Just thought I would add the latest upgrades for those who have an EPA100 and want to get more from it.

The Technics VTAF mounting base has backlash in the threads, while this is not much and can't be felt at the base, once the arm is installed the whole arm can be rotated in the base a very small amount. This is going to cause the arm to vibrate laterally negating the effect of the damping somewhat.

A new base was machined from aluminium that is a split collet arrangement. There is a small bracket at the top of the arm pillar with an M3 bolt to act as height adjustment. Loosen the locking bolt in the mount and adjust the M3 bolt for arm height, I still have a few updates to do so height can be adjusted on the fly.

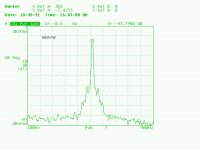

Included are measurements of the stock and modified arm. Even before the upgrades the EPA100 is a good arm, these few simple mods have stepped it up into a completely different league.

The Technics VTAF mounting base has backlash in the threads, while this is not much and can't be felt at the base, once the arm is installed the whole arm can be rotated in the base a very small amount. This is going to cause the arm to vibrate laterally negating the effect of the damping somewhat.

A new base was machined from aluminium that is a split collet arrangement. There is a small bracket at the top of the arm pillar with an M3 bolt to act as height adjustment. Loosen the locking bolt in the mount and adjust the M3 bolt for arm height, I still have a few updates to do so height can be adjusted on the fly.

Included are measurements of the stock and modified arm. Even before the upgrades the EPA100 is a good arm, these few simple mods have stepped it up into a completely different league.

Attachments

The Technics VTAF mounting base has backlash in the threads, while this is not much and can't be felt at the base, once the arm is installed the whole arm can be rotated in the base a very small amount. This is going to cause the arm to vibrate laterally negating the effect of the damping somewhat.

Movement like this is due to the lock pin or receiving slot being worn. 99% of the time it’s the pin that was damaged due to excessive axial force when the arm is mounted - twisting it in the base to position it while having the grub screws snugged up. The pin is very slightly tapered so it can be adjusted for a just-right fit - no slop but not binding. Adjusting this solves the issue.

This was not about fixing a sloppy base. The pin must have clearance so the inner can move. My base has about 0.5 mil backlash but amplify this over the length of the arm and it becomes about 1 mil. Considering a heavily modulated track would be 60um (2.3mil) this will affect response of the arm as the arm is vibrating at the base.

All top end tonearms use some kind of locking mechanism to lock the arm pillar in the base to prevent micro vibrations smearing the sound, SME V and SAT CF1 to name two of the best arms I studied before making these mods to my EPA100.

IMO the Technics arms have the potential to be up there with the best. The horizontal as well as vertical bearings use a pin in a ball cup. This arrangement greatly reduces bearing rattle as ALL balls are loaded. The EPA100 (not mk2) has a better vertical bearing arrangement where the tower is anchored both sides of the housing = greater rigidity. Gas nitiride hardened titanium arm wand = very rigid and light.

The few short comings I see have been rectified

CW not rigidly coupled to stub

Viscous damping

Rigid mounting base

Fixing these few things have made a massive improvement in SQ as shown by the plots. The audibility of this is not insignificant. The EPA100 now has better bass response. Micro detail has improved to point where talking in the background can be heard on a few tracks (Supertramp's The Logical Song for eg.).

I could go on but suffice to say this is one of the best TT I have heard period and having been a technician in the industry I've had the opportunity to listen to some of the best TT's available including a Continuum. Was the Continuum better yes slightly but that could also have been the room certainly not $150K better.

All top end tonearms use some kind of locking mechanism to lock the arm pillar in the base to prevent micro vibrations smearing the sound, SME V and SAT CF1 to name two of the best arms I studied before making these mods to my EPA100.

IMO the Technics arms have the potential to be up there with the best. The horizontal as well as vertical bearings use a pin in a ball cup. This arrangement greatly reduces bearing rattle as ALL balls are loaded. The EPA100 (not mk2) has a better vertical bearing arrangement where the tower is anchored both sides of the housing = greater rigidity. Gas nitiride hardened titanium arm wand = very rigid and light.

