Then it looks like a pretty heavy tonearm to me...but mc carts like dl103 specifically ask for that.I can understand why you need a heavy one with MC carts but B&O carts are quite the opposite in their requirements and you might have seen the original beogram 2202 tonearm already...I'm trying to decipher if mmc20en can go with a longer arm than the original B&O one, but i have a hunch that they already figured it out all when choosing a 9.5...10 inch ultralight tonearm for their carts.I might simply go with the original B&O tonearm prescriptions next if i can't make it work the way i want as i have enough heavy tonearms of all shapes around me.

10.5 inch is the minimum i can use to have it used separately form the turntable plinth and i already cut it .It will allow me to make the tonearm heavier and damped for sure, but i feel that i might choose to have it 9.5 inch on the turntable plinth which allow much better damping with lower effective mass.Little by little i get closer to the 9 inch truthHi,

Separated TA pod is I think is a good solution.

Regarding the length of the TA I like 12 Inch, but a 10 Inch good TA is probably more dynamic and faster than a 12 Inch TA.

Adelmo

Why just an arm accomodating a B&O cart if you could have more tonearms for the same price  ?

?

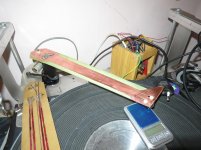

This time I went the old poor man way paved by Jiri Janda with 10 and 10.5 inch tonearms (much easier to execute the 20.5 and 21.5 degrees offset angles) using some 0.5 mm pcb...If it will be too flabby, 1mm or just two pcb's one on top of another will be considered, although i'm also thinking of using that razor blade you can see in the pictures for stiffness(some rubber damping will be needed if i'll really be using it.), but for now i'm trying this ideea to see what's all about it.It happend that i had a NAD turntable with that kind of tonearm and sold it before i even had an audition...The actual weight of the leaf tonearms without counterweight , wiring and future additional shielding are just a bit higer than half of the weight of my 9 inch tonearm found in Dual 701 which looks good to me and at least this type of tonearm should be more resonance free in theory than the hollow aluminium tube.For that reason I left that copper trace on both sides of the pcb and not only for shielding the future copper traces that will be copper taped on the back of the tonearm after they get out of the cutted aluminium tube underneath the flat leaf tonearm. .I could have removed one trace entirely from the upper side saving 1 gram weight out of 5.5 gr, but i think that second copper trace will play a role in breaking some resonances as well as offering some plasticity to the tonearm as I need to bend it for having the right angle when playing the record .When adding the wires and the copper tape the tonearm will probably be within the same range of weight of a decent 9 inch tonearm like Dual's(measured without counterweight) which is still very light , basically at least half of the weight of some other japanese turntable's tonearms i have.Of course i'll be using only one flat leaf tonearm at a time

This time I went the old poor man way paved by Jiri Janda with 10 and 10.5 inch tonearms (much easier to execute the 20.5 and 21.5 degrees offset angles) using some 0.5 mm pcb...If it will be too flabby, 1mm or just two pcb's one on top of another will be considered, although i'm also thinking of using that razor blade you can see in the pictures for stiffness(some rubber damping will be needed if i'll really be using it.), but for now i'm trying this ideea to see what's all about it.It happend that i had a NAD turntable with that kind of tonearm and sold it before i even had an audition...The actual weight of the leaf tonearms without counterweight , wiring and future additional shielding are just a bit higer than half of the weight of my 9 inch tonearm found in Dual 701 which looks good to me and at least this type of tonearm should be more resonance free in theory than the hollow aluminium tube.For that reason I left that copper trace on both sides of the pcb and not only for shielding the future copper traces that will be copper taped on the back of the tonearm after they get out of the cutted aluminium tube underneath the flat leaf tonearm. .I could have removed one trace entirely from the upper side saving 1 gram weight out of 5.5 gr, but i think that second copper trace will play a role in breaking some resonances as well as offering some plasticity to the tonearm as I need to bend it for having the right angle when playing the record .When adding the wires and the copper tape the tonearm will probably be within the same range of weight of a decent 9 inch tonearm like Dual's(measured without counterweight) which is still very light , basically at least half of the weight of some other japanese turntable's tonearms i have.Of course i'll be using only one flat leaf tonearm at a time

Attachments

Last edited:

Now this tonearm is really good sounding and couldn't hear any kind of resonance due to it...Tesla guy was genious indeed...Believe it or not, this is as good as can possibly be although setting the vertical tonearm alignement was something of a labour of love as the tonearm is very flexible...and it's very light too. Now taking into account that this is the first time I hear this cart in 10 years in all its glory ...for me at least it's some kind of an accomplisment.The only thing i really miss is a cartridge cover for mmc20e as I have to take excessive care anytime i handle it.

