Hi,

If the LT arm is properly designed and set up, the only force exerted on it is a forward pull due to initial stylus drag.

With enough airpressure applied this shouldn't be of any concern.

However, I get the feeling you guys are trying to correct for sideways skew.

A vectorial force that can apply excessive force on both cantilever and moving assembly leading to serious misstracking, even displacement of the cartridge coils in some severe cases.

This is due to excessive play between stator and rotor, pulling the rotor inward as the cariage is being moved inward whilst trying to follow the record groove.

The cantilever being the more flexible of the two then takes most of the flexure causing additional offset.

Is this the problem being corrected for with a counteracting bias arrangement?

If not, then what is it?

Sorry if it has been explained before.

Cheers,

And sled propulsion force at a linear tracking arm is another special case of it.

If the LT arm is properly designed and set up, the only force exerted on it is a forward pull due to initial stylus drag.

With enough airpressure applied this shouldn't be of any concern.

However, I get the feeling you guys are trying to correct for sideways skew.

A vectorial force that can apply excessive force on both cantilever and moving assembly leading to serious misstracking, even displacement of the cartridge coils in some severe cases.

This is due to excessive play between stator and rotor, pulling the rotor inward as the cariage is being moved inward whilst trying to follow the record groove.

The cantilever being the more flexible of the two then takes most of the flexure causing additional offset.

Is this the problem being corrected for with a counteracting bias arrangement?

If not, then what is it?

Sorry if it has been explained before.

Cheers,

I still don't get it

I understand that it would do so on a smooth surface. But a record isn't. The inner groove wall will do the stopping for you. Which in turn generates the compensation you are looking for:If you would not to incline the platter in opposite direction (relative to horizon), you arm simply run through the record from side to side

Actually the point is simple: you are pushing the cart towards inner groove, in order to compensate its tendency to be pressed against outer groove, because the slider is moved spindlewards by the record, namely by its outer groove.

Frank has made me think..

If I remember correctly from my physics class days you do NOT need a force to keep something moving at a CONSTANT speed. You only need a force to accelerate or to compensate another force (like friction for instance)

In this (assuming a perfectly flat and centric record) case you don't want any acceleration and all the drag forces are perpendicular to the direction the arm moves in and therefore play no role in this.

The only counterforce that you have to overcome is friction of the airbaring wich should not be a problem.

Things get different when the record is eccentric but then forces are pulling the arm inside AND out alternatively and this can never be compensated by a force in only one direction.

FRANK: If the LT arm is properly designed and set up, the only force exerted on it is a forward pull due to initial stylus drag.

I am just thinking out loud here:LIVEMUSIC: let’s call it “propulsion force”. Linear tracker’s slider of substantial mass is to be displaced through the record from side to side. Mechanical work has to be performed by a physical force, not by a ghost

If I remember correctly from my physics class days you do NOT need a force to keep something moving at a CONSTANT speed. You only need a force to accelerate or to compensate another force (like friction for instance)

In this (assuming a perfectly flat and centric record) case you don't want any acceleration and all the drag forces are perpendicular to the direction the arm moves in and therefore play no role in this.

The only counterforce that you have to overcome is friction of the airbaring wich should not be a problem.

Things get different when the record is eccentric but then forces are pulling the arm inside AND out alternatively and this can never be compensated by a force in only one direction.

Quesions

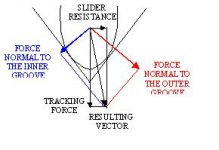

Again, koefficient of friction is way lower than in the gimbal bearing, but the mass, i.e. total mass of the arm+slider+counterweight is substantial. As long as the needle is pressed against outer groove, the clockwise moment is produced, due to larger friction force on the outer groove (D), causing cantilever to bend even further. So we have sort of "amplifier" here.

The friction forces within the air gap is proportional to the square of airflow speed and to the contact area. As long the arm stays on place, the air flows evenly around the slider and friction forces are balanced on both sides of the arm. When the slider starts to move, the friction resistance is proportional to the square of air velocity delta, multiplied by the contact area, and may not be completely negligible. I think the strong side of the air bearing, besides its lower friction value, is that the friction force is absolutely smooth and linear, not like metal-to-metal contact of conventional bearing, which inevitably induces certain vibrations.

