Hey all,

New member here about to take on a TD160 restoration project. I've scoured across the site and internet and have not found proper plans or dimensions for a new plinth.

I could take apart my TD160 and measure and all that but my wife's uncle is a woodworker and would enjoy building a new plinth but I would have to send him the dimensions/plans as he lives several hours away.

Any leads to help a guy out?

Thanks in advance.

New member here about to take on a TD160 restoration project. I've scoured across the site and internet and have not found proper plans or dimensions for a new plinth.

I could take apart my TD160 and measure and all that but my wife's uncle is a woodworker and would enjoy building a new plinth but I would have to send him the dimensions/plans as he lives several hours away.

Any leads to help a guy out?

Thanks in advance.

There's not a lot to making a plinth for a TD160 as shown in the link below.

Thorens TD160 Plinth - Layers of Beauty

The plinth shown has a 22mm thick solid hardwood frame, 12mm thick MDF baseboard and basic rubber feet.

Internal dimensions - 399mm wide x 309mm deep x 60mm high.

Shouldn't be too hard to draw out a plan from the above information. - plus some careful double checking against the dimensions of your existing plinth.

Thorens TD160 Plinth - Layers of Beauty

The plinth shown has a 22mm thick solid hardwood frame, 12mm thick MDF baseboard and basic rubber feet.

Internal dimensions - 399mm wide x 309mm deep x 60mm high.

Shouldn't be too hard to draw out a plan from the above information. - plus some careful double checking against the dimensions of your existing plinth.

Gorgeous!some inspiration, i build it from 25mm mdf.

You wouldn't have to have plans or dimensions eh? ;-)

And there are wooden blocks in the corners that support all the actual turntable (withs screws covered by plastic caps).

do you know how far these need to be below the edge of the top of the plinth?

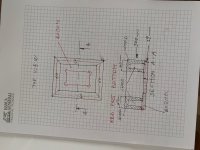

It is 12 millimeters. The top plate dimensions are: 398 x 308 mm, the internal dimensions of the plinth are 399 x 309 mm. The four screws are at 11 mm from the corners. The length of a screw is 33 mm. This is from my TD-160 Super.do you know how far these need to be below the edge of the top of the plinth?

Gorgeous!

You wouldn't have to have plans or dimensions eh? ;-)

No plans, it is really easy.

Use the measurements Icsaszar and Galu provided.

Ronny

HI,

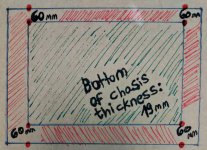

Besides the dimension of the plinth, my best sounding plinth I made for a TD 160 was with solid wood mahogany, glued with 3 pieces like a U upset down, the wall thickness 20mm the U cap 20mm therefore the total thickness of each side of the plinth was 60mm. the eight was 100mm bottom excluded. There was a left gat filled of thin leads and glue all around the plinth. The bottom was closed by a 19mm soft birch ply, but was open in the center to avoid resonance. It really sounded great.

Surface was treated with bee wax.

Adelmo

Besides the dimension of the plinth, my best sounding plinth I made for a TD 160 was with solid wood mahogany, glued with 3 pieces like a U upset down, the wall thickness 20mm the U cap 20mm therefore the total thickness of each side of the plinth was 60mm. the eight was 100mm bottom excluded. There was a left gat filled of thin leads and glue all around the plinth. The bottom was closed by a 19mm soft birch ply, but was open in the center to avoid resonance. It really sounded great.

Surface was treated with bee wax.

Adelmo

HI,

Besides the dimension of the plinth, my best sounding plinth I made for a TD 160 was with solid wood mahogany, glued with 3 pieces like a U upset down, the wall thickness 20mm the U cap 20mm therefore the total thickness of each side of the plinth was 60mm. the eight was 100mm bottom excluded. There was a left gat filled of thin leads and glue all around the plinth. The bottom was closed by a 19mm soft birch ply, but was open in the center to avoid resonance. It really sounded great.

Surface was treated with bee wax.

Adelmo

Hi Adelmo,

1. Do you have photos from your project? if do, can you please share?

2. You mean in "wall thickness" = the 4 pieces creates the frame of the base?

3. I still did not got the thing with the "3 pieces like a U upset down".

4. "eight" - what do you mean in '8'?

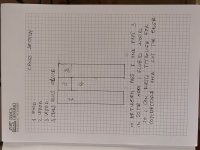

I drawed as i want to make sure I understood.

Got it right?

I own A 166 mk ii...

Thank you very much

Attachments

Last edited:

Hi Shaby,

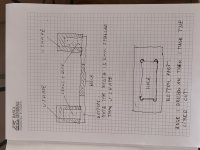

Your drawing is correct but not for the bottom drawing.

I attach here with a hand drawing ( sorry I am not good at it ) for the cross section of the 60mm frame. Kindly note that to make it you shall need to cut the edge 45 degree and there you shall need to have the whole wooden in the whole cross section so it is not a u shape in that area. The same apply where you need to drill holes for connectors or IEC plug or ground wire......