Attachments

Last edited:

Just in case you thought your friends can't envy you for carving into pcb tonearms...the whole thing , two layers without etching is 23grams.When atached to a pivot around 10 grams at the cartridge atach point ...after etching probably 6 grams .This one allows me to get a 12 inch toneram, but i'd rather stick to the previous 10.5 inch which proved to be very good already.17.85degrees offset angle won't make a big difference over 20.5 degrees offset, but i save a lot of counterweight.

Attachments

Last edited:

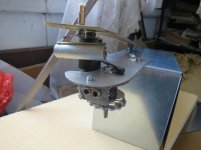

And my latest counterweight: just some 4mm brass bars stuffed inside a copper pipe hanging on some 0.16mm fishing nylon from a swinging razor blade.This time i didn't use lead inside the copper pipe cause i wouldn't want the silver on the copper pipe to get black from heat.

Attachments

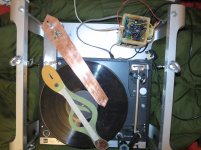

Ongoing bronze age job just before final wiring: NAD 5120 pivot with newer tonarms, horizontal, angle , height or vertical tracking adjustment all by using one spring, a stainlesss steel bolt , a brass nut and one pivot hinge made of pcb and hdd disks (like adjusting a tapehead azymuth ). Also a very simple magnet atachement through the pcb holding the tonearm adjustable mechanism to basicaly any turntablesteel plinth can be used with hard disk magnets.

Attachments

-

IMG_5878.jpg881.8 KB · Views: 52

IMG_5878.jpg881.8 KB · Views: 52 -

IMG_5881.jpg816.5 KB · Views: 48

IMG_5881.jpg816.5 KB · Views: 48 -

IMG_5886.jpg892.3 KB · Views: 33

IMG_5886.jpg892.3 KB · Views: 33 -

IMG_5887.jpg678.7 KB · Views: 34

IMG_5887.jpg678.7 KB · Views: 34 -

IMG_5890.jpg662.7 KB · Views: 33

IMG_5890.jpg662.7 KB · Views: 33 -

IMG_5893.jpg942.6 KB · Views: 40

IMG_5893.jpg942.6 KB · Views: 40 -

IMG_5905.jpg975.9 KB · Views: 47

IMG_5905.jpg975.9 KB · Views: 47 -

IMG_5909.jpg803.1 KB · Views: 38

IMG_5909.jpg803.1 KB · Views: 38 -

IMG_5926.jpg874.1 KB · Views: 62

IMG_5926.jpg874.1 KB · Views: 62 -

IMG_5903.jpg762.9 KB · Views: 58

IMG_5903.jpg762.9 KB · Views: 58

I realized there's no photo with the spring...I'd need one with a bigger diameter to have the toneram always parallel to the record, but it's fine for the moment.Gave this new toy some finish, oiled it soldered the wires and also realized that i can't allow that nut holding it together to be too high over the pcb plane as it impedes the counterweight movement, but that was solved in the end.

Attachments

New larger spring and antiskating: fishing rod, fishing line , fishing hook and lead bar  Next stop : sapphire gimbals.

Next stop : sapphire gimbals.

Attachments

Last edited:

Back to basics: 9.5 inch tonearm, the lightest of them all.

The previous one was actually 10.2 inch, not 10.5 and it seemed ok to me, but after reading some more opinions on the downsides of longer tonearms, i really need to check if there really is a point in it.Now for 12 inch tonearms some say that different alignement like Stevenson's work better and it's really difficult to rightly compare long tonearms with short ones when different alignement need to be chosen...I'll see what happens when all variations will be chequed.

The previous one was actually 10.2 inch, not 10.5 and it seemed ok to me, but after reading some more opinions on the downsides of longer tonearms, i really need to check if there really is a point in it.Now for 12 inch tonearms some say that different alignement like Stevenson's work better and it's really difficult to rightly compare long tonearms with short ones when different alignement need to be chosen...I'll see what happens when all variations will be chequed.

Attachments

Last edited:

Although I should probably make a different topic , I'll just continue sharing all my work around tonearms here.

