Hi,

I bought a new Rega Planar 3 about 6 months ago, with the Rega Elys 2 cartridge fitted. I've done the "full" SRM Tech upgrade (Ultimate Rega Enhancement Kit, inc Silent Base) to it, after noticing the motor clicking (a common fault). I didn't need to do the whole thing just to get rid of the clicking, but you no how it is, I got carried away - in a good way.

Anyway when playing a record on a reasonably loud volume, I noticed there was a hum coming from the speakers, which seemed strange. Upon investigation I found the hum went away when I turned the deck off, but when switched on it would get stronger the closer the stylus was to the motor. This doesn't seem right to me, and I don't recall the issue on my old deck. I don't think it has anything to do with the SRM Tech upgrade as that uses the original motor, pcb, and wiring.

Has anyone else noticed this, and is there a fix for it? I'm wondering if earthing the motor, or adding some shielding (earthed) between the motor and the underneath of the deck may help. The old Rega 3 had a flying earth lead in with the phono leads, the new one doesn't.

I previously had a 1980s Rega Planar 3 and cant remember having so may issues. Maybe I wasn't as fussy then?!

My set up is

Rega Planar 3 (with SRM Tech Ultimate Rega Enhancement Kit, inc Silent Base.

Vintage Nytech CA252S Amplifier (recently serviced, and recapped).

Acoustic Energy AE309 speakers.

Thanks, Rob

I bought a new Rega Planar 3 about 6 months ago, with the Rega Elys 2 cartridge fitted. I've done the "full" SRM Tech upgrade (Ultimate Rega Enhancement Kit, inc Silent Base) to it, after noticing the motor clicking (a common fault). I didn't need to do the whole thing just to get rid of the clicking, but you no how it is, I got carried away - in a good way.

Anyway when playing a record on a reasonably loud volume, I noticed there was a hum coming from the speakers, which seemed strange. Upon investigation I found the hum went away when I turned the deck off, but when switched on it would get stronger the closer the stylus was to the motor. This doesn't seem right to me, and I don't recall the issue on my old deck. I don't think it has anything to do with the SRM Tech upgrade as that uses the original motor, pcb, and wiring.

Has anyone else noticed this, and is there a fix for it? I'm wondering if earthing the motor, or adding some shielding (earthed) between the motor and the underneath of the deck may help. The old Rega 3 had a flying earth lead in with the phono leads, the new one doesn't.

I previously had a 1980s Rega Planar 3 and cant remember having so may issues. Maybe I wasn't as fussy then?!

My set up is

Rega Planar 3 (with SRM Tech Ultimate Rega Enhancement Kit, inc Silent Base.

Vintage Nytech CA252S Amplifier (recently serviced, and recapped).

Acoustic Energy AE309 speakers.

Thanks, Rob

Your on the right "track " --(no pun intended) its an earthing problem and your right first job temporary earth to the motor for a start.

I have the original RB300 of 1984 in a Dais (Nottingham ) from what I remember one wire went to the tube casing but times have changed .

I have the original RB300 of 1984 in a Dais (Nottingham ) from what I remember one wire went to the tube casing but times have changed .

I found this after doing a search. Looks like it may not be so unusual.

Copper foil cures Rega motor hum- Vinyl Engine

Copper foil cures Rega motor hum- Vinyl Engine

If as the guy says on Vinyl Engine forum its magnetic hum from the motor it doesn't say much for the motors now fitted to Rega,s record decks .

I will check to see if they are now "offshored " .

No hum off my Dias and I build high input impedance amps but the motor is top quality.

Let us know if it works .

I will check to see if they are now "offshored " .

No hum off my Dias and I build high input impedance amps but the motor is top quality.

Let us know if it works .

I've sent of for some of this copper tape, and am looking at fitting it underneath the plinth, and inside the hole where the motor is normally glued (it no longer is on mine as I'm using the SRM silent base). As this tape fix doesn't rely upon it being earthed, does anyone think there will be any advantage in running an earth wire to the metal casing of the motor too? From the motor to an earth point, but not to the copper tape?

