fixed rpm, the final speed of the motor shouldn't change. It just takes more energy to get it to that speed and keep it there.

I would also add that the temperature differential we are talking about is pretty small. Worst case scenario is probably something like 25 degrees F above or below room temp. So I can't see the affecting the actual performance of the bearing.

Unless of course the oil really is THAT thick.

Hi,HI,

@ Hiten: Interesting concept of bearing. It reduce the contact point therefore the friction, but reducing much the surface may wear sooner.

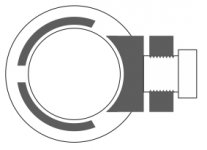

my thinking was more on line with bearing having tight tolerance.The spring can be adjusted to compensate for wear after time. or platter weight can be reduced. I understand less contact point imposes more pressure and possible more wear. alternative solution would be to cut cylindrical bush(Sleeve) bearing longitudinally in three section and one section will press against the shaft (withspring) the empty speca can hold the oil. As shown in the pic.

------------------------------

as for temperature affecting the speed, not sure but what could possible happen is when heated the bearing has more tolerance so ultimately one looses the advantage of tight tolerance bearing.

regards

Attachments

I would use a 15 or 25 mm thrust ball bearing, it will last for ever, with rubber or steel seals on both sides.

The idea that you would start a turn table on a freezing winter morning, and that the bearing needs a constant temperature, is standards room stuff for an instrument lab, this is a jury rigged home made contraption, with a design defect.

He still has not said how the top of the shaft is supported.

And takes 40 minutes to reach steady speeds, is like wow, I really think whatever you listen to must be worth the wait.

The lower bearing runs on a sphere, fine, ceramic added oil, fine.

Basic oil grade not specified.

Google says Imola 0.4 minimum, 32 maximum....so this whole temperature thing is a bug somebody has planted in your mind.

The idea that you would start a turn table on a freezing winter morning, and that the bearing needs a constant temperature, is standards room stuff for an instrument lab, this is a jury rigged home made contraption, with a design defect.

He still has not said how the top of the shaft is supported.

And takes 40 minutes to reach steady speeds, is like wow, I really think whatever you listen to must be worth the wait.

The lower bearing runs on a sphere, fine, ceramic added oil, fine.

Basic oil grade not specified.

Google says Imola 0.4 minimum, 32 maximum....so this whole temperature thing is a bug somebody has planted in your mind.

I told him to compare with those available in the market, how much speed variation is allowed, or is there in reputed brands.

If it changes from 33.333 to 33.222 or 33.444, is it allowed in real life?

Then go on what seems to be a wild goose change in the silly season.

Off Topic: I got a WhatsApp message saying that eating an egg size red onion with rock salt cures Covid in 15 minutes.

Like it says at the end of the Looney Tunes cartoons, That's All Folks

If it changes from 33.333 to 33.222 or 33.444, is it allowed in real life?

Then go on what seems to be a wild goose change in the silly season.

Off Topic: I got a WhatsApp message saying that eating an egg size red onion with rock salt cures Covid in 15 minutes.

Like it says at the end of the Looney Tunes cartoons, That's All Folks

...So long as the motor has sufficient torque and is somehow controlled to run at a fixed rpm...

Obviously it does not have these things.

HI,

When start the TT the platter speed is 32.9 RPM

After 45 minutes get 33.3 RPM

After about an hour gets 33.33 Rpm. I like the sound of my TT, generally speaking at 33.33RPM or a bit higher.....

I like the RPM Steady. Just to give you some sound info:

At 32.9 RPM i do not like the sound, is pretty shabby

At 33.1 still is shabby and not acceptable

At 33.2 high side you can start to play though not so nice

At 33.3 is getting better and you notice a difference

At 33.33 you say : now sounds well

At 33.36 or 33.38 I prefer with my TT and generally speaking any type of music. Classic music need 33.33 especially with some instruments.