Last week I started my first tangential tracking tonearm platform.Mechanical decoupling of the motor vibrations aren't realy a trivial thing and i understand now why commercial servo tracking tonearms used a fine thread or a rubber belt to move the tonearm and not a brass screwing bolt like i did, but i solved most of the problems damping anything needed to be damped.... Next week the automation will follow and maybe the final decision weather to attach the actual pivoting tonearms to the new platform or just make a shorter one.

Last week I started my first tangential tracking tonearm platform.Mechanical decoupling of the motor vibrations aren't realy a trivial thing and i understand now why commercial servo tracking tonearms used a fine thread or a rubber belt to move the tonearm and not a brass screwing bolt like i did, but i solved most of the problems damping anything needed to be damped.... Next week the automation will follow and maybe the final decision weather to attach the actual pivoting tonearms to the new platform or just make a shorter one.

Attachments

Last edited:

After seeing a Pioneer PL-L1000 turntable video i just realized the greatest weakness of this tonearm ...It takes forever to unwind the screw back until the tonearm gets to play another side of the vinyl record.At least i can use it for a vinyl cutting lathe or to carry a whole normal tonearm ...

If the only reason we still listen to a vinyl turntable is the associated ceremony, then this tonearm will bring about 3...5 minutes more of it

If the only reason we still listen to a vinyl turntable is the associated ceremony, then this tonearm will bring about 3...5 minutes more of it

Last edited:

Actually it's not that bad...full unwinding is 2min 20 sec for 10 cm at full speed, so 10 times faster than one normal side at 33rpm.Given the sole purpoe of playing a vinyl, i'd say it's ok and no other system is really needed.

For a 7.5 inch tonearm you get 1.3 degrees per minute of playing asuming the 23 min per side and max 100 mm record length.If the servo angle is set at 0.5 degrees and the servo motor goes at full speed i need a servo correction at maybe every 25 seconds(not really sure about that...forgot all mechanics formulae), but i actually think of implementing a PID to keep the angle offset much lower with an average constant worm gear speed, so that i can run the servo at much lower speed, hence less vibrations.

For a 7.5 inch tonearm you get 1.3 degrees per minute of playing asuming the 23 min per side and max 100 mm record length.If the servo angle is set at 0.5 degrees and the servo motor goes at full speed i need a servo correction at maybe every 25 seconds(not really sure about that...forgot all mechanics formulae), but i actually think of implementing a PID to keep the angle offset much lower with an average constant worm gear speed, so that i can run the servo at much lower speed, hence less vibrations.

Looking at a normal 33rpm LP i have between 9 and 11 grooves /mm.

If i'm using three different average worm gear rotating speeds , two for 45rpm normal and singles and one for 33 rpm LT, what would be the minimum and maximum angle error when tracking?

If i'd be a little bit more conservative, i'd choose to have an average speed and instead of using just one servo switch i'd use two of them, one on each side of the tonearm so that i can get a servo correction every time the tonearm pivot gets behind or ahead of the right linear tracking position by too much increasing or decreasing the speed accordingly .Thus i can have a constant 10 times lower speed and stll be able to have minimum angle error.

If i'm using three different average worm gear rotating speeds , two for 45rpm normal and singles and one for 33 rpm LT, what would be the minimum and maximum angle error when tracking?

If i'd be a little bit more conservative, i'd choose to have an average speed and instead of using just one servo switch i'd use two of them, one on each side of the tonearm so that i can get a servo correction every time the tonearm pivot gets behind or ahead of the right linear tracking position by too much increasing or decreasing the speed accordingly .Thus i can have a constant 10 times lower speed and stll be able to have minimum angle error.

Last edited:

Several comments:

Post #34 – Yes, vinyl playback is a ceremony. We all love the ceremony.

Post #35 - Reducing servo motor speed to an average continuous running speed will greatly reduce vibration and noise. A competent servo control system is not all that hard to do, and the complexity of PID control is not necessary. I have been using a very simple photoelectric control system for decades, and presented it in this thread Rabco SL8E Photoelectric Servo Control Retrofit. Think in terms of continuous analog motion instead of full speed bursts of error correction every few seconds.

Post #36 – My servo control has worked well for all variations of groove pitch that I have encountered so far. I have not needed separate optimization tweaks for 33 or 45 RPM.

Ray K

Post #34 – Yes, vinyl playback is a ceremony. We all love the ceremony.