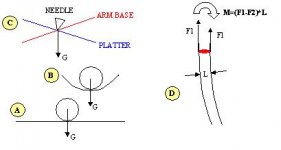

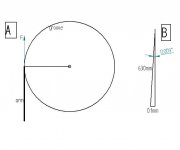

Have a look at the pictures. Ball (B) is more stable dynamically, than ball (A), so the stylus tip, positioned within the "walley"(C), as I suggested, is more stable on excentric record. Gravitation always forces it back to equilibrum. Note, that the side preload is stll there.I still don't get it

The only force to overcome is the friction between slider and rail.If I remember correctly from my physics class days you do NOT need a force to keep something moving at a CONSTANT speed.

Again, koefficient of friction is way lower than in the gimbal bearing, but the mass, i.e. total mass of the arm+slider+counterweight is substantial. As long as the needle is pressed against outer groove, the clockwise moment is produced, due to larger friction force on the outer groove (D), causing cantilever to bend even further. So we have sort of "amplifier" here.

The friction forces within the air gap is proportional to the square of airflow speed and to the contact area. As long the arm stays on place, the air flows evenly around the slider and friction forces are balanced on both sides of the arm. When the slider starts to move, the friction resistance is proportional to the square of air velocity delta, multiplied by the contact area, and may not be completely negligible. I think the strong side of the air bearing, besides its lower friction value, is that the friction force is absolutely smooth and linear, not like metal-to-metal contact of conventional bearing, which inevitably induces certain vibrations.

Attachments

Sorry, but I still don'tI still don't get it

The way I see it your drawings (A,B and C) would apply if the needle were on a grooveless smooth surface. NOT when the needle is in the groove (see pic)

Attachments

This I really don't understandAs long as the needle is pressed against outer groove, the clockwise moment is produced, due to larger friction force on the outer groove (D), causing cantilever to bend even further. So we have sort of "amplifier" here.

Friction is NOT larger on the outer groove than on the inner.

Friction is INdependent of surface area, speed (except when v = 0), and temperature.

It only depends on the nature of the surfaces in contact and is directly proportional to the normal force. (in this case tracking force)

Just google around a little to see this is true.

So there will not be an inward force resulting from this.

But then what IS happening?

Again I am just thinking aloud here:

1. If the groove were a circle instead of a spiral the arm would not move. The only force on the needle is tangential to this circle (see A)

2. The groove is in fact a spiral, which means that the needle moves inward one groove width per revolution. It also means that the center of the part circle being played doesn’t coincide exactly with the center of the record. And this means you have tracking error.

And as we all know tracking error produces a skating force.

3.What remains is the question how serious this is.

A record does 33.3 rpm. If we assume a record side takes 20 minutes to play you will have had 20*33.3=666 revolutions. (1)

During this time about 70mm of the record surface has been traveled. (2)

Or 70/666= 0.1mm travel per revolution (3)

The length (L) the needle travels in one revolution is equal to the circumference of the groove at a given point on the record.

On the outside this is about 2pi*r = 6.28*150=940mm

On the inside this is about 6.28*70=440mm

Let’s assume we are somewhere in the middle at R=100mm. Then L=630mm. (4)

Now look at picture B (remember it is nowhere near to scale)

It now follows that a resultant skating force (Fs) will be equal to:

Fs= 0.1/630*Ffriction (Ff) or 0.00015Ff. (5)

Ff= u*Fn

Where u is the friction coefficient between needle and record and Fn is the Normal force which in this case is equal to tracking force.

Lets make Fn=0.02N (2gr tracking weight) (6)

I couldn’t find an adequate figure for u. I read somewhere that u for polymers and ceramics vary between 0.04 and 0.5. So lets assume for now that

u= 0.2 (7)

Then Ff= 0.02*0.2= 0.004N (8)

And since we saw that Fs = 0.00015*Ff we now know that

Fs = 0.00015* 0.004= 0.0000006N (9)

Is this something you can compensate?