Regarding construction of the fly wheel bearing ( main problem is here ) :

Out body of the bearing is made in aluminum

Bushes made with bronze, but not sintered one

Thrust plate body made with aluminum, thrust plate made with bronze, thickness of the bronze thrust plate 6mm.

Diameter of the shaft 19mm

diameter of the thrust ceramic sphere 5mm

By the way, if you lathe a hard steel shaft with 19mm diameter at the temperature of 20 degree, you check its diameter at that temperature, later you check the diameter at 28 or 30 degree what would be the diameter difference? Because there is a difference and this difference might give the RPM variation I got. Loosen allowance could be but I do not like it in the long run.

In a very precision coupling between shaft and bushes that difference ( that is due the metal expansion ) may change the RPM of around 1.5%. I do not think the temp difference change so much the oil viscosity in fact.

In my life I had 4 TT :

A pioneer but not really HIFI product therefore its sound sucked and I trashed it long time ago.

A Thorens TD 160. I tweaked the plinth, the tonearm, the platter ringing, improved its sound, but the bearing was ratting anyhow. I believe that was one of the biggest limitation of the TT. Also speed was not that precise despite a too loosen bearing.

I have 2 Lenco, dynamic of the sound is pretty good due to the rim type drive, complex to adjust the speed with standard unit, got small variation in speed between cold and warm spinning, but I really do not like the rumble of it. Takes many many effort to possibly get rid of it.

As last this DIY TT. Platter bearing I am pretty satisfied, do not ratt, rumble is good to my ears. Single motor pod is ok and run in few seconds at 33.33 RPM.

As latest tweak to this TT I made a Motor pod with fly wheel and 2 motors.

The idea was to get better sound and possibly get closer to the Lenco dynamic without its rumble. Rumble I got pretty good, platter bearing I am satisfied, Speed reaching I am not satisfied as takes to long to reach. I cannot play immediately LPs. Therefore I am encountering some problem as above. Why I do not give up? Easy to swap from single motor to fly wheel pod as they are not attached to the TT. Well DIYer likes to make things otherwise they would not be DIYer.

I read of other people that have encountered similar problem and one has successfully solved with the bearing heating and reach the optimal speed in 10 to 20 seconds. Why not try yet the bearing heating?. Because I like to install it inside the motor pod and so far I did not find an available one with such small dimension. Well... actually I did find a Ceramic one from Nisso, but they did not ship to Europe and now is no longer available. I believe also that a steady temp of the bearing around 26 to 30 degree do not harm neither the bearing neither the oil, neither change the oil viscosity.

I am using pretty thin oil guys. The fly wheel start easily without belt slipping.

I have a laser tachometer with its fixed pod to check the speed continuously while spinning either the motor s pulley or the platter or play music as well to see if during the dragging of the cart there are any speed change.

Question: has anyone of you with your TT system ever checked the sound related to the TT RPM to see either you are doing pretty good or could be improved? If not you might be surprised of the out coming result. Also checking when you just start the TT and after 10 or 20 minutes of spinning what are the RPM. If you have a DD drive as my friend he did not notice anything with the tt strobo, but once we compared the two TT and mine sounds better than his.

I mean check with a precise tachometer that give numbers and not the standard strobo.

I do not use the cell App to check the speed as it is not that reliable and precise in my opinion.

I tks you all for the support, appreciate it.

I will post some more result after I rebuilt the thrust plate of the platter s bearing as it has a mark from the 5mm sphere that I do not like and since I disassemble it why not do a complete job.

Rgds

Adelmo

When start the TT the platter speed is 32.9 RPM

After 45 minutes get 33.3 RPM

After about an hour gets 33.33 Rpm. I like the sound of my TT, generally speaking at 33.33RPM or a bit higher.....

I like the RPM Steady. Just to give you some sound info:

At 32.9 RPM i do not like the sound, is pretty shabby

At 33.1 still is shabby and not acceptable

At 33.2 high side you can start to play though not so nice

At 33.3 is getting better and you notice a difference

At 33.33 you say : now sounds well

At 33.36 or 33.38 I prefer with my TT and generally speaking any type of music. Classic music need 33.33 especially with some instruments.