Thanks, Rob

Thanks, Rob

Rob try it, talking about it you can just talk yourself out of it .

Fault finding---in the end is trial and error nothing is perfect in life not even "sure things " . I have done this before and it worked on a deck but you must a least do something .

In doing so if it doesn't help try another earthing position .

Fault finding---in the end is trial and error nothing is perfect in life not even "sure things " . I have done this before and it worked on a deck but you must a least do something .

In doing so if it doesn't help try another earthing position .

Hi Logic800,

If I hadn't fitted the SRM kit, I might well have returned it, but at the time I thought the only issue I had was the clicking noise from the motor. There seemed to be an easy and cheap fix for this, so I thought I'd go that route as my previous Planar 3 was a nice bit of kit. Then when I started looking on the SRM site, I thought why not go the whole hog and fit a complete upgrade kit. Also my wife suggested I returned it at this point, and being a stubborn male I didn't want to admit I couldn't sort/improve it. Male chauvinism won I'm sad to say!

Also the Covid19 lockdown made thing a bit more awkward at the time - well, that's the excuse I'm using.

I'm still waiting for this copper tape to arrive, but thought I'd have a fiddle in the mean time.

I tried earthing the motor with a wire from a screw on the wall socket (good earth) directly to it, but no change.

I tried earthing the metal cover part on the Rega Elys 2 cartridge, but this just made it a bit louder.

I tried earthing the tone arm, no change.

I tried touching either bottom connection on the cartridge, but this didn't change anything.

I tried various bits of flat metal (including flattened copper pipe) between the cartridge and the motor, but this only effected it a small amount.

I also tried some aluminium kitchen foil between the platter and the mat, but this didn't help.

I guess I best wait for the copper tape, and see how I get on with this.

One interesting thing I found was that, if you hold your finger against the motor pulley it feels like it's turning smoothly, but if you hold it tight to stop it it vibrates at the same frequency as the humm coming through the speakers. The deck is fed by a dc power pack (into the control board), so I'm not sure why you get this vibration. Interestingly Rega sell an upgraded power supply, I wonder if this would help? I'm reluctant to spend anymore money up front though!

If the copper tape doesn't work I think I will contact Rega for some advice, and maybe the local (good) HiFi shop I bought it from.

If I hadn't fitted the SRM kit, I might well have returned it, but at the time I thought the only issue I had was the clicking noise from the motor. There seemed to be an easy and cheap fix for this, so I thought I'd go that route as my previous Planar 3 was a nice bit of kit. Then when I started looking on the SRM site, I thought why not go the whole hog and fit a complete upgrade kit. Also my wife suggested I returned it at this point, and being a stubborn male I didn't want to admit I couldn't sort/improve it. Male chauvinism won I'm sad to say!

Also the Covid19 lockdown made thing a bit more awkward at the time - well, that's the excuse I'm using.

I'm still waiting for this copper tape to arrive, but thought I'd have a fiddle in the mean time.

I tried earthing the motor with a wire from a screw on the wall socket (good earth) directly to it, but no change.

I tried earthing the metal cover part on the Rega Elys 2 cartridge, but this just made it a bit louder.

I tried earthing the tone arm, no change.

I tried touching either bottom connection on the cartridge, but this didn't change anything.

I tried various bits of flat metal (including flattened copper pipe) between the cartridge and the motor, but this only effected it a small amount.

I also tried some aluminium kitchen foil between the platter and the mat, but this didn't help.

I guess I best wait for the copper tape, and see how I get on with this.

One interesting thing I found was that, if you hold your finger against the motor pulley it feels like it's turning smoothly, but if you hold it tight to stop it it vibrates at the same frequency as the humm coming through the speakers. The deck is fed by a dc power pack (into the control board), so I'm not sure why you get this vibration. Interestingly Rega sell an upgraded power supply, I wonder if this would help? I'm reluctant to spend anymore money up front though!