Post #35 - Reducing servo motor speed to an average continuous running speed will greatly reduce vibration and noise. A competent servo control system is not all that hard to do, and the complexity of PID control is not necessary. I have been using a very simple photoelectric control system for decades, and presented it in this thread Rabco SL8E Photoelectric Servo Control Retrofit. Think in terms of continuous analog motion instead of full speed bursts of error correction every few seconds.

Post #36 – My servo control has worked well for all variations of groove pitch that I have encountered so far. I have not needed separate optimization tweaks for 33 or 45 RPM.

Ray K

@diyrayk " Think in terms of continuous analog motion instead of full speed bursts of error correction every few seconds. "

that was exactly my thought and i'm glad someone else already tried it.I'll be reading your topic.Thanks!

A PID with three options would be just my logical asumption when running continuous mode...

that was exactly my thought and i'm glad someone else already tried it.I'll be reading your topic.Thanks!

A PID with three options would be just my logical asumption when running continuous mode...

I found the B&O beogram 2202 tonearm and measured its length and weight at the headshell with the cartridge and counterweight removed when supported by the pivot : almost 9 inch, 25 degrees offset angle and 2.5 grams.

Did the same things on Garrad Zero 100: 7.5 inch tonearm, 23...26 grams depending on setting , at arround 1 degree offset angle obviously.

The Goldring g800 cart on Garrad has also a plastic +metal heavy headshell adapter , the whole construct plus the cartridge adding 11.7 more grams to the tonearm, while B&O mmc20e is 3.95 grams.

Maybe Garrad Zero 100 creates les skating lateral wear, but i'm not sure who's quicker at destroying the vinyls: a 25 offset angle with antiskating or 30 more grams weighing on a micron size sapphire tip on plastic to be moved around... and i heard almost all modern 3...10k tonearms have this kind of weight to accomodate for 300...5k mc carts.

After having a listen to mmc20en on my diy tonearms I'm pretty sure that there's no real evolution in the world of "high end" cartridges if the needed tonearms are 10 times faster at wearing your vinyl now that vinyl price is almost 100 times higher than in the 70's...With the price of 10...20 vinyls you can barely buy a decent mc cartridge that will wear them 10...20 tmes faster...

Tell me your secret folks! What is it that I don't get? A 1000 times more expensive setup to ruin you favourite , unobtanium 70's vinyls in a matter of 50 sessions?I could only understand that if someone is preparing the ultimate setup to get the best out of the analog world and transfer it to digital, but then there's the master tape undermining the efforts meaning making the vinyl world looking like a bozo running for ellections and less gracious ceremony in place...

Did the same things on Garrad Zero 100: 7.5 inch tonearm, 23...26 grams depending on setting , at arround 1 degree offset angle obviously.

The Goldring g800 cart on Garrad has also a plastic +metal heavy headshell adapter , the whole construct plus the cartridge adding 11.7 more grams to the tonearm, while B&O mmc20e is 3.95 grams.

Maybe Garrad Zero 100 creates les skating lateral wear, but i'm not sure who's quicker at destroying the vinyls: a 25 offset angle with antiskating or 30 more grams weighing on a micron size sapphire tip on plastic to be moved around... and i heard almost all modern 3...10k tonearms have this kind of weight to accomodate for 300...5k mc carts.

After having a listen to mmc20en on my diy tonearms I'm pretty sure that there's no real evolution in the world of "high end" cartridges if the needed tonearms are 10 times faster at wearing your vinyl now that vinyl price is almost 100 times higher than in the 70's...With the price of 10...20 vinyls you can barely buy a decent mc cartridge that will wear them 10...20 tmes faster...

Tell me your secret folks! What is it that I don't get? A 1000 times more expensive setup to ruin you favourite , unobtanium 70's vinyls in a matter of 50 sessions?I could only understand that if someone is preparing the ultimate setup to get the best out of the analog world and transfer it to digital, but then there's the master tape undermining the efforts meaning making the vinyl world looking like a bozo running for ellections and less gracious ceremony in place...

Last edited:

What do you think of your MMC20E? I had a MMC6000 that I bought new. I modified my preamp in order to load it to the specified 100K and I sized the phono cable to provide the 100pF capacitance. It was the best cartridge I ever had, and it handled everything at 1.0g VTF in a low mass arm of my own design. I have an AT 150MLX waiting in the wings but I’m not ready to mount it yet.

Ray K

Ray K

- Home

- Source & Line

- Analogue Source

- What about a 15 inch pivot tonearm?