Regarding construction of the fly wheel bearing ( main problem is here ) :

Out body of the bearing is made in aluminum

Bushes made with bronze, but not sintered one

Thrust plate body made with aluminum, thrust plate made with bronze, thickness of the bronze thrust plate 6mm.

Diameter of the shaft 19mm

diameter of the thrust ceramic sphere 5mm

By the way, if you lathe a hard steel shaft with 19mm diameter at the temperature of 20 degree, you check its diameter at that temperature, later you check the diameter at 28 or 30 degree what would be the diameter difference? Because there is a difference and this difference might give the RPM variation I got. Loosen allowance could be but I do not like it in the long run.

In a very precision coupling between shaft and bushes that difference ( that is due the metal expansion ) may change the RPM of around 1.5%. I do not think the temp difference change so much the oil viscosity in fact.

In my life I had 4 TT :

A pioneer but not really HIFI product therefore its sound sucked and I trashed it long time ago.

A Thorens TD 160. I tweaked the plinth, the tonearm, the platter ringing, improved its sound, but the bearing was ratting anyhow. I believe that was one of the biggest limitation of the TT. Also speed was not that precise despite a too loosen bearing.

I have 2 Lenco, dynamic of the sound is pretty good due to the rim type drive, complex to adjust the speed with standard unit, got small variation in speed between cold and warm spinning, but I really do not like the rumble of it. Takes many many effort to possibly get rid of it.

As last this DIY TT. Platter bearing I am pretty satisfied, do not ratt, rumble is good to my ears. Single motor pod is ok and run in few seconds at 33.33 RPM.

As latest tweak to this TT I made a Motor pod with fly wheel and 2 motors.

The idea was to get better sound and possibly get closer to the Lenco dynamic without its rumble. Rumble I got pretty good, platter bearing I am satisfied, Speed reaching I am not satisfied as takes to long to reach. I cannot play immediately LPs. Therefore I am encountering some problem as above. Why I do not give up? Easy to swap from single motor to fly wheel pod as they are not attached to the TT. Well DIYer likes to make things otherwise they would not be DIYer.

I read of other people that have encountered similar problem and one has successfully solved with the bearing heating and reach the optimal speed in 10 to 20 seconds. Why not try yet the bearing heating?. Because I like to install it inside the motor pod and so far I did not find an available one with such small dimension. Well... actually I did find a Ceramic one from Nisso, but they did not ship to Europe and now is no longer available. I believe also that a steady temp of the bearing around 26 to 30 degree do not harm neither the bearing neither the oil, neither change the oil viscosity.

I am using pretty thin oil guys. The fly wheel start easily without belt slipping.

I have a laser tachometer with its fixed pod to check the speed continuously while spinning either the motor s pulley or the platter or play music as well to see if during the dragging of the cart there are any speed change.

Question: has anyone of you with your TT system ever checked the sound related to the TT RPM to see either you are doing pretty good or could be improved? If not you might be surprised of the out coming result. Also checking when you just start the TT and after 10 or 20 minutes of spinning what are the RPM. If you have a DD drive as my friend he did not notice anything with the tt strobo, but once we compared the two TT and mine sounds better than his.

I mean check with a precise tachometer that give numbers and not the standard strobo.

I do not use the cell App to check the speed as it is not that reliable and precise in my opinion.

I tks you all for the support, appreciate it.

I will post some more result after I rebuilt the thrust plate of the platter s bearing as it has a mark from the 5mm sphere that I do not like and since I disassemble it why not do a complete job.

Rgds

Adelmo

Here we have a super-super "picky" individual, very annoyed at the tiniest deficiency or error in music reproduction.

Yes they are out there, not in large numbers, but nevertheless in a small percentage,, compared to average individuals.