If the copper tape doesn't work I think I will contact Rega for some advice, and maybe the local (good) HiFi shop I bought it from.

Maybe this will help Rob --you are not alone in this fault -

1979 Rega Planar 3 Motor Upgrade- Vinyl Engine

Read the forum advice (dated 2018 ) .

1979 Rega Planar 3 Motor Upgrade- Vinyl Engine

Read the forum advice (dated 2018 ) .

I don't think that relates to my setup. My Planar 3 came with the new style motor, and is now decoupled from the Rega Plinth by using an SRM Tech Silent base (part of a complete kit of upgrades) http://srm-tech.co.uk/epages/4c0089...23-2265-416e-a207-cc9dd8b06028/Products/UREK2 . My issue is definitely interference from the motor the closer the stylus gets too it, and this is only when the deck (and hence motor) is powered on. Interestingly I thought I'd look up about the Rega PSU upgrade I mentioned in my last post above (Rega Neo turntable power supply) and on the Audio T website the first review says this - "It’s a joy to change the speed of the Rega P3 without having the need to remove the platter. In addition, having an external power supply has improved the quality of sound and has removed a slight hum I was having before the upgrade." Interesting!

This PSU costs £236 though, so not something I'm willing to buy and see if it cures the hum, without being 100% sure it will.

I'm going to wait for the copper tape to arrive, and see if I can get a cure with that. Whatever the outcome I think I will take it to the local HiFi shop I bought it from (and all my other kit) and see what they have to say, or suggest. Maybe they will have one of the Rega Neo PSUs I can try, and if it gets rid of the hum "perhaps" some sort of deal can be struck.

This PSU costs £236 though, so not something I'm willing to buy and see if it cures the hum, without being 100% sure it will.

I'm going to wait for the copper tape to arrive, and see if I can get a cure with that. Whatever the outcome I think I will take it to the local HiFi shop I bought it from (and all my other kit) and see what they have to say, or suggest. Maybe they will have one of the Rega Neo PSUs I can try, and if it gets rid of the hum "perhaps" some sort of deal can be struck.

If the pickup acts as a receiver and gets worse the nearer it is to the motor that's a RF transmitted hum not a mechanically induced hum ( a lower frequency sitting on a higher frequency..

That being the case then the power supply has a fault assuming you didn't have that before the upgrade .

I don't know the circuit of the DC power supply but it initially requires a conversion from AC to DC if that leaks through and superimposes a signal on the DC towards the motor then the motor could radiate the AC part of it even if it was low level.

That being the case then the power supply has a fault assuming you didn't have that before the upgrade .

I don't know the circuit of the DC power supply but it initially requires a conversion from AC to DC if that leaks through and superimposes a signal on the DC towards the motor then the motor could radiate the AC part of it even if it was low level.

Do you use homeplugs or a wireless house phone? If so try unplugging them. They're a common source of rf through wall warts. The motor itself shouldn't kick out rf, but can do if its supply is polluted and earthing it won't fix it as the metal case is magnetically shielding.

If not try a different wall wart. Then mess about with my metal shielding and then earthing. Be pragmatic, keep a list of changes tried.

If not try a different wall wart. Then mess about with my metal shielding and then earthing. Be pragmatic, keep a list of changes tried.

Last edited:

...............The deck is fed by a dc power pack (into the control board), so I'm not sure why you get this vibration. Interestingly Rega sell an upgraded power supply....................

Are you sure that the PSU is DC. I believe mine is AC. Remember Rega has different pulleys for Euro-50Hz and US 60Hz!

A friend of mine had similar when running a non Rega pickup on his deck.

Turned out it was the stray magnetic field from the transformer in his pre-amp sitting on he shelf below the rega that was emitting stray fields.

Moved it further and issue went away. Have you verified that the hum goes away when you switch of the motor on the TT?