The bottom drawing of yours is not correct. the bottom need to cover the open u shape as you shall need either glue it or bolt it to the open U shape, the center hole I made was square. I attach a hand drawing. Hope can help.

I like to highlight that my plinth sounded better than the original plinth, but perhaps there are other material that may sound better than the one I used. debate on material is almost an end less issue, lately is very fashion panzer or others......

Mahogany is easy to get, easy to work with and easy to finish the surface, I think have a reasonable and good sounding quality and combined with thin leads used for guns it had a good result for me.

Hope it can help.

Rgds

Adelmo

Your drawing is correct but not for the bottom drawing.

I attach here with a hand drawing ( sorry I am not good at it ) for the cross section of the 60mm frame. Kindly note that to make it you shall need to cut the edge 45 degree and there you shall need to have the whole wooden in the whole cross section so it is not a u shape in that area. The same apply where you need to drill holes for connectors or IEC plug or ground wire......

The bottom drawing of yours is not correct. the bottom need to cover the open u shape as you shall need either glue it or bolt it to the open U shape, the center hole I made was square. I attach a hand drawing. Hope can help.

I like to highlight that my plinth sounded better than the original plinth, but perhaps there are other material that may sound better than the one I used. debate on material is almost an end less issue, lately is very fashion panzer or others......

Mahogany is easy to get, easy to work with and easy to finish the surface, I think have a reasonable and good sounding quality and combined with thin leads used for guns it had a good result for me.

Hope it can help.

Rgds

Adelmo

Attachments

Forgot to say how am I grateful for your help!

Eventually I will do it like this:

- Thick of "frame" - IPEA wood 20 mm

- Dimensions INSIDE: 39.90 cm * 30.90 cm (or shell I 40*31 ?)

- Internal height: 7 cm

- Height of TRIANGLES: 12 mm bellow bottom edge of phono plate

- Gap between TRIANGLES to edge of plinth: 11 mm.

Is it correct?

Reminds you - my tt is 166 mk ii

Thanks!

Eventually I will do it like this:

- Thick of "frame" - IPEA wood 20 mm

- Dimensions INSIDE: 39.90 cm * 30.90 cm (or shell I 40*31 ?)

- Internal height: 7 cm

- Height of TRIANGLES: 12 mm bellow bottom edge of phono plate

- Gap between TRIANGLES to edge of plinth: 11 mm.

Is it correct?

Reminds you - my tt is 166 mk ii

Thanks!

I brought solid oak wood.

The height after sanding it would be 6.4 cm = external height.

the height of the tt plate is less than 6.4 cm.

It would be possible to place everything in with external height of 6.4 cm?

- Thick of "frame" - about 6.5 cm

- Dimensions INSIDE frame (based on tt metal plate): 39.90 cm * 30.90 cm

- External height: 6.4 cm

- Height of TRIANGLES: 12 mm bellow bottom edge of phono plate

- Gap between TRIANGLES to edge of plinth: 11 mm.

Bummer that the site interface (vBulletin) does not allow to edit messages as long as there is no new replay

The height after sanding it would be 6.4 cm = external height.

the height of the tt plate is less than 6.4 cm.

It would be possible to place everything in with external height of 6.4 cm?

- Thick of "frame" - about 6.5 cm

- Dimensions INSIDE frame (based on tt metal plate): 39.90 cm * 30.90 cm

- External height: 6.4 cm

- Height of TRIANGLES: 12 mm bellow bottom edge of phono plate

- Gap between TRIANGLES to edge of plinth: 11 mm.

Bummer that the site interface (vBulletin) does not allow to edit messages as long as there is no new replay

Last edited:

Hello, newbie here.

I have questions about the 160 compared to the 160 Super:

1. Is the 160 Super plinth different in any of the 3 dimensions, especially the thickness (160 is ~0.75";

2. How thick is the 160 Super plinth?

3. I see that the dust cover is different on the 160 Super. Can anyone tell me the 3 external dimensions of the 160 Super dust cover?

4. Finally, the 160 Super has different hinges, and they are hard to find, so does anyone have a source for them or, alternatively, are the TD145 hinge very similar?

Thanks very much!!

I have questions about the 160 compared to the 160 Super:

1. Is the 160 Super plinth different in any of the 3 dimensions, especially the thickness (160 is ~0.75";

2. How thick is the 160 Super plinth?

3. I see that the dust cover is different on the 160 Super. Can anyone tell me the 3 external dimensions of the 160 Super dust cover?

4. Finally, the 160 Super has different hinges, and they are hard to find, so does anyone have a source for them or, alternatively, are the TD145 hinge very similar?

Thanks very much!!

- Home

- Source & Line

- Analogue Source

- Thorens TD160 plinth plans/dimensions