The few short comings I see have been rectified

CW not rigidly coupled to stub

Viscous damping

Rigid mounting base

Fixing these few things have made a massive improvement in SQ as shown by the plots. The audibility of this is not insignificant. The EPA100 now has better bass response. Micro detail has improved to point where talking in the background can be heard on a few tracks (Supertramp's The Logical Song for eg.).

I could go on but suffice to say this is one of the best TT I have heard period and having been a technician in the industry I've had the opportunity to listen to some of the best TT's available including a Continuum. Was the Continuum better yes slightly but that could also have been the room certainly not $150K better.

I’ve had more than a dozen through here and have seen two with the issue, both fixed as I described. Unless you have one that’s out of tolerance, if you disassemble the base you’ll realize that backlash isn’t in the picture.

I appreciate your efforts and your work looks quite nice. I’d only wish meaningful data was shared as it’d help a lot in understanding performance. A plot of a single frequency doesn’t tell us much, and before and after plots of compound changes coupled with those plots being at two very different scales obfuscate even further. If the audible differences are so great how about some needle drops?

I appreciate your efforts and your work looks quite nice. I’d only wish meaningful data was shared as it’d help a lot in understanding performance. A plot of a single frequency doesn’t tell us much, and before and after plots of compound changes coupled with those plots being at two very different scales obfuscate even further. If the audible differences are so great how about some needle drops?

Let me know what data you would like to see and if I have the appropriate test LP I'll do the measurement.

Unfortunately my Focusrite is a 2nd gen so only has mono so I can't record stereo.

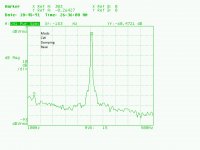

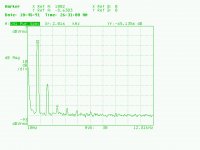

Here is a plot I did when aligning the cartridge with all tonearm modifications. Unfortunately I don't have a before for this.

LP is the Ultimate Analog (it was the only 1kHz I had at the time) and is eccentric. Cartridge is a Stanton 881s with original stylus tracking at 1g with viscous damping applied. Output was taken directly from the phono pre.

Unfortunately my Focusrite is a 2nd gen so only has mono so I can't record stereo.

Here is a plot I did when aligning the cartridge with all tonearm modifications. Unfortunately I don't have a before for this.

LP is the Ultimate Analog (it was the only 1kHz I had at the time) and is eccentric. Cartridge is a Stanton 881s with original stylus tracking at 1g with viscous damping applied. Output was taken directly from the phono pre.

Attachments

your Grazzy good Warren.

linear tonearm. custom plinth. custom platter. custom epa100

keep up the good work! your my tt diy hero

anyway I love the epa 100. I fixed the bearing after I strip it apart and found a few cracked ruby. now my Epa100 is super great and beat any low mass tonearm it meets. the magic of this tonearm lies in the ultra low friction in my opinion. fell in love with high compliance due to new found love for epa 100.i have 4 tonearms myself.

keep posting!

Best regards

anthony

linear tonearm. custom plinth. custom platter. custom epa100

keep up the good work! your my tt diy hero

anyway I love the epa 100. I fixed the bearing after I strip it apart and found a few cracked ruby. now my Epa100 is super great and beat any low mass tonearm it meets. the magic of this tonearm lies in the ultra low friction in my opinion. fell in love with high compliance due to new found love for epa 100.i have 4 tonearms myself.

keep posting!

Best regards

anthony

I just can't help myself. Here is the latest tweak.

Very scientific, I used a stethoscope on the antiskate dial and tapped the arm wand with a pencil. The arm is reasonably well damped, I added a small bit of foam ear plug just behind the headshell connector but I could still hear the arm ring slightly. 2x O rings placed on the arm tube damped the ring to a very dull thud.

I'm also a huge fan of high compliance cartridges, they impart far less energy into the tonearm so make the arms job far easier.

I use a cheap stethoscope and place it on the arm bearing (antiskate dial is convenient) and listen to the arm sing. The foam ear plug and O rings have dulled the needle talk when I listen to the arm through the stethoscope.