How is your arm grounded. Remember that the tonearm and the metal part of your pickup is grounded via the shield of the left channel phono connector. Double check that the pickup is connected with the correct color coding.

Have you rewired the tonearm or somehow accidentally damaged the grounding point inside the arm. This should only be possible if you removed the base plugg of the tonearm. Is the left channel shield on RIAA connected to gnd?

Humming along with Rega - Graham Slee Audio Forum | HiFi System Components - Page 1

I've disconnected everything else from the power extension lead, and put the deck in one wall socket, and the amp in the other one - no change.

I've tried lifting the deck to see if it's interference coming from below - no change.

I've checked that the screen from one of the phono cables is earthing the tone arm - it is.

I've tried doing the copper tape screening as suggested on the vinylengine forum, but this didn't change anything. I put down some ordinary plastic tape, then put the copper tape on top, this was to make it easier to remove if it didn't cure it.

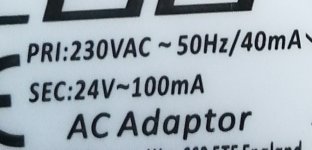

The power source (3 pin black plastic power converter that plugs in the wall socket)for the deck takes 220V ac from the wall socket, then turns it into 24V dc. That is then fed via a long cable to the pcb on the deck. I'm not sure what the pcb does though, or what type of motor it is - ac/dc/stepping?

I've contacted the local HiFi shop that I've bought all my kit from, and am taking the deck in on Tuesday, and they're going to take a look for me. I think I'll take my amp too - just in case.

I'm a bit suspicious of the quality of DC that the power converter is supplying the pcb, maybe it has noise on it. The pcb and the motor are the same as when I bought the Rega, but the pcb has been re positioned slightly to fit on the SRM Silent Base.

I will update when I know more.

I've tried lifting the deck to see if it's interference coming from below - no change.

I've checked that the screen from one of the phono cables is earthing the tone arm - it is.

I've tried doing the copper tape screening as suggested on the vinylengine forum, but this didn't change anything. I put down some ordinary plastic tape, then put the copper tape on top, this was to make it easier to remove if it didn't cure it.

The power source (3 pin black plastic power converter that plugs in the wall socket)for the deck takes 220V ac from the wall socket, then turns it into 24V dc. That is then fed via a long cable to the pcb on the deck. I'm not sure what the pcb does though, or what type of motor it is - ac/dc/stepping?

I've contacted the local HiFi shop that I've bought all my kit from, and am taking the deck in on Tuesday, and they're going to take a look for me. I think I'll take my amp too - just in case.

I'm a bit suspicious of the quality of DC that the power converter is supplying the pcb, maybe it has noise on it. The pcb and the motor are the same as when I bought the Rega, but the pcb has been re positioned slightly to fit on the SRM Silent Base.

I will update when I know more.

Attachments

What's on the other side of the wall?

Twenty years ago I got a job doing IT help in a growing office. One day I was asked to set up a computer in the office library for a new hire. When I turned on the monitor (a CRT) the display was unusably noisy. It had worked just fine before. The effect was less when I moved it away from the outside wall. Hmmm... [pun unintended]

I took a look outside. On the outside wall at a height that corresponded with table height in the library were the three cables that provided power to the building. A gauss meter confirmed a field was emanating from those cables.

I mention this because it occurred to me that at the same time the cartridge was moving closer to the motor it might also be moving closer to the wall.

Just a thought.

Twenty years ago I got a job doing IT help in a growing office. One day I was asked to set up a computer in the office library for a new hire. When I turned on the monitor (a CRT) the display was unusably noisy. It had worked just fine before. The effect was less when I moved it away from the outside wall. Hmmm... [pun unintended]

I took a look outside. On the outside wall at a height that corresponded with table height in the library were the three cables that provided power to the building. A gauss meter confirmed a field was emanating from those cables.