Remember this is all about a perfectly flat and centric record with an unmodulated groove. Meaning that in real life it is ....

Is there some truth to all this or am I on the wrong track completely? Reactions please.

Again I am just thinking aloud here:

1. If the groove were a circle instead of a spiral the arm would not move. The only force on the needle is tangential to this circle (see A)

2. The groove is in fact a spiral, which means that the needle moves inward one groove width per revolution. It also means that the center of the part circle being played doesn’t coincide exactly with the center of the record. And this means you have tracking error.

And as we all know tracking error produces a skating force.

3.What remains is the question how serious this is.

A record does 33.3 rpm. If we assume a record side takes 20 minutes to play you will have had 20*33.3=666 revolutions. (1)

During this time about 70mm of the record surface has been traveled. (2)

Or 70/666= 0.1mm travel per revolution (3)

The length (L) the needle travels in one revolution is equal to the circumference of the groove at a given point on the record.

On the outside this is about 2pi*r = 6.28*150=940mm

On the inside this is about 6.28*70=440mm

Let’s assume we are somewhere in the middle at R=100mm. Then L=630mm. (4)

Now look at picture B (remember it is nowhere near to scale)

It now follows that a resultant skating force (Fs) will be equal to:

Fs= 0.1/630*Ffriction (Ff) or 0.00015Ff. (5)

Ff= u*Fn

Where u is the friction coefficient between needle and record and Fn is the Normal force which in this case is equal to tracking force.

Lets make Fn=0.02N (2gr tracking weight) (6)

I couldn’t find an adequate figure for u. I read somewhere that u for polymers and ceramics vary between 0.04 and 0.5. So lets assume for now that

u= 0.2 (7)

Then Ff= 0.02*0.2= 0.004N (8)

And since we saw that Fs = 0.00015*Ff we now know that

Fs = 0.00015* 0.004= 0.0000006N (9)

Is this something you can compensate?

Remember this is all about a perfectly flat and centric record with an unmodulated groove. Meaning that in real life it is ....

Is there some truth to all this or am I on the wrong track completely? Reactions please.

Attachments

Hi,

As far as the stylus is concerned it is reading a straight line.

The radius of the groove wall is so small that in real life no error will occur as the record itself was cut in this exact same way anyway.

The reason for using a tangential tonearm is mainly due to the fact that no tracking error can occur as the record is supposedly read as it was cut....

BUT this assumes a perfect LT which in reality is far more tricky to do than it would seem.

To see what happens when the arm can't keep up due to its own inertia just watch the cantilever when you lower the arm onto the lead-in groove.

Cheers,

2. The groove is in fact a spiral, which means that the needle moves inward one groove width per revolution. It also means that the center of the part circle being played doesn’t coincide exactly with the center of the record. And this means you have tracking error.

As far as the stylus is concerned it is reading a straight line.

The radius of the groove wall is so small that in real life no error will occur as the record itself was cut in this exact same way anyway.

The reason for using a tangential tonearm is mainly due to the fact that no tracking error can occur as the record is supposedly read as it was cut....

BUT this assumes a perfect LT which in reality is far more tricky to do than it would seem.

To see what happens when the arm can't keep up due to its own inertia just watch the cantilever when you lower the arm onto the lead-in groove.

Cheers,

Which is exactly what the calculation showsAs far as the stylus is concerned it is reading a straight line.

The radius of the groove wall is so small that in real life no error will occur as the record itself was cut in this exact same way anyway.

I had considered making a linear tracker, but I wonder if that's has the best cost/benefit. I include effort in that cost figure. In my own limited experience, I have noticed that, contrary to the usual expectations regarding playback quality, I often have the most satisfying sound at about the inner third point of the record. I have a Teres table that uses a record clamp. It's quite apparent that the region of the record near the clamp is much more solidly held than near the outer edge of the record and this seems to correlate with a more stable feel to the sound. I'm wondering, if one is going to fiddle with air pumps, if the effort might be better spent on a vacuum platter than a linear tracker.