I an almost at the limit of mods I can think of to improve this arm. I have a servo linear tracker in the build.

Very scientific, I used a stethoscope on the antiskate dial and tapped the arm wand with a pencil. The arm is reasonably well damped, I added a small bit of foam ear plug just behind the headshell connector but I could still hear the arm ring slightly. 2x O rings placed on the arm tube damped the ring to a very dull thud.

I'm also a huge fan of high compliance cartridges, they impart far less energy into the tonearm so make the arms job far easier.

I use a cheap stethoscope and place it on the arm bearing (antiskate dial is convenient) and listen to the arm sing. The foam ear plug and O rings have dulled the needle talk when I listen to the arm through the stethoscope.

I an almost at the limit of mods I can think of to improve this arm. I have a servo linear tracker in the build.

Attachments

your Grazzy good Warren.

linear tonearm. custom plinth. custom platter. custom epa100

keep up the good work! your my tt diy hero

anyway I love the epa 100. I fixed the bearing after I strip it apart and found a few cracked ruby. now my Epa100 is super great and beat any low mass tonearm it meets. the magic of this tonearm lies in the ultra low friction in my opinion. fell in love with high compliance due to new found love for epa 100.i have 4 tonearms myself.

keep posting!

Best regards

anthony

Hi Anthony,

Thanks for massaging my ego............

The EPA100 is a fine arm and ticks a lot of boxes. The few upgrades I have done address the few things that IMO Technics did not get right. With these few mods I would put this arm up there with the very best.

Did you replace the balls with SI3N4? I had an EPA100 here a while ago that had bad bearings and you hear them click with the stethoscope. I did the stethoscope test on my arm and can hear no noises.

I have considered opening mine and replacing the balls and polishing the pins. The top bearing is open and will collect dust causing wear in the balls and pin. I did consider replacing the ball bearings with jewel Vee cups, this will be a project if I stumble across an EPA100 cheap with bad bearings.

yes I did. and also use fishing reel trick. a very small amount of graphite powder lubricant. even smoother. the original design is very special just update the material

teflon lubricant works elsewhere where they don't use ball-bearing

all courtesy of aliexpress

you need make a special H tool from a flat screwdriver.

the main thing about tension.. as lose as possible without slack. and left right of the bearing space to be same.

make sure the S arm is aligned waily verified using a blank headshell and lay flat against the platter or table..

friend got the original Epa100.. compared it and new one outperformed the bass much better. and more detailed low noise. wire better change, multistrand is fine. especially the ground since the part corroded a bit

teflon lubricant works elsewhere where they don't use ball-bearing

all courtesy of aliexpress

you need make a special H tool from a flat screwdriver.

the main thing about tension.. as lose as possible without slack. and left right of the bearing space to be same.

make sure the S arm is aligned waily verified using a blank headshell and lay flat against the platter or table..

friend got the original Epa100.. compared it and new one outperformed the bass much better. and more detailed low noise. wire better change, multistrand is fine. especially the ground since the part corroded a bit

Last edited:

Here we go again. Although this mod came out of the need to move the arm height easily for testing platters with different heights.

The previous base was so thick it was difficult to tighten and required significant force on the alan bolt. The solution was machine a sleeve for the arm post and bore the base.

The sleeve is a very tight slip fit and is held on the arm post with 2 set screws and is 32mm OD. The base is the same as before just bored for the 32mm post.

The interesting part - I was not expecting to hear an improvement in sound, mostly spacial and detail retrieval. I can only put this down to the stiffening reducing micro movement in the stock post.

The previous base was so thick it was difficult to tighten and required significant force on the alan bolt. The solution was machine a sleeve for the arm post and bore the base.

The sleeve is a very tight slip fit and is held on the arm post with 2 set screws and is 32mm OD. The base is the same as before just bored for the 32mm post.

The interesting part - I was not expecting to hear an improvement in sound, mostly spacial and detail retrieval. I can only put this down to the stiffening reducing micro movement in the stock post.

Attachments

- Home

- Source & Line

- Analogue Source

- Technics EPA100 modifications