I mention this because it occurred to me that at the same time the cartridge was moving closer to the motor it might also be moving closer to the wall.

Just a thought.

This should not be a "Mystery !! Lets clear this up -

According to Rega their -quote - 24 volt upgrade kit their motor is----

Individually hand tuned PCB to minimise vibration. Rega designed 24v low vibration, low noise synchronous AC motor assembly.

https://www.rega.co.uk/24v-motor-upgrade-kit.html#panel1

Synchronous is an AC motor term not a DC motor term so the motor is------AC .

Secondly unless their is another electronic conversion PCB inside the record deck other than the one supplied by the above link to covert it to DC ( which would make non-sense of their advert ) then its AC .

I remember reading many years ago about a DC motor but that was 10 years ago.

So my question is Rob ---have you metered the output from that power supply ?

IF ------as you say it is a "DC motor " then if the output from the mains power supply really is AC that then leaves it being converted to DC on the PCB but that's a big IF ??

If that is the case then yes your intuition is right something is wrong with the components on the PCB board .

Multimeter out--

Measure WHICH voltage is outputting from the mains "wall wart " AC or DC .

Next measure the output from the PCB directly to the motor ---THAT will clear up this indecision .

Synchronous motor - Wikipedia

Get back please.

According to Rega their -quote - 24 volt upgrade kit their motor is----

Individually hand tuned PCB to minimise vibration. Rega designed 24v low vibration, low noise synchronous AC motor assembly.

https://www.rega.co.uk/24v-motor-upgrade-kit.html#panel1

Synchronous is an AC motor term not a DC motor term so the motor is------AC .

Secondly unless their is another electronic conversion PCB inside the record deck other than the one supplied by the above link to covert it to DC ( which would make non-sense of their advert ) then its AC .

I remember reading many years ago about a DC motor but that was 10 years ago.

So my question is Rob ---have you metered the output from that power supply ?

IF ------as you say it is a "DC motor " then if the output from the mains power supply really is AC that then leaves it being converted to DC on the PCB but that's a big IF ??

If that is the case then yes your intuition is right something is wrong with the components on the PCB board .

Multimeter out--

Measure WHICH voltage is outputting from the mains "wall wart " AC or DC .

Next measure the output from the PCB directly to the motor ---THAT will clear up this indecision .

Synchronous motor - Wikipedia

Get back please.

Please see attached pictures,

The power adapter that fits in the wall takes 220/240V ac, and converts it to 24V ac. So not DC. If you measure it without a load (not plugged in) it measures 29.1V ac - well mine does. This will drop to closer to 24V ac when connected and under load - I think.

I'm taking my deck into the local HiFi shop in 2 days time, so hope to report back more after that. I don't think I'm being too fussy. The annoying thing is I cant say for definite whether this hum was there all the time, or something I've induced since fitting the SRM tech upgrade stuff (I dont think I have, as it's the original components), because due to Covid 19 most of my family were working from home so I could never play anything loud enough to notice it. It was only later when I put some volume on that I noticed it when lifting the needle at the end of a record.

There's nothing effecting it on the other side of the wall either.

Rob

The power adapter that fits in the wall takes 220/240V ac, and converts it to 24V ac. So not DC. If you measure it without a load (not plugged in) it measures 29.1V ac - well mine does. This will drop to closer to 24V ac when connected and under load - I think.

I'm taking my deck into the local HiFi shop in 2 days time, so hope to report back more after that. I don't think I'm being too fussy. The annoying thing is I cant say for definite whether this hum was there all the time, or something I've induced since fitting the SRM tech upgrade stuff (I dont think I have, as it's the original components), because due to Covid 19 most of my family were working from home so I could never play anything loud enough to notice it. It was only later when I put some volume on that I noticed it when lifting the needle at the end of a record.

There's nothing effecting it on the other side of the wall either.

Rob

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- NEW Rega Planar 3 Turntable stylus picking up noise from motor when on