Your thoughts?

Sheldon

Your thoughts?

Sheldon

Assuming the slider resistance exists, the resulting force vector is not vertical anymore (before the preload applied). See below how the normal to the grooves forces are affected by this.Friction is NOT larger on the outer groove than on the inner.

Attachments

Hi,

Unfortunately IME at least these vacuum platters cause more trouble than they're worth.

Obviously the record clamp and platter profile don't match too well in your case which gives a varting impedance as seen by the stylus resulting in chatter fed back to it.

IMO the best playback surface I've ever used was the Goldmund platter mat, a solid metacrylate with a slightly concave profile, combined with their record weight.

This gave an even contact across the entire record surface and was the most neutral sounding combo I ever tried.

Unfortunately, there's almost no info about this gizmo available on the net but it can't be too hard to machine in a workshop.

Once you've overcome the initial slider resistance (AKA stiction) by applying a preloaded force it is no longer required and if left in place it will in effect become the cause of vectorial forces itself.

Cheers,

I'm wondering, if one is going to fiddle with air pumps, if the effort might be better spent on a vacuum platter than a linear tracker.

Unfortunately IME at least these vacuum platters cause more trouble than they're worth.

Obviously the record clamp and platter profile don't match too well in your case which gives a varting impedance as seen by the stylus resulting in chatter fed back to it.

IMO the best playback surface I've ever used was the Goldmund platter mat, a solid metacrylate with a slightly concave profile, combined with their record weight.

This gave an even contact across the entire record surface and was the most neutral sounding combo I ever tried.

Unfortunately, there's almost no info about this gizmo available on the net but it can't be too hard to machine in a workshop.

Assuming the slider resistance exists, the resulting force vector is not vertical anymore (before the preload applied).

Once you've overcome the initial slider resistance (AKA stiction) by applying a preloaded force it is no longer required and if left in place it will in effect become the cause of vectorial forces itself.

Cheers,

fdegrove said:Hi,

Unfortunately IME at least these vacuum platters cause more trouble than they're worth.

Obviously the record clamp and platter profile don't match too well in your case which gives a varting impedance as seen by the stylus resulting in chatter fed back to it.

IMO the best playback surface I've ever used was the Goldmund platter mat, a solid metacrylate with a slightly concave profile, combined with their record weight.

This gave an even contact across the entire record surface and was the most neutral sounding combo I ever tried.

Unfortunately, there's almost no info about this gizmo available on the net but it can't be too hard to machine in a workshop.

Cheers,

Actually, the clamp works about as well as it could without a concave platter. The effect I mention is subtle, and not always noticable. But it's there. I can see where setting up a vacuum platter would have a number of issues to conquer, but I can't see any other way of effectively clamping the record evenly over its entire surface. I would think that the main problems would result from the pump operating while the platter is spinning, and the bearing/seal issues that entails. If an effective platter to record seal could be developed, such that no active pumping would be required during playback, then it might be feasible.

Sheldon

Hi,

Actually active pumping isn't required during playback provided you can keep the vacuum long enough to play one record side at least.

In most commercial efforts I've seen, a seal is established by using soft rubber lips around the edges of the platter and the use of a valve to keep the air inside the platter/record interface.

However, here's the rub: too high a vacuum and chances are some airpockets in the vinyl will burst open leading to damage and consequently higher surface noise.

Whatever crud is still on the bottom side, be that the platter itself or the unplayed side of the record, is pressed into the soft vinyl surface which in turn will lead to increased surface noise as well...

Too little pressure and the effect is lost entirely, the record won't sit flat on the platter anymore either.

As I toyed with both a Thorens vacuum system and an Audio Technica one as well, I speak from hands on experience.

Needless to say I gave up on the idea and settled for the, to my ears at least, excellent Golmund combo.

Another often forgotten issue with records tightly coupled to the platter via a record puck is that if the spindle is coupled to the bearing housing, it will now also transmit any bearing noise directly to the record itself....