And occasionally, these types of "perfectionists" surface, usually with a turntable not suitable for their use, in this case, an over-built non-adustable unit with speed issues that are not tolerable.

In the usual case, I suggest a quartz-locked machine with a manually adjustable speed range, of which there are many to be found.

These range from a 1970's Radio Shack machine to the current Technics SL-1200 series.

Yes they are out there, not in large numbers, but nevertheless in a small percentage,, compared to average individuals.

And occasionally, these types of "perfectionists" surface, usually with a turntable not suitable for their use, in this case, an over-built non-adustable unit with speed issues that are not tolerable.

In the usual case, I suggest a quartz-locked machine with a manually adjustable speed range, of which there are many to be found.

These range from a 1970's Radio Shack machine to the current Technics SL-1200 series.

Hi Wiseoldtech,

If you like to talk to a super super individual picky guy I introduce you one of my friends and by the way you shall listen to one of the best sounding system I ever listened.

I believe that in the DIYer community there is a normal attitude to make things good, though sometimes we built things that economically do not worth to be made, but we still make them. A commercial good Fly Wheel is costly, I suppose few thousand dollars... But also there are guys that think a turntable do not need to be precise, need just to turn, as far as it turns is ok. These guys might even use the Chinese restaurant TURNTABLE to listen LPs, I suppose....

However even I do not have so good ears anymore due to my age, but it is still possible to spot the different sound as I described above even for a modest system as mine and using the cheap Denon DL 103 cart. When the system sounds good I clap the feet following the music ...... good feeling indeed.

I do like quartz locked DD unit especially the Yamaha GT 2000 from the 80s, but too costly indeed and not DIY fun after all. My SCARRAFONE ( Italian slang to say when even an ugly thing i believe it is the most beautiful one ) have some nice solutions and after all except for the Fly unit, for the time being, my TT perform pretty good and is not too ugly as well!

AS DIY i do not have knowledge to make electronic things, especially a quartz locking unit that if not a good one provide musically worse result compared to the fixed speed one. My knowledge is more mechanical and for other solutions.

Tks n Rgds

Adelmo

If you like to talk to a super super individual picky guy I introduce you one of my friends and by the way you shall listen to one of the best sounding system I ever listened.

I believe that in the DIYer community there is a normal attitude to make things good, though sometimes we built things that economically do not worth to be made, but we still make them. A commercial good Fly Wheel is costly, I suppose few thousand dollars... But also there are guys that think a turntable do not need to be precise, need just to turn, as far as it turns is ok. These guys might even use the Chinese restaurant TURNTABLE to listen LPs, I suppose....

However even I do not have so good ears anymore due to my age, but it is still possible to spot the different sound as I described above even for a modest system as mine and using the cheap Denon DL 103 cart. When the system sounds good I clap the feet following the music ...... good feeling indeed.

I do like quartz locked DD unit especially the Yamaha GT 2000 from the 80s, but too costly indeed and not DIY fun after all. My SCARRAFONE ( Italian slang to say when even an ugly thing i believe it is the most beautiful one ) have some nice solutions and after all except for the Fly unit, for the time being, my TT perform pretty good and is not too ugly as well!

AS DIY i do not have knowledge to make electronic things, especially a quartz locking unit that if not a good one provide musically worse result compared to the fixed speed one. My knowledge is more mechanical and for other solutions.

Tks n Rgds

Adelmo

...addition to my previous post.

Besides the heat from bearing will travel to the spindle and ultimately to the record. Which is not good.

regards.

Hi HIten,

My Motor Pod it is separated from the TT therefore I doubt that the heating reach the record.

Tks n rgds

Adelmo

Attachments

Obviously it does not have these things.

That was my first thought. But he has two motors. He should have ample torque and he should have some way to govern the speed of the motors. Otherwise how can he guarantee that the motors are spinning at the same rate and not fighting themselves?

If he doesn't have adequate torque or motor control, we have a larger problem here than the bearing.

- Home

- Source & Line

- Analogue Source

- Turntable Bearing heated