Cheers,

I would think that the main problems would result from the pump operating while the platter is spinning, and the bearing/seal issues that entails. If an effective platter to record seal could be developed, such that no active pumping would be required during playback, then it might be feasible.

Actually active pumping isn't required during playback provided you can keep the vacuum long enough to play one record side at least.

In most commercial efforts I've seen, a seal is established by using soft rubber lips around the edges of the platter and the use of a valve to keep the air inside the platter/record interface.

However, here's the rub: too high a vacuum and chances are some airpockets in the vinyl will burst open leading to damage and consequently higher surface noise.

Whatever crud is still on the bottom side, be that the platter itself or the unplayed side of the record, is pressed into the soft vinyl surface which in turn will lead to increased surface noise as well...

Too little pressure and the effect is lost entirely, the record won't sit flat on the platter anymore either.

As I toyed with both a Thorens vacuum system and an Audio Technica one as well, I speak from hands on experience.

Needless to say I gave up on the idea and settled for the, to my ears at least, excellent Golmund combo.

Another often forgotten issue with records tightly coupled to the platter via a record puck is that if the spindle is coupled to the bearing housing, it will now also transmit any bearing noise directly to the record itself....

Cheers,

Hi all

I haven't read the whole thread

( which I probably should do before I say anything)

but here goes:

Regarding record clamps: I've stopped using them, don't miss them.

Anti skating:

Most of my records do NOT have the spindle hole in the center of the record.

I use a tangential tonearm, and I don't see any need at all for messing with antiskating

on that kind of arm.

Different with a conventional arm, of course.

But the little problem with non-centered records means that antiskating on

tangential tonearms is a waste of time IMHO,

even if there may be a theoretical advantage .

Watching the tonarm from the front when playing records the cantilever never moves sideways even if the record is seriously off center,

if it did there would something seriously wrong, I think.

The arm itself move , of course.

IMHO tangential tonearms may or may not sound better than convention arms,

that's beside the point really. But they are much simpler to set up and adjust,

and they are also simpler to make , I think. No problems with bearings and no antiskating.

YMMV, and all that

cheers

I haven't read the whole thread

( which I probably should do before I say anything)

but here goes:

Regarding record clamps: I've stopped using them, don't miss them.

Anti skating:

Most of my records do NOT have the spindle hole in the center of the record.

I use a tangential tonearm, and I don't see any need at all for messing with antiskating

on that kind of arm.

Different with a conventional arm, of course.

But the little problem with non-centered records means that antiskating on

tangential tonearms is a waste of time IMHO,

even if there may be a theoretical advantage .

Watching the tonarm from the front when playing records the cantilever never moves sideways even if the record is seriously off center,

if it did there would something seriously wrong, I think.

The arm itself move , of course.

IMHO tangential tonearms may or may not sound better than convention arms,

that's beside the point really. But they are much simpler to set up and adjust,

and they are also simpler to make , I think. No problems with bearings and no antiskating.

YMMV, and all that

cheers

peterr said:

This I really don't understand

Friction is NOT larger on the outer groove than on the inner.

Friction is INdependent of surface area, speed (except when v = 0), and temperature.

It only depends on the nature of the surfaces in contact and is directly proportional to the normal force. (in this case tracking force)

Just google around a little to see this is true.

So there will not be an inward force resulting from this.

First things first: I like your Ladegaard arm, peterr!

Google is not a good source for facts about friction (nor are freshman physics textbooks): Friction may very well depend on surface area, speed and temperature in a complicated fashion.

For instance, the local temperature depends on the frictional force and speed, since the rate of energy dissipation by friction is W = (friction force) x (speed). This frictional work causes local heating near the contact area, which in turn alters the friction coefficient in a way that depends on the details of the interaction between the two materials.

Furthermore, a large pressure (force/contact area) may alter the properties of one or both of the materials in contact (in this case most likely the vinyl).

So you see, the details of friction is a highly non-trivial area. Fun for the researcher, frustrating for the TT designer!

- Harald

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Ladegaard

thread!

thread!